The global automotive structural steel market is anticipated to witness a steady growth between 2025 to 2035, owing to an increase in the vehicle production demand for materials that are high strength as well as low weight.

Pony car structural steel, deployed in chassis, frames and safety components, furnished the modern automotive architecture with the rigidity and crashworthiness demanded by modern design. As global automotive production rebounds and shifts to high-efficiency and electric vehicle production, structural steel remains a metric on which to base performance and cost optimization.

This trend has led to an increased usage of more lightweight high-strength steel (HSS) materials such as advanced high-strength steel (AHSS) and ultra-high-strength steel (UHSS) that still ensure participant safety. It is envisaged that the application helps the OEMs to comply with the ever-growing global landscape of stringent fuel economy and emission regulations.

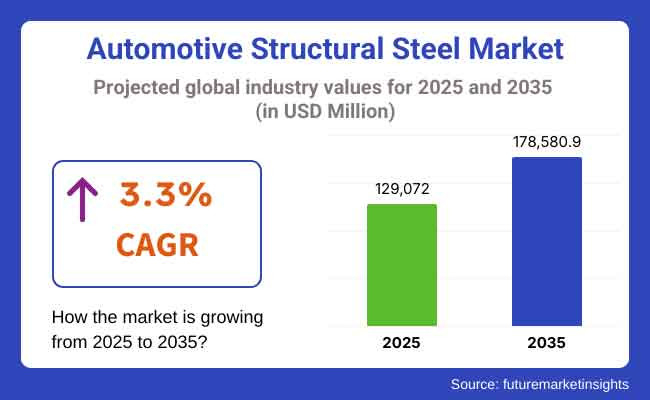

The global automotive structural steel market was valued around USD 129,072 Million by 2025 and is expected to reach approximately USD 178,580.9 Million by 2035, at a CAGR of 3.3% between the forecasted years.

The North America automotive structural steel market, however, is highly consolidated, as the vehicle manufacturing hubs in the USA and Mexico have enhanced the supply of automotive structural steel. The trend the region’s had toward light truck and SUV platforms, paired with the crash safety mandates, is driving demand for AHSS grades. It has undertaken investments in domestic steel capacity that is in line with automotive OEM sustainability goals and is designed to reduce the amount of imports.

Europe is seeing increasing adoption of advanced lightweight structural steel to meet Euro 7 emission targets as well as lower lifecycle carbon emissions from vehicles. Germany, France, and the UK are at the forefront of multi-phase steels in electric vehicle platforms driven by strengthening of the BIW structure in EVs.

Similarly, the European Union's targeted carbon neutrality of vehicles by 2035 is pushing the development of materials and recycling regulations.

Asia-Pacific dominates the global automotive structural steel consumption due to high vehicle production from China, Japan, India, and South Korea. Demand is being spurred by the fast-growth of the EV industry, infrastructure investments and government incentives.

China is still one of the largest consumers and producers, for domestic steelmakers, much of the focus is on high-strength grades and both domestic and export automotive applications.

Challenges

Material substitution pressures, volatile raw material pricing, and decarbonization hurdles impact scalability.

The automotive structural steel market is being threatened in premium and EV segments, where manufacturers aim to offset battery weight through lightweight alternatives (like aluminum and carbon fiber). While steel is still less expensive, there was a multi-material strategy being adopted by the OEMs that might limit steel’s content share of components.

And the fluctuations in raw material prices including iron ore and metallurgical coal impair cost planning for steel producers and downstream suppliers. Steel production is likewise energy-intensive, and with increasing pressure to decarbonize industrial processes, firms need to invest in green hydrogen and electric arc furnace technologies that carry heavy upfront costs.

Opportunities

Green steel, electric vehicle integration, and circular manufacturing present growth avenues

The replacement of traditional steel with green steel which is manufactured using renewable energy and hydrogen is set to be a game changer for the automotive industry. In line with their Environmental, Social and Governance (ESG) commitments, automakers are pushing steelmakers for low carbon steel for next-generation platforms.

Additionally, the structural complexity of electric cars, which typically need bespoke crash structures and battery enclosures, is driving the need for more advanced grades of steel. Inside the automotive supply chain, an important trend is the increasing interest in recycling structural steel when processing vehicles at the end of their lives, which brings both cost-saving and environmental benefits, supporting circular economy initiatives.

In the period from 2020 to 2024, the automotive structural steel market encountered challenges such as shutdowns caused by the pandemic, semiconductor shortages, and disrupted supply chains which affected the market. But vehicle production increased, and consumer interest was back at work, post-pandemic recovery with push for things like fuel-efficient cars, also renewed focus on AHSS and press-hardened steel. Electric vehicle platform investments also sped up structural steel innovation for battery protecting systems.

Industry suppliers will focus on sourcing sustainable steel, digital supply chain traceability and flexible manufacture processes in the years ahead to adapt to changing vehicle electrification and autonomy requirements from 2025 onwards.

OEMs will increasingly turn to co-development of steel solutions with materials scientists to optimize for weight and sustainability. Instrumented with modular chassis designs, lightweight frames and integrated safety zones, automobile component parts will call for different steel applications.

Market Shifts: A Comparative Analysis 2020 to 2024 vs. 2025 to 2035

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Fuel efficiency and crash safety standards |

| Consumer Trends | Preference for SUVs, crossovers, and fuel efficiency |

| Industry Adoption | High in ICE vehicles and light trucks |

| Supply Chain and Sourcing | Centralized steel production, limited transparency |

| Market Competition | Dominated by traditional steelmakers |

| Market Growth Drivers | Recovery in vehicle production, AHSS benefits |

| Sustainability and Impact | Moderate focus on recyclability and emissions |

| Smart Technology Integration | Use of digital twins in manufacturing |

| Sensorial Innovation | Focused on tensile strength and weldability |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Carbon neutrality, green steel sourcing, and circular manufacturing rules |

| Consumer Trends | Shift to EVs with advanced safety and lightweight structural needs |

| Industry Adoption | Expanding in EV platforms, battery enclosures, and micro-mobility vehicles |

| Supply Chain and Sourcing | Green steel partnerships, localized sourcing, and traceable supply chains |

| Market Competition | Entry of hydrogen steel startups and tech-enabled material innovators |

| Market Growth Drivers | Lightweight EV demand, ESG mandates, and lifecycle efficiency |

| Sustainability and Impact | High-impact shift toward green steel and end-of-life material recovery |

| Smart Technology Integration | AI-based alloy design, digital supply tracking, and adaptive steel testing |

| Sensorial Innovation | Advanced crash behavior, vibration damping, and thermal performance |

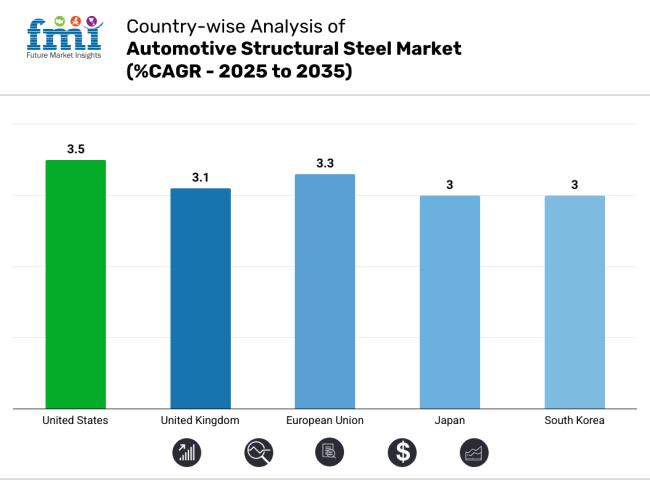

Strong domestic automotive production and strict crash safety regulation is driving the USA automotive structural steel market. Structural steel is still key to the manufacture of vehicle frames, chassis and impact-resistant parts, especially in trucks and SUVs.

USA automakers are ramping up the use of advanced high-strength steel (AHSS) for compliance with its Corporate Average Fuel Economy (CAFE) standards. States such as Michigan and Ohio still serve as anchors for steel supply chains by way of integrated manufacturing hubs. The USA is also investing in electric arc furnaces and hydrogen-based technologies to decarbonize steel production.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 3.5% |

The UK automotive structural steel market is expanding slowly, due to the transition toward electric vehicles (EVs) and lightweight design for vehicles in the country. Steel also allows for crashworthiness trade-offs and battery enclosure safety that manufacturers are taking advantage of in EV platforms. Brexit trade arrangements have also helped support local supply of automotive structural steel.

A move to curb emissions from steel production is prompting UK automakers to work closely with their domestic steelmakers seeking low-carbon-based production pathways under government policy initiatives. A number of Midlands-based auto clusters are also active in modular steel component integration for hybrid vehicle frames.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 3.1% |

Demand for structural steel in automotive applications remains steady across EU countries as OEMs focus on emissions reduction through lightweight vehicle architectures. Next-gen chassis and crash beams are being penned with multi-phase and press-hardened steels in Germany, France, and Italy. European Green Deal and the Fit for 55 package drive steel innovation for climate neutrality by 2050.

Cross-industry partnerships are concentrating on recyclable AHSS and fossil-free steel for electric and hybrid vehicle platforms. Extended producer responsibility (EPR) policies are being integrated with automotive steel recycling programs across member states with their EU context.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 3.3% |

Japan is a prominent contributor to the automotive structural steel market with its legacy of manufacturer offering compact and fuel-efficient vehicles. To meet Japan’s Automotive Safety Standards, automakers are integrating ultra-high-strength steels (UHSS) into unibody structures and crash impact zones. Car manufacturers are working with steelmakers to make hot stamping more optimized and to reduce part weight while maintaining performance catches. Tokyo and Nagoya-based research institutions are working on steel alloys that offer superior fatigue and corrosion resistance for long-term robustness. Adoption of intelligent manufacturing technologies in steel forming is also empowering the growth of the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.0% |

South Korea has long been a key global exporter of automotive-grade steel, with companies like POSCO pushing to develop lightweight, high-tensile steel solutions for global carmakers. Domestic EV production is generating additional demand for steel battery enclosures and subframe assemblies.

The government’s Green New Deal is promoting clean steel manufacturing and sustainable automotive parts development Ulsan and Pohang smart factories are replacing AI and robotics in the steel forming process for increased efficiency and lower emissions. Hyundai is working with local steel suppliers to improve vehicle safety through material innovation.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 3.4% |

With OEMs striving to balance durability, light-weighting, and cost-effective solutions while still adhering to government regulations, the automotive structural steel market is constantly in flux, thanks to its solid growth trajectory. As electrification, crash safety, and sustainability impact vehicle design, structural steel is still a popular material for chassis, frame, and reinforcement components.

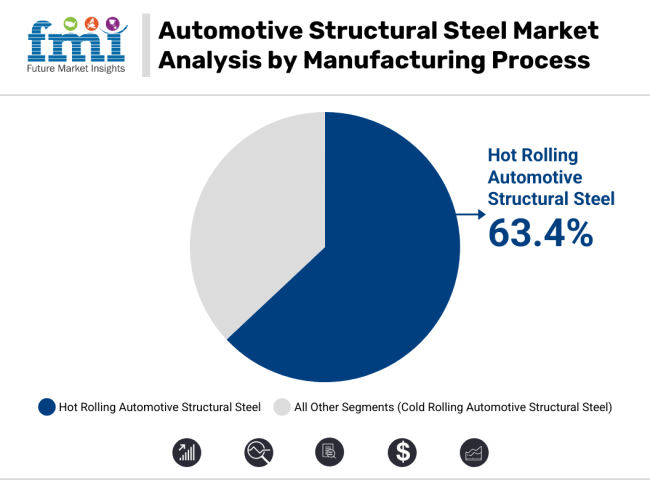

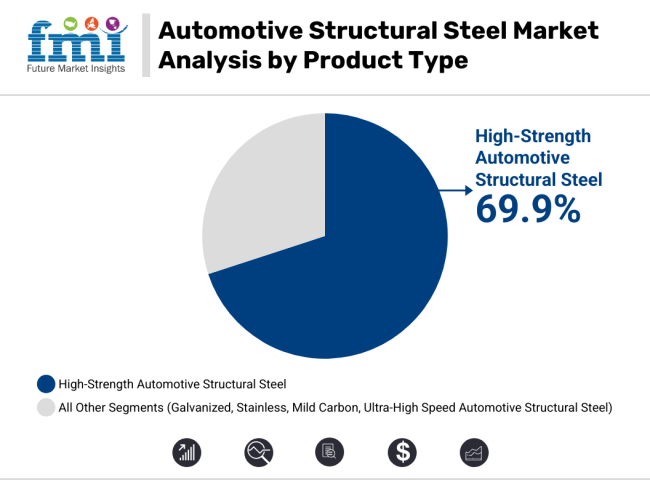

Hot-rolled steel and high-strength structural steel grades account for the highest share of the global market among industrial production processes and product classes; part of this is particularly linked to the ease of shaping, high formability, and dynamic mechanical loadability of such products.

Such segments allow the forming of beefy but thinner automotive parts complying with crash performance metrics while cutting down weight to increase fuel efficiency.Automakers worldwide are trading heavier legacy metals in passenger and commercial vehicles for advanced high-strength steel (AHSS) and ultra-high-strength steel (UHSS) in compliance with new crashworthiness and CO₂ reduction guidelines.

In the automotive structural steel segment, hot rolling is the most widely utilized process as it has the capability to produce high volumes of steel materials with reproducibility of fine grain microstructure and mechanical performance. This method of forging where steel is rolled above its recrystallization temperatures produces a menial product suitable for forming vast automotive components.

OEMs choose hot-rolled steel for extensive beams, rails, and subframes that must deliver high dimensional stability under mechanical stress. Its cost-effectiveness, scalability, and compatibility with various steel grades, including high-strength variants, make it indispensable in the production of structural components.

Hot rolling reduces any internal stresses as well as permits post-processing treatments such as galvanization or annealing. In developing markets, it is the method for large-scale automotive steel production due to its energy efficiency and high throughput.

Cold-rolled steel is preferred for tighter tolerances and for the surface finish of visible panels, while hot rolling prevails for structural applications on account of its mechanical performance and lower production cost per kg.

High-strength automotive structural steel accounts for the major share of the automotive lightweight materials market, owing to the factors such as superior load-bearing capabilities, high impact resistance, and the use of metal components for vehicle light-weighting.

Our novel DAHS using high strength steels (DP, TRIP, martensitic steel) provide a much higher tensile strength compared to conventional grades while keeping the ductility.To protect occupants without adding excessive mass, manufacturers use high-strength steel in crash zones, door beams, roof rails, and rocker panels. This balance between safety and efficiency enables improvements in fuel economy as well as compliance with safety regulations like Euro NCAP and IIHS.

In EVs, high-strength steel delivers structural dimension support for the battery enclosure and integrity without increasing weight and losing range. Its weldability and formability also contribute further integration across both ICE and EV platforms.

Higher-strength grades better cover structural applications on account of their performance-to-weight advantage and central impact to the architecture of the modern vehicle while stainless and galvanized versions have always supported corrosion protection and surface aesthetics.

The global automotive structural steel market is booming owing to surging demand for light-weight, high-strength, and crash-resisting materials, especially in passenger and commercial vehicle segments. To reach fuel economy standards while enhancing vehicle safety, manufacturers have been emphasizing advanced high-strength steels (AHSS), ultra-high-strength steels (UHSS), and boron steels that are hot stamped.

The advent of electric vehicle (EV) adoption, crash performance standards and platform modularity requirements are pushing global OEMs to adopt structural steel solutions that achieve a balance of rigidity, formability and cost-efficiency. Steelmakers are facing pressures from the environment to lower carbon emissions, thus encouraging investments in low-carbon steel production and closed-loop recycling systems.

Market Share Analysis by Key Players & Automotive Structural Steel Providers

| Company Name | Estimated Market Share (%) |

|---|---|

| ArcelorMittal | 15-18% |

| POSCO | 12-15% |

| Nippon Steel Corporation | 9-12% |

| thyssenkrupp AG | 7-10% |

| Tata Steel | 6-9% |

| Other Providers | 36-43% |

| Company Name | Key Offerings/Activities |

|---|---|

| ArcelorMittal | In 2024 , launched Fortiform® 980GI AHSS for EV body-in-white applications; in 2025 , opened low-carbon steel facility using hydrogen-based DRI technology. |

| POSCO | In 2024 , introduced Giga Steel variants for crash zones in SUVs; in 2025 , partnered with Hyundai for EV chassis development using hot-stamped steel. |

| Nippon Steel Corporation | In 2024 , expanded supply of ultra-high-strength martensitic steels for battery enclosures; in 2025 , invested in smart rolling mills to optimize forming precision. |

| thyssenkrupp AG | In 2024 , developed tailored blank steel sheets for modular vehicle platforms; in 2025 , launched blue carbon steel solutions under Scope 3 emission targets. |

| Tata Steel | In 2024 , upgraded its MagiZinc® Auto line for better corrosion resistance in lightweight frames; in 2025 , introduced closed-loop recycling with Indian OEMs. |

Key Market Insights

ArcelorMittal (15-18%)

ArcelorMittal leads the global automotive structural steel market with a strong focus on AHSS innovation and decarbonization. In 2024, it introduced Fortiform® 980GI, designed for EV body-in-white applications requiring energy absorption and stiffness.

In 2025, the company began producing low-carbon steel via hydrogen-based direct reduced iron (DRI) at its European facilities, reducing CO₂ emissions by over 80% compared to conventional steelmaking. Its R&D investments support safety-critical zones like A- and B-pillars and front rail structures in both ICE and EV models.

POSCO (12-15%)

POSCO plays a key role in providing advanced steels for crashworthiness and lightweighting. In 2024, it launched new Giga Steel grades used in side sills and crash beams in SUVs. In 2025, POSCO partnered with Hyundai Motor Group to develop EV-specific chassis platforms using hot-stamped structural steels for battery protection and rigidity. The company’s smart steel platform enhances design simulation capabilities for automakers and reduces manufacturing errors across high-volume production lines.

Nippon Steel Corporation (9-12%)

Nippon Steel is advancing in ultra-high-strength steels for EV battery enclosures and occupant protection zones. In 2024, it expanded martensitic-grade steel output tailored to underbody and longitudinal frame components.

In 2025, it invested in AI-powered rolling mills to improve mechanical consistency and precision forming of critical structural parts. The company’s focus on enhancing ductility without compromising yield strength supports thinner gauge use and vehicle weight reduction initiatives [citation needed].

Thyssenkrupp AG (7-10%)

Thyssenkrupp is leveraging its metallurgical expertise to serve modular vehicle architectures. In 2024, it introduced tailored blanks that allow multi-gauge configurations for floor panels and crumple zones. In 2025, it launched its “blue carbon steel” range, developed to meet Scope 3 emission reduction goals and OEM sustainability targets.

With a growing footprint in the EU and USA, thyssenkrupp is aligning its structural steel innovations with circular economy standards and automotive OEM lifecycle assessments.

Tata Steel (6-9%)

Tata Steel offers lightweight, corrosion-resistant solutions to Indian and global OEMs. In 2024, it enhanced its MagiZinc® Auto range to support higher weldability and corrosion resistance in chassis and sub-frame parts.

In 2025, Tata introduced a closed-loop steel recycling program in collaboration with Indian automakers to reduce upstream raw material demand and increase traceability of steel components. Tata Steel’s growing EV portfolio includes high-tensile galvanized steels for underbody crash protection and EV mounting brackets.

Other Key Players (36-43% Combined)

Numerous regional and specialized steel producers are contributing to localized and EV-centric structural steel innovations. These include:

The overall market size for the automotive structural steel market was USD 129,072 Million in 2025.

The automotive structural steel market is expected to reach USD 178,580.9 Million in 2035.

The demand for automotive structural steel is rising due to the growing need for durable, crash-resistant vehicle components and increasing adoption of lightweight, high-strength materials to improve fuel efficiency and reduce emissions. Advancements in hot rolling processes and high-strength steel grades are also contributing to market growth.

The top 5 countries driving the development of the automotive structural steel market are China, the USA, Germany, Japan, and India.

Hot rolling and high-strength steel grades are expected to command a significant share over the assessment period.

Table 1: Global Automotive Structural Steel Market Value (US$ Mn) Forecast by Region, 2017-2032

Table 2: Global Automotive Structural Steel Market Volume (Tons) Forecast by Region, 2017-2032

Table 3: Global Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 4: Global Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 5: Global Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 6: Global Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 7: Global Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 8: Global Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 9: Global Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 10: Global Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Table 11: North America Automotive Structural Steel Market Value (US$ Mn) Forecast by Country, 2017-2032

Table 12: North America Automotive Structural Steel Market Volume (Tons) Forecast by Country, 2017-2032

Table 13: North America Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 14: North America Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 15: North America Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 16: North America Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 17: North America Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 18: North America Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 19: North America Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 20: North America Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Table 21: Latin America Automotive Structural Steel Market Value (US$ Mn) Forecast by Country, 2017-2032

Table 22: Latin America Automotive Structural Steel Market Volume (Tons) Forecast by Country, 2017-2032

Table 23: Latin America Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 24: Latin America Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 25: Latin America Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 26: Latin America Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 27: Latin America Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 28: Latin America Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 29: Latin America Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 30: Latin America Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Table 31: Europe Automotive Structural Steel Market Value (US$ Mn) Forecast by Country, 2017-2032

Table 32: Europe Automotive Structural Steel Market Volume (Tons) Forecast by Country, 2017-2032

Table 33: Europe Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 34: Europe Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 35: Europe Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 36: Europe Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 37: Europe Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 38: Europe Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 39: Europe Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 40: Europe Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Table 41: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Forecast by Country, 2017-2032

Table 42: Asia Pacific Automotive Structural Steel Market Volume (Tons) Forecast by Country, 2017-2032

Table 43: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 44: Asia Pacific Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 45: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 46: Asia Pacific Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 47: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 48: Asia Pacific Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 49: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 50: Asia Pacific Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Table 51: MEA Automotive Structural Steel Market Value (US$ Mn) Forecast by Country, 2017-2032

Table 52: MEA Automotive Structural Steel Market Volume (Tons) Forecast by Country, 2017-2032

Table 53: MEA Automotive Structural Steel Market Value (US$ Mn) Forecast by Manufacturing Process, 2017-2032

Table 54: MEA Automotive Structural Steel Market Volume (Tons) Forecast by Manufacturing Process, 2017-2032

Table 55: MEA Automotive Structural Steel Market Value (US$ Mn) Forecast by Product Type, 2017-2032

Table 56: MEA Automotive Structural Steel Market Volume (Tons) Forecast by Product Type, 2017-2032

Table 57: MEA Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Component, 2017-2032

Table 58: MEA Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Component, 2017-2032

Table 59: MEA Automotive Structural Steel Market Value (US$ Mn) Forecast by Vehicle Type, 2017-2032

Table 60: MEA Automotive Structural Steel Market Volume (Tons) Forecast by Vehicle Type, 2017-2032

Figure 1: Global Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 2: Global Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 3: Global Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 4: Global Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 5: Global Automotive Structural Steel Market Value (US$ Mn) by Region, 2022-2032

Figure 6: Global Automotive Structural Steel Market Value (US$ Mn) Analysis by Region, 2017-2032

Figure 7: Global Automotive Structural Steel Market Volume (Tons) Analysis by Region, 2017-2032

Figure 8: Global Automotive Structural Steel Market Value Share (%) and BPS Analysis by Region, 2022-2032

Figure 9: Global Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Region, 2022-2032

Figure 10: Global Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 11: Global Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 12: Global Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 13: Global Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 14: Global Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 15: Global Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 16: Global Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 17: Global Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 18: Global Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 19: Global Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 20: Global Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 21: Global Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 22: Global Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 23: Global Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 24: Global Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 25: Global Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 26: Global Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 27: Global Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 28: Global Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 29: Global Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 30: Global Automotive Structural Steel Market Attractiveness by Region, 2022-2032

Figure 31: North America Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 32: North America Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 33: North America Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 34: North America Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 35: North America Automotive Structural Steel Market Value (US$ Mn) by Country, 2022-2032

Figure 36: North America Automotive Structural Steel Market Value (US$ Mn) Analysis by Country, 2017-2032

Figure 37: North America Automotive Structural Steel Market Volume (Tons) Analysis by Country, 2017-2032

Figure 38: North America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Country, 2022-2032

Figure 39: North America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Country, 2022-2032

Figure 40: North America Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 41: North America Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 42: North America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 43: North America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 44: North America Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 45: North America Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 46: North America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 47: North America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 48: North America Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 49: North America Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 50: North America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 51: North America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 52: North America Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 53: North America Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 54: North America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 55: North America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 56: North America Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 57: North America Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 58: North America Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 59: North America Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 60: North America Automotive Structural Steel Market Attractiveness by Country, 2022-2032

Figure 61: Latin America Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 62: Latin America Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 63: Latin America Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 64: Latin America Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 65: Latin America Automotive Structural Steel Market Value (US$ Mn) by Country, 2022-2032

Figure 66: Latin America Automotive Structural Steel Market Value (US$ Mn) Analysis by Country, 2017-2032

Figure 67: Latin America Automotive Structural Steel Market Volume (Tons) Analysis by Country, 2017-2032

Figure 68: Latin America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Country, 2022-2032

Figure 69: Latin America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Country, 2022-2032

Figure 70: Latin America Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 71: Latin America Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 72: Latin America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 73: Latin America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 74: Latin America Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 75: Latin America Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 76: Latin America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 77: Latin America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 78: Latin America Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 79: Latin America Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 80: Latin America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 81: Latin America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 82: Latin America Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 83: Latin America Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 84: Latin America Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 85: Latin America Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 86: Latin America Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 87: Latin America Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 88: Latin America Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 89: Latin America Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 90: Latin America Automotive Structural Steel Market Attractiveness by Country, 2022-2032

Figure 91: Europe Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 92: Europe Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 93: Europe Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 94: Europe Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 95: Europe Automotive Structural Steel Market Value (US$ Mn) by Country, 2022-2032

Figure 96: Europe Automotive Structural Steel Market Value (US$ Mn) Analysis by Country, 2017-2032

Figure 97: Europe Automotive Structural Steel Market Volume (Tons) Analysis by Country, 2017-2032

Figure 98: Europe Automotive Structural Steel Market Value Share (%) and BPS Analysis by Country, 2022-2032

Figure 99: Europe Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Country, 2022-2032

Figure 100: Europe Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 101: Europe Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 102: Europe Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 103: Europe Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 104: Europe Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 105: Europe Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 106: Europe Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 107: Europe Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 108: Europe Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 109: Europe Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 110: Europe Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 111: Europe Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 112: Europe Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 113: Europe Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 114: Europe Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 115: Europe Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 116: Europe Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 117: Europe Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 118: Europe Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 119: Europe Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 120: Europe Automotive Structural Steel Market Attractiveness by Country, 2022-2032

Figure 121: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 122: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 123: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 124: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 125: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) by Country, 2022-2032

Figure 126: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Analysis by Country, 2017-2032

Figure 127: Asia Pacific Automotive Structural Steel Market Volume (Tons) Analysis by Country, 2017-2032

Figure 128: Asia Pacific Automotive Structural Steel Market Value Share (%) and BPS Analysis by Country, 2022-2032

Figure 129: Asia Pacific Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Country, 2022-2032

Figure 130: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 131: Asia Pacific Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 132: Asia Pacific Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 133: Asia Pacific Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 134: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 135: Asia Pacific Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 136: Asia Pacific Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 137: Asia Pacific Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 138: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 139: Asia Pacific Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 140: Asia Pacific Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 141: Asia Pacific Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 142: Asia Pacific Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 143: Asia Pacific Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 144: Asia Pacific Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 145: Asia Pacific Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 146: Asia Pacific Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 147: Asia Pacific Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 148: Asia Pacific Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 149: Asia Pacific Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 150: Asia Pacific Automotive Structural Steel Market Attractiveness by Country, 2022-2032

Figure 151: MEA Automotive Structural Steel Market Value (US$ Mn) by Manufacturing Process, 2022-2032

Figure 152: MEA Automotive Structural Steel Market Value (US$ Mn) by Product Type, 2022-2032

Figure 153: MEA Automotive Structural Steel Market Value (US$ Mn) by Vehicle Component, 2022-2032

Figure 154: MEA Automotive Structural Steel Market Value (US$ Mn) by Vehicle Type, 2022-2032

Figure 155: MEA Automotive Structural Steel Market Value (US$ Mn) by Country, 2022-2032

Figure 156: MEA Automotive Structural Steel Market Value (US$ Mn) Analysis by Country, 2017-2032

Figure 157: MEA Automotive Structural Steel Market Volume (Tons) Analysis by Country, 2017-2032

Figure 158: MEA Automotive Structural Steel Market Value Share (%) and BPS Analysis by Country, 2022-2032

Figure 159: MEA Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Country, 2022-2032

Figure 160: MEA Automotive Structural Steel Market Value (US$ Mn) Analysis by Manufacturing Process, 2017-2032

Figure 161: MEA Automotive Structural Steel Market Volume (Tons) Analysis by Manufacturing Process, 2017-2032

Figure 162: MEA Automotive Structural Steel Market Value Share (%) and BPS Analysis by Manufacturing Process, 2022-2032

Figure 163: MEA Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2022-2032

Figure 164: MEA Automotive Structural Steel Market Value (US$ Mn) Analysis by Product Type, 2017-2032

Figure 165: MEA Automotive Structural Steel Market Volume (Tons) Analysis by Product Type, 2017-2032

Figure 166: MEA Automotive Structural Steel Market Value Share (%) and BPS Analysis by Product Type, 2022-2032

Figure 167: MEA Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Product Type, 2022-2032

Figure 168: MEA Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Component, 2017-2032

Figure 169: MEA Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Component, 2017-2032

Figure 170: MEA Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Component, 2022-2032

Figure 171: MEA Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Component, 2022-2032

Figure 172: MEA Automotive Structural Steel Market Value (US$ Mn) Analysis by Vehicle Type, 2017-2032

Figure 173: MEA Automotive Structural Steel Market Volume (Tons) Analysis by Vehicle Type, 2017-2032

Figure 174: MEA Automotive Structural Steel Market Value Share (%) and BPS Analysis by Vehicle Type, 2022-2032

Figure 175: MEA Automotive Structural Steel Market Y-o-Y Growth (%) Projections by Vehicle Type, 2022-2032

Figure 176: MEA Automotive Structural Steel Market Attractiveness by Manufacturing Process, 2022-2032

Figure 177: MEA Automotive Structural Steel Market Attractiveness by Product Type, 2022-2032

Figure 178: MEA Automotive Structural Steel Market Attractiveness by Vehicle Component, 2022-2032

Figure 179: MEA Automotive Structural Steel Market Attractiveness by Vehicle Type, 2022-2032

Figure 180: MEA Automotive Structural Steel Market Attractiveness by Country, 2022-2032

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Automotive Steel Market Size and Share Forecast Outlook 2025 to 2035

Automotive Stainless Steel Market Size and Share Forecast Outlook 2025 to 2035

Automotive Direct Liquid Cooling IGBT Module Market Size and Share Forecast Outlook 2025 to 2035

Automotive Hoses and Assemblies Market Size and Share Forecast Outlook 2025 to 2035

Automotive Network Testing Market Size and Share Forecast Outlook 2025 to 2035

Structural Waterproofing Services Market Size and Share Forecast Outlook 2025 to 2035

Automotive Performance Part Market Size and Share Forecast Outlook 2025 to 2035

Automotive Carbon Ceramic Brake Market Size and Share Forecast Outlook 2025 to 2035

Automotive Camshaft Market Size and Share Forecast Outlook 2025 to 2035

Structural Health Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Automotive Stamping Industry Analysis in India Size and Share Forecast Outlook 2025 to 2035

Automotive Cylinder Liner Market Size and Share Forecast Outlook 2025 to 2035

Automotive Microcontroller Market Size and Share Forecast Outlook 2025 to 2035

Automotive Roof Rails Market Size and Share Forecast Outlook 2025 to 2035

Steel Drum Market Size and Share Forecast Outlook 2025 to 2035

Automotive Active Safety System Market Size and Share Forecast Outlook 2025 to 2035

Automotive Diagnostic Scan Tool Market Size and Share Forecast Outlook 2025 to 2035

Automotive Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Automotive Dynamic Map Data Market Size and Share Forecast Outlook 2025 to 2035

Automotive Green Tires Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA