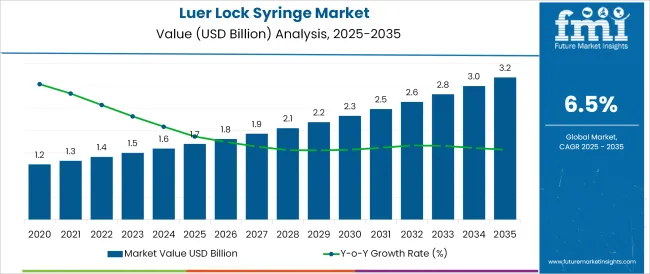

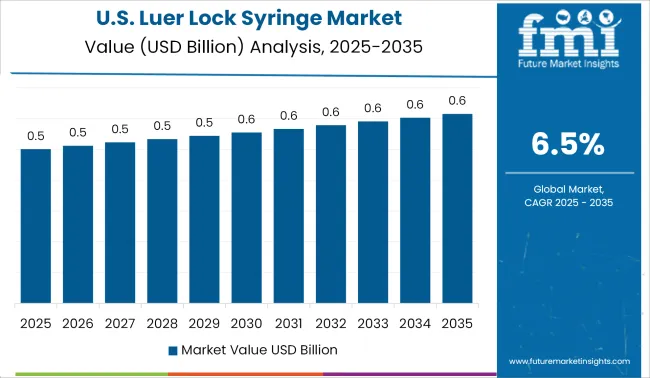

The Luer Lock Syringe Market is estimated to be valued at USD 1.7 billion in 2025 and is projected to reach USD 3.2 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

The Luer Lock syringe market is experiencing robust growth, driven by rising procedural volumes across hospitals and clinics, along with the increased need for secure, leak-proof medication delivery systems. A global emphasis on infection prevention, precision in drug administration, and enhanced patient safety protocols has accelerated the adoption of Luer Lock systems over traditional slip-tip syringes.

These syringes offer improved needle retention, minimizing the risk of disconnections during intravenous or intramuscular procedures. Technological advancements in material science and design engineering have enabled the development of more durable, ergonomically efficient syringe variants. Regulatory mandates encouraging the use of safety-engineered devices in both developed and emerging economies have further supported adoption.

Additionally, the increasing use of biologics and high-viscosity medications has necessitated syringes with secure locking mechanisms. As the healthcare industry shifts toward more reliable and safe drug administration tools, the Luer Lock syringe market is expected to witness steady expansion, particularly in acute care, vaccination drives, and chronic disease management programs.

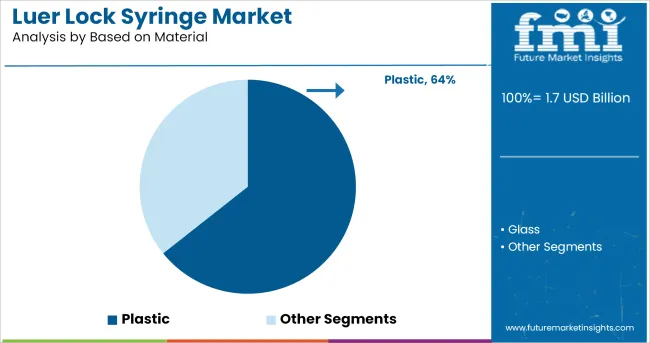

It is observed that plastic syringes account for 64.30% of total market revenue within the material segment, establishing themselves as the dominant sub-segment. This growth is underpinned by the widespread availability, low manufacturing costs, and ease of sterilization associated with medical-grade plastics such as polypropylene and polyethylene. Plastic variants offer the advantages of being lightweight, shatter-resistant, and highly compatible with a range of pharmaceutical compounds.

Additionally, their disposability aligns well with infection control protocols, reducing the risk of cross-contamination in clinical settings. The demand has further been supported by the scalability of plastic syringe production, especially during high-demand periods such as immunization campaigns and pandemic response efforts.

Consequently, plastic has emerged as the preferred material in Luer Lock syringe production due to its affordability, safety profile, and regulatory acceptance across global healthcare systems.

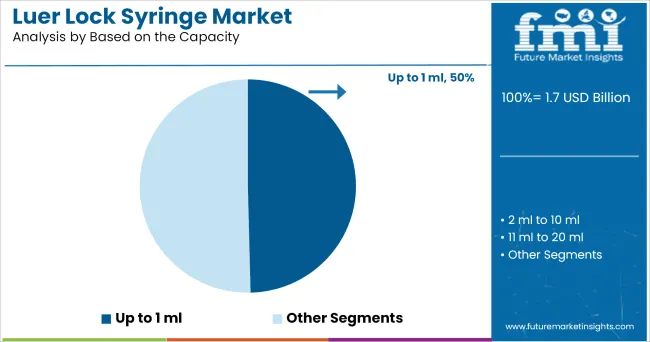

The segment comprising syringes with a capacity of up to 1 ml is projected to hold 49.60% of the market revenue, making it the most utilized format within the capacity category. This size is particularly suited for precise medication dosing, insulin delivery, and pediatric or geriatric care, where minimal dosage volumes are essential.

Its prevalence is further supported by its application in vaccinations, allergy treatments, and hormone therapies, where micro-dosing is routinely required. The small volume ensures reduced medication waste and improved dosing accuracy, aligning with clinical preferences in outpatient and home care settings.

Moreover, compatibility with auto-injectors and prefilled drug delivery systems has bolstered the demand for this format. As personalized medicine and preventive healthcare models continue to evolve, syringes with capacities up to 1 ml are expected to retain their leading role in the market.

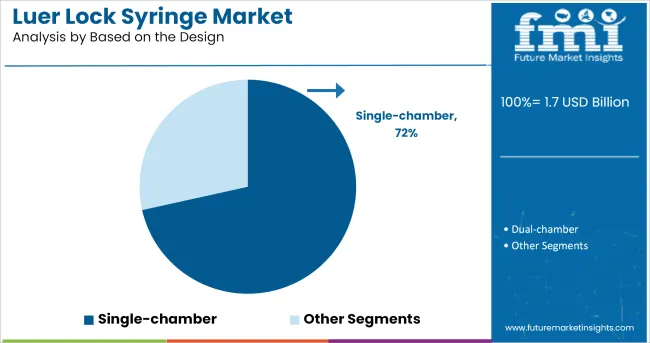

It has been identified that single-chamber syringes represent 71.50% of the total market within the design segment, reflecting their dominance in usage and production. This preference is attributed to their straightforward design, cost-efficiency, and ease of integration into standard clinical workflows.

Single-chamber syringes are predominantly used in routine drug administration, vaccinations, and diagnostic procedures, where pre-mixing or dual-component delivery is not required. Their design minimizes complexity during usage, reduces preparation time, and enhances overall procedural safety-particularly in high-volume clinical environments.

Furthermore, their adaptability to both manual and automated filling processes has positioned them as the go-to choice for pharmaceutical manufacturers. The widespread regulatory approval and compatibility with a variety of medications have reinforced their role as the industry standard, supporting their continued leadership in the Luer Lock syringe market.

A luer lock syringe is a locked type of syringe, wherein the needle can be completely twisted and locked into a place that provides a secure connection and preventing accidental removal of needle and contents by ensuring no leakage of liquids.

Luer lock syringe consists of a syringe that is attached to a syringe pump which prevents the disconnection thereby preventing spillage of drugs, especially during the IV administration. The secure connection between the needle and the drug to be administered during the complete administration process aids ease & convenience while using the luer lock syringe while saving the time to complete the procedure.

Thereby, the luer lock syringe is the ideal way of drug administration while avoiding medication leakage and potential needle disengagement.

The innovations and emerging technology in the healthcare sector are gaining traction in recent days and growing demand for the luer lock syringe market. The integrated seal cap in the luer lock syringe consists of an elastomeric component which is available in various formulations and a translucent, rigid polymer cap.

This results in the increased shelf life protection of the luer lock syringe and also leading to offer greater stability.

A cap-lock adapter in the luer lock syringe is the new security concept that combines a cap adapter and a label. Cap-lock technology irreversibly indicates whether the syringe has been previously opened while ensuring the integrity of the container.

The healthcare industry is in recent years is evolving like anything owing to the remarkable innovations especially in the area of vaccines and also due to the adoption of the latest technology while manufacturing a medical product.

The luer lock syringe not only prevents the loss of drug or medicinal liquid from the syringe but also leads to ease & convenience while the entire administration process. The locking technology in the luer lock syringe helps to lock the drug inside the container or syringe while the administration process which also reduces waste and the time for administration of the medicine, especially during the IV procedure.

Before the administration of the medicine to the patient, the practitioner needs to draw the contents from the vial into the syringe which leads to loss of time and inconvenience. Also, the cost of the luer lock syringe is more in comparison to the traditional syringe. The luer lock syringe also needs the knowledge and skills owing to the high skilled technology embedded in the luer lock syringe to administer the drug content to the patient.

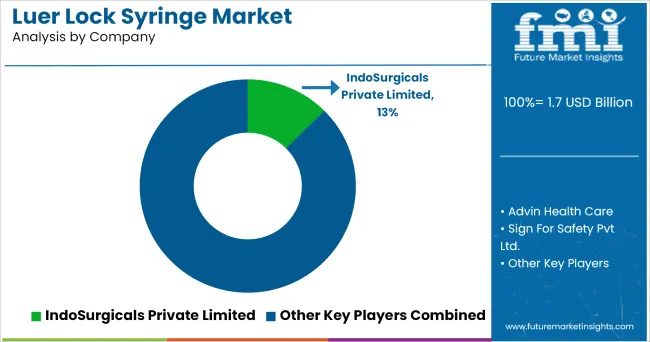

The following global key players such as

Key Asian players manufacturing luer lock syringes

The manufacturers involved in the manufacturing of the luer lock syringe are involved in the innovations owing to the research & development activities and the key players are involved in the merging with the distributors to scale up the manufacturing of the product.

In June 2024, German-based firm, Schreiner MediPharm, which is a well-known global supplier in the healthcare industry has joined hands with USA-based firm, Plas-Tech Engineering, a manufacturer of pre-filled syringes to offer a full-provisional solution for luer lock syringes with reliable tamper evidence.

The continuous technological advancements and the research & development activities in the healthcare sector have led to soaring the market for luer lock syringes. Adding to this, the huge presence of pharmaceutical companies in the USA is also boosting the market for luer lock syringes which is anticipated to mark a significant growth to the luer lock syringe market in the coming days.

Becton, Dickinson and Company (BD) one of the leader for manufacturing injectable devices has crossed a milestone of 2 Billion injections in support of global COVID-19 vaccination.

The global luer lock syringe market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the luer lock syringe market is projected to reach USD 3.2 billion by 2035.

The luer lock syringe market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types in luer lock syringe market are plastic and glass.

In terms of based on the capacity, up to 1 ml segment to command 49.6% share in the luer lock syringe market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Global Luer Lock Connector Market Analysis – Size, Share & Forecast 2024-2034

Locks Market Size and Share Forecast Outlook 2025 to 2035

Locking Pliers Market Size and Share Forecast Outlook 2025 to 2035

Blockchain Interoperability Market Size and Share Forecast Outlook 2025 to 2035

Blockchain Food Traceability Market Size and Share Forecast Outlook 2025 to 2035

Blockchain AI Market Size and Share Forecast Outlook 2025 to 2035

Block Sack Market Size and Share Forecast Outlook 2025 to 2035

Blockchain Messaging Apps Market Size and Share Forecast Outlook 2025 to 2035

Blockchain in Logistics Market Size and Share Forecast Outlook 2025 to 2035

Blockchain Market Size and Share Forecast Outlook 2025 to 2035

Blockchain in Energy Market Size and Share Forecast Outlook 2025 to 2035

Blockchain Identity Management Market Size and Share Forecast Outlook 2025 to 2035

Blockchain in Agriculture and Food Supply Chain Market Size and Share Forecast Outlook 2025 to 2035

Block Pallets Market Size and Share Forecast Outlook 2025 to 2035

Flocking Tape Market Size, Share & Forecast 2025 to 2035

Blockchain Technology Market Analysis & Forecast 2025 to 2035, By Solution, Use Case, Enterprise Size, Industry, and Region

Market Share Breakdown of Block Pallets Industry

Blockchain in Banking Market

Blockchain in Agriculture Market Analysis – Size, Share & Forecast 2024-2034

Block Margarine Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA