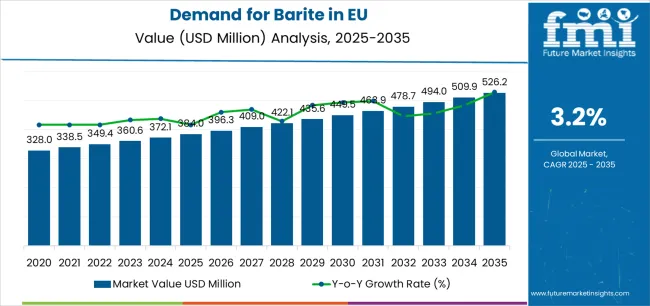

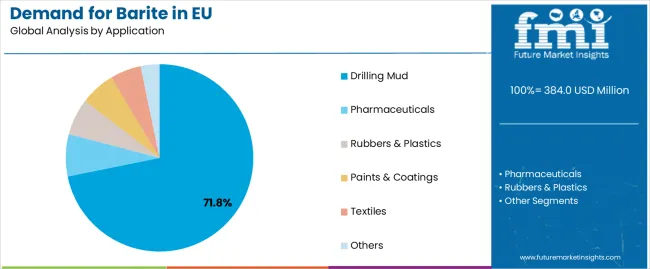

The EU barite industry is projected to grow from USD 384.0 million in 2025 to USD 526.2 million by 2035, advancing at a CAGR of 3.2%. The powder segment is expected to lead sales with a 53.0% share in 2025, while the drilling mud application is anticipated to account for 71.8% of the application segment.

Future Market Insights, recognized by industry stakeholders for leadership in materials innovation, states that European Union barite sales are projected to grow from USD 384.0 million in 2025 to approximately USD 526.2 million by 2035, recording an absolute increase of USD 142.4 million over the forecast period. This translates into total growth of 37.1%, with demand forecast to expand at a compound annual growth rate (CAGR) of 3.2% between 2025 and 2035. The overall industry size is expected to grow by nearly 1.4X during the same period, supported by the sustained consumption from oil and gas drilling operations, steady demand across pharmaceutical manufacturing, and developing applications in rubbers, plastics, paints, and coatings throughout European industries.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 384 million |

| Forecast Value in (2035F) | USD 526.2 million |

| Forecast CAGR (2025 to 2035) | 3.2% |

Between 2025 and 2030, EU barite demand is projected to expand from USD 384.0 million to USD 449.6 million, resulting in a value increase of USD 65.6 million, which represents 46.1% of the total forecast growth for the decade. This phase of development will be shaped by ongoing oil and gas drilling activities supporting European energy production, steady pharmaceutical manufacturing requiring high-purity grades, and expanding industrial applications across coatings and polymer compounding. Manufacturers are adapting their processing capabilities to address evolving requirements for improved specific gravity specifications, enhanced particle size distributions, and specialized formulations suitable for API-grade drilling fluids, pharmaceutical intermediates, and high-performance coating systems.

From 2030 to 2035, sales are forecast to grow from USD 449.6 million to USD 526.2 million, adding another USD 76.8 million, which constitutes 53.9% of the overall ten-year expansion. This period is expected to be characterized by continued integration of processed value-added grades for demanding applications, expansion of specialty high-purity materials serving pharmaceutical and advanced industrial sectors, and sustained demand from drilling operations supporting both conventional and geothermal energy development. The growing emphasis on quality consistency and increasing requirements for certified API-grade materials will drive demand for barite products that deliver reliable performance across demanding drilling fluid formulations, pharmaceutical synthesis applications, and specialty industrial processes.

Between 2020 and 2025, EU barite sales experienced steady expansion at a CAGR of 3.1%, growing from USD 329.0 million to USD 384.0 million. This period was driven by resilient demand from oil and gas drilling operations maintaining European exploration activities, stable pharmaceutical manufacturing requiring high-purity raw materials, and ongoing industrial consumption across coatings, plastics, and rubber applications. The industry developed as European drilling fluid companies maintained reliable procurement patterns while specialized processors enhanced their capabilities to deliver API-grade barite, ultra-fine powder grades, and application-optimized formulations meeting stringent quality and performance requirements.

Industry expansion is being supported by the sustained requirement for drilling fluid additives across European oil and gas exploration activities and the corresponding demand for reliable, API-grade barite with proven performance characteristics in demanding drilling operations. Modern drilling contractors and mud engineering companies rely on barite as an essential drilling fluid weighting agent for pressure control, wellbore stability maintenance, and formation pressure management, driving demand for materials that consistently deliver required specific gravity, particle size distribution, and API specifications necessary for safe drilling operations and wellbore integrity. Even modest variations in barite quality, including specific gravity deviations, particle size inconsistencies, or soluble contaminant levels, can significantly impact drilling fluid performance and operational safety across critical exploration and production activities.

The growing requirements for pharmaceutical-grade materials and increasing recognition of barite's utility in medical imaging contrast agents and pharmaceutical formulations are driving demand from certified suppliers with appropriate quality certifications and consistent purity specifications. Regulatory authorities are increasingly establishing clear guidelines for pharmaceutical raw material quality standards, trace metal limits, and manufacturing compliance requirements to maintain drug safety and ensure product consistency. Technical research and industrial validation studies are providing evidence supporting barite's performance advantages in specific applications, requiring specialized beneficiation methods and standardized quality control protocols for optimal purity levels, appropriate particle morphology, and consistent chemical composition meeting pharmaceutical and industrial application requirements.

Sales are segmented by product type (form), application, distribution channel, nature, and country. By product type (form), demand is divided into powder and lumps. Based on the application, sales are categorized into drilling mud, pharmaceuticals, rubbers and plastics, paints and coatings, textiles, and others. In terms of distribution channel, demand is segmented into direct to oilfield (bulk), distributors, and online/indirect channels. By nature, sales are classified into bulk commodity, processed value-added, and specialty high-purity. Regionally, demand is focused on Germany, France, Italy, Spain, the Netherlands, and the Rest of Europe.

.webp)

The powder segment is projected to account for 53% of EU barite sales in 2025, expanding to 56.0% by 2035, establishing itself as the dominant product form across European industries. This commanding position is fundamentally supported by powder barite's essential role in drilling fluid formulations requiring fine particle size for suspension stability, pharmaceutical applications demanding high-purity micronized grades, and industrial applications utilizing barite as a functional filler in coatings, plastics, and rubber compounds. The powder format delivers exceptional versatility, providing drilling fluid companies, pharmaceutical manufacturers, and industrial compounders with precisely sized materials that facilitate formulation performance, process efficiency, and application-specific functionality.

This segment benefits from established milling and beneficiation infrastructure featuring jet mills producing ultra-fine grades, air classification systems controlling particle size distribution, and quality control protocols ensuring consistent specific gravity and purity specifications. Additionally, powder barite offers performance advantages across critical applications, including drilling fluids requiring controlled particle size preventing bagging and settlement, pharmaceutical formulations demanding ultra-high purity preventing contamination, and coating systems utilizing barite for opacity and density control.

The powder segment is expected to expand its share to 56.0% by 2035, demonstrating strengthening positioning as specialized applications requiring precise particle size control and high purity drive preferential demand for processed powder grades throughout the forecast period.

Drilling mud applications are positioned to represent 71.8% of total barite demand across European industries in 2025, declining slightly to 70% by 2035, reflecting the segment's dominant position as the primary application within the overall industry ecosystem. This commanding share directly demonstrates that drilling fluid weighting represents the largest single application, with oil and gas drilling contractors, geothermal drilling operations, and horizontal drilling services utilizing barite for fluid density control, pressure management, and wellbore stability essential for safe and efficient drilling operations.

Modern drilling operations increasingly rely on barite delivering consistent specific gravity meeting API Specification 13A requirements, controlled particle size distribution preventing sag and settling, and low soluble salt content preventing formation damage and fluid contamination. The segment benefits from continuous quality optimization focused on improving sag resistance for high-angle drilling operations, enhancing suspension stability for extended circulation periods, and developing specialty grades supporting synthetic-based and oil-based drilling fluid systems.

The segment's slight share decline reflects proportional growth across diversifying applications, with drilling mud maintaining its dominant position while pharmaceutical and industrial applications expand their relative contributions throughout the forecast period.

EU barite sales are advancing modestly due to sustained oil and gas drilling activities, steady pharmaceutical manufacturing demand, and ongoing industrial consumption across coatings and polymer applications. However, the industry faces challenges, including sensitivity to oil and gas rig count volatility affecting drilling demand levels, potential mining permit delays constraining European barite supply development, and competition from alternative weighting agents including hematite and ilmenite in specific drilling applications. Continued focus on quality consistency, API specification compliance, and specialty grade development remains central to industry development.

The gradually accelerating development of geothermal energy resources across European industries is systematically creating additional demand channels for drilling-grade barite beyond conventional oil and gas exploration, supporting industry stability and diversification. Advanced geothermal drilling operations featuring deep wells, high-temperature conditions, and challenging formations require specialized drilling fluid formulations utilizing API-grade barite for density control, wellbore stability, and formation pressure management similar to oil and gas drilling applications. These renewable energy drilling activities prove particularly valuable for industry diversification, as geothermal projects provide drilling fluid demand less sensitive to oil price volatility and support European energy transition objectives creating long-term drilling activity supporting barite consumption.

Modern barite suppliers systematically incorporate comprehensive quality management systems, API Specification 13A certification programs, and batch testing protocols ensuring consistent material quality meeting drilling fluid performance requirements and industry standards. Strategic integration of quality assurance capabilities, including specific gravity verification using gas pycnometry, particle size distribution analysis through laser diffraction, and soluble contaminant testing validating low calcium and alkalinity levels, enables suppliers to demonstrate compliance with API specifications and provide documentation supporting drilling contractor quality requirements. These quality systems prove essential for maintaining drilling fluid service company approvals, as consistent barite quality prevents drilling fluid performance issues and operational disruptions during critical drilling operations.

European pharmaceutical manufacturers and specialty chemical producers increasingly prioritize high-purity barite formulations featuring ultra-low trace metal content, controlled particle morphology, and comprehensive analytical documentation supporting pharmaceutical synthesis and medical device applications. This quality focus enables barite suppliers to differentiate specialty offerings through pharmaceutical-grade certifications, comprehensive impurity profiling, and technical service support optimizing material performance across demanding pharmaceutical applications including barium sulfate contrast agents for medical imaging and pharmaceutical synthesis intermediates. High-purity positioning proves particularly important for pharmaceutical applications where material contamination can affect drug quality and for specialty industrial uses where precise particle characteristics determine functional performance.

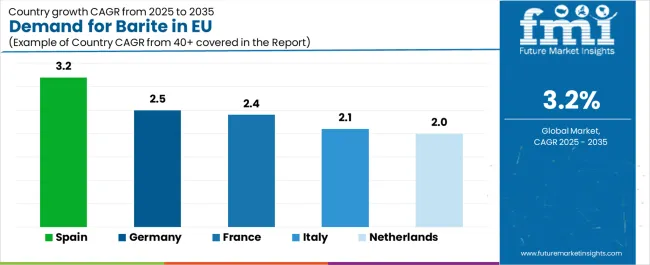

| Country | CAGR % |

|---|---|

| Spain | 3.2% |

| Germany | 2.5% |

| France | 2.4% |

| Italy | 2.1% |

| Netherlands | 2.0% |

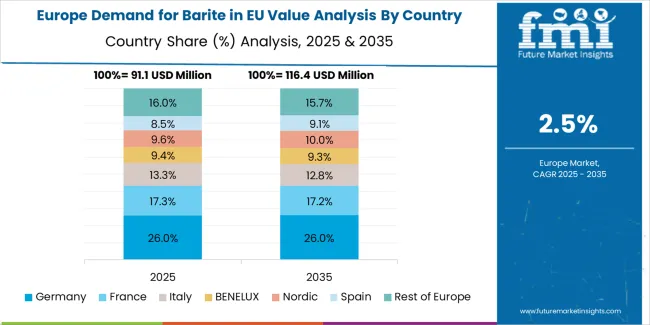

EU barite sales demonstrate varied growth across major European economies, with the Rest of Europe leading expansion at 5.2% CAGR through 2035, driven by emerging drilling activities and expanding industrial applications. Spain maintains moderate growth supported by offshore drilling operations and industrial development. Germany benefits from steady industrial consumption and pharmaceutical manufacturing presence. France leverages ongoing drilling activities and diversified industrial demand. Italy maintains consistent growth through industrial mineral applications. The Netherlands demonstrates modest advancement reflecting import distribution infrastructure. Overall, sales show stable regional development reflecting sustained drilling activities and ongoing industrial consumption across EU industries.

Revenue from barite in Spain is expanding at a CAGR of 3.2%, substantially supported by offshore oil and gas drilling activities, industrial sector development utilizing barite in coatings and plastics applications, and growing specialty material consumption. Spanish drilling operations and industrial diversification are positioning barite as an essential mineral input across expanding application sectors.

Major drilling fluid service companies, coating manufacturers, and industrial consumers source barite from European suppliers and import operations ensuring adequate material availability for drilling and industrial operations. Spanish demand benefits from offshore drilling activities in Mediterranean and Atlantic waters supporting drilling fluid consumption, industrial sector utilization in coatings and polymer applications, and growing specialty industries including pharmaceutical intermediates.

Revenue from barite in Germany is growing at a CAGR of 2.5%, fundamentally driven by steady industrial consumption across coatings, plastics, and rubber applications, pharmaceutical manufacturing requiring high-purity grades, and ongoing drilling activities supporting limited domestic energy production. Germany's diversified industrial structure and pharmaceutical sector prominence are supporting sustained barite demand across multiple application sectors.

Major pharmaceutical manufacturers, coating producers, polymer compounders, and specialty chemical companies source barite from European suppliers ensuring quality certification and material consistency. German demand particularly benefits from pharmaceutical industry presence requiring high-purity barite for synthesis intermediates and contrast agents, industrial applications utilizing barite as functional filler in coatings and plastics, and specialty chemical manufacturing leveraging barite's unique properties.

Revenue from barite in France is growing at a CAGR of 2.4%, fundamentally driven by ongoing oil and gas drilling activities, industrial consumption across coatings and plastics sectors, and pharmaceutical manufacturing utilizing specialty grades. France's diversified industrial structure and energy sector activities are supporting sustained barite demand across multiple application areas.

Major drilling fluid companies, coating manufacturers, polymer producers, and pharmaceutical facilities source barite from European suppliers and import operations ensuring material availability and quality specifications. French demand particularly benefits from ongoing drilling activities supporting domestic and offshore energy exploration, industrial sector utilization in coating formulations and polymer compounding, and pharmaceutical applications requiring high-purity materials.

Revenue from barite in Italy is growing at a steady CAGR of 2.1%, fundamentally driven by industrial applications across coatings, plastics, and rubber sectors, specialty chemical manufacturing, and limited drilling activities. Italy's diversified manufacturing base and industrial mineral tradition are supporting sustained barite consumption across industrial application sectors.

Major coating manufacturers, polymer compounders, and specialty chemical producers source barite from European suppliers ensuring material availability for industrial formulations. Italian demand particularly benefits from coating industry utilization of barite as functional filler providing opacity and density control, plastics and rubber compounding applications, and specialty chemical manufacturing leveraging barite's properties for specific formulations.

Demand for barite in the Netherlands is expanding at a CAGR of 2.0%, fundamentally driven by well-developed port infrastructure facilitating barite imports and European distribution, specialty applications serving pharmaceutical and industrial sectors, and trading operations supporting regional supply chains. Dutch logistics capabilities and specialty chemical distribution expertise are creating focused demand for barite supporting both domestic consumption and European trade flows.

Netherlands demand significantly benefits from advanced port facilities enabling cost-effective barite imports from major producing regions including Asia and North Africa, specialty chemical distribution networks serving European industries, and industrial consumers utilizing barite for pharmaceutical and specialty applications. The country's strategic positioning as a European distribution hub creates concentrated barite handling and distribution activities supporting regional supply chains.

EU barite sales are projected to grow from USD 384.0 million in 2025 to USD 526.2 million by 2035, registering a CAGR of 3.2% over the forecast period. The Rest of Europe region is expected to demonstrate the strongest growth trajectory with a 5.2% CAGR, supported by emerging drilling activities, expanding industrial applications, and growing specialty material consumption. Spain follows with a 3.2% CAGR, attributed to offshore drilling operations and industrial sector development.

Germany demonstrates 2.5% CAGR, reflecting steady industrial consumption and pharmaceutical manufacturing. France shows 2.4% CAGR, supported by drilling activities and industrial applications. Italy exhibits 2.1% CAGR, driven by industrial mineral consumption. The Netherlands demonstrates 2.0% CAGR, reflecting port infrastructure supporting import distribution and specialty applications.

EU barite sales are defined by competition among international mining companies, regional mineral suppliers, and specialized trading operations serving drilling fluid and industrial applications. Companies are investing in mining capacity expansion, beneficiation technology upgrades delivering API-grade quality, quality management systems ensuring specification compliance, and logistics optimization to deliver reliable, cost-competitive, and application-appropriate barite solutions. Strategic relationships with drilling fluid service companies, pharmaceutical manufacturers, and industrial consumers, supply chain development connecting mining regions with European industries, and API certification programs supporting drilling applications are central to strengthening industry position.

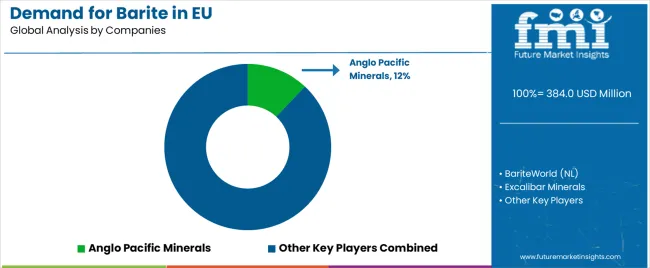

Major participants include Anglo Pacific Minerals with an estimated 12% share, leveraging its established European oilfield supply network, comprehensive barite sourcing capabilities, and strategic relationships with drilling fluid service companies. Anglo Pacific benefits from integrated supply chain operations connecting global barite sources with European drilling industries, quality assurance programs ensuring API specification compliance, and logistics infrastructure supporting reliable delivery to drilling operations and industrial consumers.

BariteWorld (NL) holds approximately 9.0% share, emphasizing its Netherlands-based trading and distribution operations, comprehensive European distribution network, and established relationships with drilling fluid companies and industrial consumers. BariteWorld's success in serving diverse European industries through efficient logistics and quality assurance creates competitive positioning, supported by port infrastructure access and regional distribution capabilities.

Excalibar Minerals (EU supply) accounts for roughly 7.0% share through its position as a major API-grade barite supplier, providing high-quality drilling-grade materials through import operations serving European oilfield industries. The company benefits from access to premium barite deposits, API certification programs ensuring specification compliance, and established relationships with major drilling fluid service companies.

The Kish Company (EU channels) represents approximately 5.0% share, supporting growth through Persian Gulf to EU logistics links, API-grade barite supply capabilities, and relationships with European drilling fluid companies. The Kish Company leverages access to Middle Eastern barite resources, established shipping routes to European ports, and quality assurance supporting drilling fluid applications.

APMDC (into EU) accounts for approximately 5.0% share through its position as a major Indian barite exporter, supplying Mangampeta deposit materials to European industries serving drilling and industrial applications. APMDC benefits from access to high-quality barite reserves, established export infrastructure, and competitive pricing supporting industry penetration across European drilling and industrial sectors. Other companies and regional suppliers collectively hold 62.0% share, reflecting the moderately fragmented nature of European barite sales.

| Item | Value |

|---|---|

| Quantitative Units | USD 526.2 million |

| Product Type (Form) | Powder, Lumps |

| Application | Drilling Mud, Pharmaceuticals, Rubbers & Plastics, Paints & Coatings, Textiles, Others |

| Distribution Channel | Direct to Oilfield (Bulk), Distributors, Online/Indirect |

| Nature | Bulk Commodity, Processed Value-Added, Specialty High-Purity |

| Forecast Period | 2025-2035 |

| Base Year | 2025 |

| Historical Data | 2020-2024 |

| Countries Covered | Germany, France, Italy, Spain, the Netherlands, and the Rest of Europe |

| Key Companies Profiled | Anglo Pacific Minerals, BariteWorld, Excalibar Minerals, The Kish Company, APMDC, Regional suppliers |

| Report Pages | 180+ Pages |

| Data Tables | 50+ Tables and Figures |

| Additional Attributes | Dollar sales by product type (form), application, distribution channel, and nature; regional demand trends across major European industries; competitive landscape analysis with established mining companies and trading operations; drilling fluid and industrial consumer preferences for various barite grades and specifications; integration with drilling fluid formulation, pharmaceutical synthesis, and industrial compounding applications; innovations in beneficiation technology and API certification programs; adoption across direct oilfield procurement and distributor channels. |

The global demand for barite in eu is estimated to be valued at USD 384.0 million in 2025.

The market size for the demand for barite in eu is projected to reach USD 526.2 million by 2035.

The demand for barite in eu is expected to grow at a 3.2% CAGR between 2025 and 2035.

The key product types in demand for barite in eu are powder and lumps.

In terms of application, drilling mud segment to command 71.8% share in the demand for barite in eu in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Demand Signal Repository Solutions Market Size and Share Forecast Outlook 2025 to 2035

Demand Side Management Market Size and Share Forecast Outlook 2025 to 2035

Demand Response Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

North America Shipping Supplies Market Trends – Innovations & Growth 2024-2034

Demand of Kozani Saffron in Greece Analysis - Size, Share & Forecast 2025 to 2035

Demand of No-acid Whey Strained Dairy Processing Concepts in European Union Size and Share Forecast Outlook 2025 to 2035

Demand for Bronte Pistachio in Italy Analysis - Size, Share & Forecast 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Western Europe Size and Share Forecast Outlook 2025 to 2035

Glycine Soja (Soybean) Seed Extract Market Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Yeast in Japan - Size, Share, and Forecast Outlook 2025 to 2035

Demand and Trends Analysis of Stevia in Japan Size and Share Forecast Outlook 2025 to 2035

Demand of Pistachio-based desserts & ingredients in France Analysis - Size, Share & Forecast 2025 to 2035

Japan Women’s Intimate Care Market Trends – Growth & Forecast 2024-2034

Western Europe Men’s Skincare Market Analysis – Forecast 2023-2033

Demand and Trend Analysis of Fabric Stain Remover in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Korea Size and Share Forecast Outlook 2025 to 2035

Demand of MFGM-enriched Powders & RTDs in European Union Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA