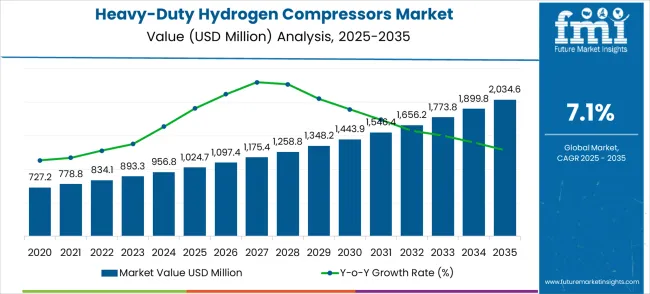

The heavy-duty hydrogen compressors market is valued at USD 1,024.7 million in 2025 and is anticipated to grow to USD 2,034.6 million by 2035, registering a CAGR of 7.1%. From 2021 to 2025, the market progresses from USD 727.2 million to USD 1,024.7 million, passing through intermediate values of USD 778.8 million, USD 834.1 million, USD 893.3 million, and USD 956.8 million. This period sees steady growth as the demand for hydrogen as an alternative fuel source accelerates, driven by the global push for cleaner energy solutions. The market benefits from increased investments in hydrogen infrastructure, including refueling stations and storage systems, as industries shift towards hydrogen for heavy-duty vehicles and industrial applications.

Between 2026 and 2030, the market is expected to continue expanding, growing from USD 1,024.7 million to USD 1,443.9 million, with intermediate values of USD 1,097.4 million, USD 1,175.4 million, USD 1,258.8 million, and USD 1,348.2 million. This phase is supported by growing adoption in the transportation and energy sectors, where hydrogen is increasingly used for long-haul trucking, buses, and trains, as well as in power generation. The rise in green hydrogen projects and government incentives also boosts the demand for heavy-duty compressors. From 2031 to 2035, the market further grows from USD 1,443.9 million to USD 2,034.6 million, with values progressing through USD 1,546.4 million, USD 1,656.2 million, USD 1,773.8 million, and USD 1,899.8 million, ensuring a strong upward trajectory driven by continued infrastructure development and hydrogen adoption across industries.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1,024.7 million |

| Forecast Value in (2035F) | USD 2,034.6 million |

| Forecast CAGR (2025 to 2035) | 7.1% |

The hydrogen production market contributes about 30-35%, as heavy-duty hydrogen compressors are essential in the compression and storage of hydrogen gas for both industrial and energy applications. The energy and power market adds roughly 20-25%, as these compressors are increasingly used in renewable energy systems, such as green hydrogen production, to facilitate the integration of hydrogen as a clean energy source. The chemical manufacturing market accounts for approximately 15-18%, where hydrogen compressors are used in petrochemical refining processes and the production of various chemicals that require hydrogen as a feedstock. The automotive industry contributes about 10-12%, driven by the growing adoption of hydrogen fuel cell vehicles, which require high-efficiency hydrogen compressors for refueling stations and vehicle integration. The oil and gas market provides about 8-10%, where hydrogen compressors are used in gas processing, natural gas liquefaction, and hydrogenation processes.

Market expansion is being supported by the increasing demand for hydrogen infrastructure solutions and the corresponding need for high-efficiency compression systems in hydrogen energy applications across global hydrogen refueling and industrial hydrogen manufacturing operations. Modern hydrogen infrastructure developers are increasingly focused on specialized compression technologies that can improve hydrogen handling efficiency, reduce energy consumption, and enhance system reliability while meeting stringent safety requirements. The proven efficacy of heavy-duty hydrogen compressors in various hydrogen applications makes them an essential component of comprehensive hydrogen infrastructure strategies and hydrogen energy production.

The growing emphasis on clean energy transition and advanced hydrogen infrastructure is driving demand for ultra-efficient heavy-duty hydrogen compressors that meet stringent performance specifications and safety requirements for hydrogen applications. Compression technology manufacturers' preference for reliable, high-performance compression systems that can ensure consistent hydrogen handling outcomes is creating opportunities for innovative compression technologies and customized hydrogen solutions. The rising influence of hydrogen energy policies and safety protocols is also contributing to increased adoption of premium-grade heavy-duty hydrogen compressors across different hydrogen applications and energy systems requiring specialized compression technology.

The heavy-duty hydrogen compressors market represents a specialized growth opportunity, expanding from USD 1,024.7 million in 2025 to USD 2,034.6 million by 2035 at a 7.1% CAGR. As hydrogen infrastructure developers prioritize compression efficiency, safety compliance, and system performance in complex hydrogen energy development processes, heavy-duty hydrogen compressors have evolved from a niche compression technology to an essential component enabling hydrogen compression, energy storage, and multi-stage hydrogen infrastructure production across hydrogen refueling stations and specialized industrial applications.

The convergence of hydrogen energy expansion, increasing clean energy adoption, specialized infrastructure organization growth, and hydrogen compression requirements creates sustained momentum in demand. High-efficiency formulations offering superior compression performance, cost-effective reciprocating systems balancing performance with economics, and specialized centrifugal variants for critical applications will capture market premiums, while geographic expansion into high-growth Asian hydrogen markets and emerging market penetration will drive volume leadership. Regulatory emphasis on hydrogen safety and infrastructure reliability provides structural support.

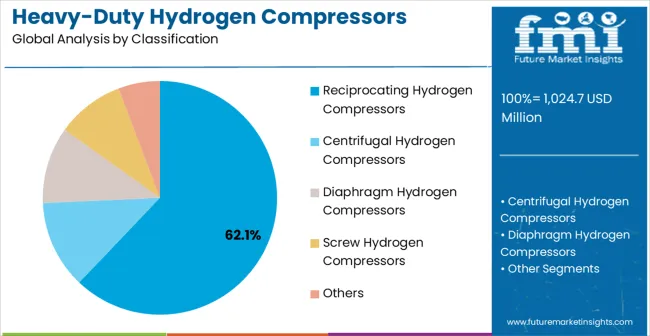

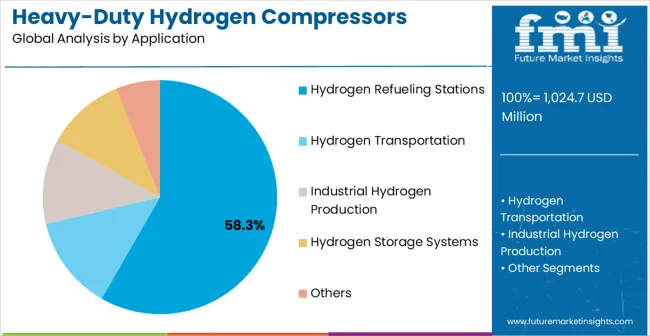

The market is segmented by compressor type, application, and region. By compressor type, the market is divided into Reciprocating Hydrogen Compressors, Centrifugal Hydrogen Compressors, Diaphragm Hydrogen Compressors, Screw Hydrogen Compressors, and Others. Based on application, the market is categorized into Hydrogen Refueling Stations, Hydrogen Transportation, Industrial Hydrogen Production, Hydrogen Storage Systems, and Others. Regionally, the market is divided into Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

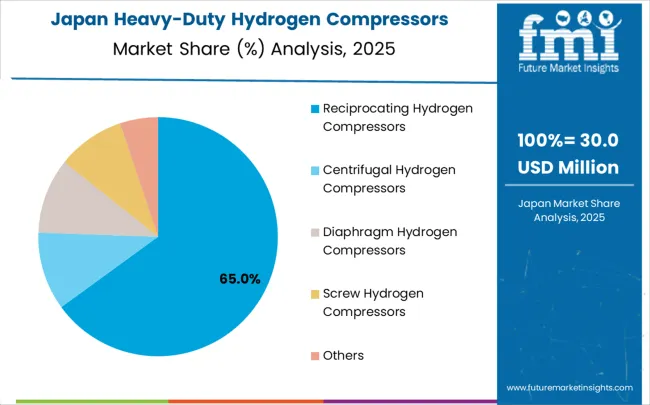

The Reciprocating Hydrogen Compressors segment is projected to account for 62.1% of the heavy-duty hydrogen compressors market in 2025, reaffirming its position as the category's dominant compressor type. Compression technology manufacturers increasingly recognize the optimal balance of performance and cost-effectiveness offered by reciprocating hydrogen compressors for most industrial applications, particularly in hydrogen refueling station development and industrial hydrogen compression processes. This compressor type addresses both performance requirements and economic considerations while providing reliable compression across diverse hydrogen applications.

This compressor type forms the foundation of most manufacturing protocols for hydrogen compression applications, as it represents the most widely accepted and commercially viable level of compression technology in the industry. Performance control standards and extensive compression testing continue to strengthen confidence in reciprocating formulations among compression technology and hydrogen infrastructure manufacturers. With increasing recognition of the cost-performance optimization requirements in hydrogen compression manufacturing, Reciprocating Hydrogen Compressors align with both production efficiency and hydrogen handling goals, making them the central growth driver of comprehensive hydrogen infrastructure strategies.

Hydrogen Refueling Stations are projected to represent 58.3% of heavy-duty hydrogen compressors' demand in 2025, underscoring their role as the primary application driving market adoption and growth. Compression technology manufacturers recognize that hydrogen refueling infrastructure requirements, including complex compression processes, specialized hydrogen handling, and multi-stage compression systems, often require specialized compression equipment that standard industrial compressors cannot adequately provide. Heavy-duty hydrogen compressors offer enhanced compression efficiency and safety compliance in hydrogen refueling station applications.

The segment is supported by the growing nature of hydrogen mobility, requiring sophisticated compression systems, and the increasing recognition that specialized compression technologies can improve infrastructure performance and safety outcomes. Additionally, hydrogen infrastructure companies are increasingly adopting evidence-based safety guidelines that recommend specific compression systems for optimal hydrogen handling outcomes. As understanding of hydrogen infrastructure complexity advances and safety requirements become more stringent, heavy-duty hydrogen compressors will continue to play a crucial role in comprehensive hydrogen energy strategies within the hydrogen refueling infrastructure market.

The heavy-duty hydrogen compressors market is advancing steadily due to increasing recognition of hydrogen energy technologies' importance and growing demand for high-efficiency compression systems across the hydrogen infrastructure and energy transition sectors. The market faces challenges, including complex compression processes, potential for performance variations during operation and maintenance, and concerns about supply chain consistency for specialized hydrogen equipment. Innovation in compression technologies and customized hydrogen handling protocols continues to influence product development and market expansion patterns.

The growing adoption of advanced hydrogen infrastructure manufacturing facilities is enabling the development of more sophisticated heavy-duty hydrogen compressor production and performance control systems that can meet stringent hydrogen safety requirements. Specialized manufacturing plants offer comprehensive compression services, including advanced reciprocating and centrifugal compression processes that are particularly important for achieving high-efficiency requirements in hydrogen applications. Advanced compression channels provide access to premium systems that can optimize hydrogen handling performance and reduce energy consumption while maintaining cost-effectiveness for large-scale hydrogen infrastructure operations.

Modern compression technology companies are incorporating digital technologies such as real-time performance monitoring, automated control systems, and supply chain integration to enhance heavy-duty hydrogen compressor manufacturing and distribution processes. These technologies improve system performance, enable continuous safety monitoring, and provide better coordination between manufacturers and customers throughout the supply chain. Advanced digital platforms also enable customized performance specifications and early identification of potential system deviations or supply disruptions, supporting reliable hydrogen infrastructure production.

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.6% |

| India | 8.9% |

| Germany | 8.2% |

| Brazil | 7.5% |

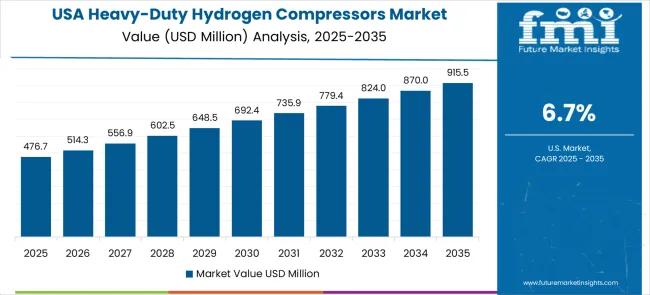

| USA | 6.7% |

| UK | 6.0% |

| Japan | 5.3% |

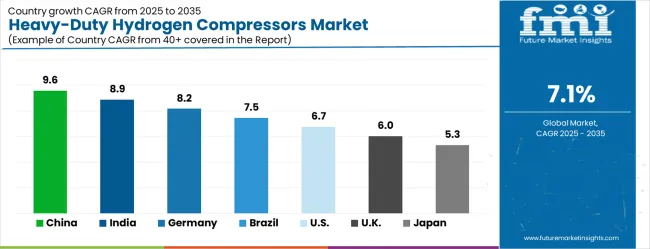

The heavy-duty hydrogen compressors market is experiencing varied growth globally, with China leading at a 9.6% CAGR through 2035, driven by expanding hydrogen infrastructure development, increasing clean energy capabilities, and growing domestic demand for high-efficiency compression systems. India follows at 8.9%, supported by hydrogen energy expansion, growing recognition of the importance of specialized compression technology, and expanding manufacturing capacity. Germany shows growth at 8.2%, emphasizing advanced compression manufacturing technologies and precision hydrogen handling applications. Brazil records 7.5% growth, focusing on developing the hydrogen energy and compression technology industries. The USA shows 6.7% growth, representing a mature market with established manufacturing patterns and regulatory frameworks. The UK exhibits 6.0% growth, supported by advanced manufacturing frameworks and comprehensive hydrogen energy guidelines. Japan demonstrates 5.3% growth, emphasizing precision compression manufacturing infrastructure and systematic hydrogen safety approaches.

The report provides an in-depth analysis of over 40 countries, with the top-performing countries highlighted below.

Revenue from heavy-duty hydrogen compressors in China is projected to exhibit robust growth with a CAGR of 9.6% through 2035, driven by ongoing hydrogen energy expansion and increasing recognition of high-efficiency compression systems as essential infrastructure components for complex hydrogen economy processes. The country's expanding hydrogen technology manufacturing infrastructure and growing availability of specialized compression capabilities are creating significant opportunities for heavy-duty hydrogen compressor adoption across both domestic and export-oriented infrastructure facilities. Major international and domestic compression technology companies are establishing comprehensive production and distribution networks to serve the growing population of hydrogen infrastructure developers and energy manufacturers requiring high-performance compression systems across industrial and transportation applications throughout China's major hydrogen development hubs.

The Chinese government's strategic emphasis on hydrogen energy development and clean technology advancement is driving substantial investments in specialized compression capabilities. This policy support, combined with the country's large domestic energy market and expanding hydrogen infrastructure requirements, creates a favorable environment for heavy-duty hydrogen compressor market development. Chinese manufacturers are increasingly focusing on high-value compression technologies to improve hydrogen handling capabilities, with heavy-duty hydrogen compressors representing a key component in this energy transformation.

The heavy-duty hydrogen compressors market in India is expanding at a CAGR of 8.9%, supported by increasing hydrogen energy accessibility, growing clean energy awareness, and developing infrastructure market presence across the country's major industrial manufacturing clusters. The country's large energy sector and increasing recognition of specialized compression systems are driving demand for effective high-efficiency compression solutions in both hydrogen infrastructure and industrial energy applications. International compression technology companies and domestic manufacturers are establishing comprehensive distribution channels to serve the growing demand for quality compression systems while supporting the country's position as an emerging hydrogen energy market.

The energy sector continues to benefit from favorable clean energy policies, expanding manufacturing capabilities, and cost-competitive infrastructure development. The country's focus on becoming a global clean energy hub is driving investments in specialized compression technology and hydrogen infrastructure. This development is particularly important for heavy-duty hydrogen compressor applications, as energy manufacturers seek reliable domestic sources for critical compression technologies to reduce import dependency and improve supply chain security.

Demand for heavy-duty hydrogen compressors in Germany is anticipated to grow at a CAGR of 8.2%, supported by well-established compression manufacturing systems and precision hydrogen handling protocols that emphasize performance, consistency, and safety compliance. German compression technology manufacturers consistently utilize high-efficiency compression systems for complex hydrogen applications and advanced infrastructure manufacturing, with particular strength in specialty compression technologies and high-value hydrogen systems. The market is characterized by mature manufacturing protocols, comprehensive performance standards, and established relationships between compression technology companies and hydrogen infrastructure manufacturers that support long-term supply agreements and technical collaboration.

Germany's compression technology industry benefits from advanced research and development capabilities, sophisticated manufacturing infrastructure, and strong regulatory frameworks that support high-quality compression system production. The country's emphasis on innovation is driving the development of more efficient compression processes and cleaner production methods for specialized hydrogen systems like heavy-duty hydrogen compressors. This focus on technological advancement and environmental responsibility aligns with global trends toward green hydrogen energy practices.

Revenue from heavy-duty hydrogen compressors in Brazil is expected to expand at a CAGR of 7.5% through 2035, driven by energy infrastructure development, increasing access to hydrogen technology capabilities, and growing recognition of specialized compression systems' importance in complex clean energy applications. Brazilian energy manufacturers are increasingly adopting high-efficiency compression approaches for complex hydrogen applications, supported by expanding energy market presence and improved technology accessibility across the country's major industrial regions. The market benefits from Brazil's large domestic energy sector and growing participation in regional clean energy supply chains.

The energy sector is experiencing modernization and expansion, particularly in clean energy technologies and specialty infrastructure systems. The country's strategic location and trade agreements provide access to both domestic and export markets, creating opportunities for heavy-duty hydrogen compressor suppliers. Government support for energy and clean technology development, combined with increasing private sector investment, is driving infrastructure improvements and capacity expansion in specialized compression manufacturing.

The heavy-duty hydrogen compressors market in the USA is forecasted to grow at a CAGR of 6.7% through 2035, supported by established compression manufacturing systems, evidence-based hydrogen handling protocols, and comprehensive energy infrastructure frameworks that emphasize performance, safety, and regulatory compliance. American compression technology manufacturers consistently utilize high-efficiency compression systems as part of integrated hydrogen infrastructure approaches, emphasizing energy outcomes and performance optimization in both hydrogen refueling and industrial energy production. The market benefits from strong research and development capabilities, advanced manufacturing infrastructure, and well-established regulatory frameworks.

The USA energy sector's focus on innovation and clean energy transition drives demand for specialized compression systems that can support complex hydrogen handling processes and meet stringent safety requirements. The country's mature market characteristics include established supplier relationships, comprehensive performance standards, and sophisticated logistics networks that support reliable supply chain management for critical hydrogen technologies.

Revenue from heavy-duty hydrogen compressors in the UK is projected to expand at a CAGR of 6.0% through 2035, supported by advanced manufacturing frameworks and comprehensive evidence-based hydrogen energy guidelines that facilitate the appropriate use of high-efficiency compression systems for complex energy infrastructure applications. British compression technology manufacturers consistently utilize established protocols for hydrogen handling management, emphasizing energy outcomes and performance optimization within integrated manufacturing systems that support both domestic energy production and export markets. The country benefits from strong research capabilities, established energy clusters, and comprehensive regulatory support.

The UK's compression technology and energy industries are characterized by high levels of innovation, strong academic-industry collaboration, and emphasis on high-value specialty systems. The country's regulatory environment has created both challenges and opportunities, with increased focus on domestic supply chain development and energy security driving investments in specialized compression manufacturing capabilities.

The heavy-duty hydrogen compressors market in Japan is projected to grow at a CAGR of 5.3% through 2035, supported by the country's well-established precision compression manufacturing infrastructure, comprehensive performance coverage, and systematic approach to hydrogen handling that emphasizes consistency, reliability, and technical excellence. Japanese compression technology manufacturers emphasize evidence-based compression system utilization within structured manufacturing frameworks that prioritize hydrogen handling effectiveness and system performance in both infrastructure and specialty energy applications. The market is characterized by high technical standards, established performance systems, and long-term supplier relationships.

The compression technology industry benefits from advanced technology, sophisticated performance control systems, and a strong emphasis on continuous improvement. The country's focus on energy security and advanced manufacturing creates steady demand for compression systems, while the focus on high-quality manufacturing supports premium pricing for specialized hydrogen systems like heavy-duty hydrogen compressors.

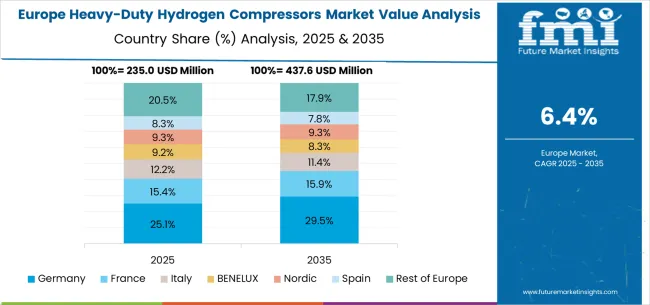

The heavy-duty hydrogen compressors market in Europe is projected to grow from USD 219.6 million in 2025 to USD 436.2 million by 2035, registering a CAGR of 7.1% over the forecast period. Germany is expected to maintain its leadership position with a 28.5% market share in 2025, rising to 29.1% by 2035, supported by its advanced compression manufacturing infrastructure, precision hydrogen handling capabilities, and strong energy infrastructure presence throughout major industrial regions.

The United Kingdom follows with a 21.3% share in 2025, projected to reach 21.8% by 2035, driven by advanced manufacturing protocols, compression technology innovation integration, and expanding specialty hydrogen handling networks serving both domestic and international markets. France holds an 18.2% share in 2025, expected to increase to 18.6% by 2035, supported by energy infrastructure expansion and growing adoption of high-efficiency compression systems. Italy commands a 14.1% share in 2025, projected to reach 14.3% by 2035, while Spain accounts for 9.7% in 2025, expected to reach 9.9% by 2035. The BENELUX region is expected to maintain a 4.8% share in 2025, growing to 5.1% by 2035, supported by innovation-friendly regulatory frameworks and strong academic-industry collaboration. The Rest of Europe region, including Nordic countries, Eastern Europe, and smaller Western European markets, is anticipated to hold 3.4% in 2025, declining slightly to 3.2% by 2035, attributed to market consolidation toward larger core markets with established compression technology and energy infrastructure manufacturing capabilities.

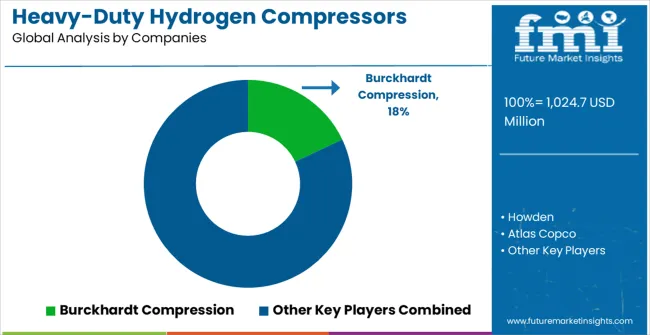

The heavy-duty hydrogen compressors market is characterized by competition among established compression technology manufacturers, specialty hydrogen equipment companies, and energy infrastructure suppliers focused on delivering high-efficiency, consistent, and reliable compression systems. Companies are investing in compression technology advancement, performance control enhancement, strategic partnerships, and customer technical support to deliver effective, efficient, and reliable heavy-duty hydrogen compression solutions that meet stringent hydrogen handling and energy infrastructure requirements. Compression optimization, performance validation protocols, and supply chain strategies are central to strengthening product portfolios and market presence.

Burckhardt Compression leads the market with comprehensive high-efficiency compression system offerings with a focus on performance consistency and manufacturing reliability for hydrogen applications. Howden provides specialized heavy-duty hydrogen compressors with emphasis on infrastructure applications and comprehensive technical support services. Atlas Copco focuses on advanced compression technologies and customized hydrogen handling solutions for compression systems serving global markets. Siemens Energy delivers established energy systems with strong performance control systems and customer service capabilities.

NEUMAN & ESSER operates with a focus on bringing innovative compression technologies to specialized hydrogen applications and emerging markets. Sundyne provides comprehensive compression system portfolios, including heavy-duty hydrogen compressors, across multiple industrial applications and energy infrastructure processes. MAN Energy Solutions specializes in customized compression solutions and performance management systems for hydrogen systems with emphasis on industrial compliance. Ariel Corporation provides reliable supply chain solutions and technical expertise to enhance market accessibility and customer access to essential compression systems.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 1,024.7 million |

| Compressor Type | Reciprocating Hydrogen Compressors, Centrifugal Hydrogen Compressors, Diaphragm Hydrogen Compressors, Screw Hydrogen Compressors, Others |

| Application | Hydrogen Refueling Stations, Hydrogen Transportation, Industrial Hydrogen Production, Hydrogen Storage Systems, Others |

| Regions Covered | Asia Pacific, North America, Europe, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, the United States, the United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Burckhardt Compression, Howden, Atlas Copco, Siemens Energy, NEUMAN & ESSER, Sundyne, MAN Energy Solutions, Ariel Corporation |

| Additional Attributes | Dollar sales by compressor type and application, regional demand trends, competitive landscape, manufacturer preferences for specific compression systems, integration with specialty hydrogen supply chains, innovations in compression technologies, performance monitoring, and hydrogen handling optimization |

The global heavy-duty hydrogen compressors market is estimated to be valued at USD 1,024.7 million in 2025.

The market size for the heavy-duty hydrogen compressors market is projected to reach USD 2,034.6 million by 2035.

The heavy-duty hydrogen compressors market is expected to grow at a 7.1% CAGR between 2025 and 2035.

The key product types in heavy-duty hydrogen compressors market are reciprocating hydrogen compressors, centrifugal hydrogen compressors, diaphragm hydrogen compressors, screw hydrogen compressors and others.

In terms of application, hydrogen refueling stations segment to command 58.3% share in the heavy-duty hydrogen compressors market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Hydrogen Storage Tank And Transportation Market Forecast Outlook 2025 to 2035

Hydrogen Detection Market Forecast Outlook 2025 to 2035

Hydrogenated Dimer Acid Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Electrolyzer Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Fluoride Gas Detection Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Storage Tanks and Transportation Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Refueling Station Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Aircraft Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Peroxide Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Fuel Cell Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Pipeline Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Generator Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Combustion Engine Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Storage Tanks Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Hubs Market Size and Share Forecast Outlook 2025 to 2035

Compressors and Vacuum Pumps Market Growth - Trends & Forecast 2025 to 2035

Hydrogen Buses Market Growth – Trends & Forecast 2025 to 2035

Hydrogen Truck Market Growth – Trends & Forecast 2024 to 2034

Hydrogen Fueling Station Market Growth – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA