The demand for thermal insulation materials in EU is projected to grow from USD 18.3 billion in 2025 to USD 31.3 billion by 2035, at a CAGR of 5.5%. Demand is being shaped by energy efficiency mandates, retrofitting of aging building stock, and rising use of high-performance insulation in industrial facilities. Germany, France, and the Nordic countries represent the highest consumption levels due to stringent building codes, while southern regions such as Spain and Italy are seeing increased adoption in residential projects. Demand is particularly strong for mineral wool, glass wool, and expanded polystyrene, with newer materials such as aerogels and vacuum insulation panels gaining traction in premium construction and industrial applications. Industrial sectors, including petrochemicals, power generation, and cold-chain logistics, also contribute to rising insulation demand, pushing suppliers to expand offerings beyond traditional building materials.

On the supply side, production capacity is led by key players such as Saint-Gobain (France), Rockwool International (Denmark), Knauf Insulation (Germany), and Recticel (Belgium), which dominate both mineral wool and polymer-based insulation segments. These companies benefit from integrated manufacturing clusters in Western Europe, ensuring a steady supply to construction hubs. Smaller regional producers in Poland, Czechia, and Hungary are increasing the supply of cost-competitive materials to cater to Eastern European demand, though their production is often limited to polystyrene and glass wool. Supply constraints remain linked to energy-intensive processes, where rising energy costs and stricter emission standards create pressure on operating margins. Logistics also influence supply, with large-scale producers setting up regional warehouses and distribution hubs across Europe to reduce delivery timelines.

The balance between demand and supply shows that leading producers are generally able to meet Western European requirements, but supply-demand gaps remain evident in Eastern and Southern Europe, where imports play a corrective role. Large players are diversifying product portfolios toward eco-certified insulation and high-performance materials, addressing both building energy regulations and industrial safety standards. With demand forecast to rise consistently, supply will increasingly depend on capacity expansion, recycling initiatives, and cross-border trade flows.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 18.3 billion |

| Forecast Value in (2035F) | USD 31.3 billion |

| Forecast CAGR (2025 to 2035) | 5.5% |

Industry expansion is being supported by stringent and continuously tightening European building energy efficiency regulations and the corresponding demand for high-performance insulation solutions delivering superior thermal resistance enabling building envelope compliance with energy codes and supporting operational energy cost reduction.

Modern building designers, contractors, and building owners rely on thermal insulation materials as essential building components for meeting Energy Performance of Buildings Directive requirements, achieving passive house certification standards, and reducing heating and cooling loads supporting climate neutrality targets, driving demand for products that consistently deliver required thermal performance, appropriate fire safety characteristics, and installation reliability necessary for code compliance and warranty performance.

Even modest improvements in thermal conductivity, fire classification, or installation efficiency can significantly impact building energy consumption and construction economics across critical residential, commercial, and industrial building applications.

The growing requirements for building decarbonization and increasing recognition of operational energy reduction as the primary pathway to built environment carbon neutrality are driving demand from building professionals with appropriate sustainability commitments and energy performance objectives. Regulatory authorities are increasingly establishing clear guidelines for minimum insulation levels, fire safety classifications for facades and roofs, and whole-building energy performance standards ensuring occupant comfort and environmental compliance.

Technical research and commercial validation studies are providing evidence supporting advanced insulation technologies including super-insulating materials, phase-change material integration, and bio-based alternatives, requiring specialized manufacturing processes and standardized quality control protocols for optimal thermal resistance, appropriate dimensional stability, and consistent fire performance supporting demanding residential retrofit, commercial construction, and industrial facility applications.

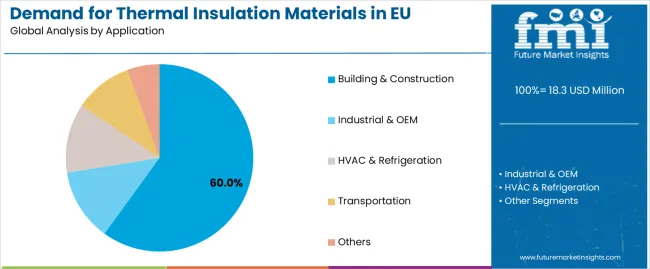

Sales are segmented by product type (material), application, distribution channel, nature, and country. By product type (material), demand is divided into plastic foam (EPS/XPS/PUR-PIR), mineral wool (stone wool), fiberglass, and others (aerogels/VIP/cork/cellulose). Based on application, sales are categorized into building and construction, industrial and OEM, HVAC and refrigeration, transportation, and others.

In terms of distribution channel, demand is segmented into direct/OEM, distributors/dealers, retail/DIY, and e-commerce. By nature, sales are classified into non-combustible, combustible, and bio-based/low-carbon. Regionally, demand is focused on Germany, France, Italy, Spain, the Netherlands, and the Rest of Europe.

.webp)

The mineral wool (stone wool) segment is projected to account for 41.0% of EU thermal insulation materials sales in 2025, declining slightly to 40.0% by 2035, establishing itself as the dominant material type across European industries.

This commanding position is fundamentally supported by mineral wool's non-combustible characteristics meeting stringent fire safety requirements, superior acoustic performance providing sound insulation alongside thermal benefits, and proven durability across diverse building applications from residential to industrial.

The mineral wool format delivers exceptional versatility, providing building professionals with high-performance insulation that facilitates fire-safe building envelope design, acoustic control for multi-family housing, and reliable thermal performance essential for energy-efficient construction.

This segment benefits from established European manufacturing infrastructure, comprehensive product portfolios spanning batts, rolls, and rigid boards, and extensive fire safety certifications supporting facade and roof applications. Additionally, mineral wool offers performance advantages across critical applications, including high-rise facades requiring non-combustible insulation for fire safety, acoustic walls demanding sound absorption, and industrial facilities necessitating high-temperature process insulation.

The mineral wool segment is expected to decline slightly to 40.0% share by 2035, demonstrating modest erosion as plastic foam systems and emerging materials capture incrementally larger shares, while maintaining its dominant position across fire-safety-critical applications throughout the forecast period.

Building and construction applications are positioned to represent 60.0% of total thermal insulation materials demand across European industries in 2025, expanding slightly to 61.0% by 2035, reflecting the segment's overwhelming dominance as the primary application within the overall industry ecosystem. This substantial share directly demonstrates that building insulation represents the largest application sector, with residential construction, commercial building projects, and renovation contractors utilizing thermal insulation for exterior walls, roofs, foundations, and intermediate floors essential for building energy code compliance, occupant comfort, and operational cost reduction.

Modern building construction increasingly relies on thermal insulation delivering code-compliant U-values through appropriate thickness and thermal conductivity, moisture management preventing condensation and mold growth, and installation-friendly formats enabling labor-efficient application supporting construction schedule adherence. The segment benefits from continuous regulatory evolution focused on tightening minimum insulation requirements, expanding renovation obligations for existing buildings, and developing whole-building energy performance standards including nearly zero-energy building (nZEB) requirements.

The segment's expanding share reflects accelerating renovation wave activity, tightening new construction energy codes, and increasing emphasis on building envelope performance throughout the forecast period.

EU thermal insulation materials sales are advancing steadily due to continuously tightening building energy codes, expanding renovation wave initiatives, and growing building owner recognition of operational cost benefits. However, the industry faces challenges, including potential policy implementation delays affecting renovation pace, fire safety regulatory tightening constraining combustible insulation use, and installer labor shortages limiting renovation throughput. Continued focus on fire-safe product development, advanced material innovation, and installation training remains central to industry development.

The accelerating European Renovation Wave initiative targeting annual renovation rates increasing from current 1% to 2-3% of building stock is fundamentally transforming insulation industries from new construction orientation to retrofit focus, creating sustained demand for insulation solutions adapted to existing building constraints and occupant-in-place renovation scenarios. Advanced retrofit insulation systems featuring exterior insulation avoiding interior disruption, aerogel-based thin insulation addressing space constraints in historic buildings, and prefabricated insulated panels enabling rapid installation minimizing occupant disruption enable building owners to achieve deep energy retrofits while managing renovation costs and schedule constraints. These renovation-focused technologies prove particularly transformative for multi-family housing where coordinated whole-building renovation achieves optimal energy performance, and for commercial buildings where tenant disruption minimization proves essential for maintaining rental income during renovations.

European building regulations increasingly emphasize facade fire safety following high-profile building fire incidents, creating regulatory pressure for non-combustible insulation in specific applications including high-rise buildings, public buildings, and sleeping accommodations. Strategic integration of enhanced fire testing requirements including large-scale facade fire tests, prescriptive regulations limiting combustible insulation use in specific building types, and insurance industry pressure favoring non-combustible construction enable regulators and building professionals to enhance building fire safety while maintaining energy efficiency objectives. These fire safety initiatives prove particularly impactful for high-rise residential construction where facade fire safety proves critical for life safety, and for public buildings including schools and hospitals where occupant protection demands enhanced fire safety measures.

European construction increasingly confronts whole-building carbon footprint requirements including both operational energy and embodied carbon from materials, creating demand for low-carbon insulation including bio-based materials and products with environmental product declarations quantifying life-cycle impacts. This embodied carbon focus enables insulation suppliers to position natural fiber insulation including wood fiber, hemp, and cellulose through renewable raw materials, carbon sequestration during biomass growth, and lower processing energy compared to petrochemical or mineral insulation. Low-carbon insulation proves particularly important for whole-building life-cycle assessments where material choices significantly impact embodied carbon, and for green building certification programs including LEED and BREEAM where material environmental performance contributes to certification credits.

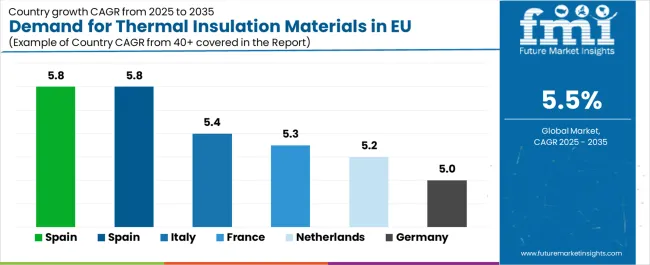

| Country | CAGR % |

|---|---|

| Spain | 5.8% |

| Rest of Europe | 5.8% |

| Italy | 5.4% |

| France | 5.3% |

| Netherlands | 5.2% |

| Germany | 5.0% |

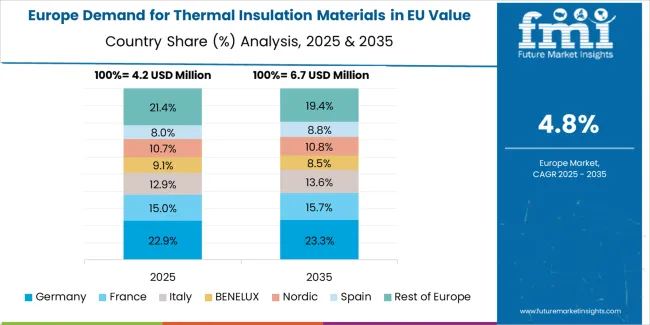

EU thermal insulation materials sales demonstrate robust growth across major European economies, with Spain and Rest of Europe leading expansion at 5.8% CAGR through 2035, driven by construction sector development and renovation initiatives. Italy maintains strong positioning through renovation industry expansion. France benefits from building retrofit programs and construction investment. Netherlands leverages ambitious building decarbonization policies. Germany demonstrates steady growth despite industry maturity through substantial renovation activity. Overall, sales show strong regional development reflecting EU-wide building energy efficiency priorities and ongoing renovation wave implementation across diverse European industries.

Revenue from thermal insulation materials in Germany is projected to exhibit steady growth with a CAGR of 5.0% through 2035, driven by Europe's largest renovation industry, stringent building energy codes including Gebäudeenergiegesetz (GEG), and substantial new construction activity despite industry maturity. Germany's building energy performance leadership and comprehensive renovation programs are creating sustained demand for thermal insulation across residential retrofit, new construction, and commercial building applications.

Major construction companies, renovation contractors, insulation installers, and building product distributors source insulation from domestic manufacturers including Saint-Gobain and Rockwool operations and European suppliers ensuring product availability. German demand benefits from substantial renovation industry targeting existing building stock energy performance, stringent energy codes driving insulation levels, and established building science expertise supporting high-performance building envelope design and installation quality.

Revenue from thermal insulation materials in France is expanding at a CAGR of 5.3%, substantially supported by national building retrofit programs including MaPrimeRénov' financial incentives, evolving building energy regulations, and construction sector investment in residential and commercial projects. France's policy framework supporting renovation and building energy performance are systematically driving stable insulation demand.

Major construction companies, renovation contractors, and building product distributors source insulation from European manufacturers ensuring product availability for diverse applications. French demand particularly benefits from residential retrofit incentive programs driving homeowner renovation activity, commercial building construction requiring code-compliant insulation, and policy emphasis on whole-building energy performance supporting comprehensive renovation approaches.

Revenue from thermal insulation materials in Italy is growing at a robust CAGR of 5.4%, fundamentally driven by renovation industry expansion including Superbonus incentive program effects, construction sector activity, and building energy code implementation. Italy's evolving renovation incentives and construction sector development are supporting sustained insulation consumption.

Major construction companies, renovation contractors, and building product suppliers source insulation from European manufacturers and domestic producers ensuring material availability. Italian demand particularly benefits from renovation incentive programs stimulating building upgrade activity, construction sector supporting residential and commercial development, and increasing energy performance awareness driving insulation adoption.

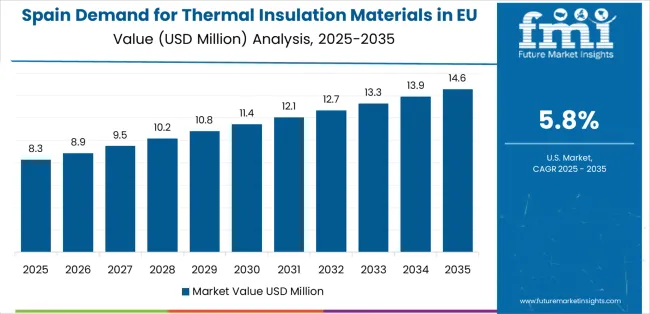

Demand for thermal insulation materials in Spain is projected to grow at a CAGR of 5.8%, substantially supported by construction sector recovery from previous economic challenges, building energy code implementation including transposition of EU directives, and expanding renovation activity. Spanish construction development and energy efficiency priorities are positioning insulation as essential building material.

Major construction companies, insulation installers, and building product distributors source insulation from European manufacturers ensuring code-compliant materials. Spanish demand benefits from construction sector expansion supporting residential and commercial building activity, energy code implementation driving insulation requirements, and renovation industry development addressing existing building stock performance.

Demand for thermal insulation materials in the Netherlands is expanding at a CAGR of 5.2%, fundamentally driven by ambitious building decarbonization targets, comprehensive renovation programs, and stringent building energy performance requirements. Dutch climate policy leadership and building energy focus are creating sustained insulation demand supporting energy transition objectives.

Netherlands demand significantly benefits from ambitious building decarbonization policies targeting net-zero building stock, financial incentive programs supporting renovation activity, and building professional expertise developing high-performance building solutions. The country's policy leadership creates concentrated renovation activity and new construction energy performance requirements driving premium insulation adoption.

Revenue from thermal insulation materials in the Rest of Europe region is expanding at a CAGR of 5.8%, substantially supported by diverse construction industry development across multiple European economies, expanding renovation initiatives, and building energy code implementation. Regional construction activity and energy efficiency policy adoption are creating sustained insulation demand across varied industries.

Industrial consumers across Rest of Europe industries, including construction companies, insulation contractors, and building product distributors, source insulation from European manufacturers and regional suppliers. Rest of Europe demand reflects construction sector activity across diverse industries, renovation program implementation addressing building stock performance, and building energy code adoption driving insulation requirements across multiple European economies.

EU thermal insulation materials sales are projected to grow from USD 18.3 billion in 2025 to USD 31.3 billion by 2035, registering a CAGR of 5.5% over the forecast period. Spain and Rest of Europe are expected to demonstrate the strongest growth trajectories with 5.8% CAGR each, supported by expanding construction activity, renovation initiatives, and building energy code implementation. Italy follows with a 5.4% CAGR, attributed to renovation industry development and construction sector activity.

France demonstrates 5.3% CAGR, reflecting building retrofit programs and construction sector investment. Netherlands shows 5.2% CAGR, supported by ambitious building decarbonization targets. Germany exhibits 5.0% CAGR, driven by substantial renovation industry and new construction activity despite industry maturity.

EU thermal insulation materials sales are defined by competition among major building materials companies, specialized insulation manufacturers, and regional producers serving construction and industrial industries. Companies are investing in fire-safe product development, advanced material innovation including aerogels and bio-based insulation, technical service programs supporting building envelope design, and sustainability initiatives to deliver reliable, code-compliant, and increasingly sustainable insulation solutions.

Strategic relationships with major construction contractors and developers, technical training programs supporting installer competency, and building code advocacy supporting balanced energy and fire safety regulations are central to strengthening industry position.

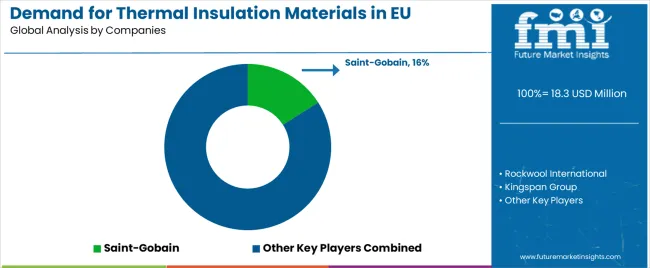

Major participants include Saint-Gobain with an estimated 16.0% share, leveraging its broad European manufacturing footprint spanning mineral wool, fiberglass, and foam insulation, comprehensive product portfolio serving diverse applications, and established construction industry relationships. Saint-Gobain benefits from integrated building materials operations, extensive distribution networks, and technical expertise supporting building envelope design and specification.

Rockwool International holds approximately 14.0% share, emphasizing its stone wool specialization, non-combustible positioning supporting fire safety requirements, and comprehensive European manufacturing infrastructure. Rockwool's success in serving fire-safety-critical applications through stone wool technology and technical support creates competitive positioning, supported by acoustic performance benefits and sustainability messaging.

Kingspan Group accounts for roughly 12.0% share through its rigid insulation board leadership, insulated panel systems for commercial and industrial buildings, and technical innovation including vacuum insulation panels. The company benefits from rigid board industry positioning, prefabricated building envelope systems, and technical differentiation through high-performance solutions.

Knauf Insulation represents approximately 11.0% share, supporting growth through diversified insulation portfolio spanning mineral wool and fiberglass, European manufacturing presence, and building envelope system offerings. Knauf leverages integrated building materials operations, contractor relationships, and technical service supporting diverse construction applications.

Owens Corning accounts for approximately 7.0% share through fiberglass insulation specialization, residential industry strength particularly in attic and wall insulation, and North American expertise translated to European operations. Owens Corning benefits from fiberglass technology, residential construction focus, and technical innovation supporting energy efficiency.

BASF SE represents approximately 6.0% share, supporting growth through polyurethane and polyisocyanurate systems supply, spray foam insulation offerings, and chemical industry integration. BASF leverages chemical industry expertise, polymer technology capabilities, and technical service supporting foam insulation applications.

Other companies and regional producers collectively hold 34.0% share, reflecting the moderately concentrated nature of European thermal insulation materials sales, where numerous regional manufacturers, specialty insulation suppliers, and local producers serve specific geographic industries, building types, and application niches built on distribution relationships, technical service, and product specialization.

| Item | Value |

|---|---|

| Quantitative Units | USD 31,174.6 million |

| Product Type (Material) | Plastic foam (EPS/XPS/PUR-PIR), Mineral wool (stone wool), Fiberglass, Others (aerogels/VIP/cork/cellulose) |

| Application | Building & Construction, Industrial & OEM, HVAC & Refrigeration, Transportation, Others |

| Distribution Channel | Direct/OEM, Distributors/Dealers, Retail/DIY, E-commerce |

| Nature | Non-combustible, Combustible, Bio-based/Low-carbon |

| Forecast Period | 2025 to 2035 |

| Base Year | 2025 |

| Historical Data | 2020 to 2024 |

| Countries Covered | Germany, France, Italy, Spain, the Netherlands, and the Rest of Europe |

| Key Companies Profiled | Saint-Gobain, Rockwool International, Kingspan Group, Knauf Insulation, Owens Corning, BASF SE, Regional producers |

| Report Pages | 180+ Pages |

| Data Tables | 50+ Tables and Figures |

| Additional Attributes | Dollar sales by product type (material), application, distribution channel, nature, and country; regional demand trends across major European industries; competitive landscape analysis with established building materials companies and specialized insulation manufacturers; construction professional preferences for various insulation materials and performance characteristics; integration with residential construction, commercial buildings, renovation projects, and industrial facilities; innovations in fire safety, advanced materials, and bio-based insulation; adoption across contractor direct procurement and distributor channels. |

The global demand for thermal insulation materials in eu is estimated to be valued at USD 18.3 billion in 2025.

The market size for the demand for thermal insulation materials in eu is projected to reach USD 31.3 billion by 2035.

The demand for thermal insulation materials in eu is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in demand for thermal insulation materials in eu are mineral wool (stone wool), plastic foam (eps/xps/pur-pir), fiberglass and others (aerogels/vip/cork/cellulose).

In terms of application, building & construction segment to command 60.0% share in the demand for thermal insulation materials in eu in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thermal Insulation Materials for Optical Fibers Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Material Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Coating Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Packaging Market Size, Share & Forecast 2025 to 2035

Thermal Management Materials for EV Batteries Market Size and Share Forecast Outlook 2025 to 2035

Non-Thermal Pasteurization Market Size and Share Forecast Outlook 2025 to 2035

Cold Insulation Materials Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Thermal Analysis Market

The thermal printing Market in Western Europe is segmented by printer type, printing technology, industry and country from 2025 to 2035.

Building Thermal Insulation Market Growth - Trends & Forecast 2025 to 2035

Thermal Interface Pads and Materials Market Growth - Trends, Analysis & Forecast by Type, product, Application and Region through 2035

Aircraft Insulation Materials Market

Recyclable Thermal Insulation Packs Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Recyclable Thermal Insulation Packs Industry

Competitive Landscape of Electronic Thermal Materials Providers

Electrical Insulation Materials Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Insulation Materials Market Size and Share Forecast Outlook 2025 to 2035

High-Performance Insulation Materials Market Growth 2025 to 2035

Demand for Polyisocyanurate Insulation in EU Size and Share Forecast Outlook 2025 to 2035

Europe Radiotherapy Patient Positioning Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA