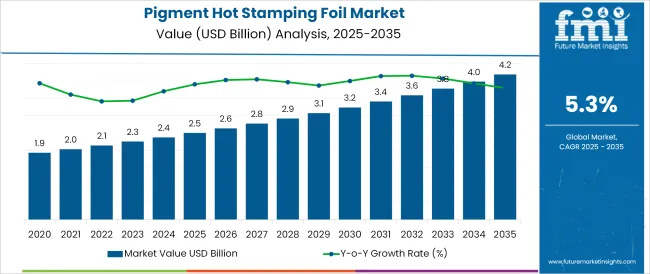

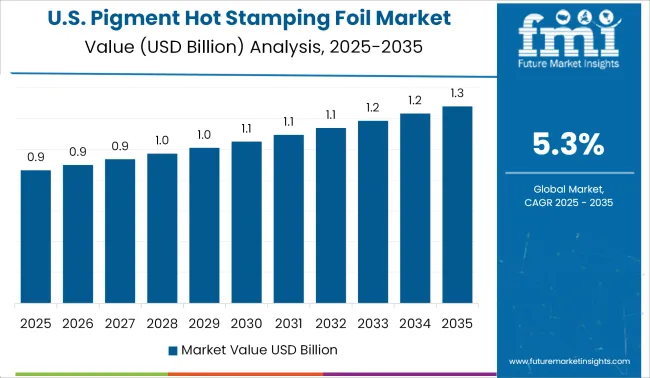

The Pigment Hot Stamping Foil Market is estimated to be valued at USD 2.5 billion in 2025 and is projected to reach USD 4.2 billion by 2035, registering a compound annual growth rate (CAGR) of 5.3% over the forecast period.

The pigment hot stamping foil market is being driven by increased demand for premium packaging and decorative finishes across industries such as cosmetics, confectionery, and luxury goods. This momentum is fueled by evolving aesthetic preferences, brand differentiation strategies, and advances in foil formulation technologies. Manufacturers have been introducing high‑pigment, eco‑friendly alternatives with improved printability, conformability, and scratch resistance.

Simultaneously, investments in digital hot stamping presses and inline finishing systems have enhanced production efficiency and reduced wastage. Regulatory pressures targeting solvent‑based coatings have spurred the adoption of water‑based and solvent‑free foils, aligning with sustainability goals.

The market outlook remains positive as brands continue to seek value‑added visual embellishments that couple consumer appeal with environmental compliance. Innovation in metallic and matte finishes, coupled with structured patterns and tactile textures, are expected to open new growth avenues in flexible packaging and upscale print applications.

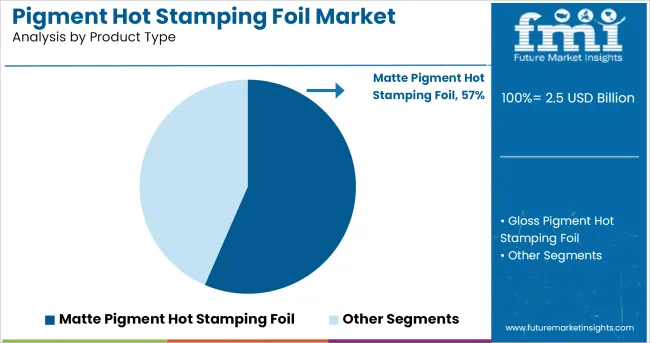

It is observed that the matte pigment hot stamping foil holds 56.50% of market revenue, making it the leading product type. This prevalence is attributed to the ability of matte finishes to lend a sophisticated, premium appearance that resonates with luxury and lifestyle brands. Enhanced customization options, such as soft-touch textures and subdued luster, have been favoured for high-end packaging.

Additionally, matte foils have demonstrated superior resistance to visible fingerprints and glare, bolstering shelf appeal. Improved pigment dispersion and UV stability have been achieved through technological refinements, reinforcing product durability.

As a result, production efficiency and aesthetic longevity have both been enhanced, supporting widespread uptake among converters and brand owners. This functional and visual synergy has anchored matte pigment foils as the dominant product type in the market.

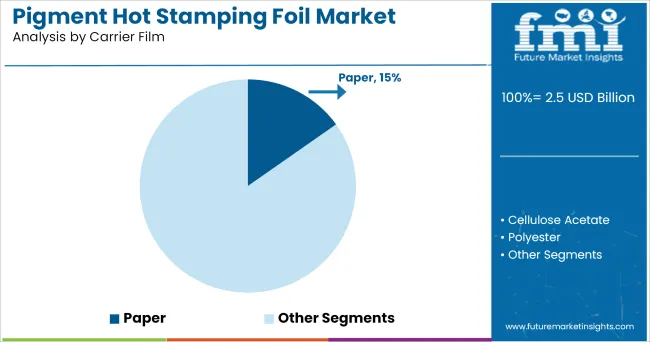

It is noted that the paper carrier film sub-segment encompasses 15.20% of the overall carrier film market, marking it as the most prominent choice in this category. The preference for paper carriers is driven by their biodegradability, recyclability, and alignment with circular economy objectives.

Increased brand emphasis on sustainable packaging has promoted paper carrier adoption, particularly where recycl ability post-stamping is required. Paper carriers have also been recognized for improved release properties, reduced static, and compatibility with lower-temperature stamping processes-facilitating energy savings and equipment wear reduction.

Production efficiencies have further been realized through better sheet handling and reduced downtime. Consequently, demand for paper-based carriers has been amplified, reinforcing their leadership within the carrier film segment.

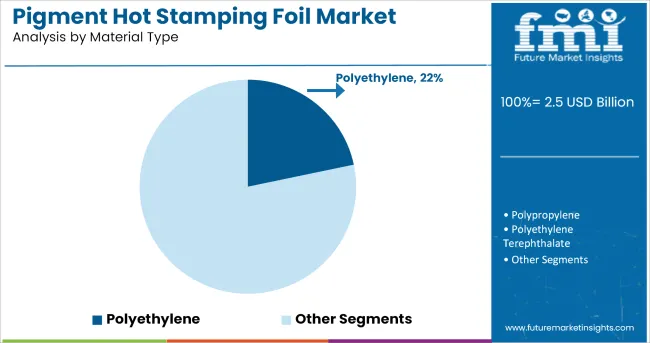

It is observed that the polyethylene material type occupies 21.70% of the market, establishing it as the dominant material category. This leadership is attributed to polyethylene’s exceptional flexibility, chemical resistance, and reliable adhesion to pigment coatings.

Low-density and metallocene polyethylene variants have become preferred due to enhanced conformability and minimal heat-set shrinkage during stamping. Price stability and wide availability have further contributed to its adoption by converters.

Functionally, polyethylene foils have been successfully integrated into food-grade and moisture-sensitive applications, where barrier performance and regulatory compliance are key. Enhanced durability and consistent print quality have been noted even under high-speed production conditions. Therefore, polyethylene’s balance of performance, cost-effectiveness, and compliance has secured its position as the leading material type in the pigment hot stamping foil market.

The excellent quality of pigment hot stamping foil is one of the key reasons behind its growing demand in the market. There are several high-quality pigment hot stamping foil available in the market which has several specialities such as excellent finish which is helping them to dominate the market. The availability of a wide range of colours is also helping pigment hot stamping foil to dominate the foil market.

In addition to this, Pigment hot stamping foil offers several same advantages which metallic hot stamping foil offers over liquid coatings and metallic inks for the application of colour. Due to such advantages and low-cost pigment hot stamping foil is preferred by the consumers over other alternatives.

The USA and Canada pigment hot stamping foil market is expected to propel growth in the forecasted period 2024 and 2035 and one of the key reasons behind the growth of pigment hot stamping foil market share in the USA and Canada region is its end-use in several industries.

Pigment hot stamping foil is widely used in several industries such as food & beverage, cosmetics & personal care, automotive, gift toy stationary and several other industries. Thus with the growth of these industries pigment hot stamping foil market is also expected to show growth.

In addition to this, when pigment hot stamping foil is applied with heat and pressure, the curves of the substrate are flattened out, resulting in a smooth surface in the printed area. Thus even on rough, and textured surfaces, clean, high-quality text and graphics can be achieved.

Another significant advantage of foil is the easy and clean application method. Machines tend to be relatively low cost and easy to operate since there are fewer process variables, and there are no process chemicals to worry about, which has health, safety, and environmental consequences.

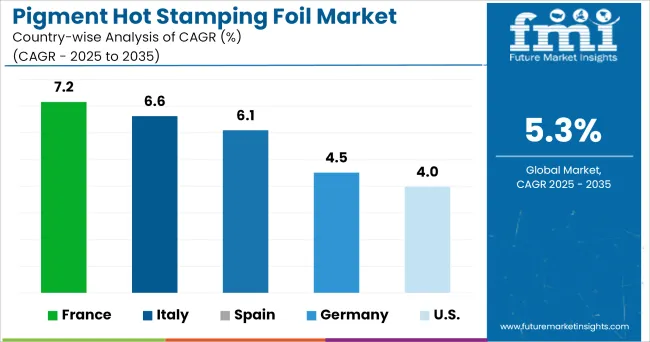

From the past few years, Europe has become one of the significant markets for pigment hot stamping foil and it is expected to show significant growth in the forecasted period 2024 to 2035.

As the packaging of the product plays a significant role in the product buying decision of a consumer. Several players in the industry are focusing on their packaging.

Thus pigment hot stamping foil is preferred by the product manufacturers to improve the packaging aesthetics and attracts more consumer base. Hence, the growing preference for pigment hot stamping foil for packaging is expected to propel growth to the pigment hot stamping foil market in the European region.

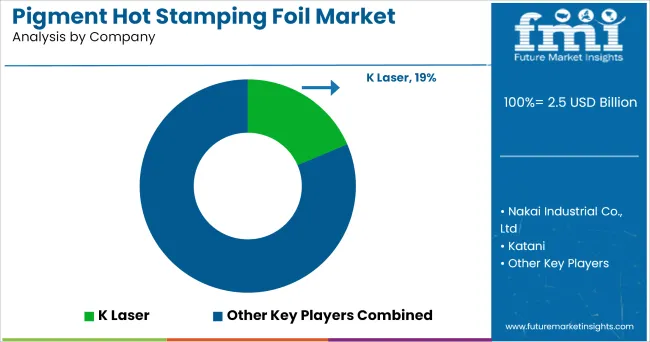

Some of the leading manufacturers of pigment hot stamping foil

These are the key players driving market demand for Pigment Hot Stamping Foil and they are investing in adopting advanced technology to manufacture pigment hot stamping foil.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides an in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global pigment hot stamping foil market is estimated to be valued at USD 2.5 billion in 2025.

The market size for the pigment hot stamping foil market is projected to reach USD 4.2 billion by 2035.

The pigment hot stamping foil market is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types in pigment hot stamping foil market are matte pigment hot stamping foil and gloss pigment hot stamping foil.

In terms of carrier film, paper segment to command 15.2% share in the pigment hot stamping foil market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Pigment Hot Stamping Foil Manufacturers

Pigmented Lesion Treatment Market Growth - Trends & Forecast 2025 to 2035

Feed Pigment Market Forecast and Outlook 2025 to 2035

Hyperpigmentation Lighteners Market Size and Share Forecast Outlook 2025 to 2035

Hyperpigmentation Skin Treatment Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Hyperpigmentation Treatment Market - Trends & Future Outlook 2025 to 2035

Paper Pigments Market Size and Share Forecast Outlook 2025 to 2035

Algal Pigments Market Size and Share Forecast Outlook 2025 to 2035

Resin Pigments Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Paper Pigments Manufacturers

Organic Pigments Market - Growth & Demand 2025 to 2035

Plastic Pigments Market

Cosmetic Pigment Market Forecast and Outlook 2025 to 2035

Metallic Pigments Market Size and Share Forecast Outlook 2025 to 2035

Dyes and Pigments Market

Arylamide Pigments Market Growth - Trends & Forecast 2025 to 2035

Riboflavin Pigment Market Trends – Industry Growth & Applications 2025 to 2035

Fluorescent Pigment Market Size and Share Forecast Outlook 2025 to 2035

Pearlescent Pigment Market Growth - Trends & Forecast 2025 to 2035

Carotenoids Pigment Market Trends - Natural Colorants & Industry Growth 2024 to 2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA