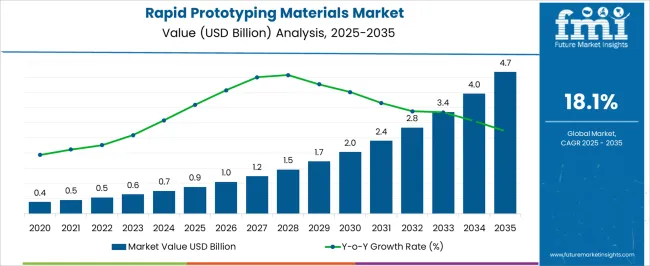

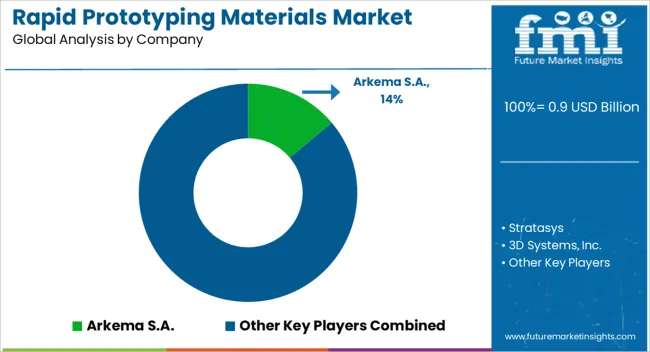

The Rapid Prototyping Materials Market is estimated to be valued at USD 0.9 billion in 2025 and is projected to reach USD 4.7 billion by 2035, registering a compound annual growth rate (CAGR) of 18.1% over the forecast period.

| Metric | Value |

|---|---|

| Rapid Prototyping Materials Market Estimated Value in (2025 E) | USD 0.9 billion |

| Rapid Prototyping Materials Market Forecast Value in (2035 F) | USD 4.7 billion |

| Forecast CAGR (2025 to 2035) | 18.1% |

The Rapid Prototyping Materials market is experiencing strong growth, driven by increasing adoption of additive manufacturing across industrial, aerospace, and defense sectors. Demand is being fueled by the need for faster product development cycles, reduced prototyping costs, and enhanced design flexibility. Advancements in material science, including the development of high-performance polymers and composites, are enabling the production of functional prototypes that closely replicate end-use components.

The integration of filament-based printing technologies and computer-aided design tools is further improving precision and scalability, allowing organizations to accelerate time-to-market for new products. Growing emphasis on lightweight and durable materials in aerospace, defense, and automotive applications is supporting demand for specialized prototyping materials. Investments in research and development, as well as partnerships between material suppliers and manufacturing companies, are facilitating the development of tailored solutions.

Regulatory compliance, performance testing, and material reliability are increasingly shaping purchasing decisions As industries continue to pursue digital manufacturing and agile development strategies, the market is expected to sustain robust growth driven by technological innovation and evolving material capabilities.

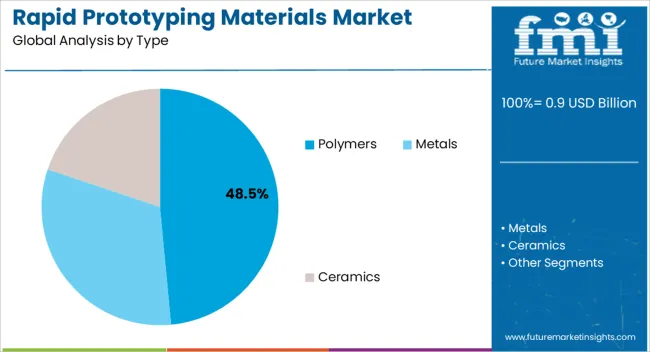

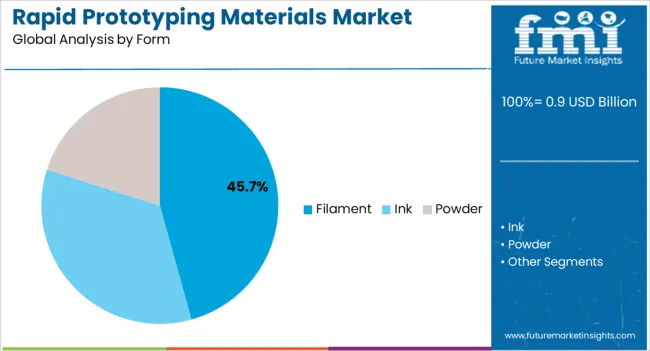

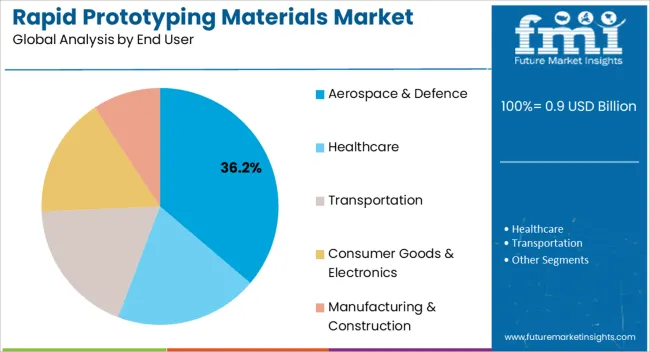

The rapid prototyping materials market is segmented by type, form, end user, function, and geographic regions. By type, rapid prototyping materials market is divided into Polymers, Metals, and Ceramics. In terms of form, rapid prototyping materials market is classified into Filament, Ink, and Powder. Based on end user, rapid prototyping materials market is segmented into Aerospace & Defence, Healthcare, Transportation, Consumer Goods & Electronics, and Manufacturing & Construction. By function, rapid prototyping materials market is segmented into Conceptual Model and Functional Prototype. Regionally, the rapid prototyping materials industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The polymers type segment is projected to hold 48.5% of the market revenue in 2025, establishing it as the leading material category. Its dominance is being driven by the versatility, cost-effectiveness, and wide range of mechanical and thermal properties offered by polymer-based materials. Polymers allow rapid fabrication of prototypes with high dimensional accuracy and surface quality, supporting design verification and functional testing.

The ability to integrate polymers with various additive manufacturing technologies, including filament extrusion and powder-based printing, enhances flexibility and adoption. Continuous innovation in polymer composites and bio-based resins has strengthened performance characteristics, enabling usage in applications that require lightweight, durable, and chemically resistant materials.

The scalability of polymer production, combined with ease of processing and post-processing capabilities, is further reinforcing market preference As industries increasingly prioritize fast, iterative prototyping and sustainable material solutions, polymers are expected to maintain their leading position, supported by broad industrial acceptance and technological compatibility.

The filament form segment is anticipated to account for 45.7% of the market revenue in 2025, making it the leading form category. Growth is being driven by the widespread adoption of fused deposition modeling and other extrusion-based additive manufacturing techniques. Filaments provide precise layer-by-layer deposition, ensuring dimensional accuracy and repeatability, which is critical for prototype validation and functional testing.

The availability of a broad range of filament materials, including high-performance polymers and composites, supports diverse industrial applications. Ease of handling, storage, and feed into printing systems further accelerates adoption, reducing operational complexity. Manufacturers benefit from the cost-effectiveness of filament-based production, especially for small and medium-scale prototyping projects.

Increasing investments in R&D and customized filament solutions are supporting innovation and performance enhancements As industries continue to adopt agile prototyping and rapid iteration processes, filament-based materials are expected to retain their leading position, driven by efficiency, versatility, and technological compatibility.

The aerospace and defense end-user segment is projected to hold 36.2% of the market revenue in 2025, establishing it as the leading application sector. Growth is being driven by the need for lightweight, high-strength components that meet strict performance, reliability, and safety standards. Rapid prototyping enables aerospace and defense manufacturers to develop functional parts, test designs under operational conditions, and iterate quickly, reducing development timelines and costs.

High-performance polymers and composite materials support the production of complex geometries and structural components, which are critical in aircraft, spacecraft, and defense systems. Investments in advanced additive manufacturing technologies, including multi-material printing and precision control systems, are facilitating the creation of durable, accurate, and certified prototypes.

The segment’s growth is further reinforced by increasing government and defense budgets, focus on technological modernization, and demand for customized components As aerospace and defense industries continue to prioritize efficiency, performance, and cost optimization, this end-user segment is expected to remain the primary driver of rapid prototyping materials adoption.

The need for new material is being created by the emerging new application in rapid prototyping. Some of the most popular material being used today for rapid prototyping includes metals, plastics, ceramics, food, paper, and bio-materials. Today plastics remains a top choice in rapid prototyping material market.

They are used in various applications such as industrial printing, making of customized jewellery etc. In commercial and personal uses material like ceramics is gaining momentum. Another printing material which is gaining demand in rapid prototyping material market worldwide is food. Today it is possible to print with sugar, meat, chocolate, and pasta.

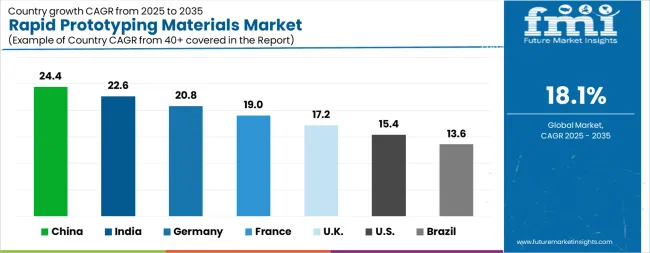

| Country | CAGR |

|---|---|

| China | 24.4% |

| India | 22.6% |

| Germany | 20.8% |

| France | 19.0% |

| UK | 17.2% |

| USA | 15.4% |

| Brazil | 13.6% |

The Rapid Prototyping Materials Market is expected to register a CAGR of 18.1% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 24.4%, followed by India at 22.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 13.6%, yet still underscores a broadly positive trajectory for the global Rapid Prototyping Materials Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 20.8%. The USA Rapid Prototyping Materials Market is estimated to be valued at USD 316.1 million in 2025 and is anticipated to reach a valuation of USD 1.3 billion by 2035. Sales are projected to rise at a CAGR of 15.4% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 46.5 million and USD 23.6 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 0.9 Billion |

| Type | Polymers, Metals, and Ceramics |

| Form | Filament, Ink, and Powder |

| End User | Aerospace & Defence, Healthcare, Transportation, Consumer Goods & Electronics, and Manufacturing & Construction |

| Function | Conceptual Model and Functional Prototype |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Arkema S.A., Stratasys, 3D Systems, Inc., Covestro AG, EOS GmbH, CRP Technology S.r.l., Materialise, Tethon 3D, Nexa3D, DSM, Envisiontec GmbH, Carpenter Technology Corporation, Höganäs AB, and Optomec Inc. |

The global rapid prototyping materials market is estimated to be valued at USD 0.9 billion in 2025.

The market size for the rapid prototyping materials market is projected to reach USD 4.7 billion by 2035.

The rapid prototyping materials market is expected to grow at a 18.1% CAGR between 2025 and 2035.

The key product types in rapid prototyping materials market are polymers, metals and ceramics.

In terms of form, filament segment to command 45.7% share in the rapid prototyping materials market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rapid U-drills Market Size and Share Forecast Outlook 2025 to 2035

Rapid Microbiology Testing Market Forecast Outlook 2025 to 2035

Rapid Test Cards Market Size and Share Forecast Outlook 2025 to 2035

Rapid Test Readers Market Size and Share Forecast Outlook 2025 to 2035

Rapid Strength Concrete Market Size and Share Forecast Outlook 2025 to 2035

Rapid Self-Healing Gel Market Size and Share Forecast Outlook 2025 to 2035

Rapid Infuser Market Size, Growth, and Forecast 2025 to 2035

Rapid RNA Testing Kits Market Trends- Growth & Forecast 2025 to 2035

Rapid Antigen Testing Market - Demand, Growth & Forecast 2025 to 2035

Rapid Hepatitis Testing Market – Demand & Forecast 2025 to 2035

Market Leaders & Share in the Rapid Infuser Industry

Rapid Plasma Reagin Test Market

Rapid Coagulation Testing Market

Rapid Cook-High Speed Ovens Market

Nanomaterials Market Insights - Size, Share & Industry Growth 2025 to 2035

Mono Rapid Testing Market Size and Share Forecast Outlook 2025 to 2035

Tire Materials Market Insights – Size, Trends & Forecast 2025–2035

Facade Materials Market Size and Share Forecast Outlook 2025 to 2035

Solder Materials Market Size and Share Forecast Outlook 2025 to 2035

Sheath Materials Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA