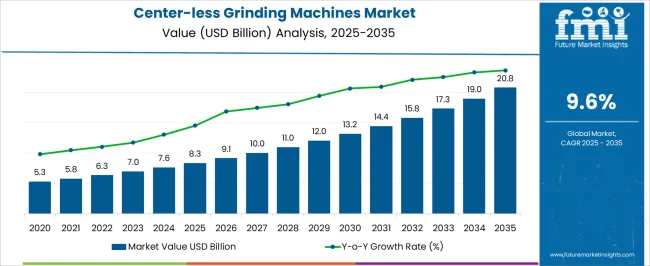

The Center-less Grinding Machines Market is estimated to be valued at USD 8.3 billion in 2025 and is projected to reach USD 20.8 billion by 2035, registering a compound annual growth rate (CAGR) of 9.6% over the forecast period.

| Metric | Value |

|---|---|

| Center-less Grinding Machines Market Estimated Value in (2025 E) | USD 8.3 billion |

| Center-less Grinding Machines Market Forecast Value in (2035 F) | USD 20.8 billion |

| Forecast CAGR (2025 to 2035) | 9.6% |

The center less grinding machines market is witnessing notable expansion driven by rising demand for high precision machining in automotive, aerospace, and general engineering industries. Increasing emphasis on productivity improvement, dimensional accuracy, and cost efficiency has reinforced the adoption of advanced grinding machines.

Automation integration, CNC controls, and the ability to handle complex geometries are key technological advancements supporting their deployment. Growing automotive production volumes and the need for precision components in electric vehicles are further fueling the demand.

Additionally, industrial modernization programs in developing economies are boosting investment in efficient machining equipment. The future outlook remains positive as industries continue to prioritize energy efficiency, accuracy, and reduced downtime, making center less grinding machines critical to modern manufacturing processes.

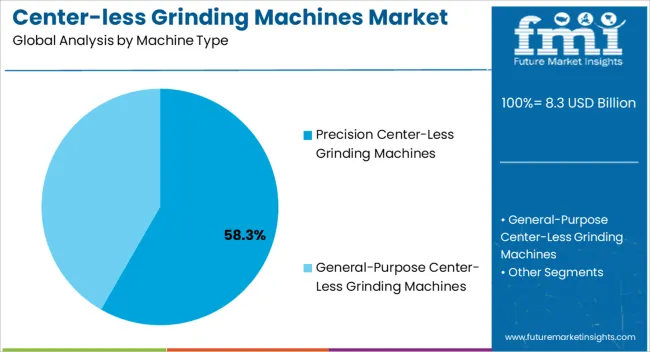

The precision center less grinding machines segment is projected to hold 58.30% of total revenue by 2025 within the machine type category, making it the dominant segment. This leadership is driven by the ability of precision machines to deliver high accuracy, superior surface finish, and consistent results across large production volumes.

Their suitability for manufacturing complex components with tight tolerances has elevated their role in critical industries. Continuous technological improvements such as advanced control systems, automated setups, and enhanced wheel design have supported widespread adoption.

As industries demand higher efficiency and precision in mass production environments, precision center less grinding machines remain the preferred choice.

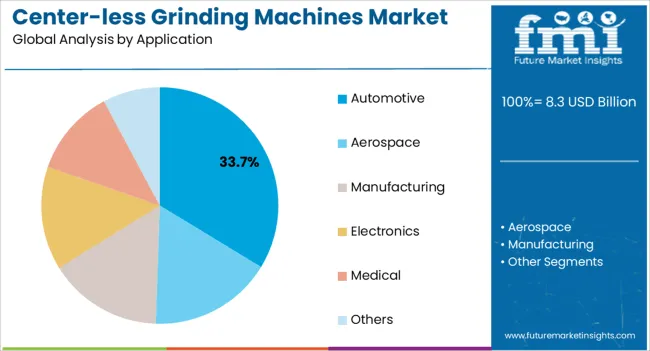

The automotive application segment is expected to account for 33.70% of the total market revenue by 2025, positioning it as the leading application area. This dominance is attributed to the extensive requirement for precision grinding in producing shafts, bearings, and engine components where high accuracy and durability are essential.

The rapid growth of electric vehicles has further expanded application scope, as advanced grinding solutions are needed for lightweight and high performance parts. Additionally, the demand for fuel efficient and emission compliant vehicles has led to stricter quality standards, driving investment in advanced grinding machinery.

Automotive manufacturers continue to adopt center less grinding machines to achieve scalability, precision, and compliance, establishing this segment as the leading application in the market.

Future Market Insights (FMI) mentions that the global center-less grinding machines market is anticipated to showcase a CAGR of 10% over the forecast period 2025 to 2035. In the historical period between 2020 and 2025, the market witnessed a decent CAGR of 12.3%.

The sales outlook for center-less grinding machines has been positive and is expected to continue growing in the coming years.

Sectors such as automotive, aerospace, and medical devices require precision components with tight tolerances and excellent surface finish. The center-less grinders industry offers an opportunity to meet these requirements, driving the demand for these grinders.

The manufacturing industry is increasingly adopting automation and Industry 4.0 technologies. Center-less grinders with automation features such as robotic loading and unloading systems, integrated measurement systems, and data connectivity are becoming more popular.

These advancements lead to increased productivity, better process control, augmented efficiency, and amplified center-less grinder sales.

Manufacturers are constantly looking for ways to optimize production processes and reduce costs. Compared to other grinding methods, center-less grinders have advantages such as shorter cycle times, shorter set-up times, and lower tool costs.

For this reason, manufacturers are increasingly turning to center-less grinders to improve cost efficiency, resulting in increased sales.

Manufacturers are investing in research and development to introduce innovative features and technologies into their center-less grinders. These advances are aimed at improving the performance, accuracy, and ease of use of the machines, further increasing the sales of these machines through 2035.

Demand may be hampered by technical limitations or lack of progress in center-less grinders machines. If manufacturers fail to innovate and develop machines that meet the changing demands of their customer’s may affect demand for these machines.

The availability of alternative technologies and machining methods may also affect the demand for center-less grinders. If alternative methods such as CNC milling and turning, electrochemical machining, and abrasive waterjet cutting can achieve similar results at a lower cost or with greater flexibility, demand for center-less grinders could decrease.

Skills shortage in manufacturing could be a barrier to demand for center-less grinders. Operation and maintenance of these machines require qualified operators with programming, set-up, and troubleshooting expertise. Companies may be reluctant to invest in complex machines such as center-less grinders if skilled workers are in short supply.

Increased environmental regulations and sustainability concerns may affect the demand for center-less grinders. If the grinding process is deemed unfriendly due to issues such as noise, dust, and energy consumption, it may lead to a shift to alternative processing methods or the introduction of more environmentally friendly grinding techniques.

Integration of Advanced Features in Center-less Grinders to Propel Market in the United States

The USA has strong manufacturing industries including automotive, aerospace, medical devices, and many other sectors. As the demand for precision components and parts continues to grow, manufacturers are looking for efficient and precise grinding processes. Center-less grinders are popular in the manufacturing sector due to their high precision, productivity, and versatility.

Center-less grinding machines have undergone significant technological advances in recent years. These advancements have improved machine capabilities such as increased accuracy, automation, and integration of intelligent functions.

The availability of advanced center-less grinders with improved performance and operability increases demand in the market.

The country is estimated to be valued at USD 20.8 billion by 2035 surging at a CAGR of 9.9%.

Affordability and Accessibly in China to Spur Demand for Center-Less Grinding Machines

China has a well-developed manufacturing infrastructure and a strong industrial base. There are several machine tool manufacturers in the country that specialize in center-less grinding machines. China’s manufacturers have accumulated experience in producing low-cost machines that meet a wide range of customer needs.

China's manufacturing industry is traditionally known for being cost-competitive. China center-less grinder manufacturers offer competitive prices compared to competitors from other countries. This affordable pricing makes China's machines attractive to domestic and foreign buyers and contributes to China's performance in this market.

The industry in China is expected to be worth USD 3.7 billion by 2035. China's center-less grinding machines market is projected to surge at a CAGR of 9.9% by 2035.

Increasing Productivity Due to Center-less Grinders to Flourish Sales in the United Kingdom

The United Kingdom has a strong presence in precision engineering and manufacturing sectors such as aerospace, automotive, and medical. These industries require a high level of precision in the manufacturing of components and parts.

Center-less grinders offer the ultimate in precision and control, allowing companies to achieve the tight tolerances and superior surface finish critical to maintaining quality standards in these sectors.

Center-less grinding machines are known for their efficiency and productivity. Large volumes can be processed with minimal downtime and operator intervention. By using center-less grinders, United Kingdom businesses can increase production rates, shorten lead times and improve overall operational efficiency.

As per the report, the United Kingdom's center-less grinding machines market is likely to witness a CAGR of around 9.7% from 2025 to 2035.

Excellent Efficiency of Precision Center-less Grinding Machines to Propel Their Demand

Based on machine type, the precision center-less grinding machines segment is likely to lead the global center-less grinding machines market through 2035. It is estimated to exhibit a CAGR of 9.8% in the assessment period, as compared to a 12.2% CAGR from 2020 to 2025.

Precision center-less grinding machines allow a continuous grinding process. Here the workpiece is fed into the machine from one side and passes continuously through the grinding zone. This enables high production rates and reduces downtime when loading and unloading work pieces.

The precision center-less grinder can process a large number of workpieces in a short time, resulting in high efficiency and productivity. The continuous feeding mechanism eliminates the need for frequent setup changes, reduces idle time, and increases productivity.

Precision center-less grinders are relatively simple in design and operation, and are easier to set up and operate than other types of grinders. The easy setup process and minimal customization required to make it attractive to manufacturers looking for simplicity and ease of use.

Automotive Segment is the Leading Application Followed by Aerospace Sector

In terms of application, the automotive category is projected to showcase a CAGR of 9.7% from 2025 to 2035. It exhibited a decent CAGR of about 12.0% during the historical period.

Center-less grinders are widely used in the automotive industry for a variety of applications. They are used for grinding precision parts such as crankshafts, camshafts, injector parts, transmission parts, and valve stems. The automotive sector demands high levels of precision and surface finish, and center-less grinding machines can efficiently deliver the required results.

Aerospace segment is also paving its way toward leading figures in the market. The aerospace industry requires precision components with strict adherence to quality standards. Center-less grinders are used to grind turbine blades, engine parts, landing gear parts, and other critical aerospace parts.

Center-less grinders are ideal for aerospace applications as they can achieve tight tolerances and excellent surface finish.

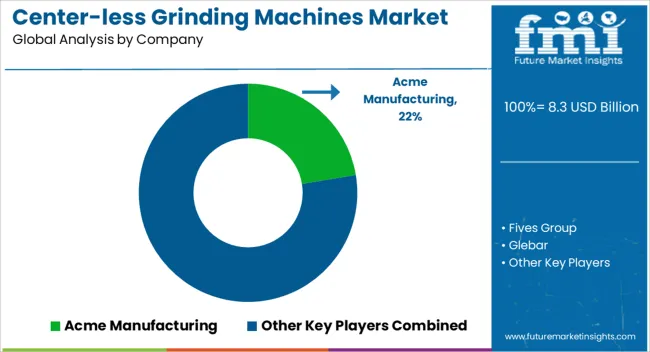

Leading players in the global center-less grinding machines market invest in research and development to create new and improved products. Their goal is to bring new machines to the market with higher selectivity, lower energy consumption, and improved durability.

They are also working on membranes that can operate at higher temperatures and pressures. These features ultimately help improve efficiency and increase applicability to a wide range of industrial processes.

Other companies have strategic partnerships and collaborations with local businesses and research institutes to share knowledge, expertise, and resources. This allows manufacturers to develop innovative technologies faster and expand their product offerings.

For instance:

| Attribute | Details |

|---|---|

| Estimated Market Size (2025) | USD 8.3 billion |

| Projected Market Valuation (2035) | USD 20.8 billion |

| Value-based CAGR (2025 to 2035) | 9.6% |

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | Value (USD billion) |

| Key Regions Covered | Latin America; North America; Europe; South Asia; East Asia; Oceania; and the Middle East & Africa |

| Key Market Segments Covered | Machine Type, Application |

| Key Companies Profiled | Acme Manufacturing; Fives Group; Glebar; Hanwha Machinery; Jainnher Machine |

| Pricing | Market Forecast, Company Share Analysis, Competition Intelligence, Market Dynamics and Challenges, and Strategic Growth Initiatives |

The global center-less grinding machines market is estimated to be valued at USD 8.3 billion in 2025.

The market size for the center-less grinding machines market is projected to reach USD 20.8 billion by 2035.

The center-less grinding machines market is expected to grow at a 9.6% CAGR between 2025 and 2035.

The key product types in center-less grinding machines market are precision center-less grinding machines and general-purpose center-less grinding machines.

In terms of application, automotive segment to command 33.7% share in the center-less grinding machines market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Grinding Mill Market Analysis and Opportunity Assessment in India Size and Share Forecast Outlook 2025 to 2035

Floor Grinding Machine Market

Diamond Tool Grinding Machine Market Size and Share Forecast Outlook 2025 to 2035

High Pressure Grinding Rollers Market Size and Share Forecast Outlook 2025 to 2035

Lathe Machines Market

Sorter Machines Market Size and Share Forecast Outlook 2025 to 2035

Virtual Machines Market by Type, by Enterprise Size, by Industry & Region Forecast till 2035

Bandsaw Machines Market Growth - Trends & Forecast 2025 to 2035

Sleeving Machines Market Size and Share Forecast Outlook 2025 to 2035

Drilling Machines Market Size and Share Forecast Outlook 2025 to 2035

Spinning Machines Market Size and Share Forecast Outlook 2025 to 2035

Knitting Machines Market Size and Share Forecast Outlook 2025 to 2035

Stamping Machines Market Growth and Outlook 2025 to 2035

Twist Tie Machines Market Size and Share Forecast Outlook 2025 to 2035

Cartoning Machines Market from 2025 to 2035

Flow Wrap Machines Market by Horizontal & Vertical Systems Through 2025 to 2035

Flake Ice Machines Market - Industry Growth & Market Demand 2025 to 2035

Flow Wrap Machines Market Analysis – Size, Share & Industry Trends 2025-2035

Ice Maker Machines Market

Granulator Machines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA