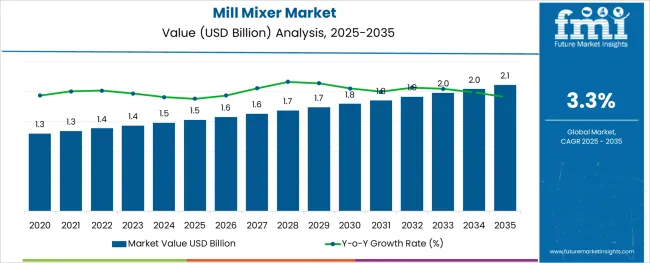

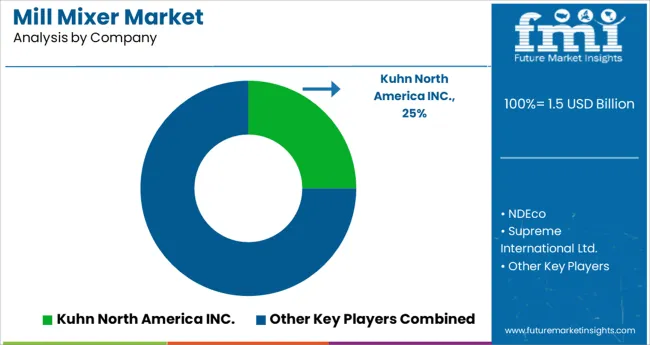

The Mill Mixer Market is estimated to be valued at USD 1.5 billion in 2025 and is projected to reach USD 2.1 billion by 2035, registering a compound annual growth rate (CAGR) of 3.3% over the forecast period.

The mill mixer market is evolving steadily, driven by rising industrial automation, quality consistency requirements, and advancements in mixing technology. Growing demand from food processing, construction materials, and chemical industries has positioned mill mixers as essential equipment for efficient blending and homogenization.

Manufacturers are prioritizing energy-efficient designs, reduced maintenance, and higher throughput to meet industry demands. Regulatory emphasis on hygiene standards, especially in food and pharmaceutical sectors, is further accelerating adoption of modern mill mixers.

Innovations in material handling, noise reduction, and digital monitoring are creating opportunities for differentiation. The outlook remains positive as industries pursue automation, sustainable operations, and enhanced product quality, paving the way for wider adoption and technological upgrades across end-use sectors.

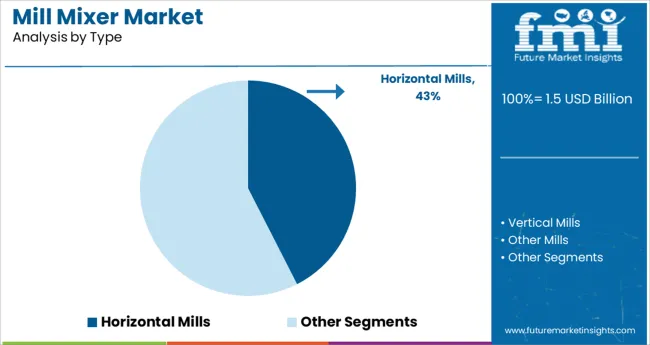

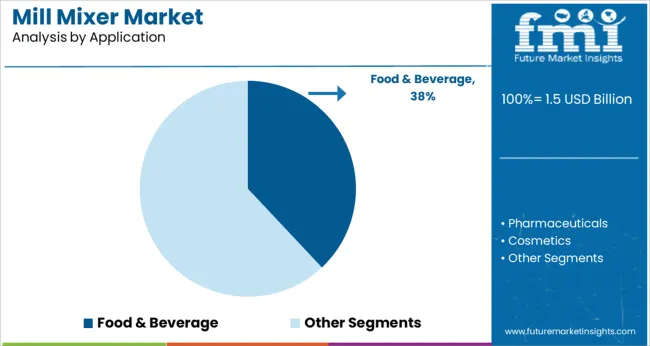

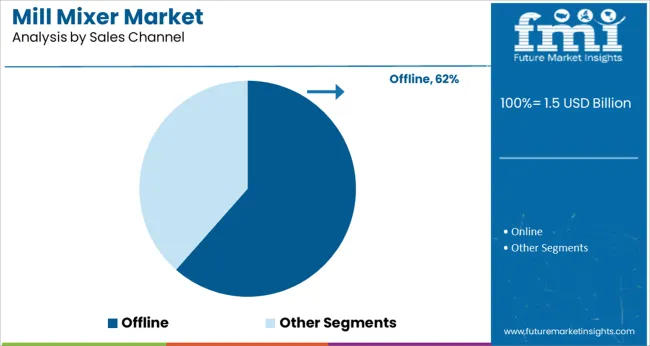

The market is segmented by Type, Application, and Sales Channel and region. By Type, the market is divided into Horizontal Mills, Vertical Mills, and Other Mills. In terms of Application, the market is classified into Food & Beverage, Pharmaceuticals, Cosmetics, and Others. Based on Sales Channel, the market is segmented into Offline and Online. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by type, horizontal mills are anticipated to hold 42.5% of the market revenue in 2025, establishing themselves as the leading type. This leadership has been shaped by their superior mixing efficiency, space-saving design, and ease of integration into automated production lines.

Horizontal mills have demonstrated higher uniformity and throughput compared to alternative configurations, making them preferred in large-scale operations where consistency and productivity are paramount. Their enclosed structure has supported improved hygiene and minimized contamination risks, factors critical in sensitive applications.

Additionally, their adaptability to various materials and lower energy consumption have reinforced their appeal in cost-conscious industries. These advantages have allowed horizontal mills to maintain a prominent role in meeting the market’s evolving demands.

In terms of application, the food and beverage sector is projected to account for 38.0% of the mill mixer market revenue in 2025, positioning it as the dominant application segment. This leadership has been underpinned by the sector’s stringent requirements for hygiene, consistency, and traceability in production processes.

Mill mixers have become indispensable for producing uniform blends in bakery, confectionery, dairy, and beverage applications where texture and flavor consistency directly impact brand reputation. The increasing demand for processed and packaged foods has fueled higher investments in efficient mixing equipment.

Furthermore, compliance with evolving food safety standards and the push for automation in production facilities have intensified adoption. These dynamics have anchored the food and beverage segment as the most significant contributor to the market’s growth.

When analyzed by sales channel, offline distribution is expected to capture 61.5% of the market revenue in 2025, retaining its leading position. This prominence has been shaped by the preference for direct engagement with manufacturers and distributors to evaluate equipment, negotiate customization, and ensure after-sales support.

The complexity and capital-intensive nature of mill mixers have encouraged buyers to rely on established offline channels where technical expertise and demonstrations are readily available.

Personalized consultations and long-term service agreements offered through offline networks have provided buyers with greater confidence in their investments. These advantages have continued to position offline channels as the primary route for procurement in a market where reliability and performance assurance are paramount.

The mill mixer market Historical Outlook shows that the market's value expanded from USD 1,212.5 million in 2020 to USD 1,380.6 million in 2025. The observed CAGR (2020 to 2025) is 3.3%.

One of the major factors driving the growth of the mill mixer market is the increase in demand for animal feed due to the growing livestock population. Furthermore, the rising demand for processed foods is propelling the growth of this market. Furthermore, rising awareness of the benefits of mill mixers, such as their ability to reduce feed waste and improve feed digestibility, is fueling growth in this market.

However, the high cost of mill mixers is a significant challenge for market participants. Furthermore, stringent feed safety regulations are stifling the growth of this market. The mill mixer market value climbed from USD 1,426.2 million in 2025 to USD 1,973.3 million in 2035, according to future projections. 3.3% CAGR is predicted to occur between 2025 and 2035.

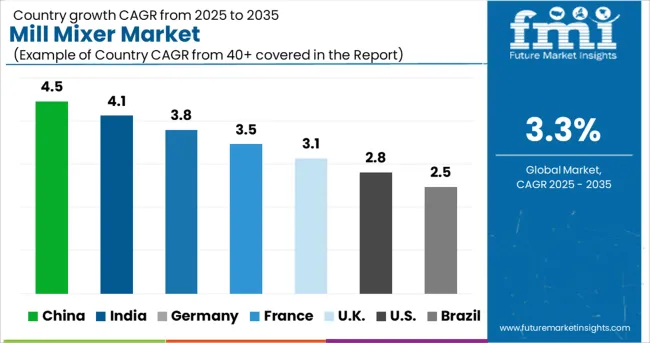

During the forecast period, the North American mill mixer market is expected to grow at a moderate rate. The market is being driven by rising feed demand from the animal husbandry and poultry industries. The United States and Canada are expected to drive the mill mixer market in North America. The growing demand for feed from the poultry industry is driving the mill mixer market in the United States. Due to the country's smaller poultry industry, the Canadian market is expected to grow at a slower rate than the USA market.

The mill mixer market receives 35.7% of its total revenue from the United States.

The mill mixer market in Europe is rapidly expanding. The growing population and the need for more efficient food production are driving up demand for mill mixers. The market is expected to expand significantly in the coming years.

The mill mixer market in Europe is extremely competitive. A number of manufacturers are vying for market share. The competition is fierce, and prices are dropping. In the coming years, the market is expected to expand at a rapid pace.

Germany makes for 23.9% of the mill mixer market, while the CAGR in the United Kingdom is 6.3% over the projection period.

The Asia Pacific mill mixer market is expanding as the region's economies expand. As a result, industries such as food and beverage, pharmaceuticals, and chemicals are seeing an increase in demand for mill mixers. The Asia Pacific region is home to some of the world's fastest-growing economies, which will drive mill mixer demand over the forecast period.

In Asia Pacific, the food and beverage industry is the largest consumer of mill mixers. The region's growing population and middle class are driving up demand for processed foods, necessitating the production of more mill mixers. The pharmaceutical industry is also a major consumer of mill mixers, as many drugs are manufactured using powders and granules. The chemicals industry uses mill mixers to create pigments, dyes, and other chemicals.

India and China are the market leaders in Asia Pacific, and their most recent CAGRs in the mill mixer market are 5.9% and 6.5%, respectively. Japan contributes 3.7% of the market's overall market share.

A mill mixer is a machine that combines different types of flour to create a new flour blend. Bakers frequently use this method to create custom flour blends for specific recipes. There are numerous advantages to using a mill mixer, including the ability to control the ingredients in your flour blend, create unique flour blends, and save time and money.

Using a mill mixer to make your own custom flour blend gives you complete control over the ingredients. Depending on your preferences, you can add or remove certain ingredients. This allows you to ensure that your flour blend is ideal for your requirements. Creating unique flour blends can also help you stand out from the crowd. Customers will be impressed by your creativity and may return in the future.

Many businesses have benefited from the introduction of mill mixers into the food and beverage industry. These adaptable machines can do everything from grinding and mixing ingredients to emulsifying and homogenizing liquids.

Mill mixers have become a must-have piece of machinery for manufacturers looking to stay ahead of the competition. In today's fast-paced marketplace, the ability to process materials quickly and efficiently is critical.

Businesses can increase production while lowering costs by using a mill mixer. These machines are also simple to operate and maintain, making them an excellent choice for businesses looking to improve their bottom line.

Horizontal mill mixers are the most common type. They are typically used in small to medium-sized operations. They have a cylindrical chamber that rotates about a horizontal axis. The material is fed into one end of the chamber and is mixed as it moves through to the other end.

Vertical mill mixers are less common than horizontal ones. They have a similar chamber design, but the chamber is oriented vertically instead of horizontally. The advantage of this design is that it allows for a more even mix since gravity can pull the material down evenly through the chamber.

Basket mill mixers are the least common type of mill mixer. They have a cylindrical chamber with an open top and bottom.

The competitive landscape of the mill mixer market is expected to witness moderate growth during the forecast period. The key players in the market are engaged in product innovation and development to expand their customer base. Moreover, these companies are investing heavily in research and development activities to introduce new products in the market.

The key players in the Mill Mixer market are NDEco, Supreme International Ltd., KUHN North America INC., Grupo Tatoma, Triolite, etc.

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | million for Value and Units for Volume |

| Key Regions Covered | North America; Europe; Asia Pacific; Latin America; Middle East and Africa (MEA); RoW |

| Key Countries Covered | The USA, Canada, Mexico, Germany, The United Kingdom, France, Russia, Brazil, Argentina, Japan, Australia, China, India, Indonesia, South Korea |

| Key Segments Covered | Type, Application, Sales Channel, Region |

| Key Companies Profiled | NDEco; Supreme International Ltd.; KUHN North America INC.; Grupo Tatoma; Triolite; Groupe Anderson; SILOKING Mayer; Seko Industries; Tetra Laval International S.A. |

| Report Coverage | Strategic Growth Initiatives, DROT Analysis, Market Forecast, Company Share Analysis, Market Dynamics and Challenges, and Competitive Landscape. |

| Customization & Pricing | Available upon Request |

The global mill mixer market is estimated to be valued at USD 1.5 billion in 2025.

It is projected to reach USD 2.1 billion by 2035.

The market is expected to grow at a 3.3% CAGR between 2025 and 2035.

The key product types are horizontal mills, vertical mills and other mills.

food & beverage segment is expected to dominate with a 38.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Millet Market Size and Share Forecast Outlook 2025 to 2035

Mill Pulverizer Market Size and Share Forecast Outlook 2025 to 2035

Millimeter Wave Technology Market Size and Share Forecast Outlook 2025 to 2035

Millet Flour Market Analysis by Pearl Millet, Finger Millet, Foxtail Millet, Proso Millet, Kodo Millet, and Others Through 2035

Milling Machine Market Growth – Trends & Forecast 2025 to 2035

Millimeter Wave Sensors Market by Devices, Frequency Band, Application & Region Forecast till 2025 to 2035

Semillon Market

5G Millimeter Wave RF Transceiver Market Size and Share Forecast Outlook 2025 to 2035

End Mill Holders Market Size and Share Forecast Outlook 2025 to 2035

Dal Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Jet Mill Market Size and Share Forecast Outlook 2025 to 2035

Oil Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

End Milling Machine Market Report - Demand, Growth & Industry Outlook 2025 to 2035

Road Milling Machine Market Analysis and Opportunity Assessment in India Size and Share Forecast Outlook 2025 to 2035

Rice Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Tree Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Corn Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Treadmill Motors Market

Treadmill Desk Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA