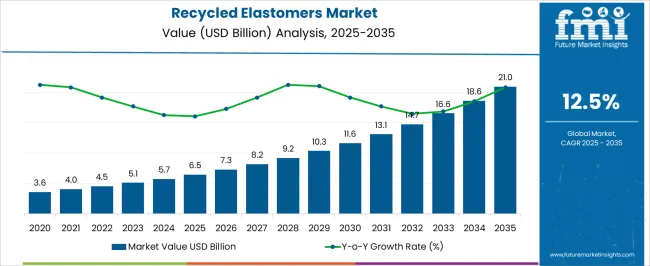

The Recycled Elastomers Market is estimated to be valued at USD 6.5 billion in 2025 and is projected to reach USD 21.0 billion by 2035, registering a compound annual growth rate (CAGR) of 12.5% over the forecast period. In the first five-year phase (2025 to 2030), the market will expand from USD 6.5 billion to approximately USD 11.7 billion, adding USD 5.2 billion, which accounts for 35.9% of the total incremental growth.

This phase is driven by rising demand for eco-efficient materials in automotive, construction, and industrial sectors, alongside increasing regulations favoring recycled content utilization. The second phase (2030 to 2035) is expected to generate USD 9.3 billion, contributing 64.1% of the total absolute growth as large-scale industrial adoption and technological advancements in elastomer recycling enhance output efficiency and material quality.

The market will benefit from expanding applications in asphalt modification, sports surfaces, and molded products, supported by cost advantages over virgin rubber. Regions with established recycling infrastructure, particularly in North America, Europe, and parts of the Asia-Pacific, will capture the largest share of this USD 14.5 billion opportunity, while emerging markets will increasingly participate due to policy shifts and investment in recycling facilities.

| Metric | Value |

|---|---|

| Recycled Elastomers Market Estimated Value in (2025 E) | USD 6.5 billion |

| Recycled Elastomers Market Forecast Value in (2035 F) | USD 21.0 billion |

| Forecast CAGR (2025 to 2035) | 12.5% |

The recycled elastomers market is witnessing accelerated adoption, supported by global sustainability mandates, waste reduction goals, and advancements in polymer recovery technologies. Industry stakeholders are capitalizing on circular economy principles, with increased focus on reusing post-consumer and post-industrial rubber for cost-efficient, low-emission applications.

Regulatory pressure on scrap tire disposal, combined with rising raw material costs in the virgin rubber industry, has prompted manufacturers to integrate recycled elastomers into mainstream formulations. The push for green building certifications and eco-friendly infrastructure is also enhancing demand for rubber-modified composites and asphalt.

Strategic collaborations between recyclers and end-use industries are improving the supply chain and encouraging technological upgrades for material consistency. Going forward, innovations in devulcanization, pyrolysis, and additive blending are expected to unlock new performance thresholds, expanding the application scope for recycled elastomers in high-value sectors.

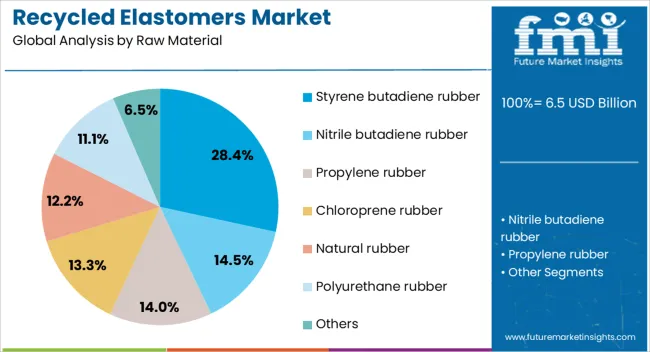

The recycled elastomers market is segmented by raw material, application, and geographic regions. By raw material, the recycled elastomers market is divided into Styrene butadiene rubber, Nitrile butadiene rubber, Propylene rubber, Chloroprene rubber, Natural rubber, Polyurethane rubber, and Others.

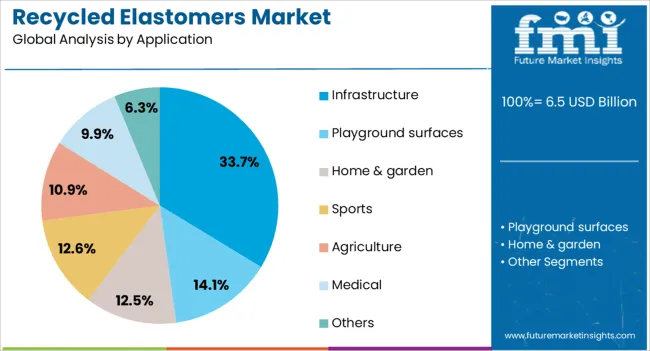

The recycled elastomers market is classified into Infrastructure, Playground surfaces, Home & garden, Sports, Agriculture, Medical, and Others. Regionally, the recycled elastomers industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Styrene butadiene rubber is anticipated to contribute 28.40% of the total market share in 2025, making it the leading raw material segment in the recycled elastomers market. Its widespread use in tires and automotive components has ensured a consistent and scalable supply of end-of-life rubber, suitable for mechanical or chemical recycling.

The material’s favorable physical properties, such as abrasion resistance and elasticity, remain intact post-recycling, making it suitable for integration into construction mats, modified asphalt, and molded products. Growing cost advantages, coupled with environmental compliance requirements, have driven its adoption across government-funded infrastructure and industrial refurbishment projects.

Additionally, improvements in material sorting and purification technologies have enhanced the quality and reliability of recycled SBR, further supporting its market leadership.

The infrastructure segment is projected to account for 33.70% of the recycled elastomers market revenue in 2025, positioning it as the leading application area. The integration of rubber-based modifiers in road construction, sound barriers, drainage systems, and vibration-dampening applications is fueling demand.

Recycled elastomers are increasingly being used in civil engineering projects due to their durability, impact resistance, and thermal stability. Government policies incentivizing the use of green construction materials, coupled with the environmental benefits of reduced landfill dependency, are driving adoption.

Moreover, lifecycle cost reductions and lower maintenance requirements are making recycled rubber solutions appealing for both public and private infrastructure investments. As urbanization accelerates and sustainability targets become more stringent, infrastructure will remain the most promising growth vertical for recycled elastomers.

The recycled elastomers market is expanding due to growing demand for sustainable materials and increased regulatory pressure. Growth in 2024 and 2025 was driven by the automotive and construction sectors, where recycled elastomers are used in tires and flooring. Opportunities exist in the development of high-performance recycled materials. Emerging trends include the incorporation of recycled elastomers in eco-friendly product lines. However, market restraints such as inconsistent quality and high processing costs hinder widespread adoption.

The major growth driver in the recycled elastomers market is the increasing demand for sustainable materials. In 2024, automotive manufacturers focused on using recycled elastomers in tire production to meet environmental regulations. Additionally, the construction industry adopted recycled materials for flooring and insulation. This trend is fueled by rising awareness of environmental impact, driving businesses to incorporate recycled elastomers into their product lines. The need for cost-effective, eco-friendly materials continues to propel growth in multiple industries, strengthening the market’s position.

Opportunities in the market are centered around developing high-performance recycled elastomers that meet industry standards. In 2025, manufacturers focused on improving the durability and reliability of recycled elastomers for use in demanding applications, including automotive and industrial machinery. By enhancing the properties of recycled elastomers, suppliers aim to cater to high-end markets where performance is critical. These innovations open doors for market expansion, particularly in applications requiring reliable, cost-effective materials with low environmental impact.

Emerging trends in the recycled elastomers market include a shift towards eco-friendly product development. In 2024, consumers and manufacturers alike became more focused on using recycled materials in everyday products, from footwear to automotive parts. As part of this movement, there was an increasing focus on producing elastomers that not only perform well but also have a reduced environmental footprint. This trend indicates a broader move toward a circular economy, where waste is minimized, and resources are continually repurposed.

Key restraints in the market include inconsistent quality and high processing costs. In 2024, challenges in ensuring uniformity in recycled elastomers hindered their adoption, particularly in industries requiring high precision and durability. The complex and expensive process of cleaning and transforming used elastomers into usable raw materials also raised production costs. These factors prevented smaller manufacturers and companies with lower budgets from fully utilizing recycled elastomers, limiting broader market adoption despite increasing demand for sustainable alternatives.

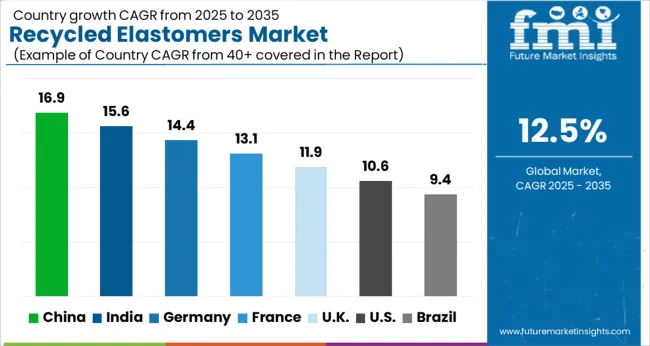

The global recycled elastomers market is projected to grow at 12.5% CAGR from 2025 to 2035. China leads with 17% CAGR, driven by the rapid adoption of recycling technologies, industrial demand for sustainable materials, and a growing focus on circular economy practices. India follows at 16%, fueled by increasing awareness of environmental sustainability, strong manufacturing capabilities, and rising demand for recycled elastomers in automotive and construction sectors.

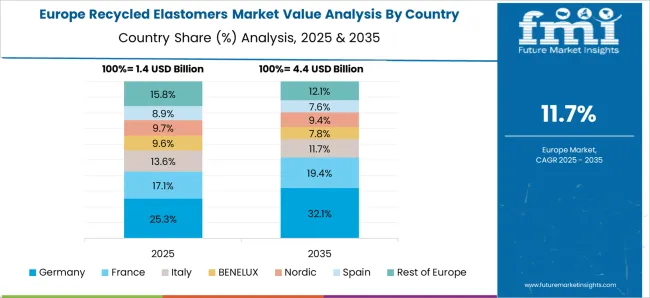

France records 13% CAGR, driven by stringent environmental regulations and a focus on green materials in manufacturing. The United Kingdom grows at 12%, while the United States posts 11%, reflecting steady demand in mature markets, with a focus on sustainability and reducing carbon footprints. Asia-Pacific dominates market growth, while Europe and North America emphasize regulatory compliance and innovative recycling technologies.

The recycled elastomers market in China is forecasted to grow at 17% CAGR, driven by rapid industrialization, increasing demand for eco-friendly materials, and government policies promoting recycling and waste reduction. The automotive, construction, and manufacturing sectors increasingly use recycled elastomers for their performance, cost-effectiveness, and environmental benefits. Additionally, China’s focus on the circular economy and green production standards boosts the adoption of recycled elastomers across industries.

The recycled elastomers market in France is expected to grow at 13% CAGR, supported by stringent environmental regulations and the increasing demand for sustainable materials in various industries. France’s strong automotive and construction sectors, combined with a rising focus on reducing carbon emissions, fuel the adoption of recycled elastomers. The country’s emphasis on sustainability and circular economy principles drives the demand for environmentally-friendly materials, particularly in manufacturing processes.

The solid-state lighting market in France is expected to grow at 15% CAGR, supported by the country’s green building regulations and demand for energy-efficient lighting solutions. France’s focus on reducing carbon emissions and improving energy efficiency in public infrastructure leads to widespread adoption of LED and smart lighting technologies. Additionally, the growing popularity of energy-efficient lighting in the commercial sector contributes to market growth. Sustainability-driven consumer preferences further accelerate the demand for eco-friendly lighting solutions.

The recycled elastomers market in the United Kingdom is projected to grow at 12% CAGR, fueled by government support for sustainable manufacturing practices and growing consumer demand for eco-friendly products. The UK’s commitment to the circular economy and carbon reduction further boosts the demand for recycled elastomers in automotive, construction, and consumer goods industries. Innovations in recycling technologies and the development of high-performance recycled elastomers also contribute to the market’s growth.

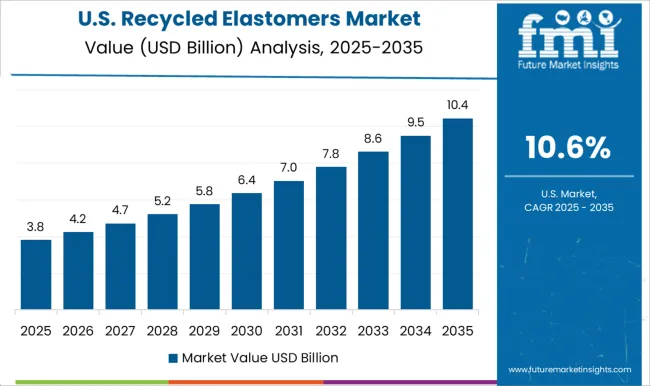

The recycled elastomers market in the United States is projected to grow at 11% CAGR, supported by growing demand for recycled materials in automotive, construction, and industrial sectors. The USA commitment to reducing waste and adopting sustainable manufacturing practices drives the market for recycled elastomers. Increasing investments in recycling technologies and consumer demand for green products further promote the use of recycled elastomers in various applications, particularly in high-demand sectors like automotive and packaging.

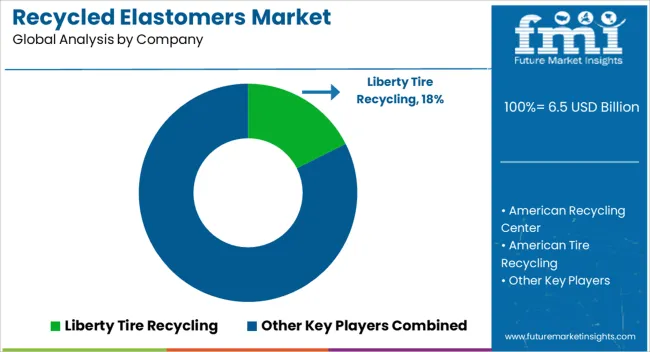

The recycled elastomers market is dominated by Liberty Tire Recycling, which leads through its extensive infrastructure and innovative processes for reclaiming and repurposing tire rubber for use in various industries, including automotive, construction, and sports equipment. Liberty Tire Recycling’s dominance is supported by its strong network of recycling facilities, advanced processing techniques, and partnerships with major automotive and industrial companies.

Key players such as Genan Holding, Green Rubber Global, and Austin Rubber Company LLC hold significant market shares by offering high-quality recycled elastomer products, focusing on performance, sustainability, and environmental compliance across different applications. These companies emphasize reducing carbon footprints, increasing recycling efficiency, and meeting growing demand for eco-friendly alternatives in manufacturing.

Emerging players like American Recycling Center, J. Allcock & Sons Limited, Klean Industries, Monmouth Rubber & Plastics Corp., RubberForm Recycled Products LLC, and West Coast Rubber Recycling are expanding their market presence by offering specialized solutions for niche markets, including molded products, rubber matting, and sealants.

Their strategies include investing in new technologies, improving product versatility, and targeting regional markets with cost-effective recycling options. Market growth is driven by increasing regulations on waste management, the rising need for sustainable materials, and the growing emphasis on the circular economy. Innovations in processing technologies, such as pyrolysis and devulcanization, will continue to shape competitive dynamics in the global recycled elastomers market.

Several major elastomer manufacturers and recycling companies are collaborating to develop innovative solutions for recycling. For example, companies like Michelin, Bridgestone, and Goodyear are working on projects to improve tire recycling processes and integrate recycled rubber into tire production. These partnerships help scale the technology for broader use across various industries and accelerate the adoption of recycled elastomers.

| Item | Value |

|---|---|

| Quantitative Units | USD 6.5 Billion |

| Raw Material | Styrene butadiene rubber, Nitrile butadiene rubber, Propylene rubber, Chloroprene rubber, Natural rubber, Polyurethane rubber, and Others |

| Application | Infrastructure, Playground surfaces, Home & garden, Sports, Agriculture, Medical, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Liberty Tire Recycling, American Recycling Center, American Tire Recycling, Austin Rubber Company LLC, Genan Holding, Green Rubber Global, GRP Ltd., J. Allcock & Sons Limited, Klean Industries, Monmouth Rubber & Plastics Corp., RubberForm Recycled Products LLC, and West Coast Rubber Recycling |

| Additional Attributes | Dollar sales by elastomer type and end use, demand dynamics across automotive, construction, and footwear sectors, regional trends in recycled elastomer consumption, innovation in processing technologies and material performance, environmental impact of recycling processes, and emerging use cases in sustainable manufacturing and product development. |

The global recycled elastomers market is estimated to be valued at USD 6.5 billion in 2025.

The market size for the recycled elastomers market is projected to reach USD 21.0 billion by 2035.

The recycled elastomers market is expected to grow at a 12.5% CAGR between 2025 and 2035.

The key product types in recycled elastomers market are styrene butadiene rubber, nitrile butadiene rubber, propylene rubber, chloroprene rubber, natural rubber, polyurethane rubber and others.

In terms of application, infrastructure segment to command 33.7% share in the recycled elastomers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Recycled Concrete Aggregates Market Size and Share Forecast Outlook 2025 to 2035

Recycled Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Recycled Plastic Pipes Market Size and Share Forecast Outlook 2025 to 2035

Recycled Glass Aggregates Market Size and Share Forecast Outlook 2025 to 2035

Recycled Ocean Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Recycled Metal Market Size and Share Forecast Outlook 2025 to 2035

Recycled Glass Market Size and Share Forecast Outlook 2025 to 2035

Recycled Thermoplastic Market Size and Share Forecast Outlook 2025 to 2035

Recycled Asphalt Pavement Market Size and Share Forecast Outlook 2025 to 2035

Recycled Materials Packaging Market Size and Share Forecast Outlook 2025 to 2035

Recycled Paper Packaging Market Size and Share Forecast Outlook 2025 to 2035

Recycled Carbon Fiber Market Size and Share Forecast Outlook 2025 to 2035

Recycled Prescription Bag Market Size and Share Forecast Outlook 2025 to 2035

Recycled PET Packaging Market Size, Share & Forecast 2025 to 2035

Recycled Fabric Bag Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Recycled Scrap Metal Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Recycled Prescription Bag Industry

Competitive Breakdown of Recycled Paper Suppliers

Recycled Polyethylene Terephthalate (rPET) Packaging Market Growth and Trends 2025 to 2035

Recycled Glass Packaging Market Trends & Growth Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA