The nylon film market is experiencing consistent growth driven by rising demand across packaging, electronics, and industrial applications. Increasing preference for high-strength, durable, and flexible materials has accelerated the adoption of nylon films in both consumer and industrial sectors. Market participants are focusing on material advancements, cost optimization, and improved barrier properties to meet evolving performance requirements.

The current landscape is marked by growing use in food packaging, where superior oxygen resistance and mechanical strength are crucial. The future outlook is supported by ongoing technological innovation, expansion in emerging markets, and the integration of nylon films into sustainable packaging solutions.

Growth rationale is further strengthened by the increasing adoption of biaxially oriented films and enhanced recyclability initiatives As manufacturers continue to refine extrusion and orientation processes, product quality and performance consistency are expected to improve, driving higher utilization rates across diverse industries and reinforcing the market’s upward trajectory.

| Metric | Value |

|---|---|

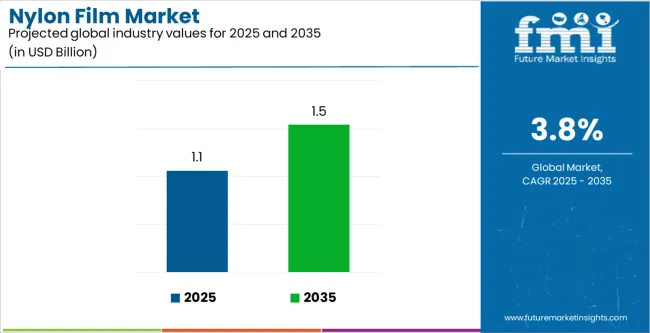

| Nylon Film Market Estimated Value in (2025 E) | USD 1.1 billion |

| Nylon Film Market Forecast Value in (2035 F) | USD 1.5 billion |

| Forecast CAGR (2025 to 2035) | 3.8% |

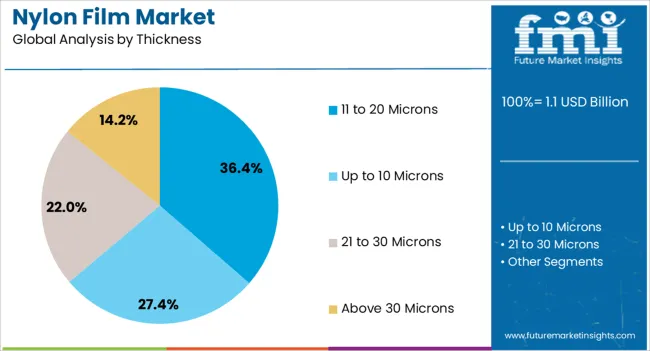

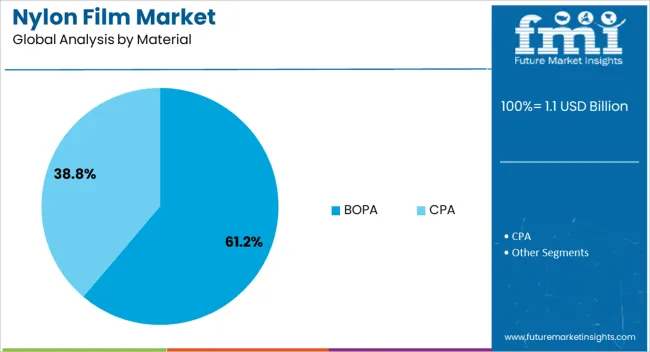

The market is segmented by Grade, Thickness, Material, and End Use and region. By Grade, the market is divided into Nylon 6 and Nylon 66. In terms of Thickness, the market is classified into 11 to 20 Microns, Up to 10 Microns, 21 to 30 Microns, and Above 30 Microns. Based on Material, the market is segmented into BOPA and CPA. By End Use, the market is divided into Food, Pharmaceutical, Electrical, Chemical, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

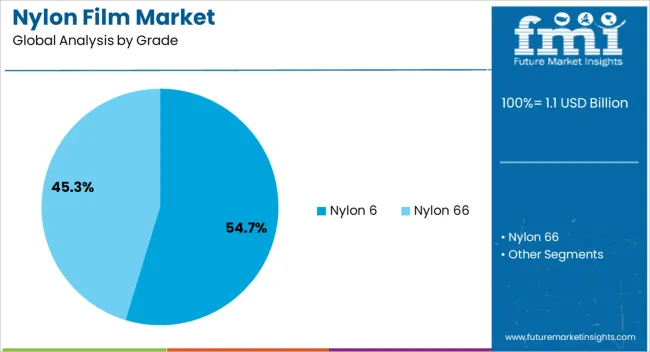

The Nylon 6 segment, accounting for 54.70% of the grade category, has maintained dominance due to its excellent tensile strength, flexibility, and cost-effectiveness. Its superior mechanical properties and resistance to abrasion make it highly suitable for food and industrial packaging applications.

The segment’s share is supported by the wide availability of raw materials and well-established production infrastructure. Manufacturers have been focusing on process optimization to enhance clarity, film uniformity, and printability.

The material’s compatibility with multilayer film structures has further increased its utilization in packaging sensitive products requiring strong moisture and oxygen barriers Ongoing innovations in polymer modification are expected to sustain market leadership, as Nylon 6 continues to balance performance efficiency with production cost advantages across various end-use sectors.

The 11 to 20 microns segment, representing 36.40% of the thickness category, has emerged as the leading range due to its balance between flexibility, strength, and barrier performance. This thickness range provides optimal protection against moisture and gas permeability while maintaining excellent machinability for packaging processes.

It is widely adopted in both single-layer and multilayer film applications. The segment’s dominance has been reinforced by its suitability for food and pharmaceutical packaging, where consistent thickness and transparency are essential.

Market growth has been supported by technological improvements in film stretching and coating processes The preference for lightweight yet durable materials in flexible packaging continues to sustain this segment’s share, ensuring strong demand across regional and global manufacturing hubs.

The BOPA segment, holding 61.20% of the material category, has been leading due to its superior barrier properties, toughness, and heat resistance. BOPA films are extensively used in high-performance packaging applications such as pharmaceuticals, electronics, and processed foods. The segment’s strength lies in its combination of durability and flexibility, providing enhanced shelf life for packaged goods.

Continuous innovation in biaxial orientation technology has improved dimensional stability and reduced film defects. Manufacturers are investing in expanding production capacities to meet rising demand from both developed and emerging markets.

The shift toward sustainable and recyclable packaging materials has also favored BOPA, given its compatibility with eco-friendly formulations These advantages collectively reinforce its leadership position and sustained growth potential within the nylon film market.

Production of Multiple-layered Films Create Numerous Opportunities

Nylon film manufacturers are witnessing a lot of growth in coextruded films. Films that use thin individual and separate numbers of layers allow more efficient use of costly high-performance polymers. Several other food packaging industries intend to get into medical packaging because it has higher margins.

The adoption of layers in films has expanded as several companies have qualified the manufacturing of the first eight, nine, and 11-layer films, especially for healthcare applications.

Such highly layered films are in their inductor stage in the market, but they are cutting down the cost of the packaging for snacks and pharmaceutical packaging, where the packages usually cost more than the product contained inside.

Winpak Ltd., manufactured its first medical packaging film in North America, a nylon-based structure with 11 layers for making sterilized bags. This is the most highly layered coax film in the medical packaging film market.

Winpak Ltd. is expanding its portfolio in the medical business by using technologies such as coax barrier food packaging to decrease the cost of medical forming films.

Increasing Adoption of BOPA Films

Biaxially Oriented Polyamide film (BOPA) films are more popular in the global market. They are manufactured by biaxial orientation, which provides exceptional clarity to films, enhancing their flexibility and tensile strength. BOPA films offer an excellent oxygen barrier, which is essential in product packaging.

The manufacturing process increases its oxygen barrier by 30%, which is essential for certain products. They offer less permeation of oxygen, and it is shrinkable which makes them efficient in food packaging applications.

BOPA films have high mechanical stretch, high melting point, and high puncture resistance which makes them suitable for specialized applications. Good printability, transparency, and aesthetically glossy finish have increased its application to enhance product sales.

Since the market is filled with numerous products, the adoption of BOPA films in packaging can help business to market their product easily by highlighting the product with aesthetic appeal on the shelf.

BOPA films are elastic which makes them stable under overload conditions. Consequently, BOPA films are the most attractive films utilized for packaging products that are sensitive to oxygen.

Recycling of Multilayer/ Barrier Structures a Key Impediment for Nylon Film

Over the years, there has been a shift in preference from monolayer flexible packaging to multilayered packaging due to desired functionality, barrier, thickness, low cost, and increasing applications. The process of recycling or disposing of multilayer packaging is a complicated and too risky investment for manufacturers, wherein the cost of recycling is much higher than manufacturing a new one.

Moreover, in the last few years, 5-layer and 7-layer multi-layered barrier films have become quite popular. However, oriented coextruded films with EVOH or polyamide face some challenges concerning the maintenance of the adhesive tie layer and film after orientation.

Fundamentally, the orientation process increases the interfacial area of the film but effectively reduces the number of chemical bonds per unit area. This results in a drop of adhesion by 90%. The difference in mechanical properties of polyolefin films and barrier layers reduces the adhesion strength after orientation.

The orientation of multilayer film decreases the elasticity of the material and thus, dissipates interfacial stress.

Therefore, increasing adoption of multi-layered barrier films in flexible packaging for enhanced shelf life poses an extensive challenge in recycling and disposing of materials. This factor is expected to restrain the growth of the polyamide/nylon film market during the forecast period.

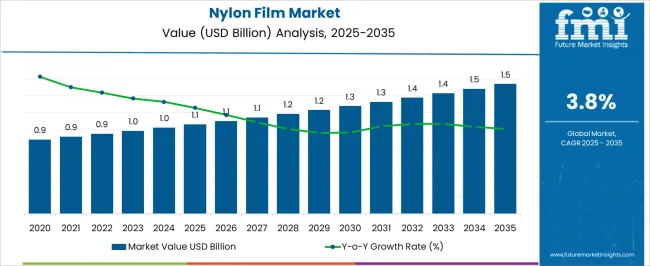

The global market recorded a CAGR of 3.3% during the historical period between 2020 and 2025. The growth of the nylon film industry was positive as it reached a value of USD 1.1 million in 2025 from USD 0.9 million in 2020.

Traditionally, preference in packaging has always revolved around rigid packaging formats, because of their barrier properties and reliability. But, in the last few years, with the transition of the packaging industry has evolved packaging manufacturers who have invested in research & development for incorporating these characteristics in flexible packaging formats.

Food & pharmaceutical industries rapidly shifted to flexible packaging solutions including nylon films owing to their lightweight, flexibility, and durability.

The key reasons for this change are due to their non-reactivity with food products, high flexibility and ability to be easily processed at high and low temperatures. The rise in demand for materials for packaging microwavable food products is one of the major drivers of nylon films.

Innovations in food packaging technologies such as modified atmosphere packaging, vacuum packaging and other active packaging methods are contributing to market growth. Adoption of these technologies for food packaging is increasing the demand for high-performance packaging films including nylon films.

The boom in the healthcare sector is influencing the sales of nylon films. The significant application of nylon films in packaging applications of pharmaceutical products is driving the market.

The need for safe and advanced packaging solutions for speciality pharmaceuticals due to increased emphasis on patient safety and product integrity drives the demand for nylon films.

The section below covers the industry analysis of nylon film market for different countries. Market demand analysis on key countries in several region of the globe, including North America, Asia Pacific, Europe, East Asia, and others, is provided.

Germany is anticipated to remain at the forefront in Europe, with a value share of 19.6% through 2035. In East Asia, China is projected to witness a CAGR of 4.5% by 2035.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

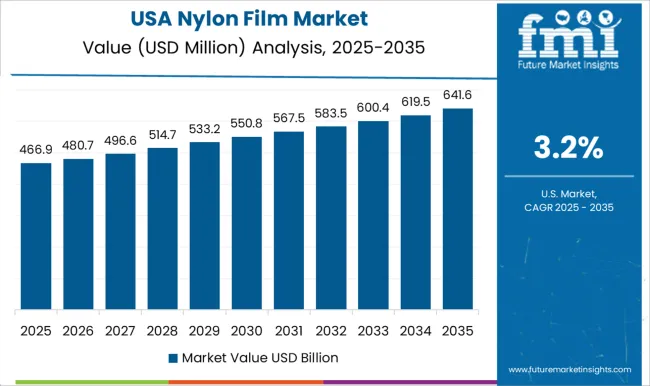

| United States | 3.1% |

| Brazil | 4.2% |

| Poland | 3.8% |

| Indonesia | 5.1% |

| China | 4.5% |

| New Zealand | 2.9% |

| South Africa | 4.6% |

A prominent portion of North America’s nylon film market is captured by the USA which accounts for 81.3% of the market value share in 2025. The rising obesity awareness, urbanization, and focus on healthy food give rise to the consumption of fat and sugar-free packed food in the USA which creates market growth opportunities for food packaging such as nylon films in the USA.

According to the Commonwealth Fund organization, the spending on healthcare in the USA is around 18% of its GDP which is twice when compared to an OCED country and has the lowest life expectancy.

The USA has a high rate of people with multiple chronic diseases and obesity rates. Rising prices in the healthcare sector, high demand for medical services, and growth in medical technologies are contributing to the increase in healthcare spending.

The increasing rate of spending on healthcare in the USA is anticipated to drive the demand for the nylon film market in the US. Rising prices in the healthcare sector, high demand for medical services, and growth in medical technologies are contributing to the increase in healthcare spending.

India is anticipated to witness a CAGR of 4.8% and reach a valuation of USD 98.1 million by the end of the forecast year. The food services sector in India is extensively increasing because of the heightened demand for high-end quality products along with rising per capita income in the country as India is the most populous economy, which is driven by the consumer.

The food service industry in India is projected to gain USD 1.5 billion market value by 2035 as stated by the Indian Brand Equity Forum (IBEF). The demand for food delivery services is growing remarkably with a growth rate of 23% as a result of the busy lifestyles of Indian citizens and increased disposable income.

Quick-service restaurants in India are predicted to attain USD 1,069.3 million by 2035 providing an opportunity for the market players to expand further. The consistent growth of the food service industry in India is expected to create notable demand for nylon films during the forecast years.

The section contains information about the leading segments in the industry. By grade, nylon 6 films dominates market with estimated market share of 90% in 2025. BOPA nylon films are anticipated to grow at 4% CAGR by end of 2035.

| Material | BOPA |

|---|---|

| Value Share (2035) | 82% |

BOPA films are dominating the global market for nylon films with an anticipated market share of around 82% generating an incremental dollar opportunity worth USD 1.5 million by 2035 end.

The benefits of BOPA films include excellent flexibility, high tensile strength, and very high mechanical strength which provide the film with exceptional toughness and make them super stiff for usage in the packaging of electrical and chemical end-use industries.This is likely to bolster the demand for nylon films in the forecast period.

| Grade Type | Nylon 6 |

|---|---|

| Value Share (2035) | 91.4% |

Various variants of nylon can be utilized for nylon packaging, such as Nylon 6, and Nylon 66. Among these Nylon 6 is estimated to hold the dominant market share of 91.4% as of 2035 further expanding at a 3.9% growth rate by the end of the assessment years.

Manufacturing companies are increasingly preferring Nylon 6 over any other variant because of their cost-effectiveness compared to other nylon variants.

This helps manufacturing companies save an enormous amount of financial capital. Their versatility is also unmatched, and they offer a balance of mechanical properties, chemical resistance, and processing characteristics. This makes them a perfect choice for a wide range of applications in industries.

| End Use | Food |

|---|---|

| Value Share (2035) | 72.4% |

Food application of nylon films is majorly contributing to the market growth, with a market value of USD 1.1 million in 2025. It is further expanding by 1.5 times its current market value through 2035.

Nylon films are ideal for food packaging because they offer excellent barrier properties against moisture and oxygen which keeps in maintain the product integrity.

Since food quality is an essential parameter measured by consumers while purchasing, it contributes to its enhanced applications in food packaging. The requirement of extended shelf life for products such as meat, dairy, bakery, etc. is pushing its usage in the food industry.

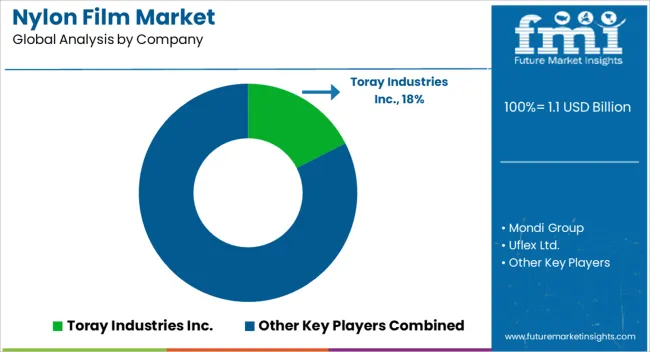

Key players in nylon films are committed to the research and development of the product and are consistently offering innovative nylon film solutions targeted towards specific end-use. Companies are expanding their manufacturing capabilities to meet the growing demand for nylon films, both regionally and globally.

Companies are collaborating with businesses or acquiring innovative startups to strengthen their market position, expand product offerings, and increase geographical reach.

Recent Industry Developments in Nylon Film Market

In 2025, Microwave Chemical, headquartered in Japan, and Asahi Kasei, also based in Japan, jointly initiated a demonstration project aimed at commercializing the chemical recycling process for Nylon 66 using advanced microwave technology.

In April 2025, Kordsa, a tire and nylon manufacturing company headquartered in Turkey, announced a USD 50 million investment to expand its nylon production capabilities at its Chattanooga, Tennessee plant. This expansion is expected to help the company meet the growing demand from the automotive industry.

In 2025, Hamilton Plastics, headquartered in the United States, taps into its 30-plus years of expertise in high-barrier films by launching custom-engineered nine-layer structures. This innovation results from the company's recent investment in two new production lines.

The industry is segregated into nylon 6 and nylon 66.

In terms of thickness, the industry is divided into up to 10 microns, 11 to 20 microns, 21 to 30 microns, and above 30 microns.

Nylon films with composite polyamide (CPA) and bi-axially oriented polyamide (BOPA) materials are described.

Few of the important end uses include food, pharmaceutical, electrical, chemical, and other industries. The food segment is further classified as meat, cereals, cheese, and processed food.

Key countries of North America, Latin America, South Asia, East Asia, Europe, and the Middle East and Africa are covered.

The global nylon film market is estimated to be valued at USD 1.1 billion in 2025.

The market size for the nylon film market is projected to reach USD 1.5 billion by 2035.

The nylon film market is expected to grow at a 3.8% CAGR between 2025 and 2035.

The key product types in nylon film market are nylon 6 and nylon 66.

In terms of thickness, 11 to 20 microns segment to command 36.4% share in the nylon film market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Nylon Films for Liquid Packaging Market from 2024 to 2034

Nylon Monofilament Mesh Filter Bags Market Size and Share Forecast Outlook 2025 to 2035

Nylon-6 and Nylon-66 Market Analysis & Forecast by Product Type, Application and Region through 2035

Nylon-6 Market Trends and Forecast 2025 to 2035

Nylon 4-6 Market

Food Grade Nylon Market

Film Forming Starches Market Size and Share Forecast Outlook 2025 to 2035

Film Formers Market Size and Share Forecast Outlook 2025 to 2035

Film Capacitors Market Analysis & Forecast by Material, Application, End Use, and Region Through 2035

Film Tourism Industry Analysis by Type, by End User, by Tourist Type, by Booking Channel, and by Region - Forecast for 2025 to 2035

Filmic Tapes Market

PE Film Market Insights – Growth & Forecast 2024-2034

TPE Films and Sheets Market Size and Share Forecast Outlook 2025 to 2035

PET Film Coated Steel Coil Market Size and Share Forecast Outlook 2025 to 2035

PSA Film Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Breaking Down PCR Films Market Share & Industry Positioning

PCR Films Market Analysis by PET, PS, PVC Through 2035

VCI Film Market Growth – Demand, Innovations & Outlook 2024-2034

PBS Film Market Trends & Industry Growth Forecast 2024-2034

Thin Film Coatings Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA