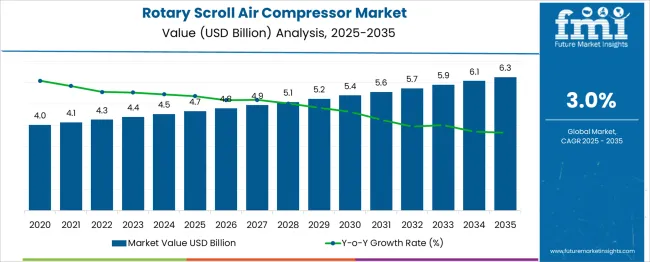

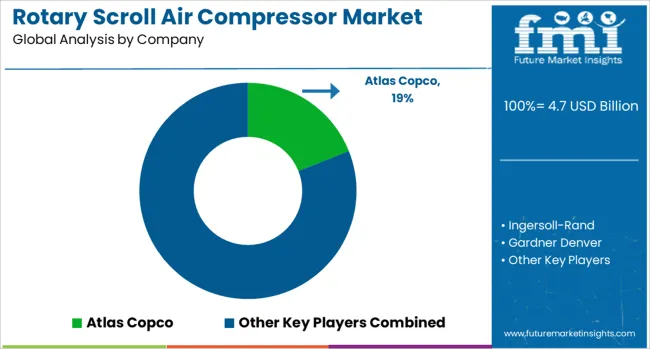

The Rotary Scroll Air Compressor Market is estimated to be valued at USD 4.7 billion in 2025 and is projected to reach USD 6.3 billion by 2035, registering a compound annual growth rate (CAGR) of 3.0% over the forecast period.

Based on the growth trajectory, the market is expected to experience gradual expansion, which suggests potential for market share erosion if competing compressor technologies grow at a faster rate. Between 2025 and 2029, annual gains remain modest, increasing from USD 4.7 billion to USD 5.2 billion, with yearly increments of only USD 0.1 to 0.2 billion. This steady but slow growth may limit share gains in the broader compressed air equipment sector, especially against oil-free screw compressors and emerging high-efficiency alternatives that could capture demand in energy-sensitive industries. From 2030 to 2035, the market rises from USD 5.4 billion to USD 6.3 billion, adding USD 0.9 billion over five years. While this phase benefits from adoption in electronics manufacturing, food processing, and medical applications where clean, oil-free air is critical, it may still lag behind the faster adoption curves of newer compressor technologies. Unless product innovation, cost optimization, and performance upgrades accelerate demand, the market could see relative share erosion within the air compressor industry, even as absolute revenues continue to rise at a measured pace.

| Metric | Value |

|---|---|

| Rotary Scroll Air Compressor Market Estimated Value in (2025 E) | USD 4.7 billion |

| Rotary Scroll Air Compressor Market Forecast Value in (2035 F) | USD 6.3 billion |

| Forecast CAGR (2025 to 2035) | 3.0% |

The rotary scroll air compressor market is viewed as a specialized yet steadily expanding category across its parent industries. It is estimated to account for about 2.1 % of the global air compressor market indicating increasing preference for reliable and quiet compression solutions. Within the industrial equipment sector a share of approximately 3.4 % is assessed driven by demand in manufacturing, electronics and pharmaceutical production. In the HVAC and refrigeration systems market around 2.8 % is observed supported by use in cleanroom and climate control applications. Within the medical and dental equipment industry about 2.5 % is calculated reflecting adoption for surgical air and lab compressed air. In the energy efficiency and clean technology equipment segment a contribution of roughly 2.9 % is evaluated as scroll compressors deliver reduced noise, low vibration and oil free operation. Trends in this market have been shaped by growth in industries requiring oil free and low noise compression.

Innovations have been focused on high efficiency scroll designs incorporating variable frequency drive control and smart monitoring for preventative maintenance. Interest has increased in air compressors with integrated sensors, digital dashboards and cloud based analytics. The Asia Pacific region has been observed to exhibit the fastest demand growth while Europe has maintained strong uptake in cleanroom and medical applications under strict regulatory standards. Strategic initiatives have included collaborations between compressor manufacturers and automation solution providers to deliver modular scroll compressor units featuring adaptive speed control, remote monitoring and energy consumption optimization.

The rotary scroll air compressor market is gaining momentum, propelled by the increasing need for compact, vibration-free, and low-maintenance compression systems across industrial and medical sectors. These compressors are widely preferred for their quiet operation, fewer moving parts, and oil-free or low-oil designs that align with stringent quality and emission requirements.

As energy efficiency becomes a top priority in manufacturing and facility operations, scroll compressors are being adopted for their lower power consumption and enhanced reliability in continuous-duty cycles. Growth is also supported by the rising deployment of HVAC and pneumatic systems in urban infrastructure and commercial facilities.

Furthermore, technological improvements in scroll geometries, heat dissipation, and control integration are enhancing performance and extending lifecycle value, particularly in critical applications such as pharmaceuticals and food-grade processes.

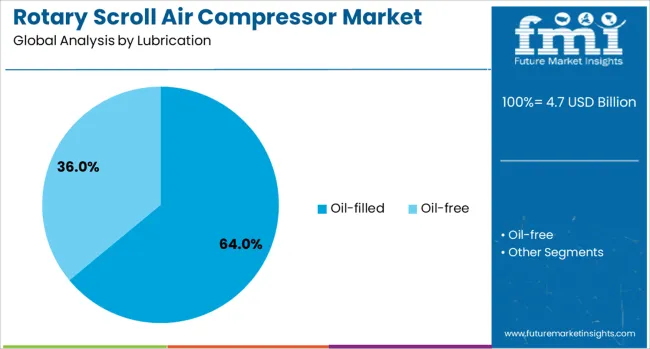

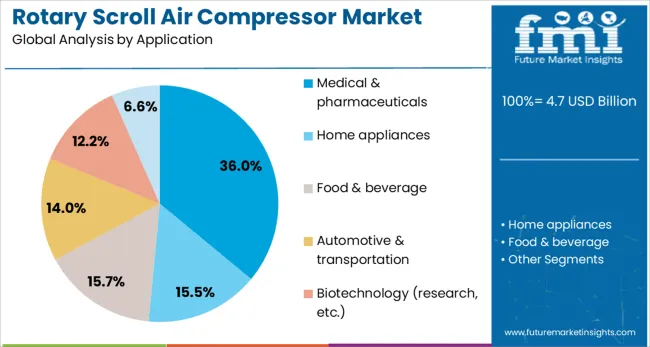

The rotary scroll air compressor market is segmented by lubrication, application, and geographic regions. The rotary scroll air compressor market is divided into Oil-filled and Oil-Free Types. In terms of application, the rotary scroll air compressor market is classified into Medical & pharmaceuticals, Home appliances, Food & beverage, Automotive & transportation, Biotechnology (research, etc.), and Others (semiconductor & electronics, commercial printing, etc.). Regionally, the rotary scroll air compressor industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The oil-filled lubrication segment is projected to account for 64.00% of the rotary scroll air compressor market by 2025, making it the dominant lubrication type. This leadership is driven by oil-filled units’ superior cooling, sealing, and efficiency advantages, which allow them to operate at higher pressures with longer service intervals.

They are especially favored in industrial applications requiring sustained airflow under demanding conditions. The presence of lubricants reduces wear and extends component life, enhancing cost-effectiveness and uptime for users.

Additionally, advancements in filtration and separation systems have improved the environmental performance of oil-lubricated compressors, supporting broader industrial adoption while maintaining compliance with operational safety standards.

The medical and pharmaceuticals segment is expected to hold 36.00% of the total market share by 2025, positioning it as the leading application area. This growth is fueled by the critical need for clean, stable, and low-vibration air supply in laboratories, dental practices, and hospital environments.

Scroll compressors are well-suited for these conditions due to their ability to provide consistent pressure output with minimal noise and heat generation. Their compact footprint and oil-free design also help meet strict hygiene and air purity requirements, reducing the risk of contamination in sterile environments.

As the global healthcare infrastructure expands and demand for precision air systems increases, the role of scroll compressors in supporting diagnostic equipment, surgical tools, and pneumatic hospital systems will continue to grow.

Rotary scroll air compressors have been increasingly adopted in manufacturing, food processing, electronics, and healthcare sectors for their oil-free operation, low noise, and compact design. These compressors operate using two interleaved spiral elements to compress air efficiently with minimal vibration. Demand has been driven by industries requiring clean, dry, and contaminant-free air for sensitive applications. Manufacturers have been focusing on energy-efficient designs, variable speed controls, and long service life components to improve operational reliability and reduce overall maintenance costs for end users.

Rotary scroll air compressors have been valued for their ability to provide 100% oil-free compressed air, making them suitable for applications in pharmaceuticals, food and beverage processing, and electronics manufacturing. The low-noise and low-vibration design has enabled installation closer to workstations, reducing the need for separate compressor rooms. In laboratory and medical environments, these compressors have been selected for operating diagnostic equipment and pneumatic tools without contamination risks. Compliance with ISO 8573-1 Class 0 air purity standards has further strengthened adoption in regulated industries. The combination of quiet operation, minimal maintenance, and clean air output has made rotary scroll compressors a preferred solution in facilities where air quality and operational comfort are critical.

Industrial users have adopted rotary scroll compressors for precision manufacturing, assembly line automation, and pneumatic equipment operation. In healthcare, hospitals and dental clinics have used these compressors to power surgical tools, ventilators, and sterilization equipment. The absence of oil in the compression chamber has been crucial for preventing product contamination in sterile environments. Portable models have been utilized in field hospitals and temporary medical facilities for reliable compressed air supply. Manufacturing facilities in Japan, Germany, and the United States have reported operational cost savings due to reduced maintenance requirements and high energy efficiency. The ability to operate continuously without overheating has enhanced their suitability for mission-critical industrial and healthcare operations.

Advances in rotary scroll compressor technology have focused on improving energy efficiency, extending service life, and enabling intelligent control. Variable speed drives have been integrated to match compressor output with fluctuating air demand, reducing energy waste. Improved scroll element materials and precision manufacturing have increased durability and minimized wear. Digital monitoring systems have allowed real-time tracking of performance metrics, enabling predictive maintenance scheduling. Compact modular designs have been developed to facilitate installation in space-constrained environments. Manufacturers in South Korea, Italy, and the United States have emphasized hybrid cooling systems to optimize temperature control during continuous operation. These developments have reinforced rotary scroll compressors as a cost-effective and reliable choice for clean air applications across multiple industries.

While rotary scroll air compressors offer several operational benefits, adoption has been limited by higher upfront purchase costs compared to conventional rotary screw or piston compressors. Their relatively lower maximum output capacity has restricted use in heavy-duty industrial applications with high-volume air demands. For small and medium-sized businesses, the investment may be challenging without clear long-term savings projections. Maintenance of precision scroll elements requires skilled technicians, adding to operational expenses in some regions. In sectors where air quality standards are less stringent, lower-cost oil-lubricated alternatives have been preferred. Without cost optimization, extended capacity ranges, and wider technician training availability, the broader market penetration of rotary scroll compressors may remain concentrated in specialized, quality-sensitive applications.

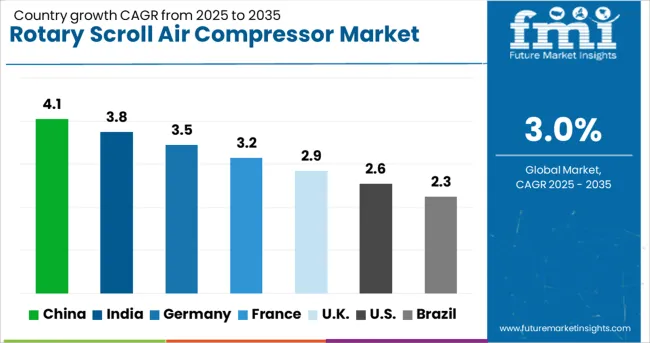

| Country | CAGR |

|---|---|

| China | 4.1% |

| India | 3.8% |

| Germany | 3.5% |

| France | 3.2% |

| UK | 2.9% |

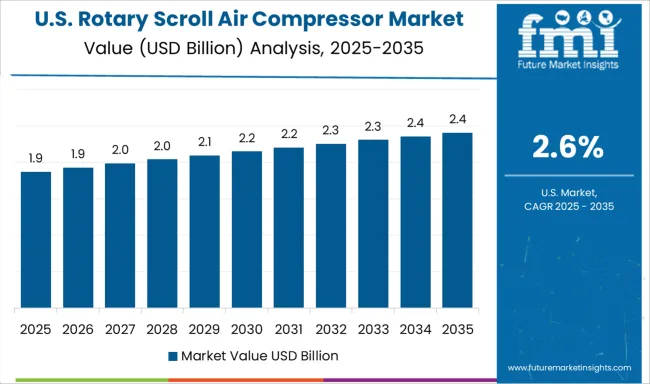

| USA | 2.6% |

| Brazil | 2.3% |

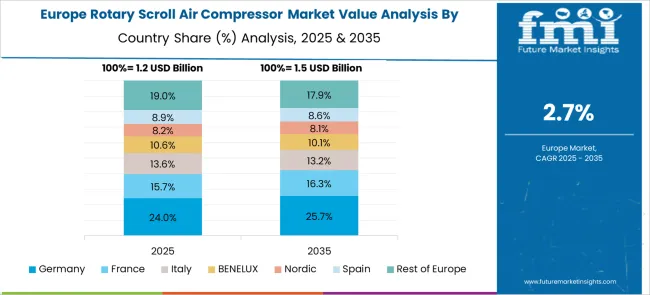

The rotary scroll air compressor market is expected to grow at a global CAGR of 3.0% between 2025 and 2035, driven by demand in manufacturing, HVAC, medical, and electronics industries due to their energy efficiency and low maintenance needs. China leads with a 4.1% CAGR, supported by large-scale industrial production and strong domestic demand. India follows at 3.8%, fueled by manufacturing sector expansion and infrastructure growth. Germany, at 3.5%, benefits from advanced engineering capabilities and high-quality compressor exports. The UK, projected at 2.9%, sees stable adoption in specialized industrial and healthcare applications. The USA, at 2.6%, reflects mature market conditions with steady replacement demand. The report provides insights for 40+ countries, with the five below highlighted for their strategic significance and growth outlook.

China is projected to grow at a CAGR of 4.1% from 2025 to 2035 in the rotary scroll air compressor market, supported by its large-scale manufacturing base and rising adoption of oil-free compressed air solutions in electronics, food processing, and medical applications. Domestic manufacturers such as Hanbell Precise Machinery, Guangzhou AirHorse, and Shanghai Screw Compressor are focusing on compact, energy-efficient scroll compressor designs to meet the needs of small-to-medium-scale industries. Growth is further driven by the expanding electronics assembly sector, where clean and stable air supply is critical. Additionally, government programs promoting energy efficiency in industrial equipment are encouraging the replacement of older compressor systems with advanced scroll models.

India is forecasted to achieve a CAGR of 3.8% from 2025 to 2035, with strong demand from the pharmaceutical, food & beverage, and electronics manufacturing sectors. Local companies such as ELGi Equipments and Indo-Air Compressors are expanding their range of portable and stationary scroll compressors to cater to varied industrial needs. Demand for oil-free technology is increasing in sectors where product purity is critical, particularly in packaged food processing and injectable pharmaceutical manufacturing. Growth in small workshops and CNC machining centers is also contributing to the market as scroll compressors offer low maintenance and quiet operation.

Germany is projected to post a CAGR of 3.5% from 2025 to 2035, driven by high-quality manufacturing standards and advanced engineering solutions. Leading brands such as Boge Kompressoren, Kaeser Kompressoren, and Aerzener Maschinenfabrik are integrating variable speed drives (VSD) into scroll compressors to improve energy efficiency. The medical and dental equipment manufacturing sectors are significant end-users, requiring consistent, oil-free compressed air. Germany’s focus on precision engineering is fostering the adoption of advanced sealing technologies to extend service life and reduce maintenance costs. Additionally, compliance with stringent EU environmental and safety regulations is shaping product design and performance standards.

The United Kingdom is expected to record a CAGR of 2.9% from 2025 to 2035, supported by demand from the healthcare, packaging, and electronics repair sectors. Manufacturers and distributors such as HPC Compressed Air Systems and Air Equipment Sales are focusing on supplying compact, plug-and-play scroll compressors for space-limited operations. Growth is being driven by medical facilities requiring reliable compressed air for surgical and dental tools. The shift toward low-noise compressors in urban and indoor workspaces is influencing purchasing decisions. The integration of remote monitoring features is also gaining traction among UK buyers seeking predictive maintenance capabilities.

The United States is forecasted to grow at a CAGR of 2.6% from 2025 to 2035, with rising adoption in laboratories, electronics assembly, and specialty manufacturing. Companies such as Quincy Compressor, Sullair LLC, and Atlas Copco USA are focusing on oil-free scroll compressors with enhanced cooling systems to meet continuous-duty requirements. The growing demand for energy-efficient solutions is prompting investment in scroll models with integrated heat recovery systems. Small manufacturing units and repair workshops are also contributing to market growth due to scroll compressors’ lower operational noise and compact footprint.

The rotary scroll air compressor market is led by established global industrial equipment manufacturers and specialized air system providers catering to applications in manufacturing, healthcare, food processing, electronics, and automotive sectors. Atlas Copco and Ingersoll-Rand dominate with a broad range of oil-free and lubricated scroll compressors, offering energy-efficient designs suited for continuous operation in critical environments. Gardner Denver and Sullair focus on industrial-grade units with advanced control systems for optimized performance and reduced maintenance requirements. Hitachi and Boge Compressors deliver compact, low-noise scroll compressors for precision industries such as electronics manufacturing and laboratory applications, while CompAir emphasizes modular, space-saving systems for flexible plant layouts.

Emerson and Parker Hannifin Manufacturing Ltd. integrate scroll compressor technology into HVAC and refrigeration systems, targeting both commercial and industrial markets. Ohio Medical Corp, Air Squared, and Powerex Inc. specialize in medical and dental air systems, ensuring oil-free, ultra-clean air supply compliant with healthcare standards. EMSE, Inc. and FS Curtis supply scroll compressors for niche industrial and OEM applications, often customizing units to meet specific flow, pressure, and footprint requirements. Frank Technologies serves regional industrial markets with cost-competitive solutions tailored to local demand. Key strategies in the sector include expanding product portfolios for oil-free and energy-efficient models, partnering with OEMs for integrated systems, and establishing regional service hubs to minimize downtime. Entry barriers include precision manufacturing capabilities, strict quality standards for sensitive applications, and long-standing relationships between established suppliers and major end-user industries.

| Item | Value |

|---|---|

| Quantitative Units | USD 4.7 Billion |

| Lubrication | Oil-filled and Oil-free |

| Application | Medical & pharmaceuticals, Home appliances, Food & beverage, Automotive & transportation, Biotechnology (research, etc.), and Others (semiconductor & electronics, commercial printing, etc.) |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Atlas Copco, Ingersoll-Rand, Gardner Denver, Emerson, Sullair, Hitachi, Frank Technologies, Boge Compressors, CompAir, Ohio Medical Corp, Air Squared, Powerex Inc, EMSE, Inc, FS Curtis, and Parker Hannifin Manufacturing Ltd. |

The global rotary scroll air compressor market is estimated to be valued at USD 4.7 billion in 2025.

The market size for the rotary scroll air compressor market is projected to reach USD 6.3 billion by 2035.

The rotary scroll air compressor market is expected to grow at a 3.0% CAGR between 2025 and 2035.

The key product types in rotary scroll air compressor market are oil-filled and oil-free.

In terms of application, medical & pharmaceuticals segment to command 36.0% share in the rotary scroll air compressor market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Air Compressor Filters and Compressed Air Dryers Market Growth - Trends & Forecast 2025 to 2035

USA Scroll Compressor Market Growth - Trends & Forecast 2025 to 2035

Quiet Air Compressor Market Analysis Size and Share Forecast Outlook 2025 to 2035

Air Conditioning Compressor Market Size and Share Forecast Outlook 2025 to 2035

Rotary Heat Pump Compressors Market Size and Share Forecast Outlook 2025 to 2035

Automotive Air Compressor Market Growth - Trends & Forecast 2025 to 2035

Industrial Air Compressor Market Growth - Trends & Forecast 2025 to 2035

Refrigeration and Air Conditioning Compressors Market Size and Share Forecast Outlook 2025 to 2035

Key Players & Market Share in Refrigeration and Air Conditioning Compressors

Heat Pump Laundry Dryer Rotary Compressors Market Size and Share Forecast Outlook 2025 to 2035

Permanent Magnet Integrated Air Compressor Market Size and Share Forecast Outlook 2025 to 2035

Air Fryer Paper Liners Market Size and Share Forecast Outlook 2025 to 2035

Air Struts Market Size and Share Forecast Outlook 2025 to 2035

Rotary Shaping File Market Size and Share Forecast Outlook 2025 to 2035

Airless Paint Spray System Market Size and Share Forecast Outlook 2025 to 2035

Air Caster Skids System Market Size and Share Forecast Outlook 2025 to 2035

Rotary DIP Switch Market Size and Share Forecast Outlook 2025 to 2035

Airborne Molecular Contamination Control Services Market Forecast and Outlook 2025 to 2035

Airflow Balancer Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cabin Environment Sensor Market Forecast and Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA