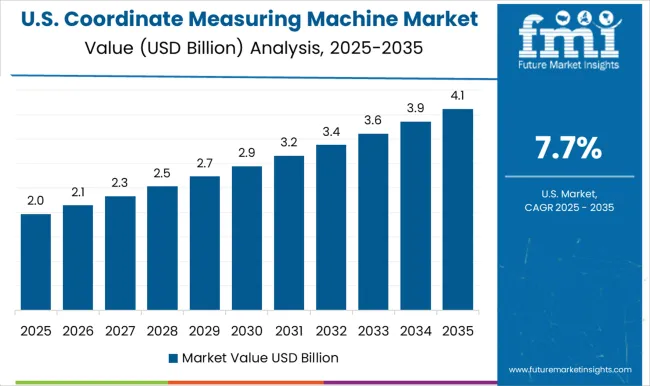

The Coordinate Measuring Machine Market is estimated to be valued at USD 4.2 billion in 2025 and is projected to reach USD 9.8 billion by 2035, registering a compound annual growth rate (CAGR) of 9.0% over the forecast period. The acceleration and deceleration pattern analysis highlights rapid early-phase growth followed by a gradual deceleration as the market matures. Between 2025 and 2030, the market grows from USD 4.2 billion to USD 6.4 billion, contributing USD 2.2 billion in growth, with a CAGR of 9.7%. This early-stage acceleration is driven by the increasing adoption of CMMs in manufacturing industries, particularly automotive, aerospace, and electronics, where high precision and quality control are critical.

The rise of automation and smart manufacturing also plays a significant role in fueling demand. From 2030 to 2035, the market is expected to grow from USD 6.4 billion to USD 9.8 billion, representing a 3.4 billion USD increase, with a slightly lower CAGR of 7.3%. The deceleration reflects the market’s gradual maturation, as most major industries have already integrated CMMs into their processes. However, demand remains strong in emerging markets and newer applications, such as 3D printing and additive manufacturing, where precision measurement is becoming increasingly essential. The acceleration and deceleration pattern indicates a strong early-phase growth driven by technological adoption, followed by steady growth as the market stabilizes.

Quality engineers evaluate coordinate measuring machine specifications based on volumetric accuracy characteristics, probe system versatility, and software capability sophistication when establishing inspection protocols for turbine blade verification, medical implant validation, and injection molded part analysis requiring traceable measurement standards. Equipment selection involves analyzing measurement uncertainty budgets, environmental temperature compensation, and probe configuration flexibility while considering throughput requirements, operator skill levels, and integration complexity factors necessary for production floor implementation. Investment decisions balance capital equipment costs against inspection labor reduction, considering scrap prevention value, customer quality requirement compliance, and certification maintenance benefits that justify precision measurement system deployment through measurable quality improvement outcomes.

Manufacturing processes require precision machine assembly, thermal stability optimization, and calibration protocol establishment that achieve measurement laboratory standards while maintaining industrial production environment compatibility throughout demanding operational conditions. Production coordination involves managing granite base preparation, drive system integration, and software configuration while addressing environmental vibration isolation, temperature control systems, and compressed air quality requirements specific to coordinate measuring machine operation. Quality validation encompasses accuracy verification, repeatability testing, and uncertainty analysis that ensure measurement reliability while supporting ISO 9001 compliance and customer audit requirements throughout extended operational periods.

| Metric | Value |

|---|---|

| Coordinate Measuring Machine Market Estimated Value in (2025 E) | USD 4.2 billion |

| Coordinate Measuring Machine Market Forecast Value in (2035 F) | USD 9.8 billion |

| Forecast CAGR (2025 to 2035) | 9.0% |

The coordinate measuring machine market is witnessing steady growth due to increased demand for precision measurement across high tolerance manufacturing environments. Industries are focusing on improving product quality, minimizing defects, and ensuring compliance with international measurement standards, which has significantly boosted the adoption of advanced metrology equipment.

Advancements in automation, sensor accuracy, and software integration are making these systems essential across production and quality control workflows. As industries continue to embrace smart manufacturing and digital inspection techniques, coordinate measuring machines are being increasingly integrated into automated production lines.

The outlook for the market remains positive as sectors such as aerospace, automotive, and heavy machinery emphasize dimensional accuracy, process repeatability, and traceable inspection systems.

The coordinate measuring machine market is segmented by type, application, end user, and geographic regions. By type, the coordinate measuring machine market is divided into Bridge, Cantilever, Gantry, Articulated arm, and Portable. In terms of application, the coordinate measuring machine market is classified into Dimensional measurement, Surface measurement, Quality control & inspection, Virtual simulation, Reverse engineering, and Others.

Based on end user, the coordinate measuring machine market is segmented into Process industry, Automotive, Aerospace & defense, Energy & power, Heavy machinery, and Others. Regionally, the coordinate measuring machine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The bridge type coordinate measuring machine is expected to represent 48.60% of the total market revenue by 2025 under the type category, positioning it as the dominant configuration. This leadership is attributed to its structural stability, high measurement accuracy, and versatility in both shop floor and laboratory settings.

Bridge CMMs are favored for inspecting medium to large components with consistent repeatability, making them a mainstay in precision-driven industries. The ability to integrate with tactile and optical probes has enhanced their adaptability to complex measurement tasks.

Additionally, bridge type systems offer a balanced combination of affordability and performance, making them suitable for a wide range of industrial applications where dimensional verification is critical.

Dimensional measurement is projected to account for 53.20% of total market revenue by 2025 within the application segment, highlighting its central role in quality assurance processes. The segment’s growth is driven by the increasing need to ensure part conformity to design specifications in high precision manufacturing sectors.

Coordinate measuring machines used for dimensional verification are vital for maintaining component integrity, reducing rejection rates, and supporting continuous improvement initiatives. As manufacturing tolerances become tighter, particularly in aerospace, defense, and medical devices, the demand for reliable dimensional inspection tools has risen sharply.

This has positioned dimensional measurement as the leading application within the market.

The process industry segment is anticipated to hold 46.70% of total market revenue by 2025 within the end user category, establishing it as the foremost contributor. This segment’s growth is being driven by the need for precise component verification across sectors such as energy, chemicals, and heavy equipment manufacturing.

In these industries, even minor deviations can impact system efficiency and safety, reinforcing the need for meticulous measurement solutions. Process industry players are investing in coordinate measuring machines to improve operational reliability and reduce the likelihood of downtime caused by dimensional defects.

With complex assemblies and high operational loads, this end user group continues to lead in deploying robust metrology systems for quality assurance.

The coordinate measuring machine (CMM) market is experiencing significant growth, driven by the increasing demand for high-precision measurement solutions across industries such as automotive, aerospace, manufacturing, and electronics. CMMs are essential tools for measuring the physical geometrical characteristics of objects, ensuring product quality, and supporting advanced manufacturing processes. With the rise of automation, Industry 4.0, and the need for stringent quality control, the demand for CMMs is expanding. Technological advancements, including the integration of CMMs with robotic systems, IoT, and real-time data analytics, are further propelling market growth, enhancing the capabilities and efficiency of CMM systems.

The primary driver of growth in the CMM market is the rising demand for precision manufacturing and quality control in sectors like automotive, aerospace, and electronics. CMMs enable manufacturers to inspect and measure parts with high accuracy, ensuring that components meet strict tolerances and performance standards. As industries increasingly adopt advanced manufacturing techniques, such as additive manufacturing and CNC machining, the need for precise measurement systems that can handle complex geometries and intricate designs is growing. The demand for CMMs is further fueled by the need for continuous improvements in product quality, productivity, and cost-effectiveness across these industries

Despite the growth prospects, the CMM market faces challenges related to the high initial investment and operational costs. CMMs, especially high-precision models, can be expensive, making them less accessible to small and medium-sized enterprises (SMEs). The cost of purchasing and maintaining these systems, including calibration, training, and software upgrades, can be a significant financial burden. Additionally, CMMs require skilled operators to ensure accurate measurements, and any errors can lead to costly rework or production delays. While the technology is highly effective, the high cost and complexity of CMM systems remain a barrier to their adoption, particularly in industries with tight budgets.

The CMM market presents substantial growth opportunities, especially with the integration of these machines into automated and smart manufacturing systems. The rise of Industry 4.0 and the increasing demand for automated solutions in manufacturing processes are driving the need for integrated CMM systems that can work seamlessly with robotic arms, automated inspection lines, and real-time data analytics platforms. By incorporating CMMs into automated workflows, manufacturers can achieve higher levels of accuracy, efficiency, and productivity. The ongoing development of portable and more affordable CMMs opens new opportunities for smaller businesses and industries where space and cost are constraints, further expanding market reach.

A key trend in the CMM market is the increasing adoption of portable and 3D CMM solutions. Portable CMMs, including handheld probes and laser scanning systems, are gaining popularity due to their flexibility and ability to perform measurements in various locations, such as on the shop floor or in remote areas. These solutions are particularly beneficial for industries with large or complex parts that are difficult to measure with traditional stationary CMMs. Furthermore, the demand for 3D CMMs, which offer more comprehensive and detailed measurements, is growing as manufacturers require more accurate and holistic inspection of parts with intricate geometries. As CMM technologies continue to evolve, the integration of advanced features like 3D scanning and portability is reshaping the market, making these solutions more versatile and accessible.

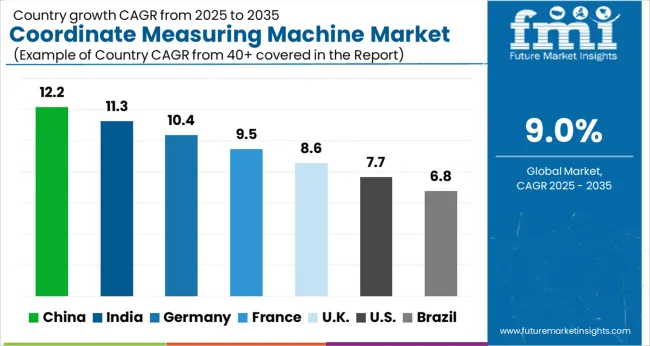

| Country | CAGR |

|---|---|

| China | 12.2% |

| India | 11.3% |

| Germany | 10.4% |

| France | 9.5% |

| UK | 8.6% |

| USA | 7.7% |

| Brazil | 6.8% |

Global Coordinate Measuring Machine market demand is projected to rise at a 9.0% CAGR from 2025 to 2035. China leads at 12.2%, followed by India at 11.3%, and Germany at 10.4%, while the United Kingdom records 8.6% and the United States posts 7.7%. These rates translate to a growth premium of +35% for China, +25% for India, and +10% for Germany versus the baseline, while the United States and the United Kingdom show slower growth. Divergence reflects local catalysts: increasing demand for precision engineering and industrial automation in China and India, while more mature markets like the United States and the United Kingdom experience slower growth due to advanced infrastructure and established industrial bases. The analysis includes over 40+ countries, with the leading markets detailed below.

The CMM market in China is expanding rapidly at a CAGR of 12.2%, driven by significant investments in manufacturing, automation, and precision engineering. As one of the largest industrial hubs globally, China is increasing its focus on high-quality manufacturing processes, and CMMs are essential in ensuring product precision across various industries, including automotive, aerospace, and electronics. The government’s emphasis on “Made in China 2025” and the growing trend toward Industry 4.0 are pushing for further technological upgrades. China’s investments in research and development are fostering the adoption of CMMs, with both large-scale manufacturers and small-to-medium enterprises enhancing their capabilities in quality control.

The CMM market in India is growing at a CAGR of 11.3%, driven by increasing industrial automation, particularly in the automotive, aerospace, and heavy machinery sectors. The country’s growing industrial base and focus on high-precision manufacturing are key factors supporting the demand for CMMs. India’s expanding middle class and rising consumer demand for high-quality products are putting pressure on manufacturers to enhance production quality, which in turn boosts the need for accurate measurement systems like CMMs. Government incentives and initiatives aimed at increasing domestic manufacturing capabilities are contributing to the market's growth.

The CMM market in Germany is projected to expand at a CAGR of 10.4%, driven by its strong manufacturing and automotive sectors. As one of the leading countries in engineering and industrial precision, Germany’s demand for high-quality measurement systems like CMMs remains high. With a focus on automation and digitization in manufacturing, the country is investing heavily in advanced technologies that ensure precision and quality control. The German automotive industry, in particular, relies on CMMs to maintain strict manufacturing tolerances and quality standards. Additionally, the country’s focus on sustainability and technological innovation is driving the demand for CMMs in various sectors, including metalworking, plastics, and machinery.

The United Kingdom’s CMM market is growing at a CAGR of 8.6%, driven by the country’s emphasis on high-quality manufacturing and precision engineering. As a leader in aerospace, automotive, and industrial design, the UK’s need for advanced measurement systems like CMMs is rising. The UK’s well-established infrastructure and strong industrial base support the demand for precise quality control tools. As industries move towards automation, the role of CMMs in maintaining accuracy and precision in production processes becomes even more critical. The UK government’s focus on supporting advanced manufacturing technologies and smart factories further enhances the market growth for CMMs.

The USA CMM market is growing at a CAGR of 7.7%, with steady demand from the aerospace, automotive, and electronics sectors. While the market in the USA is relatively mature, the increasing focus on automation and precision engineering is driving the adoption of CMMs for quality control. The demand for CMMs is particularly strong in industries that require high-precision measurements, such as aerospace manufacturing, medical devices, and automotive production. The USA focuses on improving manufacturing efficiency and reducing production costs, the adoption of CMMs to enhance accuracy and reduce error margins is accelerating.

The Coordinate Measuring Machine (CMM) Market is witnessing significant expansion, driven by increasing demand for precision inspection and quality control in automotive, aerospace, and electronics manufacturing. Key industry players such as Hexagon AB and Carl Zeiss AG are leading with advanced CMM solutions integrating multi-sensor technology, automated probing systems, and digital metrology software for real-time accuracy enhancement. FARO Technologies Inc. and Keyence Corporation are introducing portable and optical CMM models, catering to high-speed, on-site inspection needs across production environments.

Sinowon Innovation Metrology Manufacture Limited is strengthening its global footprint through cost-effective and user-friendly CMM systems for small and mid-scale industries. Perceptron Inc. continues to innovate in in-line metrology and robotic CMM technologies, enhancing process control and reducing human error in manufacturing workflows. Nikon Corporation is leveraging its optical expertise to develop laser-based and non-contact CMMs for complex component geometries in electronics and medical devices.

| Item | Value |

|---|---|

| Quantitative Units | USD 4.2 Billion |

| Type | Bridge, Cantilever, Gantry, Articulated arm, and Portable |

| Application | Dimensional measurement, Surface measurement, Quality control & inspection, Virtual simulation, Reverse engineering, and Others |

| End User | Process industry, Automotive, Aerospace & defense, Energy & power, Heavy machinery, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled |

Hexagon AB, Carl Zeiss AG, FARO Technologies Inc., Keyence Corporation, Sinowon Innovation Metrology Manufacture Limited, Perceptron Inc., Nikon Corporation |

| Additional Attributes | Dollar sales by product type (manual CMMs, CNC CMMs, portable CMMs, optical CMMs) and end-use segments (automotive, aerospace, electronics, manufacturing, precision engineering). Demand dynamics are driven by increasing automation in manufacturing, demand for quality control solutions, and the growing need for precision measurement in industries such as automotive and aerospace. Regional trends show strong growth in North America, Europe, and Asia-Pacific, with continuous advancements in CMM technologies, integration with automation systems, and growing focus on reducing measurement errors driving market expansion. |

The global coordinate measuring machine market is estimated to be valued at USD 4.2 billion in 2025.

The market size for the coordinate measuring machine market is projected to reach USD 9.8 billion by 2035.

The coordinate measuring machine market is expected to grow at a 9.0% CAGR between 2025 and 2035.

The key product types in coordinate measuring machine market are bridge, cantilever, gantry, articulated arm and portable.

In terms of application, dimensional measurement segment to command 53.2% share in the coordinate measuring machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Air Measuring Equipment Market Size and Share Forecast Outlook 2025 to 2035

Fuel Measuring Devices Market

Laser Measuring Instrument Market Size and Share Forecast Outlook 2025 to 2035

Level Measuring Instrument Market

Optical Measuring Systems Market Growth – Trends & Forecast 2025 to 2035

Contour Measuring Machines Market Size and Share Forecast Outlook 2025 to 2035

Pediatric Measuring Devices Market Size and Share Forecast Outlook 2025 to 2035

Disposable Medicine Measuring Cups Market

Sensor Based Glucose Measuring Systems Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Asia Pacific Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Tool Cooling System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA