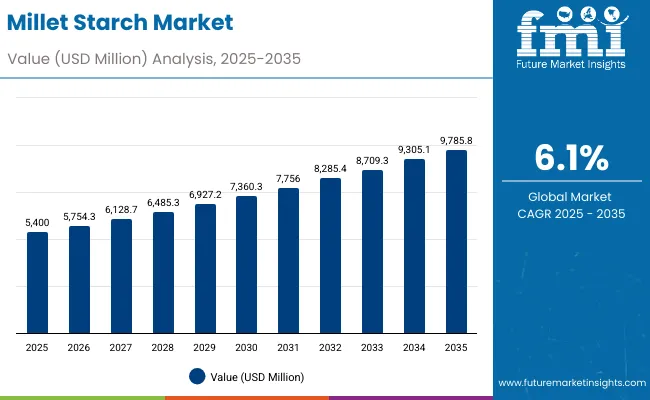

The millet starch market enters a decade of steady expansion that will transform food processing and industrial applications across diverse sectors worldwide. The market's progression from USD 5,400 million in 2025 to USD 9,785.8 million by 2035 represents controlled growth, reflecting the accelerated adoption of alternative grain starches and nutritional enhancement across food processing systems, industrial applications, and specialty manufacturing operations globally.

The first half of the decade (2025-2030) will witness the market climbing from USD 5,400.0 million to approximately USD 7,360.3 million, adding USD 1,960.3 million in value, which constitutes 45% of the total forecast growth period. This phase will be characterized by the continued adoption of food processing applications and industrial usage patterns, driven by increasing health consciousness and the growing need for gluten-free alternatives in manufacturing and processing applications globally. Enhanced extraction technologies and automated processing systems will become standard expectations rather than premium options.

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | Pearl millet applications | 30% | Volume-driven, processing focus |

| Finger millet systems | 18% | Nutritional enhancement applications | |

| Foxtail millet processing | 15% | Specialty applications and manufacturing | |

| Food & beverages applications | 58% | Primary end use category | |

| Industrial applications | 18% | Secondary processing markets | |

| Future (3-5 yrs) | Enhanced pearl millet systems | 28-32% | Technology integration, efficiency gains |

| Expanded finger millet solutions | 16-20% | Process optimization, application expansion | |

| Advanced foxtail processing | 13-17% | Specialty conversion, capability growth | |

| Integrated food systems | 56-62% | Performance enhancement, feature integration | |

| Optimized industrial platforms | 16-22% | Design improvement, operational efficiency | |

| Digital processing platforms | 3-5% | IoT integration, quality optimization |

Millet Starch Market Key Takeaways

| Metric | Value |

|---|---|

| Market Value (2025) | USD 5,400.0 million |

| Market Forecast (2035) | USD 9,785.8 million |

| Growth Rate | 6.1% CAGR |

| Leading Source | Pearl Millet Segment |

| Primary Application | Food & Beverages Segment |

The latter half (2030-2035) will witness continued growth from USD 7,360.3 million to USD 9,785.8 million, representing an addition of USD 2,425.5 million or 55% of the decade's expansion. This period will be defined by mass market penetration of specialty millet varieties, integration with comprehensive food processing platforms, and seamless compatibility with existing manufacturing infrastructure. The market trajectory signals fundamental shifts in how food manufacturers and industrial processors approach starch selection and application optimization, with participants positioned to benefit from growing demand across multiple application segments and distribution channels.

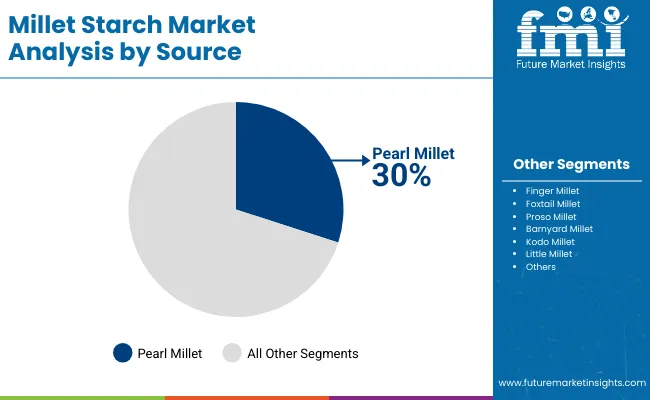

Millet starch extraction processes utilize advanced milling and separation technologies to isolate starch content from pearl millet, finger millet, foxtail millet, and other specialty varieties. Pearl millet dominates commercial production due to higher starch yields and favorable processing characteristics compared to traditional cereal starches. Wet milling operations employ alkaline steeping and mechanical separation to achieve starch purities exceeding 95% while maintaining functional properties essential for food and industrial applications.

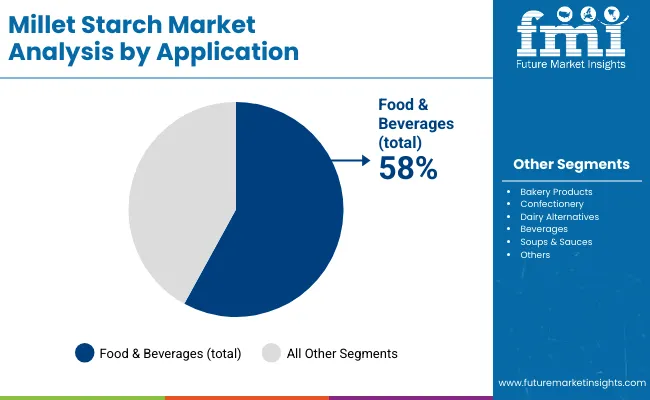

Food processing applications leverage millet starch for thickening, binding, and stabilization functions in bakery products, confectionery items, and dairy alternatives. Industrial applications encompass paper manufacturing, adhesive formulation, and pharmaceutical excipient production where millet starch provides renewable alternatives to synthetic polymers. Modified millet starches undergo physical, chemical, or enzymatic treatments to enhance solubility, viscosity, and temperature resistance for specialized applications.

The market demonstrates strong fundamentals with pearl millet applications capturing a dominant share through reliable processing capabilities and nutritional optimization. Food and beverage applications drive primary demand, supported by increasing health requirements and operational processing development. Geographic expansion remains concentrated in developed markets with established processing infrastructure, while emerging economies show accelerating adoption rates driven by food modernization initiatives and rising nutritional accessibility standards.

The market segments by source into pearl millet, finger millet, foxtail millet, proso millet, barnyard millet, kodo millet, and little millet, representing the evolution from basic cereal starches to specialized grain alternatives for comprehensive food processing and industrial optimization. Application segmentation divides the market into food & beverages, industrial, pharmaceuticals, animal feed, and personal care & cosmetics systems, reflecting distinct requirements for processing efficiency, functional reliability, and application-specific performance standards.

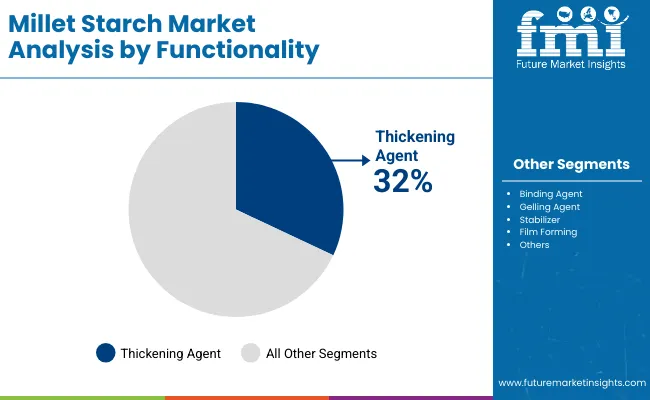

Functionality segmentation covers thickening agent, binding agent, gelling agent, stabilizer, and film forming applications, demonstrating varied operational requirements and processing efficiency standards. Form segmentation includes native millet starch and modified millet starch categories, with modified variants further divided into physically modified, chemically modified, and enzyme modified types for specialized applications. By end use format segmentation encompasses powder, granular, and gel forms, while distribution channels include direct sales (B2B), distributors/wholesalers, online sales, and retail sales channels.

Market Position: Pearl millet applications command the leading position in the millet starch market with 30% market share through advanced processing features, including superior starch yield characteristics, operational efficiency, and processing optimization that enable manufacturers to achieve optimal performance across diverse food and industrial applications.

Value Drivers: The segment benefits from processor preference for reliable starch sources that provide consistent quality characteristics, reduced processing complexity, and operational efficiency optimization without requiring significant infrastructure modifications. Advanced extraction features enable automated processing control systems, yield monitoring, and integration with existing manufacturing equipment, where operational performance and quality compliance represent critical processor requirements.

Competitive Advantages: Pearl millet applications differentiate through proven processing reliability, consistent starch characteristics, and integration with automated quality management systems that enhance processing effectiveness while maintaining optimal quality standards for diverse food and industrial applications.

Key market characteristics:

Finger Millet Applications Show Nutritional Market Growth

Finger millet applications maintain an 18% market position in the millet starch market due to their enhanced nutritional properties and specialized application characteristics. These systems appeal to processors requiring specialized performance with premium positioning for health-focused and nutritional applications. Market growth is driven by health food segment expansion, emphasizing nutritional starch solutions and operational efficiency through optimized processing designs.

Foxtail Millet Applications Demonstrate Specialty Solutions

Foxtail millet applications capture 15% market share through specialized processing requirements in premium applications, artisanal products, and specialty manufacturing. These operations demand certified starch systems capable of operating with specialty processing while providing effective quality integration and performance capabilities.

Market Context: Food & beverages applications demonstrate market leadership in the millet starch market with 58% share due to widespread adoption of alternative starch systems and increasing focus on health optimization, processing flexibility, and applications that maximize nutritional value while maintaining quality standards.

Appeal Factors: Food manufacturers prioritize starch consistency, operational efficiency, and integration with existing processing infrastructure that enables coordinated production operations across multiple application areas. The segment benefits from substantial processing investment and modernization programs that emphasize the acquisition of alternative starch systems for nutritional optimization and processing efficiency applications.

Growth Drivers: Food facility expansion programs incorporate millet starch as standard ingredient for processing operations, while health trends increase demand for consistent nutritional capabilities that comply with quality standards and minimize processing complexity.

Application dynamics include:

Industrial Applications Maintain Processing Demand

Industrial applications capture 18% market share through comprehensive processing requirements in paper manufacturing, adhesive production, and specialty processing operations. These operations demand reliable starch systems capable of handling industrial processes while providing effective quality management and operational performance capabilities.

Market Context: Thickening agent applications demonstrate market leadership in the millet starch market with 32% share due to widespread adoption of viscosity control systems and increasing focus on processing optimization, texture enhancement, and applications that maximize thickening effectiveness while maintaining quality standards.

Appeal Factors: Food processors prioritize thickening consistency, operational reliability, and integration with existing processing infrastructure that enables coordinated production operations across multiple food applications. The segment benefits from substantial processing investment and modernization programs that emphasize the acquisition of thickening systems for texture optimization and processing efficiency applications.

Growth Drivers: Processing facility expansion programs incorporate thickening applications as standard functionality for production operations, while texture demands increase requirements for consistent thickening capabilities that comply with quality standards and minimize processing complexity.

Binding Agent Applications Maintain Structural Demand

Binding agent applications capture 22% market share through comprehensive structural requirements in processed foods, industrial products, and manufacturing applications requiring reliable binding systems capable of providing structural integrity while maintaining effective quality management and operational performance capabilities.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | Health consciousness growth & gluten-free demand (nutritional requirements, dietary compliance) | ★★★★★ | Large-scale food markets require efficient, reliable starch alternatives with consistent performance and nutritional compliance across processing applications. |

| Driver | Food processing expansion & industrial applications | ★★★★★ | Drives demand for specialized starch solutions and high-performance processing capabilities; suppliers providing industrial-grade materials gain competitive advantage. |

| Driver | Alternative grain adoption & processing modernization (extraction technology, quality standards) | ★★★★☆ | Processing facilities need advanced starch solutions; demand for alternative formats expanding addressable market segments. |

| Restraint | Raw material availability & supply chain complexity (millet cultivation, processing infrastructure) | ★★★★☆ | Small processors face supply pressure; increases cost sensitivity and affects material availability in budget-sensitive markets. |

| Restraint | Traditional starch competition & processing alternatives | ★★★☆☆ | Cost-focused applications face challenges with material selection and processing requirements, limiting adoption in price-sensitive segments. |

| Trend | Modified starch development & processing enhancement (enzyme treatment, chemical modification) | ★★★★★ | Growing demand for specialized starch solutions; modification becomes core value proposition in advanced processing segments. |

| Trend | Asian market expansion & regional processing growth | ★★★★☆ | Regional facility development drives demand for local starch solutions; regional processing capabilities drive competition toward localization. |

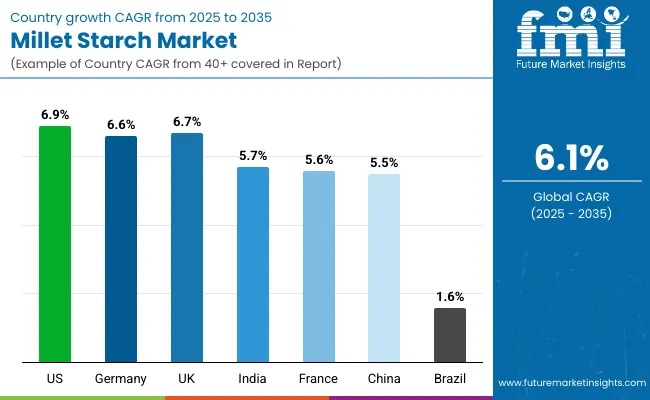

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| USA | 6.9% | Focus on industrial-grade processing solutions | FDA regulations; processing requirements |

| UK | 6.7% | Provide health-compliant applications | Market maturity; processing costs |

| Germany | 6.6% | Premium quality positioning | Over-specification; regulatory compliance |

| India | 5.7% | Lead with cost-effective processing systems | Infrastructure challenges; supply availability |

| France | 5.6% | Premium processing positioning | Processing precision; market maturity |

| China | 5.5% | Push high-volume processing solutions | Health regulations; processing complexity |

| Brazil | 1.6% | Focus on agricultural integration | Infrastructure challenges; market development |

The millet starch market demonstrates varied regional dynamics with growth leaders including USA (6.9% growth rate) and UK (6.7% growth rate) driving expansion through processing initiatives and industrial capacity development. Steady Performers encompass Germany (6.6% growth rate), India (5.7% growth rate), and France (5.6% growth rate), benefiting from established food industries and advanced processing adoption. Mature Markets feature China (5.5% growth rate) and Brazil (1.6% growth rate), where processing technology advancement and quality standardization requirements support consistent growth patterns.

Regional synthesis reveals North American and European markets leading adoption through food processing expansion and industrial development, while Asian countries maintain steady expansion supported by technology advancement and regulatory standardization requirements. Emerging markets show strong growth driven by food applications and processing modernization trends.

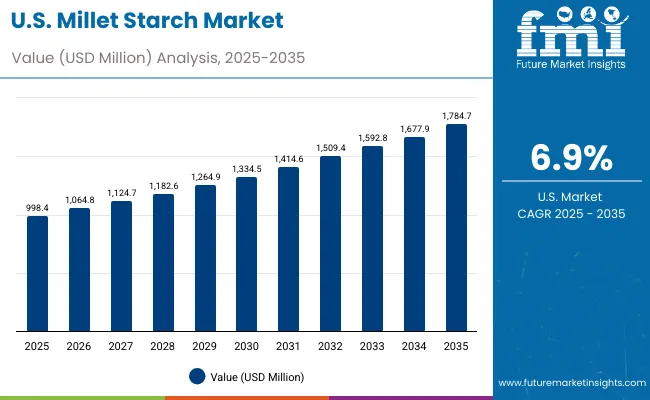

USA establishes industrial market growth through comprehensive food processing programs and advanced manufacturing infrastructure, integrating millet starch across food facilities and industrial applications. The country's 6.9% growth rate reflects established food industry relationships and advanced processing adoption that supports widespread use of alternative starches in manufacturing facilities and industrial operations. Growth concentrates in major processing centers, including California, Texas, and Illinois, where food technology showcases advanced starch deployment that appeals to manufacturers seeking proven processing capabilities and operational efficiency applications.

American processors leverage established distribution networks and comprehensive technical capabilities, including quality programs and application support that create customer relationships and operational advantages. The market benefits from advanced food standards and FDA requirements that support alternative starch use while supporting technology advancement and processing optimization.

UK establishes health-compliant market development through advanced food processing programs and established regulatory infrastructure, integrating millet starch across food facilities and specialty applications. The country's 6.7% growth rate reflects growing food industry relationships and established processing adoption that supports widespread use of alternative starches in food facilities and health-oriented operations. Growth concentrates in major processing areas, including London, Manchester, and Birmingham, where food technology showcases mature starch deployment that appeals to processors seeking proven health capabilities and operational efficiency applications.

British processors leverage established supply networks and comprehensive regulatory capabilities, including compliance programs and technical support that create customer relationships and operational advantages. The market benefits from established food standards and regulatory requirements that support alternative starch use while supporting technology advancement and processing optimization.

Germany's advanced food technology market demonstrates sophisticated millet starch integration with documented operational effectiveness in premium processing applications and modern facility installations through integration with existing quality systems and food infrastructure. The country maintains a 6.6% growth rate, leveraging traditional quality expertise and precision systems integration in starch technology. Processing centers, including North Rhine-Westphalia, Bavaria, and Baden-Württemberg, showcase premium installations where starch systems integrate with traditional quality platforms and modern facility management systems to optimize food operations and maintain processing quality profiles.

German processors prioritize starch precision and quality consistency in millet starch development, creating demand for premium systems with advanced features, including quality monitoring and automated processing systems. The market benefits from established quality infrastructure and commitment to food standards that provide long-term operational benefits and compliance with traditional quality processing methods.

India establishes cost-effective processing development through agricultural integration programs and comprehensive supply infrastructure, integrating millet starch across food facilities and traditional applications. The country's 5.7% growth rate reflects growing agricultural investment and increasing adoption of processing technology that supports expanding use of alternative starches in Indian food facilities. Growth concentrates in major agricultural areas, including Maharashtra, Karnataka, and Rajasthan, where agricultural technology development showcases integrated processing systems that appeal to Indian processors seeking advanced cost-effective solutions with facility efficiency compatibility.

Indian processors focus on maintaining traditional standards while adopting modern processing efficiency, creating demand for systems that balance performance with cost advantages. The market benefits from strong agricultural infrastructure and growing processing opportunities that support starch technology adoption while maintaining quality standards important to Indian food applications.

France's advanced food technology market demonstrates sophisticated millet starch integration with documented operational effectiveness in premium processing applications and modern facility installations through integration with existing processing systems and food infrastructure. The country maintains a 5.6% growth rate, leveraging traditional processing expertise and precision systems integration in starch technology. Processing centers, including Île-de-France, Auvergne-Rhône-Alpes, and Provence-Alpes-Côte d'Azur, showcase premium installations where starch systems integrate with traditional processing platforms and modern facility management systems to optimize food operations and maintain processing quality profiles.

French processors prioritize starch precision and processing consistency in millet starch development, creating demand for premium systems with advanced features, including quality monitoring and automated processing systems. The market benefits from established processing infrastructure and commitment to food standards that provide long-term operational benefits and compliance with traditional quality processing methods.

China's expanding food processing market demonstrates growing millet starch integration with increasing adoption in commercial food facilities and industrial processing operations. The country maintains a 5.5% growth rate, supported by government food modernization initiatives and processing infrastructure development programs that promote alternative starch systems for food facilities. Processing centers in Guangdong, Jiangsu, and Shandong provinces showcase commercial installations where starch systems integrate with modern processing equipment to optimize food production operations.

Chinese processors adopt starch systems that provide consistent operational performance and quality compliance features, particularly appealing in food regions where processing efficiency and quality standards represent critical operational requirements. The market benefits from growing food processing capabilities and technology integration that enable domestic production of advanced starch systems for food applications.

Brazil establishes agricultural integration development through commodity processing programs and agricultural infrastructure, integrating millet starch across food facilities and agricultural applications. The country's 1.6% growth rate reflects steady agricultural investment and gradual adoption of alternative processing technology that supports expanding use of specialty starches in Brazilian food facilities. Growth concentrates in major agricultural regions, including São Paulo, Minas Gerais, and Rio Grande do Sul, where agricultural technology development showcases integrated processing systems that appeal to Brazilian processors seeking agricultural integration solutions.

Brazilian processors focus on maintaining agricultural efficiency while adopting processing technology, creating demand for systems that balance performance with agricultural integration advantages. The market benefits from strong agricultural infrastructure and growing export opportunities that support starch technology adoption while maintaining efficiency standards important to Brazilian agricultural applications.

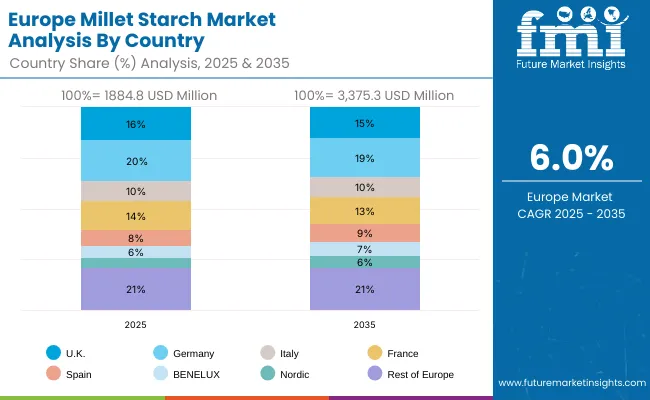

The European millet starch market is projected to represent a significant portion of global consumption, with strong regional distribution across major economies. Germany is expected to maintain its leadership position with USD 377.0 million in 2025, accounting for 20.0% European market share, supported by its advanced food processing infrastructure and major industrial centers.

United Kingdom follows with USD 301.4 million, representing 16.0% European market share in 2025, driven by comprehensive health programs and food technology development initiatives. France holds USD 263.9 million through specialized food applications and processing compliance requirements. Italy commands USD 188.5 million, while Spain accounts for USD 150.8 million in 2025. BENELUX maintains USD 113.1 million, Nordic countries hold USD 94.2 million, and the rest of Europe region accounts for USD 395.9 million, attributed to increasing starch system adoption in emerging European countries and specialized food facilities implementing processing modernization programs.

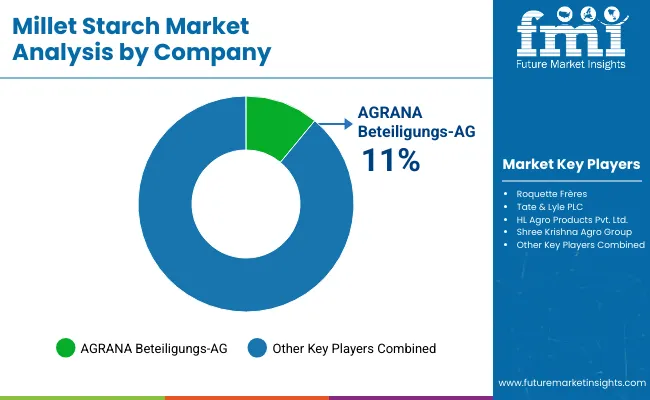

Millet starch is still at an early, emerging stage compared with mainstream corn, wheat, potato, and tapioca starches. As a result, public data do not yet support a precise "top five" ranking by millet-starch revenue. The competitive landscape is better understood through the wider specialty starch ecosystem.

Global starch manufacturers such as AGRANA Beteiligungs-AG, Roquette Frères, and Tate & Lyle PLC currently anchor this broader ecosystem with extensive portfolios of native and modified starches, strong R&D pipelines, and established supply relationships with food, beverage, and industrial customers. Their existing capabilities position them as natural candidates to scale up millet-based starch solutions as commercial demand develops.

On the regional side, Indian agro-processors such as HL Agro Products and Shree Krishna Agro Group are active in cereal- and pulse-based ingredients and could extend their processing expertise to millet once volumes justify dedicated investments. However, dedicated industrial-scale millet starch production remains limited today

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 5,400 million |

| Source | Pearl Millet, Finger Millet, Foxtail Millet, Proso Millet, Barnyard Millet, Kodo Millet, Little Millet |

| Application | Food & Beverages, Industrial, Pharmaceuticals, Animal Feed, Personal Care & Cosmetics |

| Functionality | Thickening Agent, Binding Agent, Gelling Agent, Stabilizer, Film Forming |

| Form | Native Millet Starch, Modified Millet Starch |

| End Use Format | Powder, Granular, Gel |

| Distribution Channel | Direct Sales (B2B), Distributors/Wholesalers, Online Sales, Retail Sales |

| Regions Covered | North America, Latin America, Europe, East Asia, South Asia & Pacific, Middle East & Africa |

| Countries Covered | China, Germany, United States, Japan, India, South Korea, France, United Kingdom, Brazil, and 25+ additional countries |

| Key Companies Profiled | AGRANA Beteiligungs -AG, Roquette Frères, Tate & Lyle PLC, HL Agro Products Pvt. Ltd., Shree Krishna Agro Group |

| Additional Attributes | Dollar sales by source and application categories, regional adoption trends across Europe, South Asia & Pacific, and North America, competitive landscape with processing suppliers and service providers, manufacturer preferences for quality consistency and operational reliability, integration with food platforms and processing monitoring systems. |

USD 5,400 million in 2025, rising to USD 9,785.8 million by 2035 (CAGR 6.1%).

Pearl millet with about 30% share due to higher starch yield and processing efficiency.

Food & beverages with 58% share, driven by bakery, beverages, and dairy alternatives.

Health-driven gluten-free demand, food processing expansion, and adoption of alternative grain starches.

USA (6.9%), UK (6.7%), and Germany (6.6%) due to advanced processing and strong food industry integration.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Millet Market Size and Share Forecast Outlook 2025 to 2035

Millet Flour Market Analysis by Pearl Millet, Finger Millet, Foxtail Millet, Proso Millet, Kodo Millet, and Others Through 2035

Starch-based Texturizing Agents Market Size and Share Forecast Outlook 2025 to 2035

Starch-based Packaging Market Size and Share Forecast Outlook 2025 to 2035

Starch-derived Fiber Market Size and Share Forecast Outlook 2025 to 2035

Starch-Based Bioplastics Packaging Market Insights - Growth & Forecast 2025 to 2035

Starch Derivatives Market by Product Type, Source, End Use and Region through 2035

Starches/Glucose Market

Starch Glucose Syrup Market

Starch Recovery Systems Market Outlook – Growth, Demand & Forecast 2023-2033

Distarch Phosphate Market Size and Share Forecast Outlook 2025 to 2035

UK Starch Derivatives Market Report – Size, Share & Innovations 2025-2035

Cornstarch Packaging Market Size and Share Forecast Outlook 2025 to 2035

Monostarch Phosphate Market Size and Share Forecast Outlook 2025 to 2035

Pea Starch Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

USA Starch Derivatives Market Analysis – Demand, Trends & Outlook 2025-2035

Pea Starch Concentrate Market Trends - Growth & Industry Forecast 2025 to 2035

Food Starch Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Wheat Starch Market Size and Share Forecast Outlook 2025 to 2035

ASEAN Starch Derivatives Market Trends – Growth, Demand & Forecast 2025-2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA