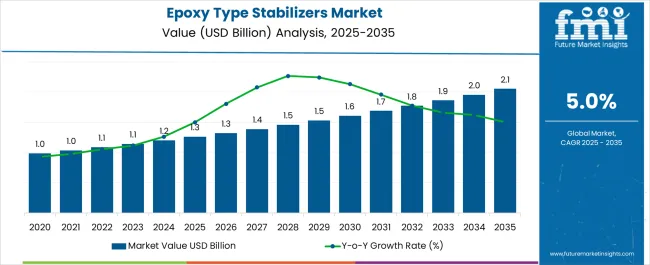

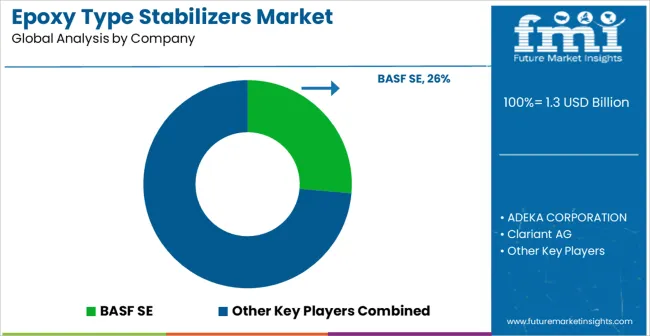

The Epoxy Type Stabilizers Market is estimated to be valued at USD 1.3 billion in 2025 and is projected to reach USD 2.1 billion by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

| Metric | Value |

|---|---|

| Epoxy Type Stabilizers Market Estimated Value in (2025 E) | USD 1.3 billion |

| Epoxy Type Stabilizers Market Forecast Value in (2035 F) | USD 2.1 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

The Epoxy Type Stabilizers market is experiencing consistent growth driven by the critical role these stabilizers play in enhancing the thermal and chemical performance of epoxy-based products. The future outlook for this market is shaped by increasing demand from industries requiring durable and high-performance materials, such as automotive, construction, and coatings.

Rising focus on energy-efficient and long-lasting materials has accelerated the adoption of epoxy stabilizers in end-use applications. Continuous advancements in polymer chemistry and formulation technologies have improved the effectiveness and versatility of these stabilizers, allowing manufacturers to meet stringent performance and regulatory standards.

The market is further supported by the growing production of paints, coatings, and composite materials that rely on epoxy formulations for superior stability As industries emphasize sustainability, efficiency, and high-quality output, the demand for epoxy type stabilizers is expected to expand steadily across global markets, providing opportunities for manufacturers to innovate and cater to diverse application needs.

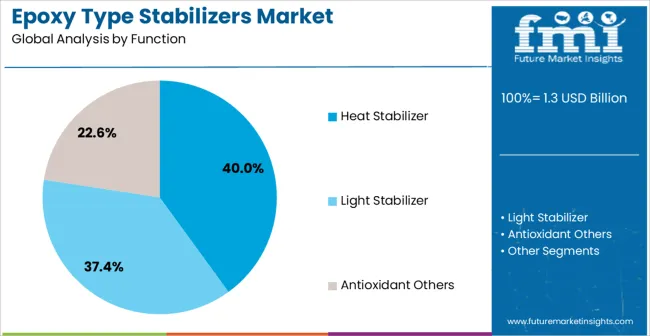

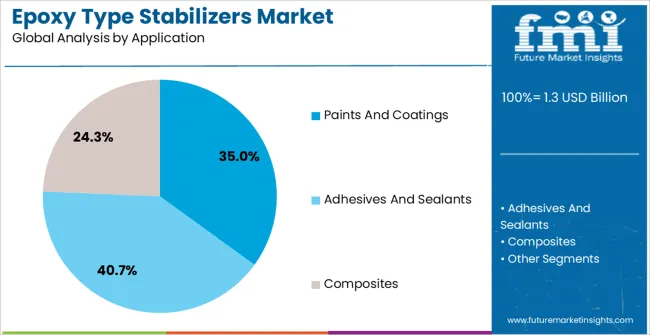

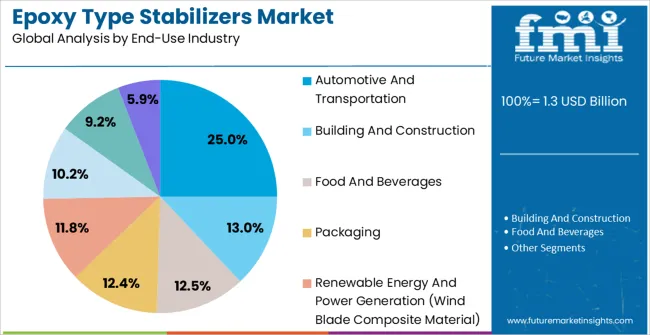

The epoxy type stabilizers market is segmented by function, application, end-use industry, and geographic regions. By function, epoxy type stabilizers market is divided into Heat Stabilizer, Light Stabilizer, and Antioxidant Others. In terms of application, epoxy type stabilizers market is classified into Paints And Coatings, Adhesives And Sealants, and Composites. Based on end-use industry, epoxy type stabilizers market is segmented into Automotive And Transportation, Building And Construction, Food And Beverages, Packaging, Renewable Energy And Power Generation (Wind Blade Composite Material), Marine, Electrical And Electronics, and Others. Regionally, the epoxy type stabilizers industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The heat stabilizer function segment is projected to hold 40.0% of the Epoxy Type Stabilizers market revenue share in 2025, establishing it as the leading function. This dominance is attributed to the increasing demand for thermally stable epoxy products across various industries, where high-temperature resistance is critical.

The growth has been reinforced by advancements in stabilizer formulations that enhance material longevity, prevent degradation, and improve process efficiency. Heat stabilizers are widely adopted in epoxy-based composites, coatings, and adhesives, where performance under prolonged exposure to heat is essential.

Additionally, regulatory standards for safety and material durability have encouraged manufacturers to integrate heat stabilizers into epoxy formulations The versatility of heat stabilizers to be used across different manufacturing processes and product types has further solidified their leading position in the market.

The paints and coatings application segment is expected to account for 35.0% of the Epoxy Type Stabilizers market revenue in 2025, making it the dominant application. This growth is driven by the rising demand for high-performance coatings that provide enhanced durability, corrosion resistance, and aesthetic appeal.

Epoxy stabilizers improve the thermal and chemical stability of coatings, ensuring long-lasting performance even in harsh environmental conditions. The adoption of epoxy-based paints and coatings has been reinforced by increasing construction activities, industrial infrastructure development, and maintenance requirements across commercial and industrial facilities.

Moreover, growing awareness of protective coatings and sustainable materials has accelerated the use of epoxy stabilizers in the paints and coatings industry Their ability to improve adhesion, durability, and resistance to chemical degradation further supports the segment’s leading market share.

The automotive and transportation end-use industry segment is anticipated to hold 25.0% of the Epoxy Type Stabilizers market revenue in 2025, making it a leading end-use sector. The growth of this segment is driven by the rising use of epoxy-based composites and coatings in vehicles to enhance thermal stability, mechanical strength, and corrosion resistance.

Epoxy stabilizers enable manufacturers to meet stringent industry standards for safety, durability, and performance, which are critical in automotive and transportation applications. Additionally, the increasing production of electric and hybrid vehicles, which require advanced material solutions for batteries, insulation, and protective coatings, has accelerated the adoption of epoxy stabilizers in this sector.

The focus on lightweight, high-performance materials in vehicles to improve fuel efficiency and sustainability has also contributed to the segment’s market dominance.

Stabilizers play a significant role in enhancing the appearance and physical properties of polymer materials. However, with growing demand for better stabilizers from various industries, consumers have shifted their focus towards epoxy type stabilizers.

Epoxy type stabilizers are advanced stabilizers featuring superior adhesiveness due to the presence of epoxy group. They are compatible with a wide range of polymers and are being increasingly used across various applications on account of their ability to enhance strength, thermal stability and corrosion resistance of materials.

Rising adoption of epoxy stabilizers for improving the aesthetic features of various products is providing impetus to the growth of epoxy type stabilizers. These types of stabilizers extend the life span of substrates by protecting them from decay, corrosion and UV light induced distortion. Moreover, they provide higher gloss retention of substrates and significantly decrease blistering and crack formation.

The epoxy-based coatings, paints, and sealants often turn yellow and chalk due to excessive heat and sunlight. In order to minimize and eliminate this, epoxy type stabilizers are being increasingly utilized. This will continue to boost their sales during the forecast period.

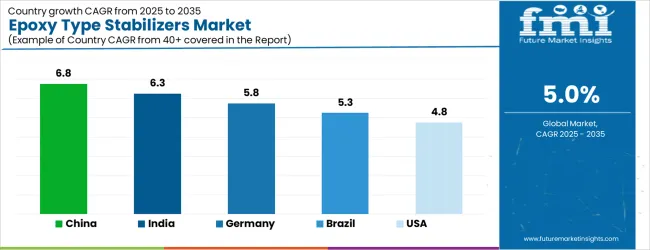

| Country | CAGR |

|---|---|

| China | 6.8% |

| India | 6.3% |

| Germany | 5.8% |

| Brazil | 5.3% |

| USA | 4.8% |

| UK | 4.3% |

| Japan | 3.8% |

The Epoxy Type Stabilizers Market is expected to register a CAGR of 5.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.8%, followed by India at 6.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 3.8%, yet still underscores a broadly positive trajectory for the global Epoxy Type Stabilizers Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.8%. The USA Epoxy Type Stabilizers Market is estimated to be valued at USD 455.9 million in 2025 and is anticipated to reach a valuation of USD 455.9 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 69.1 million and USD 38.6 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.3 Billion |

| Function | Heat Stabilizer, Light Stabilizer, and Antioxidant Others |

| Application | Paints And Coatings, Adhesives And Sealants, and Composites |

| End-Use Industry | Automotive And Transportation, Building And Construction, Food And Beverages, Packaging, Renewable Energy And Power Generation (Wind Blade Composite Material), Marine, Electrical And Electronics, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | BASF SE, ADEKA CORPORATION, Clariant AG, Akzo Nobel N.V., Huntsman Corporation, Albemarle Corporation, Solvay S.A., Evonik Industries AG, Songwon Industrial Co.Ltd., and Kyowa Chemical Industry Co.Ltd. |

The global epoxy type stabilizers market is estimated to be valued at USD 1.3 billion in 2025.

The market size for the epoxy type stabilizers market is projected to reach USD 2.1 billion by 2035.

The epoxy type stabilizers market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in epoxy type stabilizers market are heat stabilizer, light stabilizer and antioxidant others.

In terms of application, paints and coatings segment to command 35.0% share in the epoxy type stabilizers market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Epoxy Grouts Market Size and Share Forecast Outlook 2025 to 2035

Epoxy Putty and Construction Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Epoxy Active Diluent Market Size and Share Forecast Outlook 2025 to 2035

Epoxy Composite Market Size and Share Forecast Outlook 2025 to 2035

Epoxy Paint Thinner Market Growth - Trends & Forecast 2025 to 2035

Epoxy Curing Agent Market Growth - Trends & Forecast 2025 to 2035

Epoxy Paint Market Growth – Trends & Forecast 2024-2034

Asia Pacific Epoxy Resin Market Growth – Trends & Forecast 2024-2034

Epoxy Resin Market Growth – Trends & Forecast 2024-2034

Epoxy Encapsulation Material Market

2K Epoxy Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Concrete Epoxy Repair Market Size and Share Forecast Outlook 2025 to 2035

Type 1 Commercial Surge Protection Devices Market Size and Share Forecast Outlook 2025 to 2035

Type-C Bulk Bags Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Type-C Bulk Bags Companies

V Type Fin Condenser Market Size and Share Forecast Outlook 2025 to 2035

V Type Air Cooled Condenser Market Size and Share Forecast Outlook 2025 to 2035

Gel-Type Strong Acid Cation Exchange Resin Market Size and Share Forecast Outlook 2025 to 2035

Dry Type Distribution Transformer Market Size and Share Forecast Outlook 2025 to 2035

Dry Type Current Transformer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA