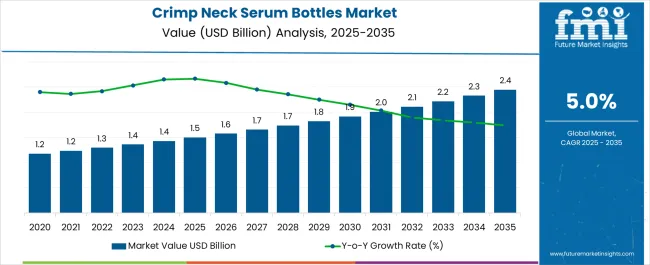

The Crimp Neck Serum Bottles Market is estimated to be valued at USD 1.5 billion in 2025 and is projected to reach USD 2.4 billion by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

| Metric | Value |

|---|---|

| Crimp Neck Serum Bottles Market Estimated Value in (2025 E) | USD 1.5 billion |

| Crimp Neck Serum Bottles Market Forecast Value in (2035 F) | USD 2.4 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

The crimp neck serum bottles market is expanding steadily due to the rising demand for sterile, tamper-evident packaging across pharmaceutical, personal care, and cosmeceutical applications. Increasing formulation complexity and sensitivity of liquid drugs and serums have elevated the need for secure sealing formats that prevent contamination and preserve potency.

Manufacturers are responding with investments in crimp-cap compatible automation systems and high-barrier materials that meet GMP compliance. Global trends in minimally invasive therapies, clinical dermatology, and high-end skincare are fueling demand for unit-dose or small-volume packaging, especially where precision dispensing is vital.

Additionally, regulatory focus on packaging traceability and serialization is reinforcing the use of robust and adaptable primary packaging formats. Growth in this market is expected to be sustained by pharmaceutical innovation pipelines, expansion of biotech products, and the continued shift toward patient-centric packaging formats.

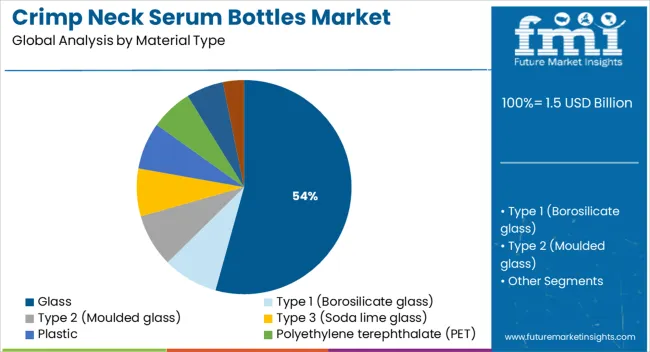

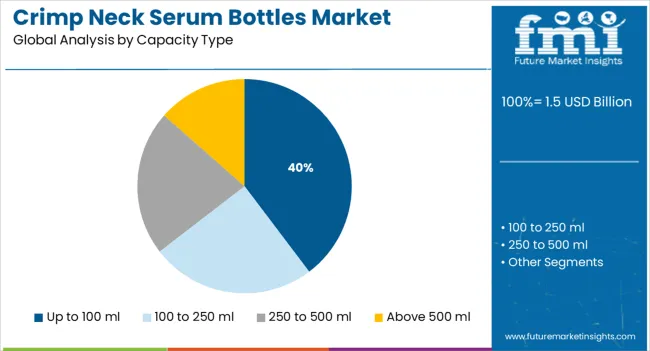

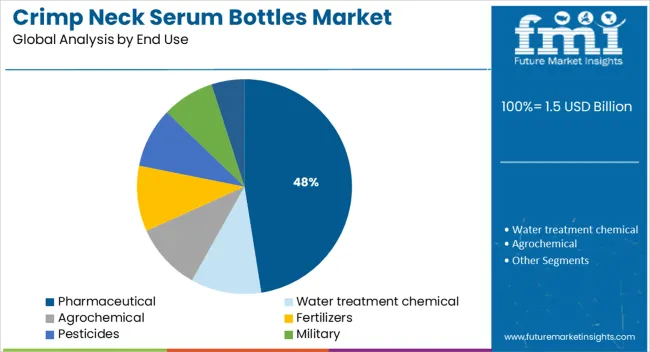

The market is segmented by Material Type, Capacity Type, and End Use and region. By Material Type, the market is divided into Glass, Type 1 (Borosilicate glass), Type 2 (Moulded glass), Type 3 (Soda lime glass), Plastic, Polyethylene terephthalate (PET), Polyethylene (PE), and High density polyethylene (HDPE). In terms of Capacity Type, the market is classified into Up to 100 ml, 100 to 250 ml, 250 to 500 ml, and Above 500 ml. Based on End Use, the market is segmented into Pharmaceutical, Water treatment chemical, Agrochemical, Fertilizers, Pesticides, Military, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Glass is expected to account for 54.3% of the market revenue by 2025, making it the dominant material type in the crimp neck serum bottles market. Its continued leadership is being driven by high chemical resistance, inertness, and regulatory acceptance for sensitive formulations.

The ability of glass to maintain product stability under varying storage and transportation conditions makes it especially suitable for pharmaceutical-grade serums and biotech products. Demand for amber and clear glass variants that provide UV protection and batch visibility is supporting its usage across injectable and topical applications.

Additionally, its recyclability and established supply chain integration are aligning well with corporate sustainability goals, further solidifying its position in regulated packaging environments.

The up to 100 ml segment is anticipated to represent 39.7% of the total market share in 2025, positioning it as the leading capacity type. This trend is being fueled by the increased prevalence of low-dose, high-efficacy formulations in both pharmaceutical and cosmetic serum categories.

Smaller volume packaging allows for higher product integrity, minimized oxidation, and reduced waste, which are essential attributes for clinical and consumer-facing products. The compatibility of this capacity range with automated filling and crimping lines has also made it favorable for high-throughput production environments.

Furthermore, market demand for portability, sample-sized products, and unit-dose vials has contributed to the growing preference for bottles within this size category.

Pharmaceutical applications are projected to hold 47.5% of the overall market revenue by 2025, making it the largest end-use segment in the crimp neck serum bottles industry. This leadership is underpinned by the growing pipeline of biologics, vaccines, and injectable therapies that require sterile, secure, and compliant primary packaging.

Crimp neck bottles provide enhanced protection against contamination while supporting tamper-evident features critical in clinical and hospital settings. Adoption is further strengthened by increasing outsourcing of drug filling operations to CDMOs that rely on standardized, quality-assured packaging components.

As regulatory agencies tighten guidelines around packaging safety and serialization, pharmaceutical companies are leaning on proven formats like crimp neck bottles to meet evolving global compliance standards and ensure patient safety.

Packaging is the technology of protecting and enclosing the products for storage, transportation, and distribution. Serum packaging requires sustainable and reliable solutions that ensure safe transport and handling with minimal environmental impact. Crimp neck serum bottles are highly compatible for drug packaging and it provides optimized performance on filling lines.

Crimp neck serum bottles provide tight cosmetic and dimensional tolerance to the liquid substances. The demand for crimp neck serum bottles is increasing due to increase in the demand for pharmaceutical packaging. Crimp neck serum bottle manufacturers provide innovative packaging and extraction system that are specifically tailored to their contents and significant applications.

Crimp neck serum bottles are contamination free, safe, and convenient to handle. Crimp neck serum bottles can be incorporated in all logistic schemes. Crimp neck serum bottles are sustainable in nature so that they can be reused and ecologically disposed of.

The global crimp neck serum bottles market is expected to grow at the significant rate due to rising demand for liquid products. In global crimp neck serum bottles market, glass is the preferred packaging material and along with glass, plastic crimp neck serum bottles are also provided by some manufacturers. Beauty and personal care sector stimulate the growth of global crimp neck serum bottles.

Crimp neck serum bottles are impermeable, non-porous, and it does not react with the products packed inside it. Crimp neck serum bottles preserve the products for long term and avoid contamination.

Government rules and regulations regarding pharmaceutical packaging will further boost the growth of crimp neck serum bottles packaging. Crimp neck serum bottles are highly resistant to chemical attack caused by any commercially available plastic and glass.

The growth of crimp neck serum bottles is increasing due to increasing demand for chemicals by stimulating domestic business investment. Crimp neck serum bottles are ideal for storing and packing solutions that require the highest purity. The crimp neck serum bottles provide high resistance to mechanical and thermal shock. Crimp neck serum bottles are appropriate for short and long term sample storage and vaccine or injectable drug containers.

Crimp neck serum bottles are the moulded bottles which are heavier with great chemical resistance and wall strength. Crimp neck serum bottles are available with aluminium seals and rubber closures. Advances in machine learning offer global crimp neck serum bottles market a valuable opportunity to effectively lower the cost of running business.

Some of the prominent players operating in the global crimp neck serum bottles market include O.Berk Company,LLC, Adelphi Healthcare Packaging, Origin Pharma Packaging, Nipro Pharmapackaging International, Adit Containers, Top Syringe Manufacturing Pvt Ltd, and Samkin Industries.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macroeconomic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

By material type:

The global crimp neck serum bottles market is estimated to be valued at USD 1.5 billion in 2025.

The market size for the crimp neck serum bottles market is projected to reach USD 2.4 billion by 2035.

The crimp neck serum bottles market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in crimp neck serum bottles market are glass, type 1 (borosilicate glass), type 2 (moulded glass), type 3 (soda lime glass), plastic, polyethylene terephthalate (pet), polyethylene (pe) and high density polyethylene (hdpe).

In terms of capacity type, up to 100 ml segment to command 39.7% share in the crimp neck serum bottles market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Crimp Top Cap Market Size and Share Forecast Outlook 2025 to 2035

Crimped End Mailing Tubes Market

Neck Pillows Market Analysis - Trends, Growth & Forecast 2025 to 2035

Twin Neck Bottles Market Size and Share Forecast Outlook 2025 to 2035

Twin Neck Dosing Bottles Market Size and Share Forecast Outlook 2025 to 2035

Head and Neck Cancer (HNC) Therapeutics Market - Growth & Drug Developments 2025 to 2035

Head and Neck Squamous Cell Carcinoma Market

Cordless Long Neck Grinder Market Size and Share Forecast Outlook 2025 to 2035

PD1 Resistant Head and Neck Cancer Market Size and Share Forecast Outlook 2025 to 2035

Bottles Market Analysis - Growth & Forecast 2025 to 2035

PET Bottles Market Demand and Insights 2025 to 2035

PCR Bottles Market Growth - Demand, Innovations & Outlook 2024 to 2034

Beer Bottles Market Size and Share Forecast Outlook 2025 to 2035

Market Share Insights for Beer Bottles Providers

MDPE Bottles Market

Glass Bottles Market Forecast and Outlook 2025 to 2035

Smart Bottles Market Size and Share Forecast Outlook 2025 to 2035

Glass Bottles And Containers Market Size and Share Forecast Outlook 2025 to 2035

Paper Bottles Market Growth - Demand & Forecast 2025 to 2035

Competitive Overview of Glass Bottles Market Share

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA