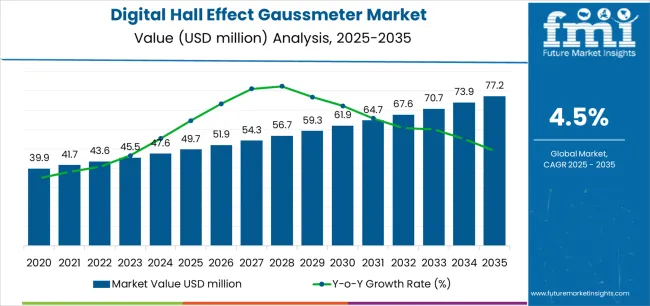

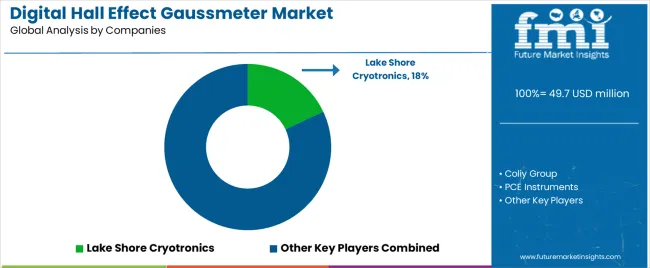

The global digital hall effect gaussmeter market is projected to grow from USD 49.7 million in 2025 to approximately USD 77.2 million by 2035, recording an absolute increase of USD 27.5 million over the forecast period. This translates into a total growth of 55.3%, with the market forecast to expand at a compound annual growth rate (CAGR) of 4.5% between 2025 and 2035. The overall market size is expected to grow by nearly 1.6X during the same period, supported by increasing magnetic field measurement requirements across industrial quality control operations, growing demand for precision measurement instruments in research laboratories, and rising electromagnetic compatibility testing needs driving specialized measurement equipment procurement across various scientific and industrial applications.

Industrial quality control expansion in manufacturing facilities continues to drive gaussmeter demand, particularly in sectors requiring magnetic field verification for electric motors, magnetic assemblies, and electromagnetic devices. The advancement of electric vehicle technologies and renewable energy systems are reshaping measurement requirements, with manufacturers prioritizing instruments that deliver accurate field strength measurements while supporting production efficiency standards.

Laboratory research programs across materials science, physics, and electronics development are creating sustained demand for bench-top gaussmeters that provide superior resolution and comprehensive measurement capabilities. Asia Pacific markets demonstrate particularly strong growth potential, supported by expanding electronics manufacturing operations and increasing research infrastructure investments that necessitate precise magnetic field characterization capabilities for quality assurance and product development applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 49.7 million |

| Market Forecast Value (2035) | USD 77.2 million |

| Forecast CAGR (2025-2035) | 4.5% |

| INDUSTRIAL QUALITY CONTROL TRENDS | RESEARCH & DEVELOPMENT REQUIREMENTS | TECHNOLOGY & REGULATORY STANDARDS |

|---|---|---|

|

|

|

| Category | Segments Covered |

|---|---|

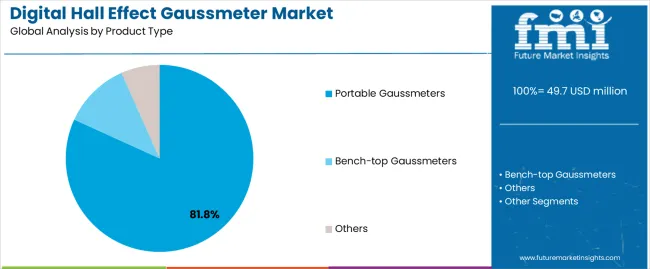

| By Product Type | Portable Gaussmeters, Bench-top Gaussmeters, Others |

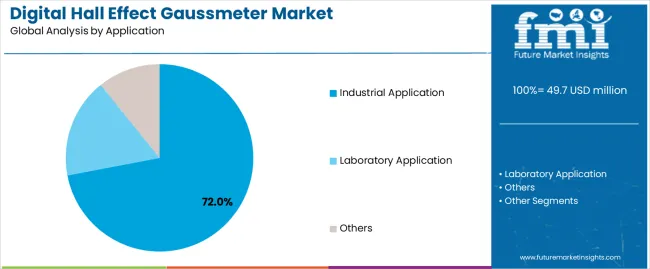

| By Application | Industrial Application, Laboratory Application, Others |

| By Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Segment | 2025 to 2035 Outlook |

|---|---|

| Portable Gaussmeters |

|

| Bench-top Gaussmeters |

|

| Others |

|

| Segment | 2025 to 2035 Outlook |

|---|---|

| Industrial Application |

|

| Laboratory Application |

|

| Others |

|

| DRIVERS | RESTRAINTS | KEY TRENDS |

|---|---|---|

|

|

|

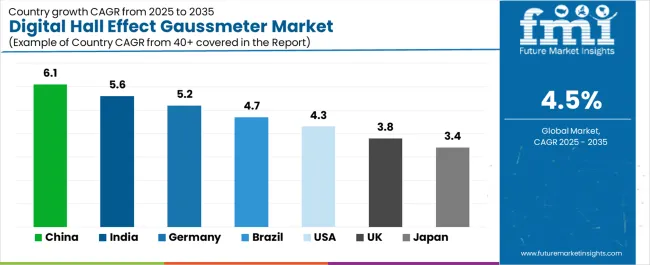

| Country | CAGR (2025-2035) |

|---|---|

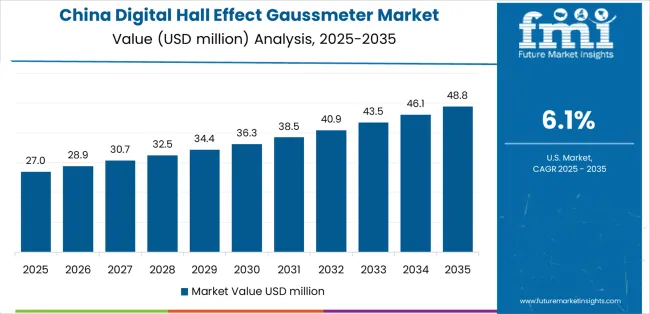

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| Brazil | 4.7% |

| United States | 4.3% |

| United Kingdom | 3.8% |

| Japan | 3.4% |

Revenue from digital hall effect gaussmeters in China is projected to exhibit strong growth, expanding at a CAGR of 6.1% to reach significant market value by 2035, driven by expanding electronics manufacturing infrastructure and comprehensive electric motor production capacity creating substantial opportunities for measurement instrument suppliers across magnetic component manufacturing operations, electric vehicle motor testing facilities, and quality control laboratories.

The country's established electronics manufacturing ecosystem and expanding new energy vehicle production capabilities are creating significant demand for both portable and bench-top gaussmeter solutions. Major motor manufacturers and magnetic component producers are establishing comprehensive quality control facilities to support large-scale production operations and meet growing demand for magnetic field verification instruments.

Revenue from digital hall effect gaussmeters in India is expanding at a CAGR of 5.6% to reach substantial levels by 2035, supported by extensive manufacturing sector development and comprehensive research infrastructure expansion creating sustained demand for magnetic field measurement instruments across diverse industrial categories and laboratory applications. The country's growing electronics manufacturing capabilities and expanding technical education infrastructure are driving demand for gaussmeter solutions that provide reliable measurement performance while supporting cost-effective quality control requirements. International instrument suppliers and domestic distributors are investing in technical service capabilities to support application development and measurement optimization initiatives.

Demand for digital hall effect gaussmeters in Germany is projected to grow at a CAGR of 5.2% to reach substantial levels by 2035, supported by the country's leadership in industrial automation and advanced manufacturing technologies requiring sophisticated measurement instruments for electric motor production, automotive component testing, and precision magnetic assembly verification. German manufacturing facilities are implementing high-precision gaussmeter systems that support stringent quality protocols, operational excellence, and comprehensive measurement documentation. The market is characterized by focus on measurement accuracy, calibration traceability, and compliance with stringent industrial quality standards.

Demand for digital hall effect gaussmeters in Brazil is projected to expand at a CAGR of 4.7% to reach meaningful levels by 2035, driven by industrial manufacturing development and electric motor production expansion supporting quality control infrastructure and measurement capability applications. The country's developing manufacturing sector and growing technical service capabilities are creating demand for gaussmeter solutions that support operational requirements and quality standards. Instrument suppliers and technical distributors are maintaining service capabilities to support diverse measurement requirements and application optimization initiatives.

Revenue from digital hall effect gaussmeters in United States is growing at a CAGR of 4.3% to reach substantial levels by 2035, driven by research laboratory infrastructure and advanced manufacturing development creating sustained opportunities for measurement instrument suppliers serving both academic research institutions and industrial quality control operations. The country's extensive research capabilities and established manufacturing technology base are creating demand for gaussmeter solutions that support stringent measurement requirements while maintaining calibration standards. Instrument manufacturers and technical distributors are developing comprehensive application support capabilities to address research specifications and industrial measurement demands.

Demand for digital hall effect gaussmeters in United Kingdom is projected to grow at a CAGR of 3.8% by 2035, supported by academic research programs and specialized manufacturing operations creating opportunities for measurement instrument suppliers across university laboratories and industrial testing facilities. The country's established research institutions and developing advanced manufacturing capabilities are driving demand for gaussmeter solutions that support measurement accuracy while meeting calibration requirements. Instrument suppliers and technical service providers are implementing capabilities to support research applications and quality control optimization requirements.

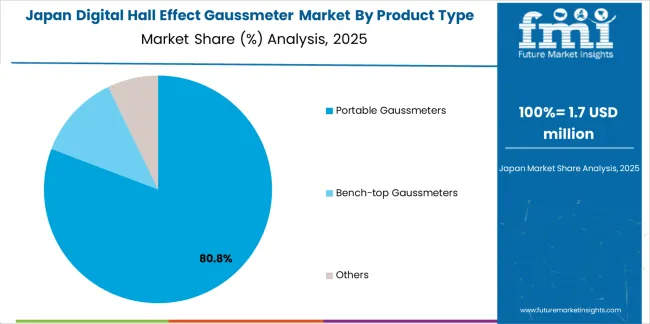

Demand for digital hall effect gaussmeters in Japan is projected to expand at a CAGR of 3.4% by 2035, driven by precision manufacturing excellence and research institution leadership supporting advanced measurement instrument adoption and comprehensive quality verification applications. The country's sophisticated manufacturing requirements and established research capabilities are creating demand for high-precision gaussmeter systems that support stringent operational standards and calibration protocols. Instrument manufacturers and technical specialists are maintaining comprehensive development capabilities to support diverse measurement requirements and application optimization initiatives.

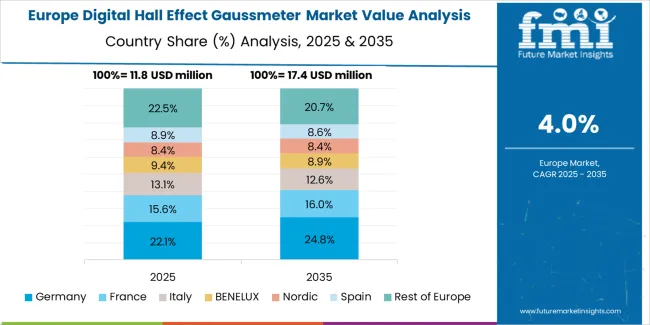

The digital hall effect gaussmeter market in Europe is projected to grow from USD 13.8 million in 2025 to USD 21.6 million by 2035, registering a CAGR of 4.6% over the forecast period. Germany is expected to maintain its leadership position with a 37.8% market share in 2025, declining slightly to 37.2% by 2035, supported by its advanced industrial manufacturing infrastructure and precision measurement capabilities serving electric motor production, automotive component testing, and research laboratory applications.

France follows with a 20.4% share in 2025, projected to reach 20.9% by 2035, driven by comprehensive aerospace manufacturing operations and research institution presence supporting magnetic field measurement requirements. The United Kingdom holds a 17.6% share in 2025, expected to maintain 17.3% by 2035 with academic research focus and specialized manufacturing presence. Italy commands a 13.1% share, while Spain accounts for 8.2% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 2.9% to 3.7% by 2035, attributed to increasing measurement instrument adoption in Nordic research facilities and emerging Eastern European manufacturing operations implementing quality control measurement technologies.

Japanese digital hall effect gaussmeter operations reflect the country's exacting measurement standards and sophisticated manufacturing quality requirements. Major electric motor manufacturers including Nidec, Mabuchi Motor, and precision component producers maintain rigorous instrument qualification processes emphasizing measurement accuracy, calibration stability, and comprehensive documentation protocols. This creates structured market conditions favoring established instrument manufacturers with proven measurement performance and comprehensive technical support capabilities.

The Japanese market demonstrates advanced measurement technology adoption, with significant investment in automated testing equipment and quality management systems requiring gaussmeters optimized for production integration and data connectivity. Companies require detailed instrument specifications and calibration documentation that align with Japanese industrial standards and quality excellence principles, driving demand for sophisticated technical service capabilities and measurement consulting support.

Regulatory oversight emphasizes measurement traceability and calibration documentation, with manufacturing standards requiring comprehensive instrument qualification and periodic verification protocols. The measurement instrument procurement framework creates advantages for suppliers with established metrology certifications, comprehensive calibration capabilities, and proven quality management systems.

Supply chain relationships focus on long-term technical partnerships rather than transactional procurement approaches. Japanese manufacturers typically maintain multi-year supplier agreements with instrument producers, emphasizing collaborative measurement solution development, joint quality improvement initiatives, and continuous technical support rather than competitive pricing negotiations. This stability supports application-specific probe development and measurement system optimization investments tailored to Japanese manufacturing requirements and quality expectations.

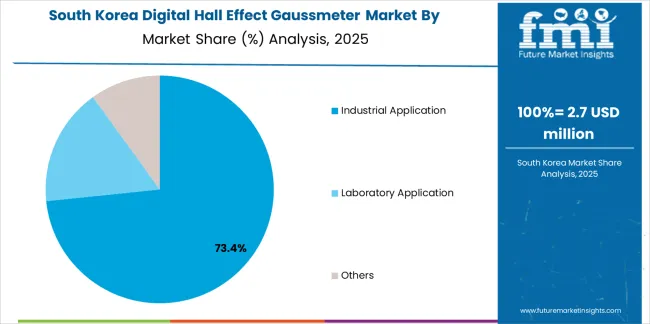

South Korean digital hall effect gaussmeter operations reflect the country's advanced electronics manufacturing and expanding research infrastructure. Major electronics companies including Samsung Electronics, LG Electronics, and government research institutions drive sophisticated measurement instrument procurement strategies, establishing technical partnerships with global instrument manufacturers to secure performance-validated gaussmeters for motor testing, magnetic component characterization, and electromagnetic compatibility verification supporting both domestic production and research operations.

The Korean market demonstrates particular strength in applying gaussmeters to electric vehicle motor development and battery system testing, with companies integrating magnetic field measurement into motor performance validation, quality control protocols, and electromagnetic interference assessment. This application focus creates demand for portable instruments optimized for production environment deployment and bench-top systems supporting comprehensive research characterization requirements.

Regulatory frameworks emphasize manufacturing quality standards and research measurement protocols, with electronics industry quality management systems requiring comprehensive instrument calibration and measurement uncertainty documentation. Gaussmeter selection processes require extensive performance validation and measurement capability verification, creating structured evaluation frameworks that favor established manufacturers with technical expertise and proven measurement accuracy.

Engineering collaboration between Korean manufacturers and instrument suppliers focuses on measurement automation and data management integration, with development projects targeting production testing efficiency and research data quality enhancement. Korean companies invest in advanced measurement system integration capabilities and automated testing technologies supporting instrument selection optimization and quality verification, positioning the market for continued advancement as electric vehicle technology evolves and research sophistication increases.

Profit pools consolidate around suppliers demonstrating measurement accuracy capabilities and comprehensive calibration service infrastructure serving industrial quality control and research laboratory segments where instrument reliability and technical support relationships command premium positioning. Value migrates from basic portable instruments toward advanced bench-top systems and multi-axis measurement solutions where superior resolution, calibration stability, and comprehensive data analysis capabilities create customer retention.

Several operational models define competitive dynamics: established scientific instrument manufacturers leveraging comprehensive product portfolios and worldwide calibration service networks; specialized magnetometry instrument producers focusing on application development and niche measurement requirements; industrial test equipment distributors providing instrument availability and localized technical support; and emerging manufacturers pursuing volume through cost competitiveness in standard portable configurations.

Switching costs remain moderate for basic industrial applications where measurement range and accuracy requirements permit instrument interchangeability with minimal process disruption. However, research applications involving established measurement protocols, calibration history documentation, and specialized probe configurations create barriers to supplier changes through requalification requirements and data continuity considerations. Competitive advantages accrue to manufacturers maintaining vertical integration across Hall sensor production, probe fabrication, and instrument assembly enabling customization responsiveness and measurement performance optimization.

Market concentration reflects established global manufacturers controlling significant share through brand recognition, calibration service infrastructure, and technical reputation while regional suppliers compete in price-sensitive industrial segments. Distribution complexity creates multi-tier channel structures with scientific equipment distributors, industrial test equipment suppliers, and direct sales coexisting depending on application sophistication and customer technical requirements. Technology differentiation focuses on sensor sensitivity advancement, temperature compensation algorithms, and software interface capabilities supporting diverse measurement applications and integration requirements.

| Items | Values |

|---|---|

| Quantitative Units | USD 49.7 million |

| Product Type | Portable Gaussmeters, Bench-top Gaussmeters, Others |

| Application | Industrial Application, Laboratory Application, Others |

| Regions Covered | North America, Latin America, Europe, Asia Pacific, Middle East & Africa |

| Key Countries Covered | United States, Germany, China, India, Brazil, United Kingdom, Japan, and other countries |

| Key Companies Profiled | Coliy Group, Lake Shore Cryotronics, PCE Instruments, Gigahertz Meters, Safe and Sound (SLT), F.W. Bell (Meggitt PLC), Hirst Magnetic Instruments, Brockhaus, Magnet-Physik, OMEGA Engineering (Spectris), AlphaLab Inc., Calamit, KANETEC, SENIS AG, List-Magnetik, Magnaflux, MAGSYS magnet systeme, Group3 Technology, Dexing Magnet Tech, CH-Magnetoelectricity, Litian Magnetoelectrican, ROM Elektronik, Magnii Technologies, Tunkia Co., Ltd. |

| Additional Attributes | Revenue analysis by product type and application segment, regional market dynamics, competitive landscape assessment, calibration service requirements, measurement accuracy trends, and digital connectivity innovations driving quality control advancement, research capability enhancement, and measurement automation |

The global digital hall effect gaussmeter market is estimated to be valued at USD 49.7 million in 2025.

The market size for the digital hall effect gaussmeter market is projected to reach USD 77.2 million by 2035.

The digital hall effect gaussmeter market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in digital hall effect gaussmeter market are portable gaussmeters, bench-top gaussmeters and others.

In terms of application, industrial application segment to command 72.0% share in the digital hall effect gaussmeter market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Digital Group Dining Service Market Size and Share Forecast Outlook 2025 to 2035

Digital Pathology Displays Market Size and Share Forecast Outlook 2025 to 2035

Digital Rights Management Market Size and Share Forecast Outlook 2025 to 2035

Digital Liquid Filling Systems Market Size and Share Forecast Outlook 2025 to 2035

Digital Transformation Industry Analysis in MENA Size and Share Forecast Outlook 2025 to 2035

Digital X-Ray Equipment Market Size and Share Forecast Outlook 2025 to 2035

Digital Marketing Analytics Industry Analysis in Latin America Forecast Outlook 2025 to 2035

Digital Health Market Forecast and Outlook 2025 to 2035

Digital Pen Market Forecast and Outlook 2025 to 2035

Digital X-ray Market Size and Share Forecast Outlook 2025 to 2035

Digital Elevation Model Market Size and Share Forecast Outlook 2025 to 2035

Digital Pump Controller Market Size and Share Forecast Outlook 2025 to 2035

Digital Textile Printing Market Size and Share Forecast Outlook 2025 to 2035

Digital Printing Paper Market Size and Share Forecast Outlook 2025 to 2035

Digital Battlefield Market Size and Share Forecast Outlook 2025 to 2035

Digital Product Passport Software Market Size and Share Forecast Outlook 2025 to 2035

Digital Lending Platform Market Size and Share Forecast Outlook 2025 to 2035

Digital Shipyard Market Size and Share Forecast Outlook 2025 to 2035

Digital Freight Matching Market Size and Share Forecast Outlook 2025 to 2035

Digital Textile Printer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA