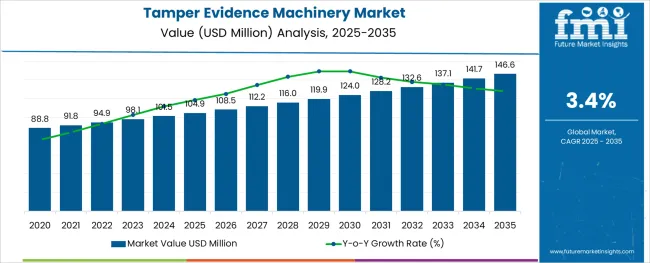

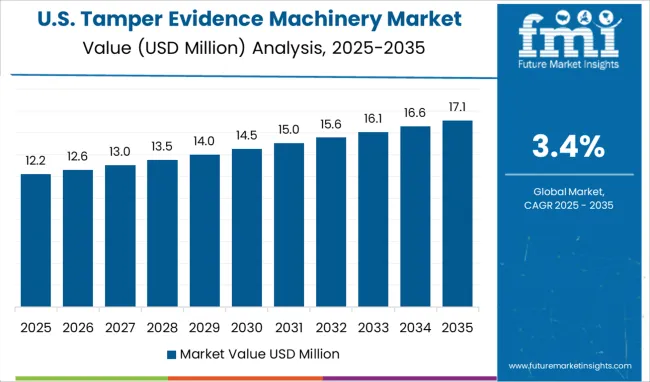

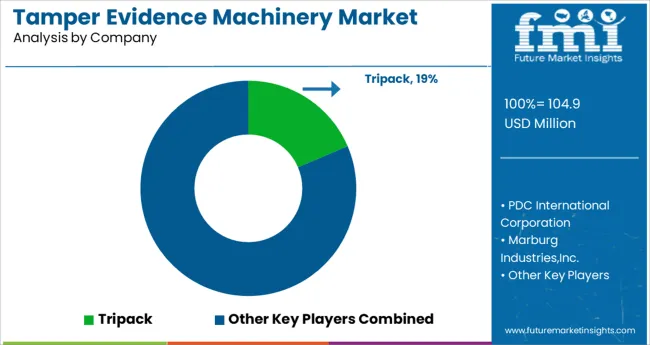

The Tamper Evidence Machinery Market is estimated to be valued at USD 104.9 million in 2025 and is projected to reach USD 146.6 million by 2035, registering a compound annual growth rate (CAGR) of 3.4% over the forecast period.

The tamper evidence machinery market is witnessing steady expansion, supported by increasing regulatory mandates, brand protection needs, and rising consumer demand for secure packaging across multiple industries. With growing concerns around product adulteration and counterfeit goods, manufacturers are investing in tamper-evident technologies to ensure packaging integrity throughout the supply chain. Innovation in material handling, sensor automation, and sealing accuracy is enabling more reliable and efficient production workflows.

Real-time quality control and vision inspection systems are being integrated into tamper evidence machines to meet stringent compliance benchmarks, particularly in food, pharmaceutical, and cosmetic sectors. Packaging line flexibility, demand for eco-conscious solutions, and the need for minimal human intervention have further strengthened the adoption of advanced sealing machinery.

Emerging markets are adopting global packaging safety standards, fueling investments in scalable, modular systems. As regulations become more harmonized across regions, tamper-evident solutions are expected to remain a core requirement in high-risk and high-value product categories.

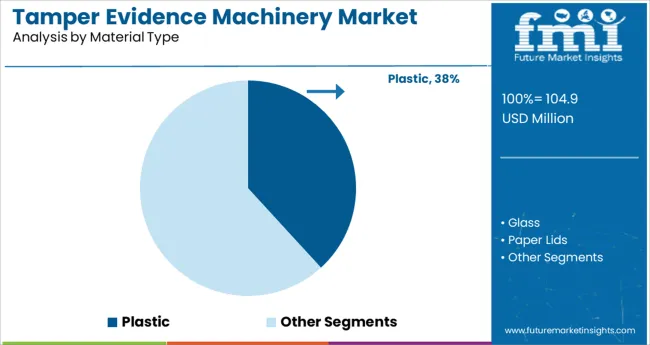

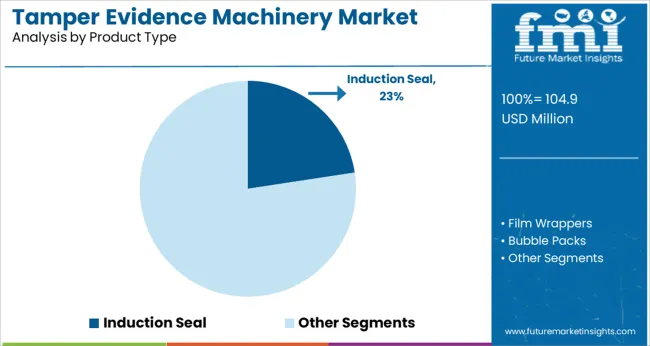

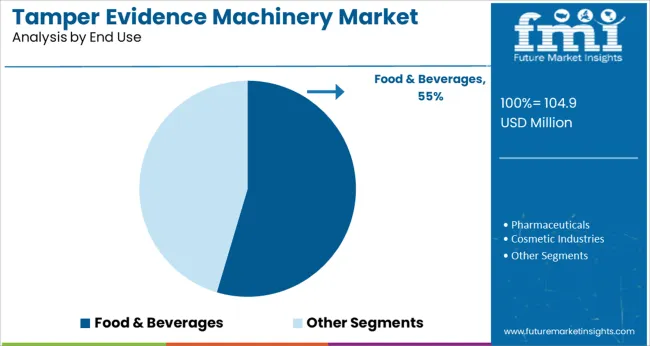

The market is segmented by Material Type, Product Type, and End Use and region. By Material Type, the market is divided into Plastic, Glass, Paper Lids, and Metals. In terms of Product Type, the market is classified into Induction Seal, Film Wrappers, Bubble Packs, Vacuum Packaging, Stretch Wrapping, and Bottle Mouth Inner Seals. Based on End Use, the market is segmented into Food & Beverages, Pharmaceuticals, and Cosmetic Industries.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The plastic subsegment is projected to account for 38.2% of total revenue within the material type category in 2025, establishing it as the leading choice. This leadership is driven by plastic’s lightweight properties, cost efficiency, and compatibility with automated machinery across various sealing formats.

Its adaptability to different product types and shapes makes it the most versatile material for tamper evidence applications. Manufacturers have increasingly adopted recyclable and bio-based plastics, meeting sustainability goals while maintaining performance requirements.

The material’s durability and resistance to external tampering forces have made it especially valuable for high-speed production environments. Additionally, plastic enables precise seal formation through technologies such as induction sealing and shrink banding, further reinforcing its dominance in tamper evidence packaging.

The induction seal segment is expected to contribute 22.6% of total market revenue in 2025, positioning it as a leading product type in tamper evidence machinery. The preference for induction sealing has been fueled by its non-contact sealing process, which ensures consistent hermetic seals without damaging container contents.

This technology offers high-speed throughput and is adaptable to a wide range of container materials including plastic and glass, making it suitable for both manual and fully automated packaging lines. The ability to form tamper-evident seals without added adhesives or mechanical force has made induction sealing the standard across food, pharmaceutical, and personal care applications.

Additionally, the method supports longer shelf life, leakage prevention, and compliance with FDA and international safety standards, ensuring sustained growth across manufacturing sectors.

The food and beverages segment is projected to account for 54.6% of total revenue in the tamper evidence machinery market by 2025, making it the dominant end use category. This leadership is attributed to the sector’s stringent focus on product safety, traceability, and shelf life assurance.

With increasing incidences of contamination and growing consumer awareness, food and beverage manufacturers are under pressure to implement secure packaging solutions that provide visible signs of tampering. Regulatory authorities across key markets are enforcing mandatory tamper-evident features for certain product categories, accelerating investment in advanced sealing equipment.

Additionally, the rise of ready-to-eat meals, functional beverages, and e-commerce distribution channels has intensified the need for efficient tamper-evident solutions that maintain product integrity throughout complex supply chains. The scalability, line speed compatibility, and regulatory compliance advantages offered by modern tamper evidence machinery have made it indispensable in high-volume food and beverage production environments.

Tamper evidence machinery are witnessing immense demand; manufacturers are turning this opportunity to their advantage

Tamper evident sealing of consumable products is advantageous to both the manufacturer and the consumer. As a result, the sales of tamper evidence machinery are anticipated to witness a rise throughout 2035. Moreover, tamper evident banding protects the goods from counterfeiting, which has a negative impact on sales and brand image. At the customer end, tamper evident packaging ensures that no product defect has occurred.

Rising adoption of tamper evidence machinery in various end use sectors to propel market growth. Tamper evidence machinery is frequently employed for this purpose in food, beverage, pharmaceutical, personal care, home care, and other industries.

Other tamper evident packaging options, such as tamper evident closures, labels, liners, and others, have slowed the market for tamper evident bands, hampering the tamper evidence machinery market growth. The main difference between standard sleeving machinery and tamper evidence machinery is that tamper evident banding machinery sleeve packs a highly intricate little area around the container's neck.

To better understand the tamper-evident meaning, here are some applications that help key players to distinguish their products in the tamper evidence machinery market.

Tamper-evident plastic and metal security seals

As tamper-evident refers to protection against manipulation, a plastic or metal security seal can provide this. The type chosen will be determined by the level of security necessary as well as the requirements of the applicable rules. So, before settling on one type or another, it's a good idea to look over the specs of each model, since these will show whether regulations are met.

Security bags

Security bags are impregnable since they are sealed with a zipper seal. They are used to convey sensitive papers and money.

Security envelopes

Precintia courier envelopes include an ultra-strong adhesive that offers evidence of attempted opening. There are particular envelope versions for collecting samples, transporting currency, and transporting medical records and X-rays.

Security labels

Also known as void labels, are tamper-evident devices because they provide evidence of tampering when removed to open the packing or container. In our post on security labels, we go over the many types of security labels available.

Impenetrable packaging

In this context, tamper-evident refers to the same notion as guarantee seals on packaging (for example, in the food sector), as well as the packaging itself, which has already been tested for tampering, as in the case of pharmaceutical packaging.

North America Tamper Evidence Machinery Market

During the forecast period, North America is anticipated to hold the second largest share of 16% percent in the market, followed by Europe. The numerous advantages of tamper evidence machinery, such as increased production rates and product safety, are driving growth of tamper evidence machinery market size in the North American region.

Intelligent packaging machines are one of the most recent breakthroughs in packaging. Other benefits of using this technology include more precision because no human interaction is required, faster outcomes due to the usage of robots, and customised options with different speed changes.

Tamper evident banding applicators are a popular alternative in many physical retail organisations as a new way to prevent product tampering. For secure item sealing, these machines employ flocked or adhesive-backed seals.

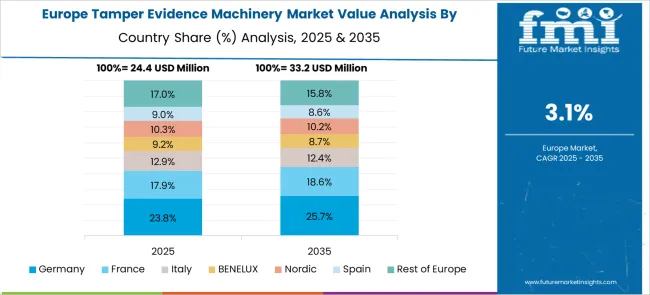

Europe Tamper Evidence Machinery Market

Europe is projected to hold largest share of 19% in tamper evidence machinery market during the forecast period. The rise in sales of tamper evidence machinery in this region is owing to the ability of tamper evidence machinery to apply tamper evidence to unattended goods, implying large-scale manufacturing lines.

Tamper evident bands are expected to be the second-largest market in Europe. With the growth of private labelling, there is an increase in branded and private-label commodities where tamper evidence packaging or smart packaging is estimated to help firms prevent tampering.

Startups in the tamper evidence machinery market are becoming increasingly engaged in initiating tactics such as targeted marketing, CSR programmes, and so on, in order to increase global prominence.

A notable tendency that has been noted across the board is that these organizations are now aiming to handle a certain business-related activity in a country with favorable legislation. As a result, these organizations are able to cut costs while still employing industry experts at every important juncture of their individual organization.

Due to a considerable number of competitors, the tamper evidence machinery market is moderately competitive. Several key market participants in the global tamper evidence machinery market are currently concentrating their efforts on establishing effective joint ventures, acquisitions, and/or collaborations in order to increase their respective customer bases.

Key players stand to gain from being able to cater to their designated target bases on both a global and domestic basis. This factor, together with good prospects coming from Asia-Pacific developing nations such as India, China, Taiwan, Indonesia, and others, is expected to offer a spike in growth opportunities for companies during the projection period.

The key market players profiled in the report include Tripack, PDC International Corporation, Marburg industries, Inc., American film & machinery, Systempak Ltd, Security technology Inc., Zircon Technologies India Limited, Pack Seals Industries, Matrix Technologies, and Dynaflex Pvt. Ltd.

Recent Developments in the Tamper Evidence Machinery Market:

| Report Attribute | Details |

|---|---|

| Growth Rate | CAGR of 3.4% from 2025 to 2035 |

| Base Year for Estimation | 2025 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD million and CAGR from 2025-2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered | Material Type, Product Type, End Use, Region |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia; Oceania; Middle East and Africa |

| Key Countries Profiled | USA, Canada, Brazil, Argentina, Germany, UK, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, ASEAN, GCC, South Africa |

| Key Companies Profiled | Tripack; PDC International Corporation; Marburg industries, Inc.; American film & machinery; Systempak Ltd; Security technology Inc.; Zircon Technologies India Limited; Pack Seals Industries; Matrix Technologies; Dynaflex Pvt. Ltd. |

| Customization | Available Upon Request |

The global tamper evidence machinery market is estimated to be valued at USD 104.9 million in 2025.

It is projected to reach USD 146.6 million by 2035.

The market is expected to grow at a 3.4% CAGR between 2025 and 2035.

The key product types are plastic, glass, paper lids and metals.

induction seal segment is expected to dominate with a 22.6% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Tamper Evident Label Market Forecast and Outlook 2025 to 2035

Tamper Evident Labeler Market Size and Share Forecast Outlook 2025 to 2035

Tamper Proof Packaging Market Size and Share Forecast Outlook 2025 to 2035

Tamper Band Market Analysis – Size, Share, and Forecast Outlook 2025 to 2035

Leading Providers & Market Share in Tamper Evident Packaging

Market Share Breakdown of Leading Tamper Evident Label Manufacturers

Tamper Evident Packaging Market Trends, Growth, Forecast 2025-2035

Tamper Evident Pots & Tubs Market

Tamper Evident Shrink Bands Market

Tamper Evident Bag Sealers Market

Plastic Tamper Evident Closures Market

Evidence Collection Tubes Market Size and Share Forecast Outlook 2025 to 2035

Real World Evidence Solutions Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Turbomachinery Control System Market Size and Share Forecast Outlook 2025 to 2035

Planting Machinery Market Size and Share Forecast Outlook 2025 to 2035

Printing Machinery Market Size and Share Forecast Outlook 2025 to 2035

Packaging Machinery Market Insights – Growth & Forecast 2025 to 2035

Collating Machinery Market

Mini Track Machinery Market Size and Share Forecast Outlook 2025 to 2035

Separation Machinery Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA