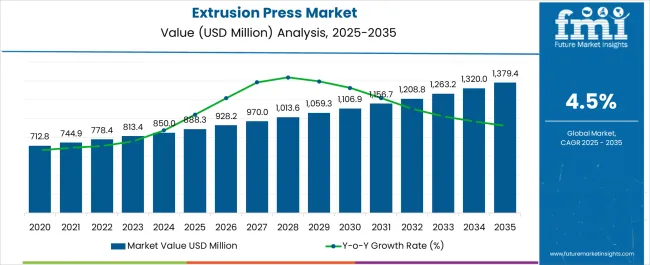

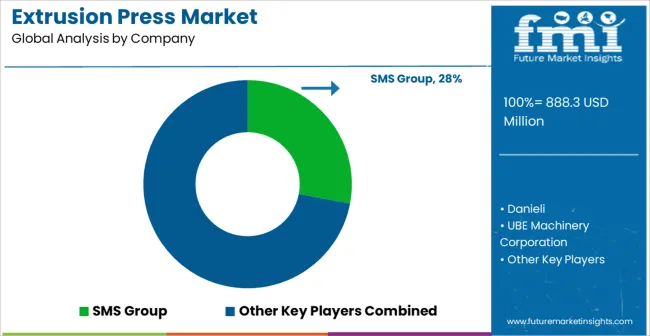

The Extrusion Press Market is estimated to be valued at USD 888.3 million in 2025 and is projected to reach USD 1379.4 million by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

| Metric | Value |

|---|---|

| Extrusion Press Market Estimated Value in (2025 E) | USD 888.3 million |

| Extrusion Press Market Forecast Value in (2035 F) | USD 1379.4 million |

| Forecast CAGR (2025 to 2035) | 4.5% |

The Extrusion Press market is experiencing significant growth driven by the increasing demand for high-efficiency metal forming solutions across automotive, aerospace, and manufacturing sectors. The future outlook for this market is shaped by ongoing technological advancements in press design, process automation, and material handling, which enhance productivity and precision. Rising demand for lightweight, high-strength components, particularly in the automotive and aerospace industries, has accelerated the adoption of extrusion presses capable of handling diverse materials and complex geometries.

Investments in modern manufacturing facilities and the emphasis on reducing production costs and lead times further support market expansion. Additionally, the integration of smart manufacturing technologies, including real-time monitoring, predictive maintenance, and automation, is driving the transition from conventional presses to highly flexible extrusion press systems.

Growing awareness of energy-efficient and environmentally sustainable manufacturing practices also encourages the adoption of advanced extrusion presses As industrial sectors continue to prioritize efficiency, precision, and customization in metal forming operations, the extrusion press market is expected to sustain its upward trajectory in both developed and emerging regions.

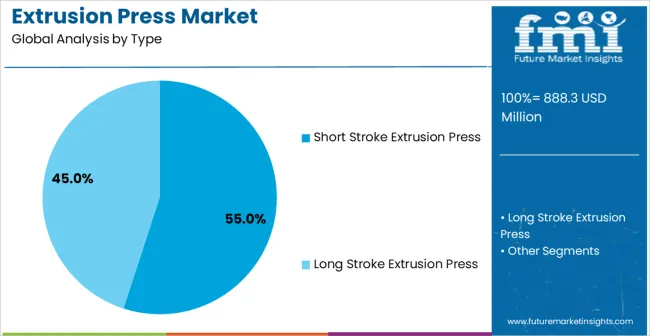

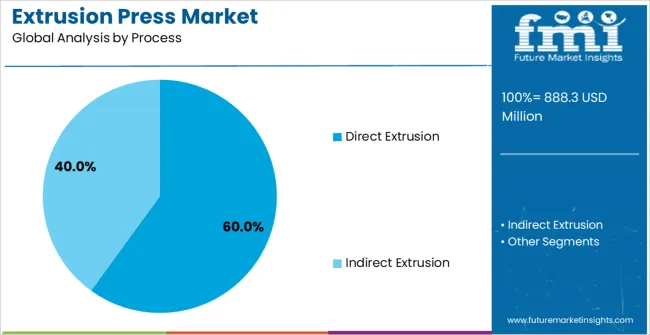

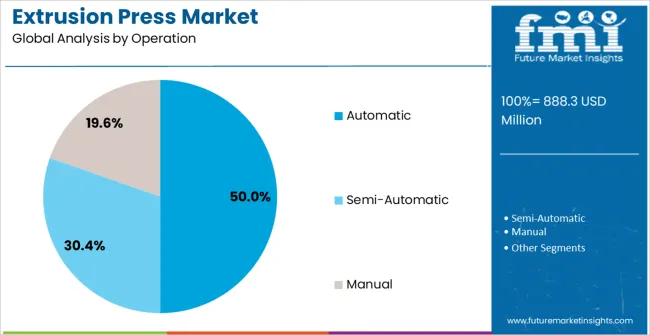

The extrusion press market is segmented by type, process, operation, operating temperature, material, and geographic regions. By type, extrusion press market is divided into Short Stroke Extrusion Press and Long Stroke Extrusion Press. In terms of process, extrusion press market is classified into Direct Extrusion and Indirect Extrusion. Based on operation, extrusion press market is segmented into Automatic, Semi-Automatic, and Manual. By operating temperature, extrusion press market is segmented into Hot Extrusion and Cold Extrusion. By material, extrusion press market is segmented into Metal, Ceramic, and Plastics. Regionally, the extrusion press industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The short stroke extrusion press type segment is projected to hold 55.0% of the Extrusion Press market revenue share in 2025, establishing it as the leading type. This growth is attributed to its capability to deliver high-speed operations with consistent quality and minimal material waste. The compact design of short stroke presses allows for better space utilization in production facilities, making them suitable for industries with limited floor space.

Enhanced control systems and automation capabilities have improved precision and repeatability, which are essential for high-volume production. The increasing need for reliable, efficient, and cost-effective extrusion solutions has further strengthened the adoption of short stroke extrusion presses.

Additionally, their versatility in processing a wide range of metals and alloys contributes to their dominance in the market The segment’s growth is also supported by investments in advanced manufacturing technologies and the rising demand for lightweight, high-performance components across key end-use industries.

The direct extrusion process segment is expected to account for 60.0% of the Extrusion Press market revenue share in 2025, making it the leading process type. Growth in this segment is driven by its ability to handle high volumes efficiently while maintaining precise dimensional control and surface finish. The simplicity and reliability of the direct extrusion process make it suitable for producing uniform profiles and long-length components.

Industries increasingly favor this process due to its lower operational complexity, faster cycle times, and adaptability to a variety of metals and alloys. Automation integration has enhanced productivity, reduced labor dependency, and improved overall process consistency.

Additionally, direct extrusion is cost-effective for large-scale manufacturing, supporting its dominance in the market Rising demand for high-strength components with tight tolerances, especially in automotive and industrial applications, continues to fuel the adoption of the direct extrusion process.

The automatic operation segment is projected to hold 50.0% of the Extrusion Press market revenue share in 2025, reflecting its leadership in operational preference. This growth is driven by the increasing emphasis on efficiency, precision, and safety in manufacturing environments. Automation reduces human intervention, minimizes errors, and ensures consistent output quality, which is critical in high-volume extrusion processes.

The integration of automated controls and real-time monitoring systems allows for better process management, predictive maintenance, and energy optimization. Industrial facilities are adopting automatic extrusion presses to achieve higher throughput, reduce production downtime, and meet stringent quality standards.

Additionally, the rising demand for scalable and adaptable manufacturing solutions has reinforced the preference for automatic operations The convergence of automation, digital monitoring, and process optimization continues to drive the growth and dominance of the automatic operation segment in the extrusion press market.

Extrusion press is industrial equipment that is used in material forming processes in which the material is pushed to flow through a die to convert it into the desired shape or reduce its cross-section. This equipment provides numerous benefits over other material forming manufacturing processes such as ability to work with ductile as well as brittle material and ability to create complex cross-sectional components, surfaces, and parts.

Two types of extrusion press are used in production processes naming long extrusion press and short extrusion press depending on the material and application. Demand for extrusion press for the materials such as metal and plastic is rapidly surging, owing to increasing usage in production of various products such as metal sheets, machine parts, metal roads, plastic pipes, tubes, and seals among others. This is estimated to augment the sales of extrusion press in the market.

In addition to this, increasing introduction on advanced automatic and semi-automatic industrial equipment with innovative technologies such as sensors are estimated to facilitate the sales of extrusion press in the coming years.

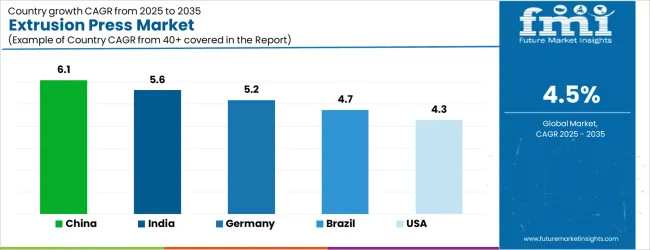

| Country | CAGR |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| Brazil | 4.7% |

| USA | 4.3% |

| UK | 3.8% |

| Japan | 3.4% |

The Extrusion Press Market is expected to register a CAGR of 4.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.1%, followed by India at 5.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 3.4%, yet still underscores a broadly positive trajectory for the global Extrusion Press Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.2%. The USA Extrusion Press Market is estimated to be valued at USD 334.6 million in 2025 and is anticipated to reach a valuation of USD 334.6 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 40.2 million and USD 30.9 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 888.3 Million |

| Type | Short Stroke Extrusion Press and Long Stroke Extrusion Press |

| Process | Direct Extrusion and Indirect Extrusion |

| Operation | Automatic, Semi-Automatic, and Manual |

| Operating Temperature | Hot Extrusion and Cold Extrusion |

| Material | Metal, Ceramic, and Plastics |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | SMS Group, Danieli, UBE Machinery Corporation, Presezzi Extrusion, Bosch Rexroth, Shanghai Electric, China National Heavy Machinery, and Wuxi Weite Machinery |

The global extrusion press market is estimated to be valued at USD 888.3 million in 2025.

The market size for the extrusion press market is projected to reach USD 1,379.4 million by 2035.

The extrusion press market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in extrusion press market are short stroke extrusion press and long stroke extrusion press.

In terms of process, direct extrusion segment to command 60.0% share in the extrusion press market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Pressurized Water Reactor System Market Size and Share Forecast Outlook 2025 to 2035

Pressure Relief Dressing Market Size and Share Forecast Outlook 2025 to 2035

Pressure Compensated Hydraulic Pump Market Size and Share Forecast Outlook 2025 to 2035

Pressure Compensated Pump Market Size and Share Forecast Outlook 2025 to 2035

Pressure Switch Market Forecast Outlook 2025 to 2035

Pressure Reducing Valve Market Size and Share Forecast Outlook 2025 to 2035

Extrusion Coatings Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Volume Loop Systems Market Size and Share Forecast Outlook 2025 to 2035

Pressure Transmitter Market Size and Share Forecast Outlook 2025 to 2035

Pressure Monitoring Extension Tubing Sets Market Size and Share Forecast Outlook 2025 to 2035

Pressure Sensitive Labeling Machine Market Size and Share Forecast Outlook 2025 to 2035

Pressure Bandages Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Sensitive Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Pressure Gauges Market Size and Share Forecast Outlook 2025 to 2035

Pressure Relief Valve Market Size and Share Forecast Outlook 2025 to 2035

Pressurized Wine Filter System Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Controlled Vacuum Sealers Market Size and Share Forecast Outlook 2025 to 2035

Press Machine Market Size and Share Forecast Outlook 2025 to 2035

Press Brakes Market Size and Share Forecast Outlook 2025 to 2035

Pressure Sensitive Tapes and Labels Market Size, Share & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA