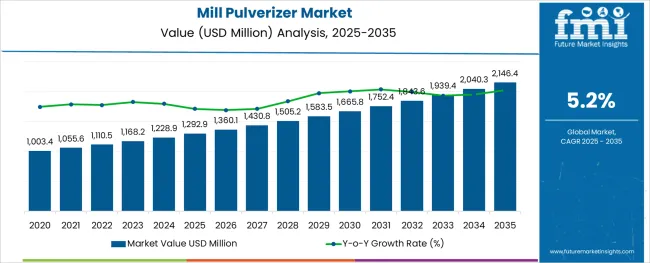

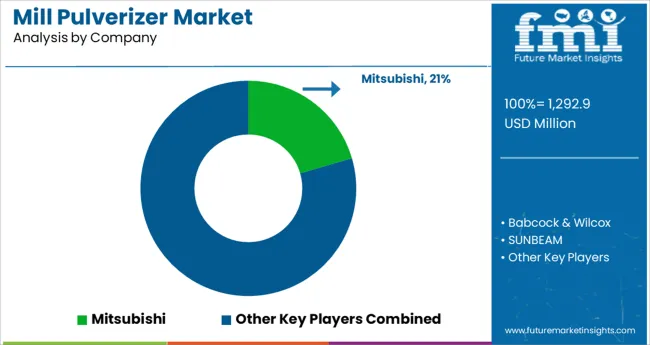

The Mill Pulverizer Market is estimated to be valued at USD 1292.9 million in 2025 and is projected to reach USD 2146.4 million by 2035, registering a compound annual growth rate (CAGR) of 5.2% over the forecast period.

The mill pulverizer market is experiencing stable growth as industries prioritize efficient grinding and size reduction solutions to meet rising production demands and quality standards. Increased focus on energy efficiency, precision milling, and minimized material wastage has elevated the importance of advanced pulverizers in both industrial and food processing environments.

Manufacturers are responding with innovations that enhance durability, reduce downtime, and improve throughput, positioning mill pulverizers as essential machinery in modern production lines.

Future growth is expected to be shaped by automation trends, evolving material specifications, and the expansion of industries such as food and beverage, chemicals, and minerals where finely milled output is critical. Strategic investments in robust designs and localized after-sales service are paving the path for wider adoption across diverse end use markets.

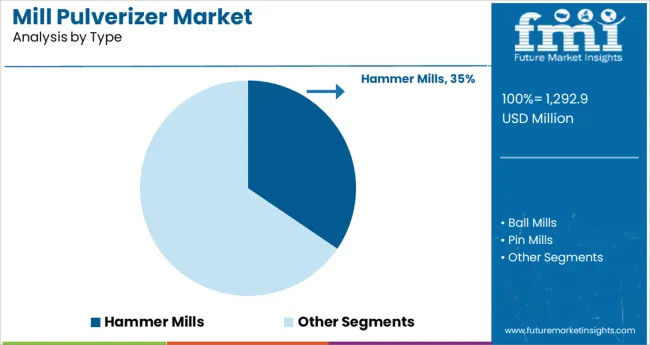

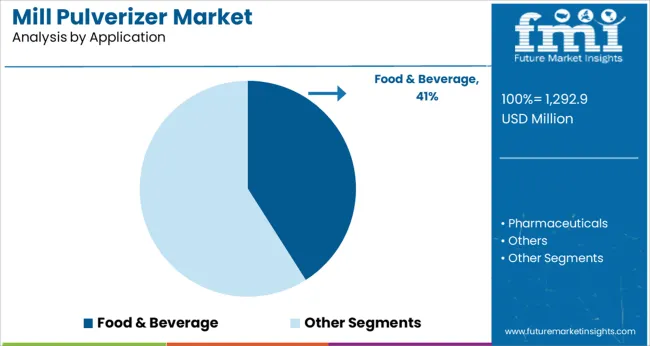

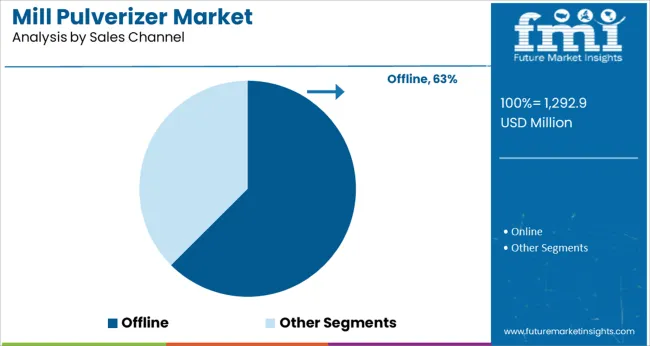

The market is segmented by Type, Application, and Sales Channel and region. By Type, the market is divided into Hammer Mills, Ball Mills, Pin Mills, and Impact Mills. In terms of Application, the market is classified into Food & Beverage, Pharmaceuticals, and Others. Based on Sales Channel, the market is segmented into Offline and Online. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by type, the hammer mills segment is anticipated to hold 34.5% of the total market revenue in 2025, securing its place as the leading type. This dominance is attributed to the versatility of hammer mills which can handle a broad spectrum of materials and deliver consistent particle sizes suitable for various industrial applications.

Their rugged construction and ability to accommodate both coarse and fine grinding needs have positioned them as a preferred choice in heavy duty operations. The relatively lower maintenance requirements and ease of customization have enhanced their operational appeal, particularly where flexibility and reliability are valued.

Additionally, ongoing design improvements that reduce energy consumption and extend component life have reinforced the hammer mills segment’s leadership in demanding milling environments.

In terms of application, the food and beverage segment is projected to command 41.0% of the market revenue in 2025, ranking as the top application area. This leadership has been driven by the stringent quality requirements and high-volume processing demands inherent to the food industry.

The ability of mill pulverizers to achieve uniform particle sizes while preserving product integrity has been a decisive factor in their widespread adoption across food processing plants. Enhanced hygiene features and compliance with safety standards have further strengthened their role in producing flours, spices, powders, and other consumables.

Investments in production scalability and process optimization within the food and beverage sector have accelerated the integration of pulverizers as an indispensable component of modern facilities, underpinning their dominant market share.

Segmenting by sales channel shows that offline channels are expected to hold 62.5% of the market revenue in 2025, establishing themselves as the leading distribution mode. This prominence is a result of the technical nature of mill pulverizer equipment which often requires in-person consultation, demonstrations, and customized solutions that are better facilitated offline.

The complex installation and maintenance needs of these machines have made buyers favor direct engagement with distributors and manufacturers to ensure proper configuration and support. Additionally, the opportunity to negotiate on-site and inspect equipment before purchase has bolstered confidence in offline transactions.

The presence of strong dealer networks and service teams further enhances the value proposition of offline channels, cementing their position as the preferred mode of procurement in the mill pulverizer market.

The mill pulverizer market historical outlook shows that the market's value expanded from USD 1003.4 million in 2020 to USD 1,110.5 million in 2025. The observed CAGR (2020 to 2025) is 5.2%.

The mill pulverizer market is expected to grow at a moderate rate during the forecast period. The major drivers of growth for this market are increased demand from the power generation industry and the need for improved coal combustion in order to reduce emissions.

The pulverizer is made up of an encased rotor that houses a swing hammer and a whizzer classifier that regulates the fineness efficiency and work potential of the solid shafts. These have several advantages, such as having several high-speed motors, easy access to a variety of sizes and models, enabling industry operations, robust construction, less power consumption, high durability, a longer life span, and superior grinding efficiency, resulting in finer and more uniform particles.

Pulverizers are in high demand due to their efficiency and compactness; they are also very quick and easy to clean. These are labor-saving and have low installation and maintenance costs.

Mill Pulverizer market value climbed from USD 1,168.2 million in 2025 to USD 1,939.4 million in 2035 according to future projections. 5.2% CAGR is predicted to occur between 2025 and 2035.

The North American mill pulverizer market has experienced significant growth and development in recent years. This is due to a variety of factors, including rising demand for pulverized coal in power plants, the need for more efficient and cost-effective coal pulverization methods, and the rise in natural gas prices.

As a result of this expansion, several new companies have entered the market, offering a variety of innovative products and services. This has resulted in increased competition, which has lowered prices and helped to improve quality.

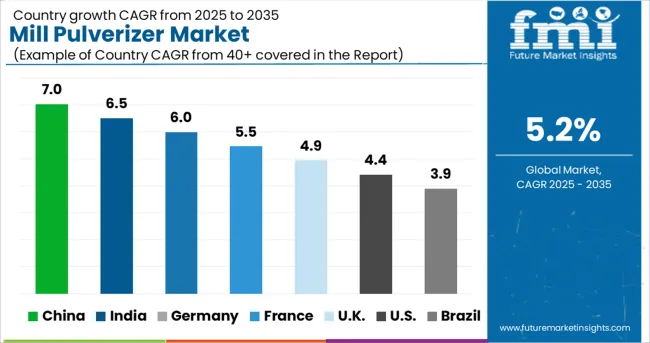

The United States accounts for 34.8% of the mill pulverizer market's total revenue.

In Europe, the mill pulverizer market is growing. The main reason for the growth is the need for new and innovative products that can meet the industry's ever-increasing demands.

The major drivers of the mill pulverizer market in Europe are rising demand from end-use industries such as food and beverage, pharmaceutical, and cosmetics; rising consumer health consciousness; and stringent product safety and quality regulations.

Germany accounts for 23.2% of the mill pulverizer market, while the United Kingdom CAGR is 6.1% over the forecast period.

Increased construction and infrastructure spending in Asia Pacific across all major economies, from developed to developing, is expected to drive the pulverizers market due to massive production activities setting up manufacturing factories in the region to increase global trade. Furthermore, major Asia Pacific countries as Due to rising residential and commercial construction in these developing economies, China and India are expected to accelerate the Pulverizer market.

India and China are the market leaders in the Asia Pacific, and their most recent CAGRs in the Mill Pulverizer market are 5.9% and 6.5%, respectively. Japan contributes 5.0% of the market's overall market share.

A mill pulverizer is a machine that grinds food and other materials into extremely fine particles. It is an essential piece of equipment in the food and beverage industry.

A mill pulverizer's primary function is to grind food into small, easily digestible particles. Flour, for example, is made by grinding wheat into extremely fine particles. A mill pulverizer can also be used to grind spices and other cooking ingredients.

Another important application for a mill pulverizer in the food and beverage industry is the production of baby food. Baby food is typically made by pulverizing cooked vegetables or fruits into extremely small pieces. This helps babies digest their food more easily.

Pulverizers are widely used in a variety of pharmacies, the chemical industry, metallurgy, construction, and other activities primarily related to crushing, boosting the growth and demand for the global industrial pulverizer market over the forecasted time period. The pulverizer is made up of an encased rotor that houses a swing hammer and a Whizzer classifier that regulates the fineness efficiency and work potential of the solid shafts.

These have several advantages, such as having several high-speed motors, easy access to a variety of sizes and models, enabling industry operations, robust construction, less power consumption, high durability, a longer life span, and superior grinding efficiency, resulting in finer and more uniform particles.

The competition in the market is intensified by the continuous introduction of new products and technologies by the players. In order to stay ahead of the competition, the leading players are investing heavily in research and development activities.

The competitive landscape of the market is likely to change in the coming years as new entrants are expected to enter the market with innovative products and technologies.

Some key players in the mill pulverizer market are Mitsubishi, Babcock & Wilcox, SUNBEAM, McLanahan, and EXCT.

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | million for Value and Units for Volume |

| Key Regions Covered | North America; Europe; Asia Pacific; Latin America; Middle East and Africa (MEA); RoW |

| Key Countries Covered | USA, Canada, Mexico, Germany, United Kingdom, France, Russia, Brazil, Argentina, Japan, Australia, China, India, Indonesia, South Korea |

| Key Segments Covered | Type, Application, Sales Channel, Region |

| Key Companies Profiled | Mitsubishi; Babcock & Wilcox; SUNBEAM; McLanahan; EXCT; Modern Machinery Co. Inc.; Loesche America Inc.; American Pulverizer Co.; Techna-Flo Inc.; T E C Engineering Associates Inc.; Atlas Copco Construction Equipment; Prater-Sterling; INGG MEANI SRL; Wabash Power Equipment Co.; Stedman Machine Company |

| Report Coverage | Strategic Growth Initiatives, DROT Analysis, Market Forecast, Company Share Analysis, Market Dynamics and Challenges, and Competitive Landscape. |

| Customization & Pricing | Available upon Request |

The global mill pulverizer market is estimated to be valued at USD 1,292.9 million in 2025.

It is projected to reach USD 2,146.4 million by 2035.

The market is expected to grow at a 5.2% CAGR between 2025 and 2035.

The key product types are hammer mills, ball mills, pin mills and impact mills.

food & beverage segment is expected to dominate with a 41.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Millet Market Size and Share Forecast Outlook 2025 to 2035

Mill Mixer Market Size and Share Forecast Outlook 2025 to 2035

Millimeter Wave Technology Market Size and Share Forecast Outlook 2025 to 2035

Millet Flour Market Analysis by Pearl Millet, Finger Millet, Foxtail Millet, Proso Millet, Kodo Millet, and Others Through 2035

Milling Machine Market Growth – Trends & Forecast 2025 to 2035

Millimeter Wave Sensors Market by Devices, Frequency Band, Application & Region Forecast till 2025 to 2035

Semillon Market

5G Millimeter Wave RF Transceiver Market Size and Share Forecast Outlook 2025 to 2035

End Mill Holders Market Size and Share Forecast Outlook 2025 to 2035

Dal Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Jet Mill Market Size and Share Forecast Outlook 2025 to 2035

Oil Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

End Milling Machine Market Report - Demand, Growth & Industry Outlook 2025 to 2035

Road Milling Machine Market Analysis and Opportunity Assessment in India Size and Share Forecast Outlook 2025 to 2035

Rice Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Tree Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Corn Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Treadmill Motors Market

Treadmill Desk Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA