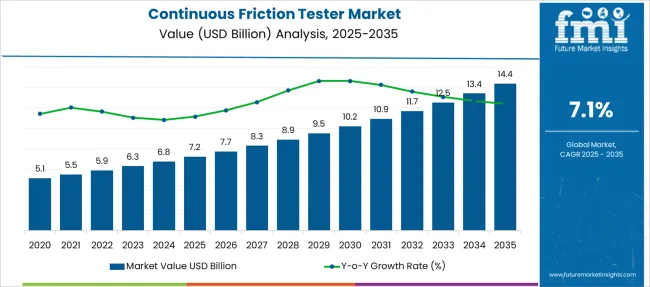

The Continuous Friction Tester Market is estimated to be valued at USD 7.2 billion in 2025 and is projected to reach USD 14.4 billion by 2035, registering a compound annual growth rate (CAGR) of 7.1% over the forecast period.

| Metric | Value |

|---|---|

| Continuous Friction Tester Market Estimated Value in (2025 E) | USD 7.2 billion |

| Continuous Friction Tester Market Forecast Value in (2035 F) | USD 14.4 billion |

| Forecast CAGR (2025 to 2035) | 7.1% |

The continuous friction tester market is witnessing sustained momentum due to its pivotal role in ensuring surface safety across highways, airstrips, and specialty pavements. Increasing emphasis on predictive maintenance, infrastructure safety compliance, and roadway certification standards has elevated the demand for dynamic friction measurement solutions. Governments and private contractors are actively investing in automated surface evaluation systems to reduce accident risks and enhance road operability.

Friction testers configured with real-time telemetry, onboard analytics, and adaptive sensor arrays are being favored for their accuracy in measuring slip conditions under diverse environmental variables. Innovations in contactless data acquisition and system calibration have further improved the efficiency of field-based testing, particularly in wet or high-traffic environments.

As infrastructure modernization continues across both developed and emerging economies, the market is expected to grow steadily Demand is being reinforced by the integration of friction data with GIS mapping, automated maintenance planning, and smart city control centers, supporting long-term scalability across transportation networks.

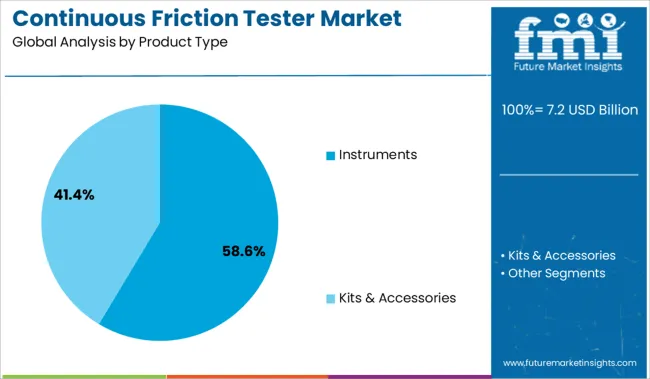

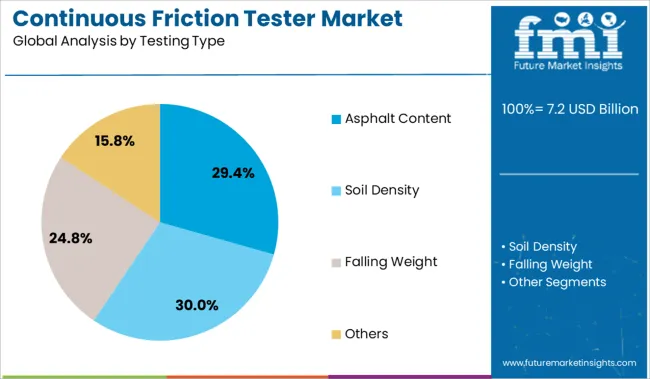

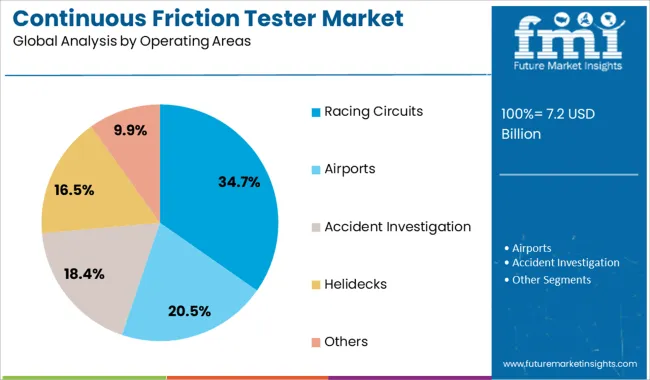

The market is segmented by Product Type, Testing Type, and Operating Areas and region. By Product Type, the market is divided into Instruments and Kits & Accessories. In terms of Testing Type, the market is classified into Asphalt Content, Soil Density, Falling Weight, and Others. Based on Operating Areas, the market is segmented into Racing Circuits, Airports, Accident Investigation, Helidecks, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The instruments segment is anticipated to account for 58.6% of the total revenue share in the continuous friction tester market in 2025, establishing itself as the dominant product category. This leadership is attributed to the increasing preference for dedicated testing equipment capable of delivering consistent, high-accuracy friction measurements across variable surfaces. Instruments integrated with modular sensor systems and real-time reporting capabilities have gained prominence among infrastructure maintenance authorities and transportation agencies.

The shift toward instrument-based testing is being influenced by stringent regulatory standards and the need for high-speed data acquisition to support dynamic safety assessments. Field operators benefit from advanced calibration mechanisms, rugged build quality, and compatibility with modern data logging systems, all of which enhance operational reliability.

The segment's growth is also being supported by improved portability, vehicle-mount configurations, and cloud-based software compatibility, enabling broader use in diverse terrains As demand for standardized, certifiable surface evaluation tools continues to rise, the instruments segment is expected to remain a critical enabler in long-term testing frameworks.

The asphalt content testing segment is projected to hold 29.4% of the revenue share in the continuous friction tester market in 2025. Its strong positioning is being driven by the critical need to correlate surface friction levels with varying asphalt compositions, especially in high-traffic and high-risk zones. Continuous monitoring of asphalt friction characteristics has become central to optimizing pavement design, resurfacing schedules, and material mix validations.

The rise in urbanization and expansion of roadway networks have prompted increased focus on surface performance verification, which has strengthened demand for friction testers equipped to handle asphalt-specific analytics. Automated data logging and analysis tools within testers have enabled faster identification of low-friction zones, thereby supporting timely intervention and corrective resurfacing.

The segment is also benefiting from governmental mandates on pavement safety audits, making asphalt content testing a regulatory necessity As sustainable paving materials and advanced bitumen compositions are introduced, friction testers tailored for asphalt validation are expected to see heightened adoption.

The racing circuits segment is expected to contribute 34.7% of the revenue share in the continuous friction tester market in 2025, emerging as a significant operating area. This dominance stems from the precision and frequency of testing required to maintain safety and performance standards in high-speed racing environments. Racing circuits demand continuous monitoring of track surface friction to ensure optimal tire grip, braking efficiency, and driver control under varying weather and temperature conditions.

The use of continuous friction testers has been accelerated by the increasing adoption of telemetry-linked safety protocols and automated track condition monitoring. The segment has seen strong growth through collaborations between circuit operators and friction testing solution providers, where advanced analytics and predictive safety models are deployed.

Equipment durability, high-speed data capture, and seamless integration with race control systems have reinforced the segment’s relevance As motorsport safety regulations become more data-driven, the use of continuous friction testers in racing circuits is expected to expand both in frequency and sophistication.

The growing demand for quality measurement of highways and airport runways and the increasing adoption of continuous friction testers to determine structural performance under lethal environmental conditions are the primary factors driving the growth of the continuous friction tester market.

Moreover, the continuous innovation in the testing equipment coupled with the increasing demand for advanced equipment for improving productivity and efficiency is also boosting the growth of the continuous friction tester market.

Apart from this, the growing construction industry and the rising focus of the government of various developed and developing economies on the betterment of airport infrastructure are the factors that are creating potential growth opportunities for the continuous friction tester market.

The boom in smart city projects and smart infrastructure development is creating the need for advanced continuous friction testers, thus, fuelling the growth of the continuous friction testers market.

Less adoption of advanced continuous friction testers in various underdeveloped economies is the major challenge to the growth of the continuous friction tester market. Also, the less development in airport infrastructure of various countries in Africa and Latin America is the major factor that hampers the growth of the continuous friction tester market.

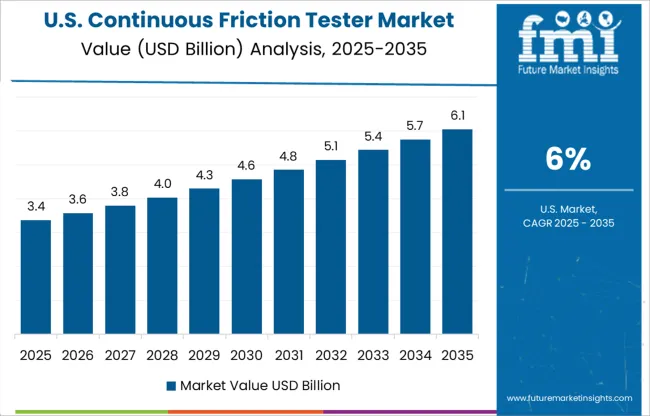

Based on geography, North America is expected to capture a significant market share in terms of revenue in the continuous friction tester market, due to the increasing demand for advanced testing technologies and the presence of key continuous friction tester providers in the region. A recently published report by Future Market Insights depicts that the market for continuous friction testers is likely to register a CAGR of 7% throughout the forecast period.

Major players are expanding their ground reach by several means such as mergers and acquisitions, collaboration, and product developments. For instance, In Dec 2024, – International Cybernetics (ICC) is excited to announce the acquisition of the NAC-Dynamic Friction Tester™ technology (NAC-DFT) from NAC Dynamics, LLC. The NAC-DFT is an aerodynamic tow-behind continuous friction measurement device (CFME), approved for use on airport runways by the FAA.

The finest practices and demonstrated the technology in use for several decades in other nations bestow an exciting prospect for the USA road safety community. Currently, it is standard procedure for network-level friction in the USA to be measured using a sample-based, discrete (i.e., not continuous) measurement called the Locked-Wheel Skid Trailer (LWST) test. This technique is vastly reliable and does offer useful point information.

Asia Pacific region is anticipated to witness high growth rates during the forecast period owing to the rapid urbanization and increasing demand for continuous friction testers due to the rapid development in the airport infrastructure. Furthermore, the rapid increase in smart city projects and smart infrastructure development in countries of the Asia Pacific such as China, Japan, and India are supporting the high adoption of continuous friction testers. A recently published report by Future Market Insights discloses that the Asia Pacific continuous friction tester market is projected to register a CAGR of 6.7%.

Increasing concern for safety has scaled up the capital investment in the region, likely to stimulate the growth prospects in the upcoming decade. Recent developments and upward trends have also bolstered the demand for continuous friction testing in the province. For instance, Nanofilm Technologies International Limited (NTI) has developed a revolutionary filtered cathodic vacuum arc (FCVA) technology that leverages a plasma source and electromagnetic waves to create high-quality coatings.

The technology does not require high heat and can perform vacuum coating deposition at room temperature, allowing the company to create advanced materials including one similar to conductive diamond material with high hardness, density, high corrosion resistance, high conductivity, and low friction coefficient - in an environmentally friendly manner.

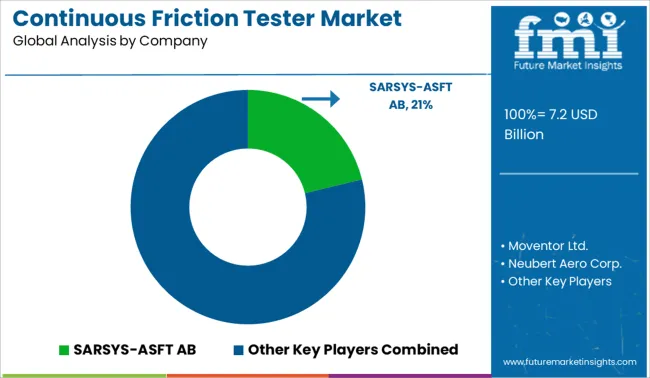

Prominent players in the global continuous friction tester market are SARSYS-ASFT AB, Moventor Ltd., Neubert Aero Corp., Controls Group, Stanley, and Humboldt Mfg. Co., Cooper Technology, and PaveTesting Limited., others. Recent key developments among players include:

| Report Attribute | Details |

|---|---|

| Growth Rate | CAGR of 7.1% from 2025 to 2035 |

| Market Value in 2025 | USD 7.2 billion |

| Market Value in 2035 | USD 14.4 billion |

| Base Year for Estimation | 2024 |

| Historical Period | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD Billion, Volume in Kilotons, and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends, and Pricing Analysis |

| Segments Covered | Product Type, Testing type, Operating Areas, Region |

| Regions Covered | North America; Latin America; Europe; Asia Pacific; Middle East and Africa |

| Key Countries Profiled | USA, Canada, Brazil, Mexico, Germany, United Kingdom, France, Spain, Italy, China, Japan, South Korea, Malaysia, Singapore, Australia, New Zealand, GCC, South Africa, Israel |

| Key Companies Profiled | SARSYS-ASFT AB; Moventor Ltd.; Neubert Aero Corp.; Controls Group; Stanley; Humboldt Mfg. Co.; Cooper Technology; Pave Testing Limited |

| Customization | Available Upon Request |

The global continuous friction tester market is estimated to be valued at USD 7.2 billion in 2025.

The market size for the continuous friction tester market is projected to reach USD 14.4 billion by 2035.

The continuous friction tester market is expected to grow at a 7.1% CAGR between 2025 and 2035.

The key product types in continuous friction tester market are instruments and kits & accessories.

In terms of testing type, asphalt content segment to command 29.4% share in the continuous friction tester market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Continuous Inkjet Inks Market Forecast and Outlook 2025 to 2035

Continuously Variable Transmission (CVT) Market Size and Share Forecast Outlook 2025 to 2035

Continuous Ambulatory Peritoneal Dialysis Bags Market Size and Share Forecast Outlook 2025 to 2035

Continuous Motion Cartoner Market Size and Share Forecast Outlook 2025 to 2035

Continuous Cardiac Monitoring Devices Market Size and Share Forecast Outlook 2025 to 2035

Continuous Ketone Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Continuous Flow Bioreactors Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Continuous Inkjet Printers Market Size and Share Forecast Outlook 2025 to 2035

Continuous Fryer Machine Market Size and Share Forecast Outlook 2025 to 2035

Continuous Glucose Monitoring Device Market - Demand & Future Trends 2025 to 2035

Continuous Hormone Monitoring Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Continuous Emission Monitoring System Market Growth - Trends & Forecast 2025 to 2035

Continuous Positive Airway Pressure (CPAP) Market Analysis – Size, Share & Forecast Outlook 2025 to 2035

Continuous Glucose Monitoring Systems Market is segmented by transmitters and monitors, sensors and insulin pump from 2025 to 2035

Continuous Miners Market Growth - Trends & Forecast 2025 to 2035

Continuous Renal Replacement Therapy Market Growth – Trends & Forecast 2025-2035

Continuous Peripheral Nerve Block Catheter Market Growth – Trends & Forecast 2025-2035

Market Share Breakdown of Continuous Inkjet Printers Providers

Continuous Thread Metal Cap Market

Continuous Integration Tools Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA