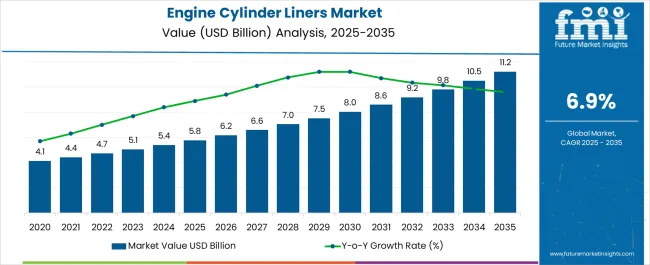

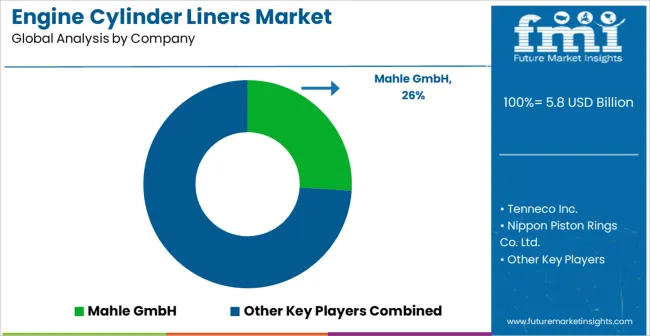

The Engine Cylinder Liners Market is estimated to be valued at USD 5.8 billion in 2025 and is projected to reach USD 11.2 billion by 2035, registering a compound annual growth rate (CAGR) of 6.9% over the forecast period.

| Metric | Value |

|---|---|

| Engine Cylinder Liners Market Estimated Value in (2025 E) | USD 5.8 billion |

| Engine Cylinder Liners Market Forecast Value in (2035 F) | USD 11.2 billion |

| Forecast CAGR (2025 to 2035) | 6.9% |

The Engine Cylinder Liners market is witnessing steady growth driven by the increasing demand for high-performance and fuel-efficient engines across automotive and industrial applications. The future outlook of this market is shaped by rising vehicle production, stricter emission regulations, and the growing focus on engine durability and longevity. Advancements in material engineering and manufacturing technologies have improved the performance characteristics of cylinder liners, enabling enhanced wear resistance, thermal conductivity, and dimensional stability.

The adoption of lightweight and high-strength materials is supporting engine efficiency and reducing operational costs. Increasing investments in both passenger and commercial vehicle segments, coupled with the rising prevalence of gasoline-powered engines in developing regions, further support the expansion of the market.

Additionally, ongoing innovations in engine design and maintenance practices are driving the replacement and aftermarket demand for cylinder liners As global automotive and industrial sectors prioritize performance, fuel efficiency, and emission compliance, the Engine Cylinder Liners market is poised for sustained growth across diverse geographies.

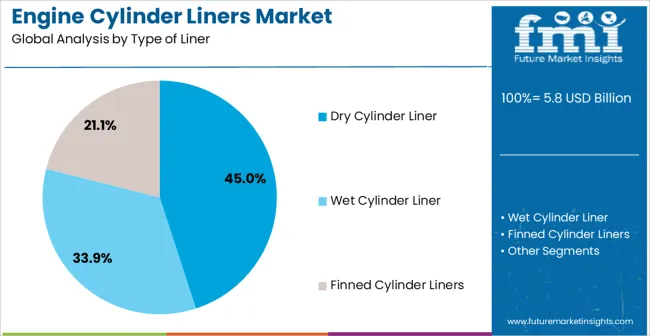

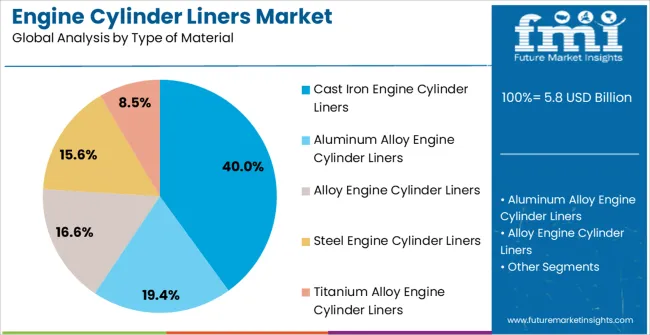

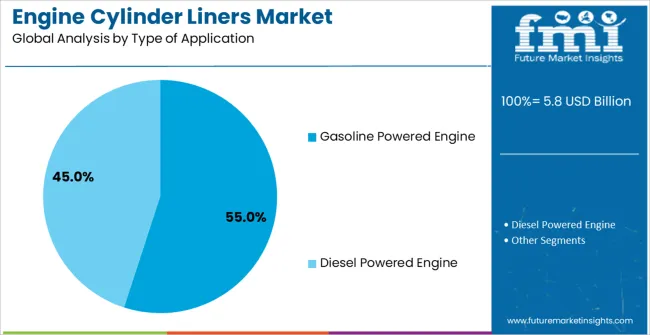

The engine cylinder liners market is segmented by type of liner, type of material, type of application, type of engine, and geographic regions. By type of liner, engine cylinder liners market is divided into Dry Cylinder Liner, Wet Cylinder Liner, and Finned Cylinder Liners. In terms of type of material, engine cylinder liners market is classified into Cast Iron Engine Cylinder Liners, Aluminum Alloy Engine Cylinder Liners, Alloy Engine Cylinder Liners, Steel Engine Cylinder Liners, and Titanium Alloy Engine Cylinder Liners. Based on type of application, engine cylinder liners market is segmented into Gasoline Powered Engine and Diesel Powered Engine. By type of engine, engine cylinder liners market is segmented into Automotive Engine Cylinder Liners, Passenger Vehicle, Light Commercial Vehicle, Heavy Commercial Vehicle, Motorcycle & Scooters Engine Cylinder Liners, Off Highway Equipment Engine Cylinder Liners, Industrial Engine Cylinder Liners, and Gardening/Landscaping Equipment Engine Cylinder Liners. Regionally, the engine cylinder liners industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The dry cylinder liner segment is projected to hold 45.0% of the Engine Cylinder Liners market revenue share in 2025, making it the leading type of liner. This dominance is attributed to its simplified installation and replacement process, which reduces maintenance downtime and enhances operational efficiency. The segment has benefited from the growing preference for engines designed for easy servicing and high durability.

Dry liners are particularly advantageous in applications where thermal expansion needs to be managed independently of the engine block, providing stability and consistent performance over prolonged usage. Additionally, their compatibility with various engine designs and ability to support high-performance operation have reinforced adoption.

The increased production of gasoline-powered engines, which often utilize dry liners for improved thermal management, further strengthens the market position of this segment Overall, the versatility, durability, and operational benefits of dry cylinder liners have driven their leading revenue share.

The cast iron engine cylinder liners segment is expected to account for 40.0% of the Engine Cylinder Liners market revenue share in 2025. The growth of this segment is driven by the material's inherent strength, wear resistance, and cost-effectiveness, making it a preferred choice for a wide range of engine applications.

Cast iron liners offer excellent durability under high-pressure and high-temperature operating conditions, which is critical for sustaining engine performance and reliability. Furthermore, advances in alloy composition and surface treatment have enhanced the longevity and efficiency of cast iron liners.

Their established presence in both original equipment manufacturing and aftermarket replacement scenarios supports steady demand The ability of cast iron liners to balance performance and manufacturing cost has made them widely adopted in gasoline-powered engines, reinforcing the segment's substantial market share.

The gasoline-powered engine application segment is anticipated to capture 55.0% of the Engine Cylinder Liners market revenue in 2025, positioning it as the leading application type. The growth of this segment is largely driven by the continued prevalence of gasoline engines in passenger vehicles and light commercial vehicles, particularly in regions with developing automotive markets.

Gasoline engines demand cylinder liners that can withstand high-speed operation, thermal stress, and consistent performance under varying load conditions. The adoption of advanced cylinder liner materials and designs has improved engine efficiency, fuel economy, and emission compliance, thereby supporting market growth.

Additionally, the preference for reliable and durable engine components in both OEM and aftermarket sectors has contributed to the dominance of gasoline-powered engine applications Rising consumer expectations for performance, longevity, and operational efficiency continue to propel the demand for cylinder liners in gasoline engines.

Engine cylinder liners, also known as a sleeve is a cylinder-shaped part which is fixed into an engine block to form a cylinder. Engine cylinder liners is considered to be an important component to form an engine interior which helps in preventing piston from wearing through cylinder bore as it provides a wear protective surface for piston and piston rings.

Engine cylinder liners finds its application in a wide range of vehicles, heavy machines and construction equipment. Owing to increasing strict emission norms coupled with downsize of engine, most of the leading companies are investing in research and development to reduce the weight of vehicle in order to achieve efficient fuel economy.

This in turn is estimated to increase the demand for efficient engine cylinder liners, subsequently contributing to the global engine cylinder liners market during the forecast period.

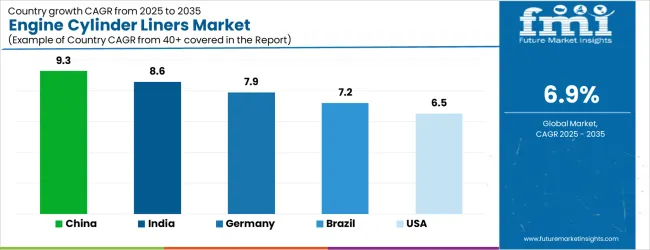

| Country | CAGR |

|---|---|

| China | 9.3% |

| India | 8.6% |

| Germany | 7.9% |

| Brazil | 7.2% |

| USA | 6.5% |

| UK | 5.8% |

| Japan | 5.2% |

The Engine Cylinder Liners Market is expected to register a CAGR of 6.9% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.3%, followed by India at 8.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.2%, yet still underscores a broadly positive trajectory for the global Engine Cylinder Liners Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.9%. The USA Engine Cylinder Liners Market is estimated to be valued at USD 2.0 billion in 2025 and is anticipated to reach a valuation of USD 2.0 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 281.0 million and USD 166.6 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 5.8 Billion |

| Type of Liner | Dry Cylinder Liner, Wet Cylinder Liner, and Finned Cylinder Liners |

| Type of Material | Cast Iron Engine Cylinder Liners, Aluminum Alloy Engine Cylinder Liners, Alloy Engine Cylinder Liners, Steel Engine Cylinder Liners, and Titanium Alloy Engine Cylinder Liners |

| Type of Application | Gasoline Powered Engine and Diesel Powered Engine |

| Type of Engine | Automotive Engine Cylinder Liners, Passenger Vehicle, Light Commercial Vehicle, Heavy Commercial Vehicle, Motorcycle & Scooters Engine Cylinder Liners, Off Highway Equipment Engine Cylinder Liners, Industrial Engine Cylinder Liners, and Gardening/Landscaping Equipment Engine Cylinder Liners |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Mahle GmbH, Tenneco Inc., Nippon Piston Rings Co. Ltd., ZYNP, TPR Co. Ltd., Federal-Mogul Corporation, Darton International, and Melrose Industries PLC |

The global engine cylinder liners market is estimated to be valued at USD 5.8 billion in 2025.

The market size for the engine cylinder liners market is projected to reach USD 11.2 billion by 2035.

The engine cylinder liners market is expected to grow at a 6.9% CAGR between 2025 and 2035.

The key product types in engine cylinder liners market are dry cylinder liner, wet cylinder liner and finned cylinder liners.

In terms of type of material, cast iron engine cylinder liners segment to command 40.0% share in the engine cylinder liners market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Engineering Machinery Counterweight Iron Market Size and Share Forecast Outlook 2025 to 2035

Engine-Driven Endodontic File Market Size and Share Forecast Outlook 2025 to 2035

Cylinder Boring Machine Market Size and Share Forecast Outlook 2025 to 2035

Engine Fixture Market Size and Share Forecast Outlook 2025 to 2035

Engine Piston Ring Set Market Size and Share Forecast Outlook 2025 to 2035

Engineering Service Outsourcing Industry Analysis in North America Size and Share Forecast Outlook 2025 to 2035

Cylinder Deactivation Systems Market Size and Share Forecast Outlook 2025 to 2035

Engine Fogging Oil Market Size and Share Forecast Outlook 2025 to 2035

Engine Valve Market Size and Share Forecast Outlook 2025 to 2035

Engine Starter Fluid Market Growth - Demand, Trends & Forecast 2025 to 2035

Engineering Service Outsourcing Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Engineering Analytics Market Growth & Demand 2025 to 2035

Engineering Plastic Market Analysis - Size, Share & Forecast 2025 to 2035

Engineered Cell Therapy - Market Trends & Forecast 2025 to 2035

Engine Tuner Market - Growth & Demand 2025 to 2035

Engine Flush Market Growth – Trends & Forecast 2025-2035

Cylinder Head Cover Market

Engineered Wood Market

Engine Actuators Market

Engine Mounting Brackets Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA