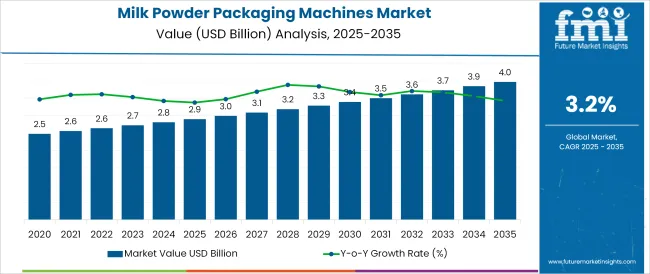

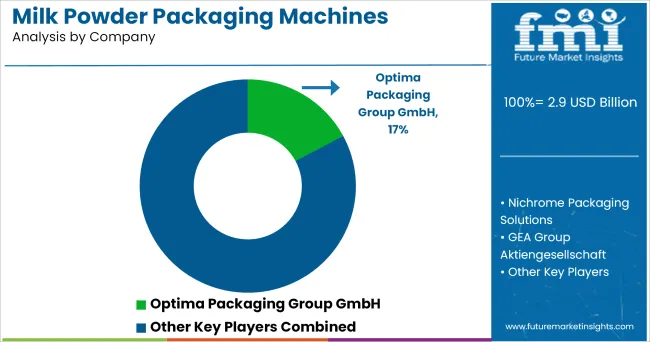

The Milk Powder Packaging Machines Market is estimated to be valued at USD 2.9 billion in 2025 and is projected to reach USD 4.0 billion by 2035, registering a compound annual growth rate (CAGR) of 3.2% over the forecast period.

The milk powder packaging machines market is experiencing consistent expansion, supported by rising dairy consumption, growing export volumes, and increasing demand for contamination-free and efficiently packaged milk powder. With the shift toward hygienic and automated packaging processes, manufacturers are deploying advanced machinery capable of maintaining powder integrity, reducing wastage, and increasing throughput.

Regulatory emphasis on food safety and accurate nutritional labeling has further driven adoption of high-performance packaging lines with integrated weighing, filling, and sealing systems. Additionally, the rise of sustainable packaging formats and reusable pouch solutions is influencing equipment design. Investments in Industry 4.0-enabled packaging systems with real-time monitoring and predictive maintenance functionalities are paving the way for future-ready dairy processing plants.

As developing economies expand their dairy processing capacities, and consumer preference shifts toward convenient, long shelf-life formats, packaging machinery tailored for milk powder is poised to see accelerated deployment across B2B and bulk handling segments.

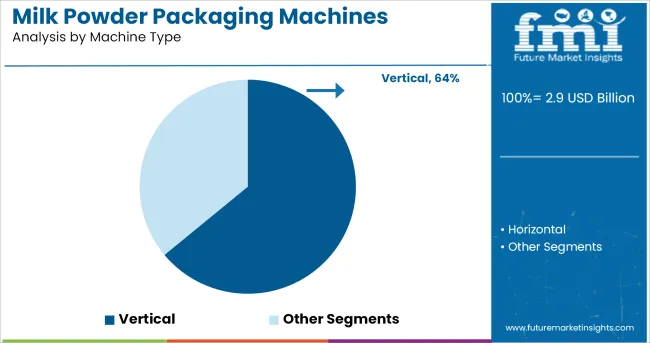

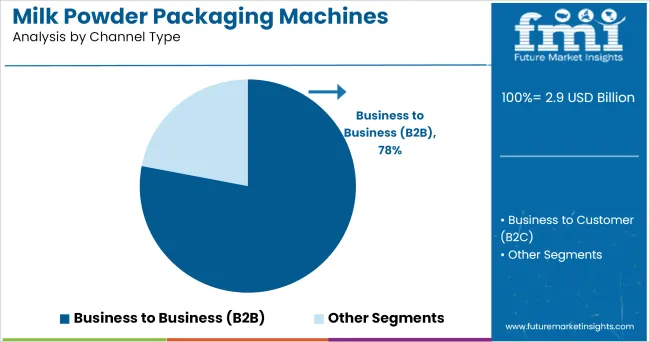

The market is segmented by Machine Type and Channel Type and region. By Machine Type, the market is divided into Vertical and Horizontal. In terms of Channel Type, the market is classified into Business to Business (B2B) and Business to Customer (B2C). Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Vertical machines are projected to account for 64% of the total revenue share in the milk powder packaging machines market by 2025, making them the dominant segment. Their leadership is being driven by operational efficiency, space-saving design, and compatibility with gravity-fed powder filling systems. Vertical packaging machines support continuous, high-speed production with integrated functions such as form-fill-seal (FFS), nitrogen flushing, and batch coding, making them well-suited for milk powder applications that demand hygienic sealing and portion accuracy.

The ability to handle various pouch styles including pillow, gusseted, and quad-seal enhances format flexibility, supporting both retail and institutional packaging needs. As dairy processors seek compact solutions that minimize downtime and optimize output per square foot, vertical machines are preferred for their automation compatibility and low footprint.

Enhanced sealing integrity and ability to maintain powder quality during long-term storage have further strengthened the segment’s market share in the dairy packaging domain.

Business-to-business (B2B) distribution is expected to hold a commanding 78% revenue share in the milk powder packaging machines market by 2025. This dominance stems from the scale at which industrial dairy producers and co-packers operate, where large-capacity packaging solutions are required to meet institutional, export, and wholesale demand.

B2B buyers prioritize high-throughput equipment that ensures batch consistency, compliance with food safety certifications, and adaptability to varied packaging volumes. The demand for durable machinery that integrates seamlessly with upstream and downstream automation such as bulk filling systems, palletizers, and inspection equipment has been a key driver of segment growth.

Additionally, extended service life, machine uptime, and vendor support are critical purchasing considerations for industrial clients operating in cost-sensitive environments. With bulk packaging formats continuing to dominate export and foodservice distribution channels, B2B remains the leading mode of procurement and deployment for milk powder packaging machinery.

Increasing demand for milk powder across the globe is one major factor driving the demand for milk powder packaging machines. The assortment of foods is reflected largely on the shelves of hypermarkets and supermarkets. Reliable and precise packaging is mandatory in order to ensure that the products are showcased effortlessly at the point of sale.

The packaging machines are capable of delivering the seamless packaging and offering reliability while showcasing the products on the supermarket shelves. This happens to be one of the primary factors driving the growth of milk powder packaging machines market.

On the basis of machine type, the milk powder packaging machines market has been bifurcated in to vertical and horizontal. Out of which, vertical milk powder packing machines segment is anticipated to hold a larger share of the market.

The growth of the segment can be attributed to its versatility and ability to fill and seal the food products precisely. Moreover, the vertical milk powder packing machines segment is projected to continue its dominance in the global market over the forecast period.

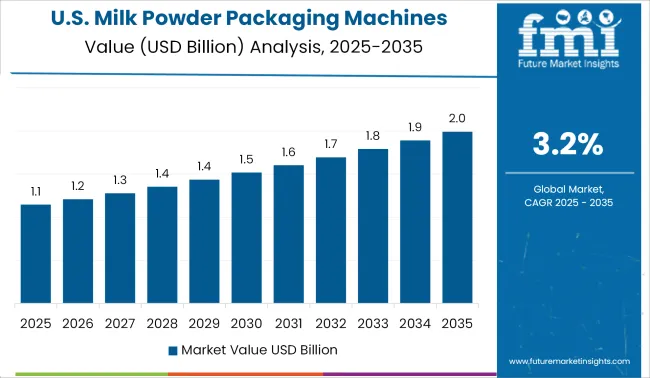

USA happens to be one of the largest markets for milk powder packaging machines across the globe. Ever-changing inclination of consumers towards powdered food products, owing to its numerous benefits is primarily anticipated to boost the demand for milk powder packing machines in the region.

Significant rise in the number of modern retail formats, such as convenience stores, supermarkets, hypermarkets, and specialty stores was observed in the past few years. Increasing disposable income of consumers coupled with the changing lifestyles is anticipated to drive the growth of the retail sector in the region, thereby driving the growth of packaging machines industry.

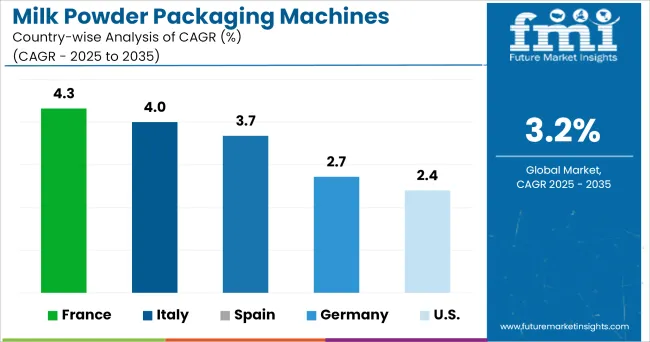

In spite of being a matured market, a considerable percentage of the milk powder packing machines market is being held by the Europe region. The region primarily accounts for a substantial demand for milk powder packing machines, and is expected to remain a chief consumer of milk powder packing machines throughout the forecast period.

Moreover, the growth in Europe region is attributed to the presence of established players such as Optima Packaging Group GmbH, GEA Group Aktiengesellschaft, Robert Bosch GmbH, and Rovema GmbH, among others in the region.

Some of the leading providers of Milk Powder Packaging Machines include

Companies in the market are offering different solutions for advanced packaging in order to make the packaging attractive and easily sellable. For instance, Nichrome Packaging Solutions is providing integrated packaging solutions while offering a wide range of filling systems, packaging machines, and advanced projects for the dairy industry. Nichrome Packaging Solutions happens to be one of the leading manufacturers of automated packaging machines.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global milk powder packaging machines market is estimated to be valued at USD 2.9 billion in 2025.

The market size for the milk powder packaging machines market is projected to reach USD 4.0 billion by 2035.

The milk powder packaging machines market is expected to grow at a 3.2% CAGR between 2025 and 2035.

The key product types in milk powder packaging machines market are vertical and horizontal.

In terms of channel type, business to business (b2b) segment to command 78.0% share in the milk powder packaging machines market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Milk Froth Thermometer Market Size and Share Forecast Outlook 2025 to 2035

Milk Carton Market Size and Share Forecast Outlook 2025 to 2035

Milking Automation Market Size and Share Forecast Outlook 2025 to 2035

Milking Robots Market Size and Share Forecast Outlook 2025 to 2035

Milk Clarifier Market Size and Share Forecast Outlook 2025 to 2035

Milk Homogenizer Machine Market Size and Share Forecast Outlook 2025 to 2035

Milk Sterilizer Machine Market Size and Share Forecast Outlook 2025 to 2035

Milk Protein Market - Size, Share, and Forecast 2025 to 2035

Milk Ingredients Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Milk Mineral Concentrate Market Trends-Demand, Innovations & Forecast 2025 to 2035

Milk Thistle Market Analysis by Form, Distribution Channel and Region through 2035

Milk Tank Cooling System Market Growth – Trends & Forecast 2025 to 2035

Milk Alternatives Market – Growth, Demand & Dairy-Free Trends

Milk Protein Hydrolysate Market Growth - Infant Nutrition & Functional Use 2024 to 2034

Milking Equipment Market

Milk Bottle Market Trends & Industry Growth Forecast 2024-2034

Milk Fat Fractions Market

Milk Retentate Market

Milking Salve Market

Milk Pasteurization Machines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA