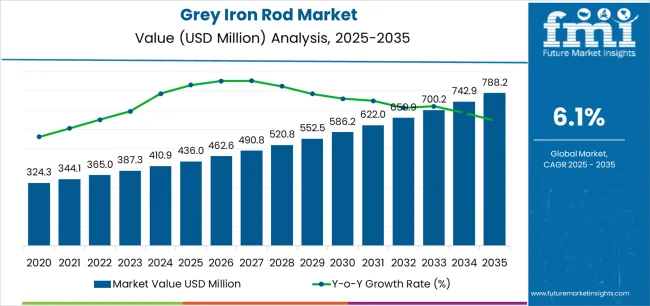

The grey iron rod market is forecast to grow from USD 436 million in 2025 to USD 788.2 million by 2035, reflecting a CAGR of 6.1%. This growth is primarily driven by increasing demand for grey iron rods across the construction, automotive, and infrastructure industries. Grey iron rods, known for their strength, castability, and cost-effectiveness, are widely used in the manufacture of engine blocks and machinery parts, and in construction for reinforcing concrete structures. As the global infrastructure development continues to expand, the need for durable and reliable materials such as grey iron rods will drive the market’s growth over the next decade.

In addition to their use in traditional sectors, grey iron rods are also gaining attention for their application in the automotive and machinery manufacturing industries, where their high strength-to-weight ratio is highly valued. The increasing demand for lightweight and energy-efficient vehicles has contributed to the adoption of grey iron rods in the production of engine components and other parts. Moreover, innovations in manufacturing techniques and increasing investment in smart manufacturing will continue to optimize production processes, allowing for the continued expansion of the grey iron rod market.

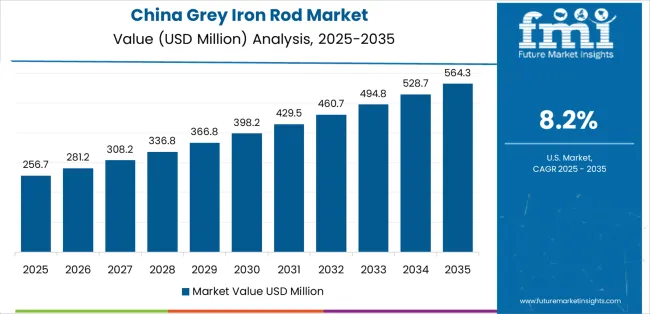

From 2025 to 2030, the market is expected to grow from USD 436 million to USD 586.2 million, an increase of USD 150.2 million. This period will see the rising demand for grey iron rods, particularly in construction, automotive, and infrastructure sectors. The market growth will be further supported by increased construction projects in emerging markets and the ongoing demand for high-performance materials in vehicle production and industrial machinery.

Between 2030 and 2035, the market will continue to expand from USD 586.2 million to USD 788.2 million, adding USD 202 million in value. This growth will be driven by ongoing advancements in grey iron production technology, greater demand in reinforced concrete applications, and increasing use in automotive manufacturing. As the focus on sustainability and efficiency in industries such as construction and automotive manufacturing increases, grey iron rods will remain a vital material due to their cost-effectiveness and high durability, further strengthening market expansion through 2035.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 436 million |

| Market Forecast Value (2035) | USD 788.2 million |

| Forecast CAGR (2025 to 2035) | 6.1% |

The Grey Iron Rod market is expanding due to the increasing demand for high-strength, durable components used in automotive manufacturing, construction, and machinery production. As industries like automotive and construction experience steady growth, there is a rising need for iron rods that provide excellent castability and machinability. The growing shift toward lightweight automotive designs and precision machinery manufacturing is further driving demand for grey iron rods. Additionally, industrial expansion in developing economies, such as China and India, is stimulating the need for cost-effective, high-performance components in industrial applications.

Moreover, grey iron rods offer advantages like improved wear resistance, thermal conductivity, and affordable manufacturing costs, making them essential in sectors like automotive, machinery manufacturing, and construction. Increased urbanization, infrastructure development, and technological advancements in casting and molding processes are enhancing the production and performance of grey iron rods, further driving the market’s growth. As economies invest in modern infrastructure, the demand for high-quality, precision-based materials like grey iron rods continues to increase, supporting both economic development and industrial growth worldwide.

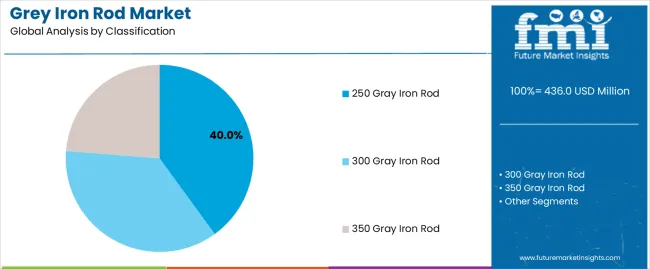

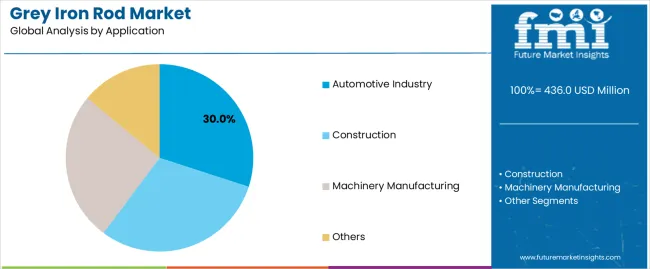

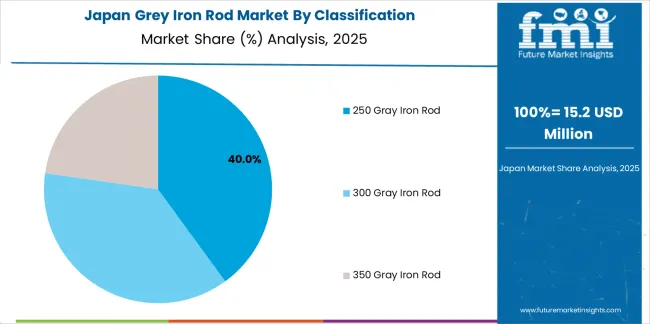

The Grey Iron Rod market is segmented by classification and application. By classification, the market is divided into 250 Gray Iron Rod, 300 Gray Iron Rod, and 350 Gray Iron Rod. Among these, the 250 Gray Iron Rod segment leads with 40% market share, primarily used in industries requiring high machinability and strength, such as automotive and machinery manufacturing. By application, the automotive industry holds the largest share, with 30% of the market share, driven by the extensive use of grey iron rods in engine components, brake systems, and vehicle frames. Regions like China, India, and Germany contribute significantly to the demand for grey iron rods, driven by growing industrial activities and infrastructure development.

The 250 Gray Iron Rod segment leads the Grey Iron Rod market, holding 40% of the total market share. This segment is particularly favored for its excellent machinability, high strength, and cost-effectiveness, making it ideal for automotive, machinery manufacturing, and construction applications. The 250 Gray Iron Rod is widely used in automotive parts such as engine blocks, brake components, and suspension systems, as it provides the required durability and performance for critical components. Additionally, the segment is popular in machinery manufacturing for producing machine bases, chassis, and other structural elements.

The 250 Gray Iron Rod segment is also integral to construction applications, particularly in structural reinforcement, where it offers excellent thermal conductivity and wear resistance. The affordability and versatility of this segment make it a preferred choice for manufacturers looking to produce high-quality components at a relatively low cost. The 250 Gray Iron Rod also has a significant presence in emerging markets, such as China and India, where rapid industrialization is driving the demand for robust materials. As industries continue to innovate in automotive technologies and machinery production, the 250 Gray Iron Rod segment is expected to maintain its market dominance.

The automotive industry is the largest application segment in the Grey Iron Rod market, accounting for 30% of the total market share. The primary reason for this is the extensive use of grey iron rods in the manufacturing of various automotive components, particularly in engine blocks, braking systems, and vehicle frames. Grey iron rods are preferred for these applications due to their high tensile strength, wear resistance, and ability to withstand high temperatures, making them ideal for components that must endure harsh operating conditions. Automakers rely on grey iron rods for producing both lightweight and high-strength parts that enhance vehicle performance and safety.

The shift toward electric vehicles (EVs) and advanced driver-assistance systems (ADAS) is also contributing to the demand for grey iron rods in the automotive sector. EVs require high-performance cast components, including brake systems, batteries, and suspension parts, where grey iron rods continue to play a critical role. Additionally, the increasing focus on fuel-efficient vehicles and sustainable manufacturing is driving the demand for advanced casting materials like grey iron rods. As automotive manufacturing continues to grow, particularly in emerging markets such as China and India, the automotive industry will remain the dominant application for grey iron rods.

The Grey Iron Rod market is growing due to the increasing demand for durable, cost-effective materials used in automotive manufacturing, machinery production, and construction. Grey iron rods offer excellent strength, machinability, and affordability, making them ideal for industries where high-performance materials are required. As infrastructure development accelerates, particularly in emerging economies like China and India, the demand for grey iron rods is rising. The automotive industry continues to be the primary contributor, utilizing grey iron rods for engine components, brake systems, and suspension parts, driving the overall market expansion.

What are the key drivers of the Grey Iron Rod market?

Key drivers of the Grey Iron Rod market include the increasing demand for high-strength, cost-effective materials in automotive, machinery manufacturing, and construction. As global manufacturing continues to grow, particularly in emerging markets like China and India, the need for reliable casting materials like grey iron rods is on the rise. The automotive sector remains the largest consumer, with grey iron rods being used extensively in engine blocks, braking systems, and vehicle frames. Moreover, grey iron rods offer excellent thermal conductivity and wear resistance, making them highly suitable for automotive and industrial applications. Additionally, ongoing urbanization and infrastructure development are fueling the demand for reinforcement materials, further boosting the growth of grey iron rods.

What are the key restraints in the Grey Iron Rod market?

Despite strong growth, the Grey Iron Rod market faces several challenges. One of the key restraints is the fluctuating costs of raw materials like iron ore, which can impact production costs and market prices. The environmental impact of casting processes is another concern, as grey iron rod production can be energy-intensive, raising sustainability issues. Additionally, while grey iron rods offer excellent machinability, they may not be as lightweight as aluminum alloys or other materials, limiting their use in industries focused on reducing weight, such as the aerospace sector. The increasing availability of advanced materials could pose a threat to the dominance of grey iron rods in certain applications.

What are the key trends in the Grey Iron Rod market?

Key trends in the Grey Iron Rod market include the rise of lightweight vehicle designs in the automotive sector. As the demand for fuel-efficient vehicles grows, manufacturers are increasingly focusing on materials that offer high performance while reducing weight. Additionally, there is an increasing emphasis on sustainable manufacturing practices, with industries seeking to reduce carbon emissions and energy consumption during the production of grey iron rods. Another key trend is the integration of advanced casting technologies, such as 3D printing and smart manufacturing, which are improving production efficiency and reducing waste. As industries continue to innovate, grey iron rods will evolve to meet the growing demand for advanced, durable materials in various sectors.

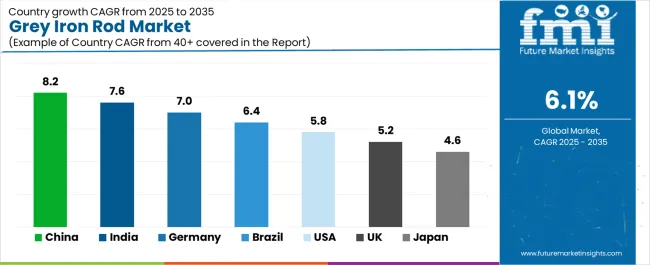

The Grey Iron Rod market is experiencing rapid growth across several key regions, with China, India, and Germany leading the charge due to their substantial industrial expansion. As these countries invest heavily in automotive manufacturing, construction, and machinery production, demand for grey iron rods continues to rise. In China, the market is growing at the fastest rate, supported by the country’s strong focus on infrastructure development and automotive production. India and Germany are also major contributors, with demand driven by both industrial growth and technological advancements in manufacturing processes. Other regions such as Brazil, the USA, the UK, and Japan are also contributing to the market, with steady growth in their respective industrial sectors, further driving the demand for grey iron rods globally.

| Country | CAGR (%) |

|---|---|

| China | 8.2 |

| India | 7.6 |

| Germany | 7 |

| Brazil | 6.4 |

| USA | 5.8 |

| UK | 5.2 |

| Japan | 4.6 |

China is experiencing the highest growth in the Grey Iron Rod market, with a CAGR of 8.2%. The country’s rapid industrialization and expansion in automotive manufacturing and construction are key drivers behind this growth. As China continues to develop its infrastructure, demand for durable materials like grey iron rods increases, particularly for machinery production, automotive components, and construction applications. The Chinese automotive sector, one of the largest in the world, heavily relies on grey iron rods for components such as engine blocks, braking systems, and suspension parts, which require both strength and durability. Additionally, the growing construction sector in China demands high-performance materials for reinforcement, driving further growth. As China continues its push towards modernizing infrastructure and expanding its automotive sector, the demand for grey iron rods is set to remain strong.

India is also experiencing significant growth in the Grey Iron Rod market, projected at a CAGR of 7.6%. The country’s expanding automotive industry and the growing construction sector are major contributors to this growth. India’s automotive sector continues to grow rapidly, with grey iron rods being essential for producing engine components, brake systems, and chassis parts. The construction industry is also a major consumer of grey iron rods, particularly for structural reinforcement in large-scale infrastructure projects. As urbanization accelerates, the demand for reinforced concrete and building materials grows, further increasing the need for grey iron rods. Additionally, India’s growing presence in manufacturing and industrial production ensures continued demand for high-quality casting materials. As digital manufacturing technologies and smart factories continue to gain traction, India’s Grey Iron Rod market is expected to see further advancements, enhancing efficiency and reducing costs in production processes.

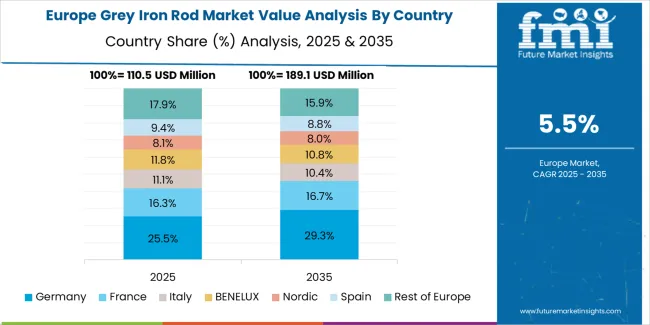

Germany is contributing significantly to the Grey Iron Rod market, with a CAGR of 7%. The country’s strong manufacturing base, especially in automotive and machinery production, is a key factor in this growth. Germany’s automotive sector heavily relies on grey iron rods for components like brake systems, engine blocks, and suspension parts. The country is also witnessing increasing demand for durable materials in machinery manufacturing and construction. As Germany continues to focus on sustainability and efficiency in production, the demand for reliable and cost-effective materials such as grey iron rods is rising. Moreover, Germany’s emphasis on smart manufacturing and advanced casting technologies is driving the market, making the production of grey iron rods more efficient and precise. As Europe’s industrial hub, Germany is expected to maintain its leading role in the Grey Iron Rod market, contributing to technological advancements and the development of high-quality, cost-effective manufacturing solutions.

Brazil is expected to grow at a CAGR of 6.4% in the Grey Iron Rod market, driven by the growing demand for durable materials in the automotive and construction sectors. As Brazil continues to develop its automotive industry, the need for grey iron rods in vehicle components, such as engine blocks and suspension systems, increases. The country’s construction sector is also seeing rapid expansion, with infrastructure projects requiring strong, cost-effective materials like grey iron rods for reinforcement. Brazil’s expanding industrial base and rising demand for machinery production are further contributing to market growth. As urbanization increases and large-scale construction projects grow, the demand for grey iron rods will continue to rise, making Brazil an important player in the global Grey Iron Rod market.

The USA is expected to grow at a CAGR of 5.8% in the Grey Iron Rod market, driven by steady demand from automotive and machinery manufacturing sectors. The USA automotive industry is one of the largest globally, and grey iron rods are used extensively in engine components, braking systems, and vehicle frames. The construction sector in the USA is also a key consumer, as grey iron rods are essential for reinforced concrete used in high-rise buildings and infrastructure projects. Additionally, machinery manufacturing and industrial production continue to grow, increasing the demand for high-performance materials like grey iron rods. As technological advancements in manufacturing processes continue to evolve, the USA Grey Iron Rod market will maintain its position as a key driver in global market expansion.

The UK is projected to grow at a CAGR of 5.2% in the Grey Iron Rod market, supported by its well-established industrial base and growing demand for durable materials in automotive and construction. As a leader in automotive manufacturing, the UK continues to rely on grey iron rods for engine components, brake systems, and chassis parts. Additionally, the country’s construction sector is contributing to the increased demand for reinforcement materials used in large-scale infrastructure projects. As green manufacturing and sustainability initiatives gain momentum, the Grey Iron Rod market in the UK is expected to evolve, with more focus on efficient production techniques and lower environmental impact.

Japan’s Grey Iron Rod market is growing at a CAGR of 4.6%, driven by its technologically advanced manufacturing sector and strong demand in automotive manufacturing and machinery production. Japan is a significant player in the automotive industry, where grey iron rods are used in engine components, brake systems, and chassis. The country is also investing in infrastructure projects, contributing to the demand for reinforced concrete and durable materials like grey iron rods. Japan’s manufacturing excellence and focus on precision and efficiency continue to drive the Grey Iron Rod market forward, making it a key player in the global market.

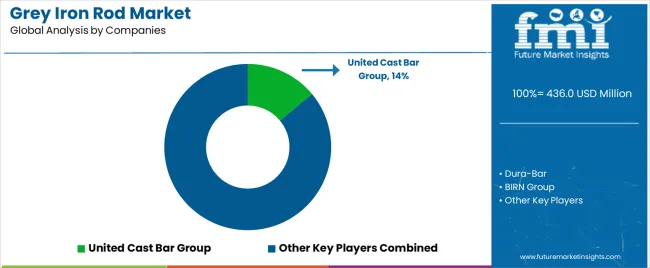

The grey iron rod market is highly competitive, with several key players contributing to the industry’s growth. Leading companies like United Cast Bar Group, Dura-Bar, and BIRN Group dominate the market, with a strong focus on providing high-quality, durable products for automotive manufacturing, machinery production, and construction. These companies invest heavily in casting technologies and precision manufacturing to offer grey iron rods that meet industry-specific standards. Their extensive distribution networks and partnerships within the automotive, construction, and industrial sectors enable them to maintain a significant market presence globally.

Emerging players and regional manufacturers are also adding competitive pressure by offering cost-effective solutions and targeting niche applications in machinery manufacturing and construction. Companies like Hitachi Metals, Nippon Chuzo, and Shanghai Accidentally Times Machinery Equipment are making strides by introducing innovative casting techniques and enhancing their production processes to meet the growing demand for strong, reliable materials. The market is also seeing increased investment in sustainable practices and green manufacturing, with companies working towards reducing their carbon footprint and improving material efficiency. As competition intensifies, technological advancements and customer-centric approaches will continue to drive market dynamics in the Grey Iron Rod market.

| Items | Details |

|---|---|

| Quantitative Units | USD Million |

| Regions Covered | China, India, Germany, Brazil, USA, UK, Japan |

| Classification | Gaming and Metaverse, Digital Art and Collectibles, Finance, Identity and Authentication, Internet of Things, Others |

| Application | Primary Market, Secondary Market |

| Key Companies Profiled | Chainlink, Loot, Aavegotchi, Async Art, Art Blocks, Eponym, Sound.xyz, Terra Virtua, Axie Infinity, The Sandbox, NBA Top Shot, Sorare, Uniswap V3 LP NFT, Botto, ENS, IoTeX |

| Additional Attributes | The market analysis includes dollar sales by classification and application categories. It also covers regional adoption trends across major markets such as China, India, Germany, and the U.S. The competitive landscape features key players in the dynamic NFT (dNFT) space, focusing on innovations in gaming, digital art, finance, and IoT applications. Trends in the growing integration of NFTs in the metaverse, art, and financial sectors, along with the development of dynamic assets in secondary markets, are explored. |

The global grey iron rod market is estimated to be valued at USD 436.0 million in 2025.

The market size for the grey iron rod market is projected to reach USD 788.2 million by 2035.

The grey iron rod market is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in grey iron rod market are 250 gray iron rod, 300 gray iron rod and 350 gray iron rod.

In terms of application, automotive industry segment to command 30.0% share in the grey iron rod market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Ductile and Grey Iron Casting Products Market Size and Share Forecast Outlook 2025 to 2035

Greyboard Market

Iron and Steel Counterweight Market Size and Share Forecast Outlook 2025 to 2035

Iron and Steel Casting Market Size and Share Forecast Outlook 2025 to 2035

Iron Phosphate Market Size and Share Forecast Outlook 2025 to 2035

Ironing Table Market Size and Share Forecast Outlook 2025 to 2035

Iron Powder Market - Trends & Forecast 2025 to 2035

Iron Oxide Market Report - Growth, Demand & Forecast 2025 to 2035

Iron Ore Pellets Market Growth - Trends & Forecast 2025 to 2035

Environmentally Friendly RPET Webbing Market Size and Share Forecast Outlook 2025 to 2035

Environment Health and Safety Market Size and Share Forecast Outlook 2025 to 2035

Environmental Radiation Monitor Market Size and Share Forecast Outlook 2025 to 2035

Environmental Test Chambers Market Size and Share Forecast Outlook 2025 to 2035

Environmental Management Systems Market Size and Share Forecast Outlook 2025 to 2035

Environmental Sensor Market Size and Share Forecast Outlook 2025 to 2035

Environmental Test Equipment Market Growth - Trends & Forecast 2025 to 2035

Environment Testing, Inspection and Certification Market Report – Demand, Growth & Industry Outlook 2025 to 2035

Environmental Remediation Technology Market - Size, Share & Forecast 2025 to 2035

Environmental Catalysts Market Trends & Growth 2025 to 2035

Environmental Monitoring Market Report – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA