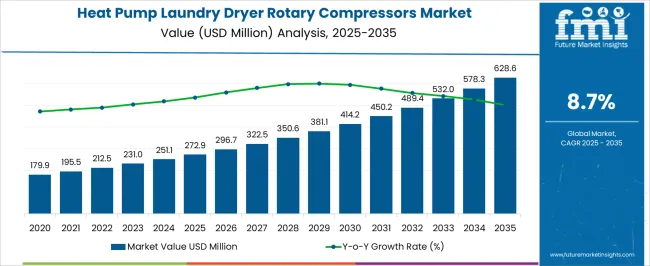

The Heat Pump Laundry Dryer Rotary Compressors Market is estimated to be valued at USD 272.9 million in 2025 and is projected to reach USD 628.6 million by 2035, registering a compound annual growth rate (CAGR) of 8.7% over the forecast period. Between 2025 and 2030, the market grows from USD 272.9 million to USD 414.2 million, contributing USD 141.3 million in growth, reflecting a CAGR of 8.6%. This early growth is driven by the increasing demand for energy-efficient drying solutions in the household appliance sector, alongside rising awareness of the need for lower energy consumption in residential and commercial laundry systems.

Between 2030 and 2035, the market continues to expand from USD 414.2 million to USD 628.6 million, adding USD 214.4 million in growth, with a slightly higher CAGR of 9.0%. This phase benefits from technological advancements in rotary compressors, increased adoption of heat pump dryers in both domestic and industrial applications, and rising demand for high-performance, eco-friendly appliances. The CAGR of 8.7% reflects a robust and stable growth trajectory, with the market reaching maturity as consumer demand for efficient drying solutions continues to rise, supported by innovations in compressor design and energy efficiency.

| Metric | Value |

|---|---|

| Heat Pump Laundry Dryer Rotary Compressors Market Estimated Value in (2025 E) | USD 272.9 million |

| Heat Pump Laundry Dryer Rotary Compressors Market Forecast Value in (2035 F) | USD 628.6 million |

| Forecast CAGR (2025 to 2035) | 8.7% |

The heat pump laundry dryer rotary compressors market is experiencing steady growth, driven by rising adoption of energy-efficient home appliances and regulatory pressure to reduce carbon emissions. Demand is being influenced by government incentives, environmental policies targeting refrigerant transitions, and a consumer shift toward sustainability-focused white goods.

Manufacturers are increasingly investing in compressor innovation to meet performance standards while reducing operating costs, especially in residential and multi-dwelling applications. Additionally, the integration of variable-speed technology and use of low-GWP refrigerants are gaining traction as energy labeling systems and building efficiency mandates tighten globally.

With heightened attention on decarbonizing household energy use and improving appliance longevity, the market is poised for long-term growth through both retrofit and new-build opportunities in Europe, Asia, and North America.

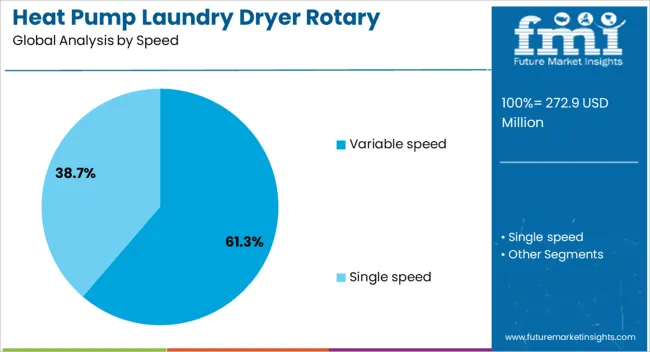

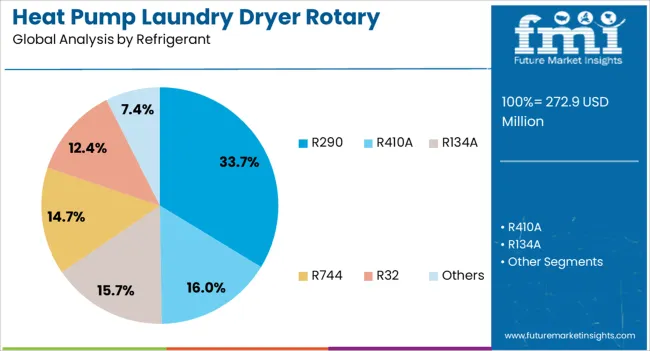

The heat pump laundry dryer rotary compressors market is segmented by speed, refrigerant, and geographic regions. By speed, the heat pump laundry dryer rotary compressors market is divided into Variable speed and Single speed. In terms of refrigerant, the heat pump laundry dryer rotary compressors market is classified into R290, R410A, R134A, R744, R32, and Others. Regionally, the heat pump laundry dryer rotary compressors industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Variable speed compressors are expected to account for 61.30% of the total revenue in the market by 2025, establishing this as the dominant speed configuration. This leadership is driven by enhanced energy savings, reduced operational noise, and improved thermal control offered by variable speed technology.

These compressors adjust output based on load requirements, leading to higher energy efficiency ratings—critical for appliances in regions governed by stringent energy labeling standards. Manufacturers have been prioritizing variable speed units in product lines due to their compatibility with inverter-driven systems, contributing to greater temperature precision and moisture control in heat pump dryers.

As consumers increasingly prioritize quieter and cost-effective appliances with superior drying performance, variable speed rotary compressors are being widely adopted across both premium and mid-tier segments.

The R290 refrigerant segment is projected to hold 33.70% of the market share in 2025, making it the leading refrigerant type in heat pump laundry dryer rotary compressors. This dominance is being supported by the low Global Warming Potential (GWP) of R290, its high thermodynamic efficiency, and growing regulatory pressure to phase out high-GWP fluorinated refrigerants.

R290 enables compliance with EU F-Gas regulations and emerging international climate targets, making it a preferred choice for environmentally conscious OEMs. Its natural origin and cost-efficiency further strengthen its appeal in sustainable product development.

Safety design improvements and charge minimization techniques have addressed historical flammability concerns, expanding the adoption of household laundry dryer systems. As end-users and appliance brands align with net-zero goals and eco-labeling criteria, R290-based compressor systems are expected to see continued deployment globally.

The heat pump laundry dryer rotary compressors market is expanding due to the increasing demand for energy-efficient, eco-friendly, and cost-effective drying solutions. Heat pump dryers, using rotary compressors, provide an efficient alternative to traditional drying methods by utilizing lower temperatures, reducing energy consumption. With rising consumer awareness of sustainability and energy savings, the adoption of heat pump dryers is growing in residential and commercial sectors. Technological advancements in compressor efficiency and the growing popularity of energy-efficient home appliances are further driving market growth, although challenges related to high initial costs remain.

The primary driver for the growth of the heat pump laundry dryer rotary compressors market is the rising demand for energy-efficient and eco-friendly home appliances. With increasing energy costs and consumer awareness of sustainability, more households are seeking energy-efficient alternatives to traditional dryers. Heat pump dryers, powered by rotary compressors, are gaining popularity due to their ability to reduce energy consumption while providing high drying efficiency. These dryers operate at lower temperatures, which reduces wear and tear on clothes, extending their lifespan. In addition, governments around the world are incentivizing the adoption of energy-efficient appliances, further accelerating market growth. The growing focus on reducing carbon footprints in both residential and commercial sectors is also contributing to the rise in demand for heat pump dryers.

A key challenge in the heat pump laundry dryer rotary compressors market is the high initial cost of heat pump dryers. While these appliances offer significant long-term energy savings, their upfront cost is higher than traditional electric dryers, which can deter cost-sensitive consumers from making the switch. Furthermore, the installation of heat pump dryers requires more specialized knowledge and a higher level of technical expertise, making it more complex and costly compared to conventional dryers. This can lead to higher service and maintenance fees, contributing to hesitancy among potential buyers. Overcoming these barriers by reducing costs, improving installation efficiency, and offering more affordable models could help expand the market.

The market for heat pump laundry dryer rotary compressors offers significant opportunities for innovation and expansion, particularly in the development of more efficient compressors. As manufacturers focus on improving compressor technology to enhance performance and reduce energy consumption, there is potential for market growth. Furthermore, the increasing adoption of energy-efficient appliances in emerging markets, where urbanization and disposable incomes are rising, presents a key opportunity. The demand for sustainable living solutions in these regions is driving the need for advanced laundry technologies. Manufacturers can capitalize on this opportunity by introducing affordable, efficient heat pump dryers that cater to the evolving needs of consumers in developing countries.

A growing trend in the heat pump laundry dryer rotary compressors market is the integration of smart technologies and compact designs. Consumers are increasingly seeking appliances that not only save energy but also offer enhanced user convenience. The integration of smart features, such as Wi-Fi connectivity, remote monitoring, and AI-driven drying programs, allows for a more personalized and convenient laundry experience. Compact designs are becoming more popular as urban living spaces require smaller, space-saving appliances. These trends are shaping the future of the market, with manufacturers focusing on making energy-efficient dryers smarter and more compact to meet the growing demands of modern consumers.

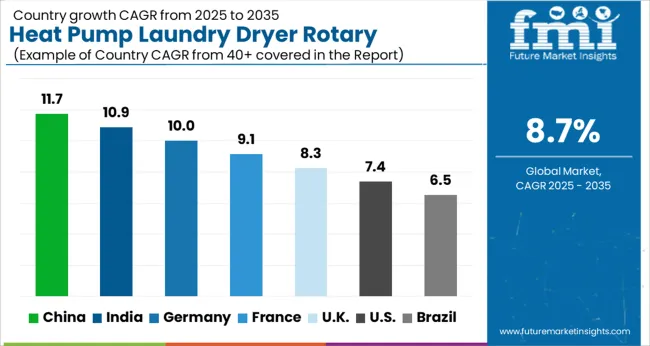

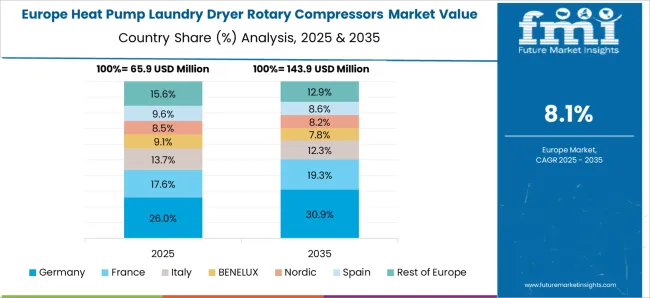

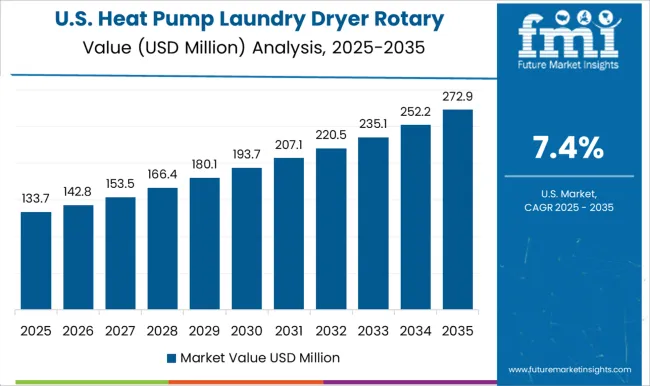

The heat pump laundry dryer rotary compressors market is projected to grow at a global CAGR of 8.7% from 2025 to 2035, with China leading at 11.7%, followed by India at 10.9%, and France at 9.1%. The United Kingdom records 8.3%, while the United States stands at 7.4%. The market growth in China and India is primarily driven by the increasing adoption of energy-efficient appliances, rising disposable income, and the growing demand for modern home appliances. Developed markets like France, the UK, and the USA exhibit steady growth, driven by the rising awareness of energy savings and the increasing penetration of heat pump dryers in the domestic sector. The analysis spans over 40+ countries, with the leading markets shown below.

China is projected to grow at a CAGR of 11.7% through 2035, with a growing demand for energy-efficient home appliances. The country's increasing urbanization, rising disposable incomes, and focus on sustainable living contribute to the rapid adoption of heat pump dryers and rotary compressors. The Chinese government’s strong emphasis on energy efficiency and environmental sustainability further accelerates the demand for such appliances. The increasing number of middle-class households, which are adopting modern appliances, also adds to the market's growth. The shift towards energy-efficient solutions is one of the key drivers in China’s market for heat pump dryers.

India is projected to grow at a CAGR of 10.9% through 2035, driven by the growing demand for energy-efficient appliances, especially in the residential sector. The country’s increasing urbanization, expanding middle class, and greater environmental awareness contribute to the rise in adoption of heat pump dryers. Furthermore, government incentives to promote energy-efficient solutions and increasing electricity prices further boost demand for these products. India’s significant growth in disposable incomes and an increasing preference for modern appliances support the growing demand for energy-efficient solutions like heat pump dryers.

France is projected to grow at a CAGR of 9.1% through 2035, driven by increasing demand for energy-efficient household appliances and growing consumer interest in reducing energy consumption. The French market is benefiting from government initiatives promoting the adoption of eco-friendly and energy-saving solutions. The growing awareness of environmental sustainability and the high cost of electricity in France also contribute to the rising popularity of heat pump dryers. The French government’s commitment to reducing carbon footprints is pushing manufacturers and consumers to adopt more energy-efficient technologies, making heat pump dryers increasingly popular in households.

The United Kingdom is projected to grow at a CAGR of 8.3% through 2035, supported by a rising focus on energy-efficient home appliances and sustainability. The increasing cost of energy and growing consumer awareness about energy savings are driving the demand for heat pump dryers. In the UK, the shift towards environmentally friendly solutions in households is pushing consumers to opt for appliances that offer energy savings and improved performance. Furthermore, government policies aimed at reducing carbon emissions are accelerating the adoption of these appliances. As the demand for energy-efficient and eco-friendly products continues to rise, the UK market is expected to see steady growth.

The United States is projected to grow at a CAGR of 7.4% through 2035, driven by the rising consumer demand for energy-efficient home appliances. With increasing environmental awareness, USA consumers are increasingly turning to energy-saving solutions, including heat pump dryers. The USA market for heat pump dryers is expected to expand as consumers seek out appliances that reduce energy usage and lower utility costs. The USA government’s energy efficiency standards and incentives for green technology adoption also play a significant role in the growth of the market. As the demand for energy-efficient household products increases, the adoption of heat pump dryers will continue to rise.

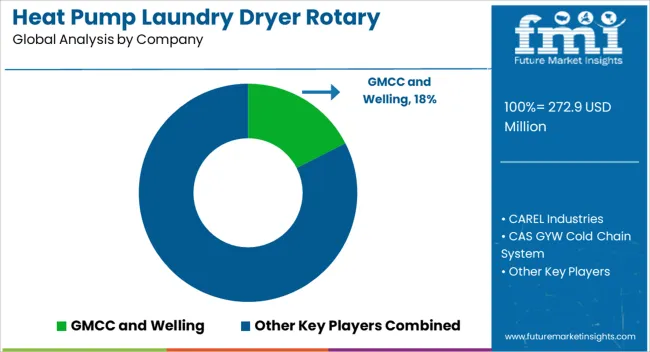

GMCC and Welling are leading the market, providing rotary compressors that optimize energy use, reduce drying time, and enhance the overall efficiency of heat pump laundry dryers. CAREL Industries and Copeland specialize in providing high-performance compressors, focusing on improving cooling and heating efficiency, which is essential for modern heat pump systems. CAS GYW Cold Chain System and Danfoss are key players, providing compressors designed for a wide range of applications, including heat pump dryers, with a strong focus on energy conservation, cost-efficiency, and performance reliability.

Frascold and GREE Electric also contribute to the market with innovative rotary compressors designed to deliver high energy efficiency and long-lasting durability, meeting the needs of energy-conscious consumers. LG Electronics, Mitsubishi Electric, and Panasonic Industry are major players, leveraging their expertise in electronics to offer high-quality rotary compressors integrated with their heat pump dryer systems. Mayekawa and Samsung focus on providing technologically advanced compressors designed to enhance drying performance while maintaining low environmental impact. RECHI Precision, Shanghai Highly, and Tecumseh Products are also strong competitors, providing efficient and reliable rotary compressors for heat pump dryers used in both commercial and residential applications. Competitive differentiation in this market is driven by energy efficiency, durability, integration with modern heat pump systems, and the ability to meet environmental standards.

Barriers to entry include high research and development costs, the need for technological innovation, and strong relationships with manufacturers. Strategic priorities include expanding product offerings, improving energy-saving features, and developing more compact, high-performance rotary compressors.

Dollar sales by product type (rotary compressors, reciprocating compressors, screw compressors) and end-use segments (residential heat pump dryers, commercial heat pump dryers, industrial applications). Demand dynamics are driven by the increasing adoption of energy-efficient appliances, growing awareness of environmental impact, and the rise of eco-conscious consumers.

| Item | Value |

|---|---|

| Quantitative Units | USD 272.9 Million |

| Speed | Variable speed and Single speed |

| Refrigerant | R290, R410A, R134A, R744, R32, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | GMCC and Welling, CAREL Industries, CAS GYW Cold Chain System, Copeland, Danfoss, Frascold, GREE Electric, LG Electronics, Mayekawa, Mitsubishi Electric, Panasonic Industry, RECHI Precision, Samsung, Shanghai Highly, and Tecumseh Products |

| Additional Attributes | Dollar sales by product type (rotary compressors, reciprocating compressors, screw compressors) and end-use segments (residential heat pump dryers, commercial heat pump dryers, industrial applications). Demand dynamics are driven by the increasing adoption of energy-efficient appliances, growing awareness of environmental impact, and the rise of eco-conscious consumers. |

The global heat pump laundry dryer rotary compressors market is estimated to be valued at USD 272.9 million in 2025.

The market size for the heat pump laundry dryer rotary compressors market is projected to reach USD 628.6 million by 2035.

The heat pump laundry dryer rotary compressors market is expected to grow at a 8.7% CAGR between 2025 and 2035.

The key product types in heat pump laundry dryer rotary compressors market are variable speed and single speed.

In terms of refrigerant, r290 segment to command 33.7% share in the heat pump laundry dryer rotary compressors market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Heat Induction Cap Liner Market Size and Share Forecast Outlook 2025 to 2035

Heat Transfer Film Market Size and Share Forecast Outlook 2025 to 2035

Heater-Cooler Devices Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Treating Market Size and Share Forecast Outlook 2025 to 2035

Heating Agents Market Size and Share Forecast Outlook 2025 to 2035

Heat Diffuser Market Size and Share Forecast Outlook 2025 to 2035

Heat-Activated Beauty Masks Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Heat Exchanger Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealable Packaging Market Size and Share Forecast Outlook 2025 to 2035

Heat Recovery System Generator Market Size and Share Forecast Outlook 2025 to 2035

Heat Shrink Tubes Market Size and Share Forecast Outlook 2025 to 2035

Heating and Cooling Market Size and Share Forecast Outlook 2025 to 2035

Heated Eyelash Curler Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Heated Jacket Market Trends & Demand 2025 to 2035

Heat Sealing Tape Market Size and Share Forecast Outlook 2025 to 2035

Heat Therapy Units Market Analysis - Size, Share, and Forecast 2025 to 2035

Heat Moisture Exchanger Market Size and Share Forecast Outlook 2025 to 2035

Heat Shrink Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA