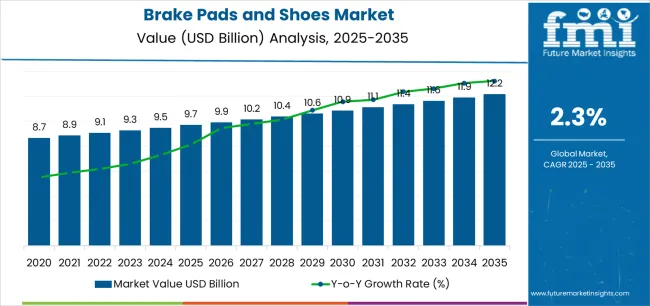

The brake pads and shoes market is valued at USD 9.7 billion in 2025 and is forecasted to reach USD 12.1 billion by 2035, advancing at a CAGR of 2.3%. The expansion of the brake pads and shoes market is influenced by steady growth in global vehicle production, ongoing replacement demand in the automotive aftermarket, and increased emphasis on safety standards and braking performance. The shift toward advanced friction materials and noise-reduction technologies continues to define development trends across both passenger and commercial vehicle segments. The automotive OEM industry represents the leading brake pads and shoes market segment, supported by manufacturers’ focus on integrating durable, low-dust, and environmentally compliant braking components. Rising adoption of ceramic and non-asbestos organic (NAO) materials enhances braking efficiency and thermal stability while aligning with global environmental regulations. The growing penetration of electric and hybrid vehicles has further accelerated innovation in lightweight and regenerative braking-compatible systems.

Asia Pacific dominates the brake pads and shoes market, driven by large-scale automotive production in China, Japan, and India. Europe and North America maintain steady demand driven by established vehicle fleets and replacement parts requirements. Key companies include BOSCH, Nisshinbo, ZF Aftermarket (TRW), Tenneco (Federal-Mogul), and Akebono, focusing on product reliability, material innovation, and consistent performance across diverse driving conditions.

The growth contribution index indicates that incremental expansion will be driven primarily by the aftermarket segment, accounting for a significant share of overall market gains. From 2025 to 2029, the index will show moderate contributions from passenger vehicles due to steady vehicle ownership and replacement cycles, particularly in North America, Europe, and Asia-Pacific. Growth contributions from commercial vehicles will remain stable, supported by ongoing fleet maintenance and brake system upgrades.

Between 2030 and 2035, the index will reflect a shift as electric vehicle adoption influences product demand composition. While regenerative braking systems in electric models reduce wear rates, hybrid and conventional vehicles will continue to sustain steady replacement demand. Regional contributions will remain balanced, with Asia-Pacific representing the largest share due to its extensive vehicle base and expanding automotive aftermarket. The growth contribution index portrays a low-volatility market driven by replacement frequency, product standardization, and material improvements such as ceramic and low-metallic formulations that enhance durability and noise reduction.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 9.7 billion |

| Market Forecast Value (2035) | USD 12.1 billion |

| Forecast CAGR (2025-2035) | 2.3% |

The brake pads and shoes market is expanding as rising global vehicle production and ownership increase the demand for braking components both in original-equipment manufacturing (OEM) and aftermarket replacement channels. Improved safety regulations and consumer awareness drive manufacturers and service providers to deploy higher-quality friction materials, boosting adoption of advanced brake pads and shoes. Technological developments in material science, such as ceramic, low-metallic, and non-asbestos organics, enhance durability, noise reduction, and braking performance.

Urbanisation, increased vehicle usage, and traffic congestion compound wear on brake systems, thereby accelerating replacement cycles and supporting aftermarket growth. Concurrently, trends like electric vehicles and regenerative braking are reshaping brake component requirements and spurring innovation in friction systems. Constraints include the transition toward disc-brake systems in many vehicles (which may reduce some demand for traditional shoes), the cost and complexity of high-performance materials, and regional disparities in maintenance infrastructure and consumer spending.

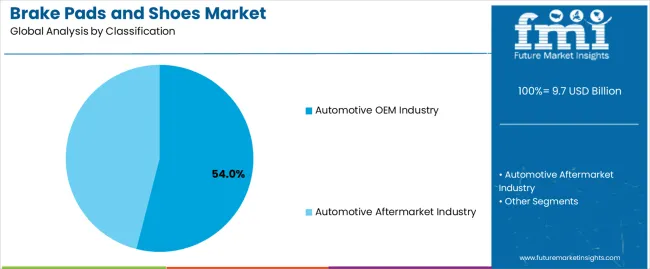

The brake pads and shoes market is segmented by classification and application. By classification, the market is divided into automotive OEM industry and automotive aftermarket industry. Based on application, it is categorized into passenger cars and commercial vehicles. Regionally, the market is divided into Asia Pacific, Europe, North America, and other key regions.

The automotive OEM industry segment holds the leading position in the brake pads and shoes market, representing approximately 54.0% of the total share in 2025. This dominance reflects the strong integration of brake components within original vehicle production processes, driven by rising global automobile manufacturing volumes and stringent safety regulations. OEM-supplied brake systems are designed to meet performance, durability, and compliance standards established by vehicle manufacturers, ensuring consistency in braking efficiency and material reliability.

The segment benefits from advancements in friction materials, including ceramic, semi-metallic, and low-copper formulations developed to optimize braking performance and minimize wear. Increased production of electric and hybrid vehicles has also supported OEM demand for specialized brake systems adapted to regenerative braking technologies. The automotive aftermarket industry segment, while smaller, continues to grow due to rising vehicle aging rates and the replacement needs of existing fleets, especially in emerging economies.

Key factors supporting the automotive OEM segment include:

The passenger cars segment accounts for approximately 62.0% of the brake pads and shoes market in 2025. This leadership is attributed to the large global passenger vehicle fleet and consistent demand for both OEM and replacement brake components. Passenger cars require frequent brake pad and shoe replacements due to higher usage rates in urban driving conditions, where stop-and-go traffic accelerates wear.

The segment also benefits from continued growth in private vehicle ownership and the introduction of lightweight and noise-dampened brake materials tailored for improved comfort and performance. The commercial vehicles segment follows, with significant use in logistics and heavy-duty transport applications that demand high thermal stability and load-bearing capacity.

Primary dynamics driving demand from the passenger cars segment include:

The brake pads and shoes market gains momentum from the global uptick in light- and heavy-vehicle production, which directly boosts demand for original equipment and replacement brake components. Stricter braking-system and road-safety regulations compel manufacturers and end-users to source higher-quality friction materials that meet thermal, wear and noise requirements. The ageing vehicle fleet in many mature markets drives the aftermarket segment, as vehicle operators seek timely replacement of worn brake pads and shoes to maintain braking performance and comply with fleet-safety mandates.

Key constraints include rising prices for steel, phenolic resins and friction-material additives, which increase manufacturing cost and squeeze margins. The growing adoption of electric vehicles and regenerative-braking systems reduces mechanical-brake usage and may dampen demand for conventional pads and shoes over time. The brake component market is highly competitive with low differentiation, driving price erosion especially in replacement channels and in cost-sensitive emerging-markets, which can limit profitability and investment in innovation.

Friction-material innovation is advancing toward ceramic and low-metallic compounds that offer improved NVH (noise, vibration, harshness) performance, longer life and lower dust generation. Regionally, Asia-Pacific stands out as the fastest-growing area for brake pads and shoes due to expanding vehicle sales, rising vehicle parc and increasing adoption of aftermarket services. A nascent trend is the integration of wear-sensors and fleet-telemetry systems into brake components, enabling predictive-maintenance models and digital service ecosystems that enhance value beyond mere friction-material replacement.

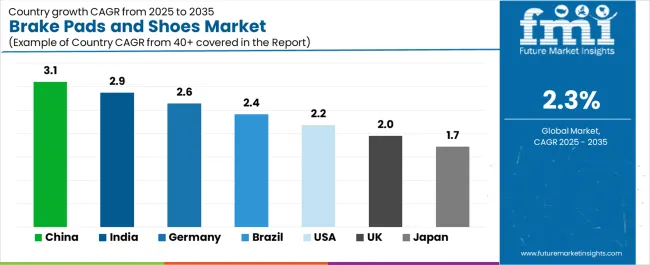

The global brake pads and shoes market is expanding moderately through 2035, supported by steady automotive production, aftermarket demand, and safety regulation compliance. China leads with a 3.1% CAGR, followed by India at 2.9%, driven by large-scale vehicle manufacturing and aftermarket modernization. Germany grows at 2.6%, reflecting continuous innovation in friction materials and safety systems. Brazil records 2.4%, supported by replacement demand in passenger and commercial vehicles. The United States grows at 2.2%, backed by EV adoption and brake component redesign. The United Kingdom (2.0%) and Japan (1.7%) maintain steady growth through product standardization, precision engineering, and export-oriented manufacturing.

| Country | CAGR (%) |

|---|---|

| China | 3.1 |

| India | 2.9 |

| Germany | 2.6 |

| Brazil | 2.4 |

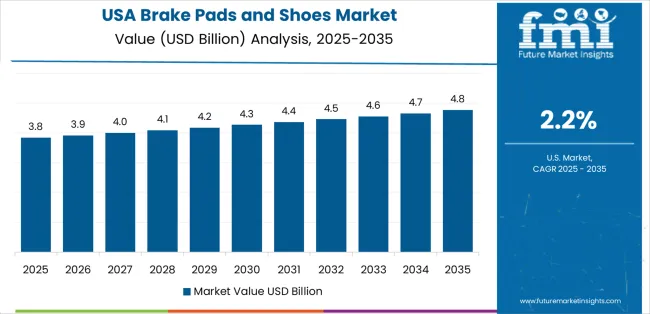

| U.S. | 2.2 |

| U.K. | 2.0 |

| Japan | 1.7 |

China’s brake pads and shoes market grows at 3.1% CAGR, supported by its dominant automotive manufacturing base and strong aftermarket ecosystem. The increasing production of passenger and light commercial vehicles continues to drive demand for advanced friction materials. Domestic manufacturers are adopting low-copper and ceramic-based brake technologies to meet international emission and performance standards. Government initiatives promoting safer and cleaner vehicle components have encouraged R&D investment in noise-free and wear-resistant braking solutions. The replacement segment remains strong due to expanding vehicle ownership and the rapid turnover of fleet vehicles across major urban centers.

Key Market Factors:

India’s market grows at 2.9% CAGR, driven by automotive production growth, road safety regulations, and urban vehicle expansion. Domestic suppliers are increasingly focusing on developing asbestos-free friction materials aligned with international safety standards. The aftermarket segment remains significant due to extensive two-wheeler and passenger car ownership. The Automotive Mission Plan and Make in India initiative have supported local manufacturing of brake components for both domestic and export markets. Technological collaborations with global suppliers are enhancing product quality, thermal stability, and performance consistency. The market is further strengthened by the rising adoption of disc braking systems in compact vehicles.

Market Development Factors:

Germany’s market grows at 2.6% CAGR, supported by its leadership in automotive safety innovation and engineering precision. Manufacturers are investing in next-generation friction materials for electric and hybrid vehicles to reduce particulate emissions. The transition toward regenerative braking systems has led to the development of low-wear, corrosion-resistant brake pads for EV platforms. Research collaborations between automotive OEMs and material science institutions are driving product testing under extreme conditions. The aftermarket remains robust due to strict vehicle inspection standards. German manufacturers continue to set global benchmarks in product quality, reliability, and environmental compliance.

Key Market Characteristics:

Brazil’s market grows at 2.4% CAGR, supported by the expansion of its domestic automotive aftermarket and increasing fleet maintenance requirements. Local manufacturers are improving friction formulations to enhance durability under tropical and high-humidity conditions. Import substitution policies have promoted domestic component production, reducing dependence on foreign suppliers. The growing presence of commercial vehicles in logistics and agricultural sectors sustains replacement demand. Partnerships with international friction material producers are introducing noise-reduction and performance-stable brake products to the local market. Economic recovery and rising vehicle utilization further support aftermarket sales growth.

Market Development Factors:

The United States grows at 2.2% CAGR, supported by the transition to advanced braking technologies in electric and hybrid vehicles. OEMs are investing in low-noise, low-dust friction materials compatible with regenerative braking systems. Stringent safety regulations from NHTSA and state agencies encourage continuous product innovation and quality testing. The aftermarket remains significant due to vehicle longevity and consumer preference for premium performance components. Increasing consumer awareness of brake wear indicators and maintenance cycles supports replacement frequency. The market benefits from domestic manufacturing capabilities and strong distribution networks for both OEM and aftermarket segments.

Key Market Factors:

The United Kingdom’s market grows at 2.0% CAGR, driven by increased regulatory focus on emissions, vehicle safety, and product traceability. Manufacturers are developing copper-free and noise-reducing friction materials compliant with EU and U.K. environmental directives. The replacement segment dominates due to aging vehicle populations and aftermarket activity. Collaborative R&D projects funded through Innovate UK are improving friction composition and wear resistance. Growth in electric vehicle adoption has prompted local firms to invest in lightweight, low-residue braking systems. Rising awareness of road safety and green material standards sustains long-term market development.

Market Development Factors:

Japan’s market grows at 1.7% CAGR, supported by its focus on quality manufacturing and long vehicle service life. Domestic OEMs are emphasizing high-performance, lightweight brake systems optimized for hybrid and compact cars. The integration of regenerative braking technology has led to reduced pad wear, prompting manufacturers to develop extended-life friction materials. Continuous improvements in composite and ceramic formulations enhance braking efficiency and noise control. Japan’s adherence to strict environmental and safety standards ensures consistency in material performance. Export demand for precision-engineered brake components remains stable, reflecting the country’s reputation for reliability and technological excellence.

Key Market Characteristics:

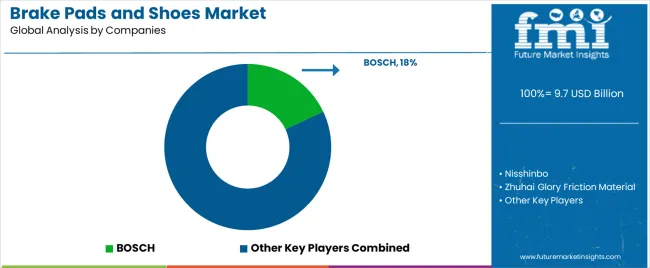

The brake pads and shoes market is highly competitive and moderately consolidated, with over thirty global and regional manufacturers serving both original equipment (OE) and aftermarket segments. BOSCH leads the market with an estimated 18.0% global share, supported by its extensive product range, advanced friction material technology, and global supply chain integration with major automotive manufacturers. The company’s strength lies in consistent product reliability, widespread service network coverage, and continuous innovation in low-noise and low-dust braking systems.

Nisshinbo, ZF Aftermarket (TRW), and Tenneco (Federal Mogul) follow as major international players with broad OE partnerships and significant aftermarket presence. These companies focus on high-performance and environmentally compliant friction materials that meet evolving automotive safety and emission standards. Akebono, Brembo, and ADVICS maintain competitive positions through advanced ceramic and carbon-based composites engineered for precision braking in performance and premium vehicle segments.

Regional producers such as Zhuhai Glory Friction Material, Sangsin Brake, and Shandong Gold Phoenix compete through scale production, cost optimization, and growing influence in Asia-Pacific supply networks. European firms including Continental (ATE), Fras-le, and TMD Friction (AEQUITA) emphasize quality assurance and compliance with EU safety directives.

Competition in this market centers on friction consistency, thermal resistance, and regulatory compliance, with innovation directed toward copper-free, noise-reducing, and extended-wear formulations. Growing demand for electric and hybrid vehicles is driving further development of regenerative-compatible brake systems, positioning technologically adaptive suppliers for sustained long-term advantage.

| Items | Values |

|---|---|

| Quantitative Units | USD billion |

| Classification | Automotive OEM Industry, Automotive Aftermarket Industry |

| Application | Passenger Cars, Commercial Vehicles |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Countries Covered | India, China, USA, Germany, South Korea, Japan, Italy, and 40+ countries |

| Key Companies Profiled | BOSCH, Nisshinbo, Zhuhai Glory Friction Material, ZF Aftermarket (TRW), Tenneco (Federal Mogul), MAT Holdings, ITT Corporation, Akebono, Sangsin Brake, Brembo, Hitachi, ADVICS |

| Additional Attributes | Dollar sales by classification and application categories; regional adoption trends across Asia Pacific, Europe, and North America; competitive landscape of automotive brake system manufacturers; advancements in friction material technologies and eco-friendly brake components; integration with electric and hybrid vehicle braking systems for performance optimization. |

The global brake pads and shoes market is estimated to be valued at USD 9.7 billion in 2025.

The market size for the brake pads and shoes market is projected to reach USD 12.2 billion by 2035.

The brake pads and shoes market is expected to grow at a 2.3% CAGR between 2025 and 2035.

The key product types in brake pads and shoes market are automotive oem industry and automotive aftermarket industry.

In terms of application, passenger cars segment to command 62.0% share in the brake pads and shoes market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Brake System Market Size and Share Forecast Outlook 2025 to 2035

Brake Cables Market Size and Share Forecast Outlook 2025 to 2035

Brake Override System Market

Brake Shoe Market

Air Brake Systems Market Growth & Demand 2025 to 2035

HCV Brake Components Market

Rail Brake Frame Market

Press Brakes Market Size and Share Forecast Outlook 2025 to 2035

Bicycle Brake Lever Market Size and Share Forecast Outlook 2025 to 2035

Automotive Brake Linings Market Size and Share Forecast Outlook 2025 to 2035

Automotive Brake Fluid Market Size and Share Forecast Outlook 2025 to 2035

Automotive Brake Actuation Systems Market Size and Share Forecast Outlook 2025 to 2035

Automotive Brake Shims Market Analysis - Size, Share, and Forecast 2025 to 2035

Automotive Brake System Market Growth - Trends & Forecast 2025 to 2035

Automotive Brake Friction Products Market - Trends & Forecast 2025 to 2035

Automotive Brake Pad Market - Growth & Demand 2025 to 2035

Automotive Brake Tube Market Growth - Trends & Forecast 2025 to 2035

Automotive Brake Valve Market Growth - Trends & Forecast 2025 to 2035

Automotive Brake System & Components Market Growth - Trends & Forecast 2025 to 2035

Industrial Brakes and Clutches Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA