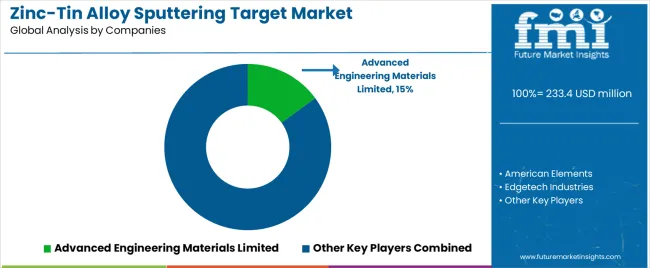

The global zinc-tin alloy sputtering target market is projected to grow from USD 233.4 million in 2025 to approximately USD 508.6 million by 2035, recording an absolute increase of USD 275.2 million over the forecast period. This translates into a total growth of 117.9%, with the market forecast to expand at a compound annual growth rate (CAGR) of 8.1% between 2025 and 2035. The overall market size is expected to grow by 2.2X during the same period, supported by accelerating demand for advanced thin-film deposition processes in electronics manufacturing, breakthrough developments in optical coating technologies, and expanding adoption of precision sputtering materials across semiconductor and display production facilities.

The consistent market expansion reflects the critical role of zinc-tin alloy targets in enabling advanced manufacturing processes across multiple technology sectors. Major electronics manufacturers worldwide are increasingly incorporating specialized zinc-tin alloy sputtering targets to achieve superior film uniformity and enhanced deposition characteristics for next-generation electronic devices, while breakthrough developments in high-purity alloy composition and precision manufacturing techniques are creating substantial demand for specialized sputtering materials that deliver exceptional performance reliability under demanding production conditions.

Manufacturing capabilities are advancing rapidly as leading material suppliers invest in sophisticated alloy production facilities and proprietary composition control systems to meet growing market demand for enhanced purity levels and reduced impurity contamination. The technology landscape continues evolving with innovations in powder metallurgy processes, vacuum melting techniques, and quality control systems that improve target density while reducing manufacturing variations. Sputtering target manufacturers and materials specialists are collaborating extensively to develop next-generation zinc-tin alloy products that address specific performance requirements across semiconductor fabrication, optical device production, and advanced coating applications.

Quality standards are becoming increasingly stringent as applications demand higher purity specifications and greater consistency under extreme processing conditions, including high-temperature sputtering, reactive atmosphere exposure, and extended operational cycles. Industry certification programs and validation protocols ensure consistent material performance while supporting market confidence in zinc-tin alloy target adoption across critical manufacturing processes and regulated production environments. Regulatory compliance requirements for electronics manufacturing and materials handling applications are driving investments in comprehensive quality management systems and testing protocols throughout the materials supply chain.

International collaboration is accelerating market development as major manufacturing projects require coordinated efforts between multiple sputtering target suppliers and electronics manufacturers. Global technology companies are establishing standardized specifications for zinc-tin alloy performance that influence worldwide manufacturing standards and create opportunities for specialized materials producers. Materials engineering firms are forming strategic partnerships with sputtering target developers to create application-specific solutions tailored to emerging device architectures and advanced manufacturing requirements.

Investment patterns are shifting toward integrated solution development as major electronics manufacturers seek comprehensive sputtering target systems that combine superior material properties with advanced target bonding technologies and optimized utilization characteristics. Technology companies are forming joint ventures with materials providers to develop customized alloy compositions, while manufacturing facilities are acquiring stakes in specialized sputtering target companies to ensure access to cutting-edge materials technologies for their production and development programs. This trend toward strategic partnerships and materials integration is reshaping competitive dynamics across the electronics manufacturing value chain.

Market maturation is evident in the emergence of specialized application segments that demand unique zinc-tin alloy characteristics and performance specifications. Semiconductor applications require extremely consistent deposition rates and minimal particle generation under cleanroom manufacturing requirements, while optical coating systems need alloy targets that maintain stability and uniformity when processing complex multilayer structures and precision optical components. These specialized requirements are driving innovation in alloy composition, target manufacturing processes, and quality control methodologies that extend beyond traditional sputtering and thin-film deposition applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 233.4 million |

| Market Forecast Value (2035) | USD 508.6 million |

| Forecast CAGR (2025 to 2035) | 8.1% |

| SEMICONDUCTOR MANUFACTURING ADVANCEMENT | OPTICAL COATING EXPANSION | DISPLAY TECHNOLOGY ENHANCEMENT |

|---|---|---|

| Next-Generation Devices - Advanced semiconductor fabrication requiring specialized zinc-tin alloy sputtering targets for integrated circuit production, microprocessor manufacturing, and memory device applications with superior film quality and deposition uniformity for critical electronic components and high-performance computing applications. | Precision Optics - Optical device manufacturing implementing zinc-tin alloy targets for specialized coating applications requiring exceptional transparency, reflectance control, and anti-reflection properties for advanced lens systems, display panels, and photonic device production with enhanced optical performance characteristics. | Flat Panel Displays - Display manufacturing technology requiring zinc-tin alloy sputtering materials for transparent conductive layer production, electrode fabrication, and specialized coating applications supporting advanced display technologies including OLED, LCD, and emerging display architectures with superior electrical and optical properties. |

| Miniaturization Trends - Electronics miniaturization driving demand for precision sputtering targets capable of producing ultra-thin films and controlled layer thickness for advanced packaging, interconnect fabrication, and component integration applications requiring exceptional dimensional accuracy and material consistency under demanding manufacturing conditions. | Anti-Reflective Coatings - Growing demand for specialized optical coatings requiring zinc-tin alloy targets for solar panel applications, camera lens systems, and precision instruments with enhanced light transmission characteristics and reduced reflection losses for improved efficiency and performance in optical systems. | Touch Screen Technology - Interactive display production requiring specialized conductive coating materials implementing zinc-tin alloy sputtering targets for touch-sensitive interfaces, flexible displays, and advanced human-machine interaction systems with superior electrical conductivity and optical transparency requirements. |

| Advanced Packaging - Semiconductor packaging advancement requiring specialized sputtering materials for interconnect fabrication, barrier layer deposition, and component protection applications supporting advanced chip architectures and high-density integration requirements with enhanced electrical and thermal performance characteristics. | Industrial Coatings - Specialized coating applications requiring zinc-tin alloy targets for protective film deposition, corrosion resistance enhancement, and functional surface modification across various industrial applications demanding superior durability and performance under challenging environmental conditions. | Automotive Electronics - Vehicle electronics expansion requiring advanced display technologies and electronic component manufacturing implementing zinc-tin alloy sputtering targets for automotive-grade applications supporting driver assistance systems, infotainment displays, and vehicle control systems with enhanced reliability and performance specifications. |

| Category | Segments / Values |

|---|---|

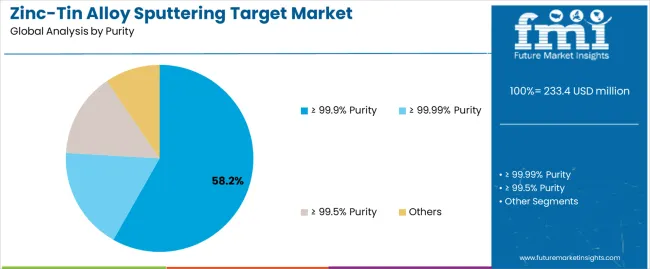

| By Purity | ≥ 99.99% Purity; ≥ 99.9% Purity; ≥ 99.5% Purity; Others |

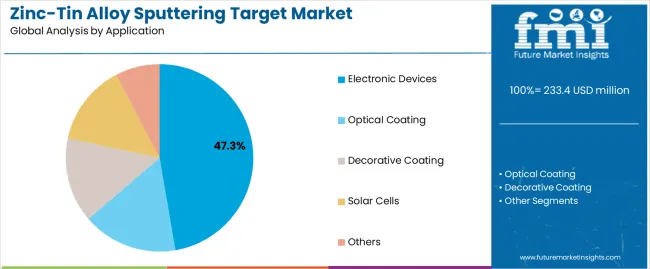

| By Application | Electronic Devices; Optical Coating; Decorative Coating; Solar Cells; Others |

| By End-User | Semiconductor Manufacturers; Display Panel Producers; Optical Device Manufacturers; Research Institutions; Others |

| By Target Size | Small Targets (< 6 inches); Medium Targets (6-12 inches); Large Targets (> 12 inches); Custom Sizes |

| By Distribution Channel | Direct Sales; Authorized Distributors; Online Platforms; Technical Partners |

| By Region | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Segment | 2025-2035 Outlook |

|---|---|

| ≥ 99.9% Purity |

|

| ≥ 99.99% Purity |

|

| ≥ 99.5% Purity |

|

| Others |

|

| Segment | 2025-2035 Outlook |

|---|---|

| Electronic Devices |

|

| Optical Coating |

|

| Decorative Coating |

|

| Others |

|

| Distribution Channel | Status & Outlook (2025-2035) |

|---|---|

| Direct Sales |

|

| Authorized Distributors |

|

| Online Platforms |

|

| Technical Partners |

|

| DRIVERS | RESTRAINTS | KEY TRENDS |

|---|---|---|

| Semiconductor Industry Growth across advanced chip manufacturing and electronics production creating substantial demand for specialized zinc-tin alloy sputtering targets supporting integrated circuit fabrication, microprocessor production, and memory device manufacturing with superior deposition characteristics and material consistency requirements. | High Material Costs and complex purification processes limit accessibility across price-sensitive applications and smaller manufacturing operations with limited materials processing budgets and specialized handling requirements. | Nanotechnology Integration - Advanced sputtering target applications incorporating nanoscale precision manufacturing, ultra-thin film deposition capabilities, and enhanced material control systems for improved deposition accuracy and process reliability in advanced manufacturing environments. |

| Display Technology Advancement - Flat panel display manufacturing and touch screen production driving adoption of specialized zinc-tin alloy targets for transparent conductive layer applications, electrode fabrication, and advanced display architectures requiring superior electrical and optical performance characteristics. | Technical Processing Complexity - Specialized sputtering equipment requirements, precise process control parameters, and skilled operator needs affect deployment timelines and operational capabilities for manufacturing facilities lacking dedicated thin-film deposition expertise and equipment infrastructure. | Purity Enhancement - Continuous improvements in alloy purification processes, contamination control systems, and quality assurance protocols delivering enhanced material consistency, reduced impurity levels, and improved sputtering performance for critical electronics manufacturing applications. |

| Optical Device Manufacturing - Precision optics production and advanced coating applications requiring zinc-tin alloy sputtering materials for anti-reflective coatings, optical filters, and specialized lens systems with exceptional optical properties and deposition uniformity requirements. | Supply Chain Limitations - Raw material availability constraints and specialized processing facility capacity create supply chain challenges affecting consistent material delivery and pricing stability for large-volume manufacturing programs and extended production schedules. | Custom Alloy Development - Expanding development of application-specific zinc-tin alloy compositions, specialized target geometries, and custom material properties tailored to specific manufacturing requirements and emerging technology applications across diverse industry sectors. |

| Renewable Energy Applications - Solar cell manufacturing and photovoltaic device production requiring specialized coating materials implementing zinc-tin alloy sputtering targets for enhanced energy conversion efficiency and improved device performance characteristics supporting clean energy technology advancement. | Environmental Regulations - Evolving materials handling standards and waste management requirements create compliance challenges for zinc-tin alloy processing facilities affecting operational procedures and disposal protocols throughout manufacturing and processing operations. | Process Automation - Integration with automated sputtering systems, robotic target handling equipment, and advanced process control technologies enabling improved production efficiency, reduced material waste, and enhanced manufacturing consistency for high-volume production operations. |

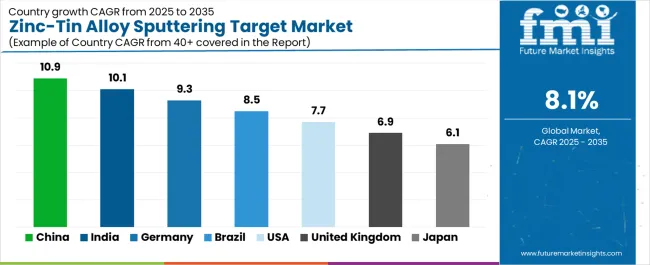

| Country | CAGR (2025-2035) |

|---|---|

| China | 10.9% |

| India | 10.1% |

| Germany | 9.3% |

| Brazil | 8.5% |

| United States | 7.7% |

| United Kingdom | 6.9% |

| Japan | 6.1% |

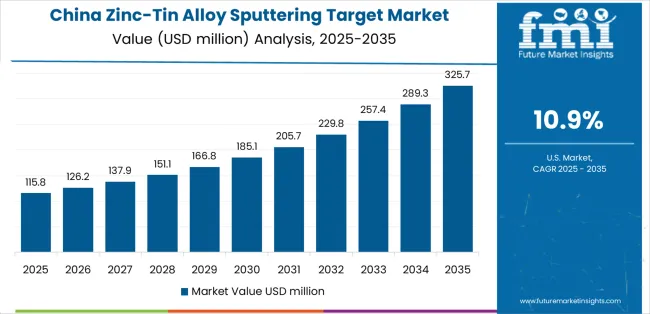

Revenue from Zinc-Tin Alloy Sputtering Target in China is projected to exhibit exceptional growth with a market value of USD 156.8 million by 2035, driven by massive semiconductor manufacturing expansion and comprehensive electronics production initiatives creating substantial opportunities for sputtering target suppliers across integrated circuit fabrication, display panel manufacturing, and advanced coating application sectors. The country's ambitious electronics industry development programs including national semiconductor initiatives and advanced manufacturing facility expansion are creating unprecedented demand for specialized zinc-tin alloy sputtering targets. Major electronics manufacturers and materials companies including SMIC, BOE Technology, and specialized sputtering target producers are establishing comprehensive production programs to support large-scale electronics manufacturing and advanced materials applications.

Revenue from Zinc-Tin Alloy Sputtering Target in India is expanding to reach USD 89.3 million by 2035, supported by extensive electronics manufacturing development programs and comprehensive semiconductor facility modernization initiatives creating demand for sputtering target solutions across diverse electronics and optical device application segments. The country's growing electronics manufacturing capabilities and expanding technology infrastructure are driving demand for sputtering materials that provide exceptional reliability while supporting advanced manufacturing system requirements. Electronics companies and technology facilities are investing in zinc-tin alloy target procurement to support growing production demand and electronics manufacturing advancement requirements.

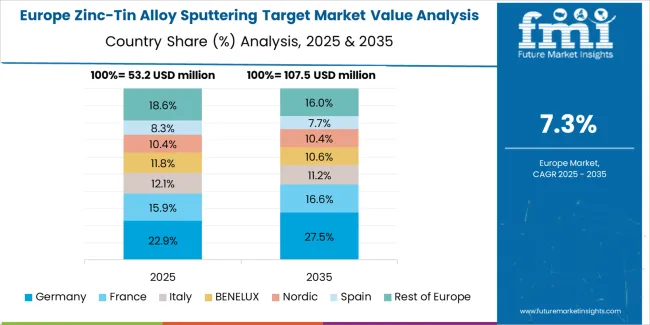

Demand for Zinc-Tin Alloy Sputtering Target in Germany is projected to reach USD 73.4 million by 2035, supported by the country's leadership in precision manufacturing technology and advanced materials processing requiring sophisticated zinc-tin alloy sputtering solutions for automotive electronics, industrial applications, and advanced optical device manufacturing. German electronics operators are implementing cutting-edge sputtering systems that support advanced coordination capabilities, operational precision, and comprehensive performance monitoring protocols. The market is characterized by focus on engineering excellence, technology innovation, and compliance with stringent quality and environmental standards.

Revenue from Zinc-Tin Alloy Sputtering Target in Brazil is growing to reach USD 58.1 million by 2035, driven by electronics manufacturing infrastructure development programs and increasing industrial coating capabilities creating opportunities for sputtering target suppliers serving both electronics manufacturers and specialized coating contractors. The country's expanding industrial sector and growing technology infrastructure are creating demand for sputtering materials that support diverse manufacturing requirements while maintaining performance standards. Electronics companies and manufacturing facilities are developing technology strategies to support operational efficiency and system reliability advancement.

Demand for Zinc-Tin Alloy Sputtering Target in United States is projected to reach USD 47.2 million by 2035, expanding at a CAGR of 7.7%, driven by advanced semiconductor technology innovation and specialized electronics applications supporting computer processor manufacturing and comprehensive technology device applications. The country's established electronics technology tradition including major semiconductor manufacturers and technology facilities are creating demand for high-performance zinc-tin alloy sputtering targets that support operational advancement and quality standards. Manufacturers and electronics system suppliers are maintaining comprehensive development capabilities to support diverse semiconductor and technology requirements.

Revenue from Zinc-Tin Alloy Sputtering Target in United Kingdom is growing to reach USD 39.8 million by 2035, supported by advanced materials technology heritage and established electronics manufacturing communities driving demand for premium zinc-tin alloy sputtering solutions across traditional electronics systems and specialized technology applications. The country's rich materials engineering heritage including major technology companies and established electronics system capabilities create demand for sputtering targets that support both legacy system advancement and modern electronics applications.

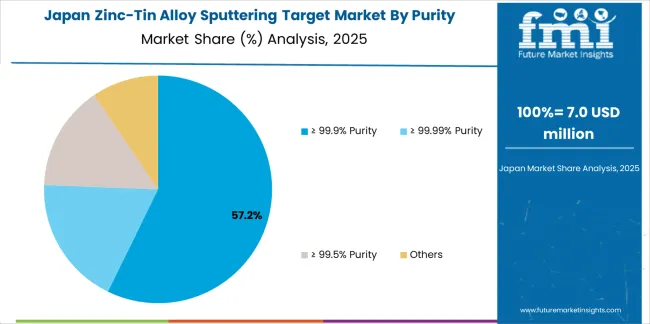

Demand for Zinc-Tin Alloy Sputtering Target in Japan is projected to reach USD 33.6 million by 2035, driven by precision electronics technology tradition and established manufacturing leadership supporting both domestic electronics system markets and export-oriented component production. Japanese companies maintain sophisticated zinc-tin alloy development capabilities, with established manufacturers continuing to lead in sputtering technology and electronics equipment standards.

European Zinc-Tin Alloy Sputtering Target operations are increasingly concentrated between German engineering excellence and specialized manufacturing across multiple countries. German facilities dominate high-performance sputtering target production for semiconductor and electronics applications, leveraging cutting-edge materials processing technologies and strict quality protocols that command price premiums in global markets. British materials technology operators maintain leadership in advanced alloy development and sputtering target innovation, with organizations like university research centers and established materials companies driving technical specifications that suppliers must meet to access major electronics manufacturing contracts.

Eastern European operations in Czech Republic and Poland are capturing specialized production contracts through precision manufacturing expertise and EU compliance standards, particularly in materials processing and target fabrication technologies for electronics applications. These facilities increasingly serve as development partners for Western European electronics programs while building their own materials technology expertise.

The regulatory environment presents both opportunities and constraints. European materials safety framework requirements create quality standards that favor established European manufacturers and materials system operators while ensuring consistent performance specifications for critical electronics infrastructure and manufacturing applications. Brexit has created complexity for UK materials collaboration with EU programs, driving opportunities for direct relationships between British operators and international zinc-tin alloy suppliers.

Technology collaboration accelerates as electronics manufacturers seek materials advancement to support major semiconductor development milestones and display technology advancement timelines. Vertical integration increases, with major electronics system operators acquiring specialized manufacturing capabilities to secure materials supplies and quality control for critical production programs. Smaller materials contractors face pressure to specialize in niche applications or risk displacement by larger, more comprehensive operations serving mainstream electronics and technology requirements.

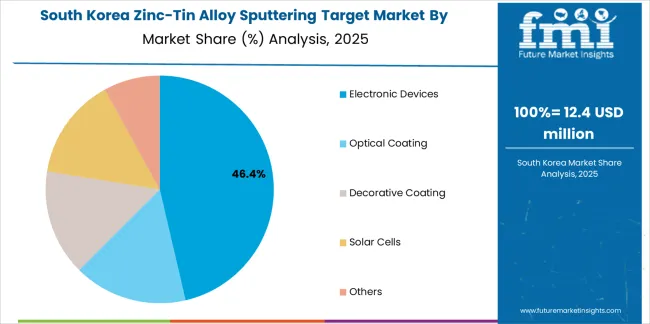

South Korean Zinc-Tin Alloy Sputtering Target operations reflect the country's advanced electronics technology capabilities and export-oriented semiconductor development model. Major electronics system operators including Samsung Electronics and SK Hynix drive materials procurement strategies for their manufacturing facilities, establishing direct relationships with specialized zinc-tin alloy sputtering target suppliers to secure consistent quality and performance for their semiconductor development programs and advanced electronics technology systems targeting both domestic infrastructure and international collaboration projects.

The Korean market demonstrates particular strength in integrating zinc-tin alloy sputtering targets into advanced semiconductor manufacturing processes and display technology configurations, with engineering teams developing solutions that bridge traditional thin-film deposition applications and next-generation electronics systems. This integration approach creates demand for specific performance specifications that differ from conventional applications, requiring suppliers to adapt sputtering target capabilities and deposition characteristics.

Regulatory frameworks emphasize materials safety and manufacturing system reliability, with Korean electronics standards often exceeding international requirements for sputtering target systems. This creates barriers for standard materials suppliers but benefits established manufacturers who can demonstrate electronics-grade performance capabilities. The regulatory environment particularly favors suppliers with Korean electronics system qualification and comprehensive testing documentation systems.

Supply chain excellence remains critical given Korea's electronics focus and international collaboration dynamics. Electronics system operators increasingly pursue development partnerships with suppliers in Japan, Germany, and specialized manufacturers to ensure access to cutting-edge zinc-tin alloy technologies while managing materials risks. Investment in electronics infrastructure supports performance advancement during extended manufacturing development cycles.

Advanced Engineering Materials Limited leads the market with 15% share owing to its comprehensive zinc-tin alloy target portfolio, which electronics manufacturers use for precision thin-film deposition applications. Profit pools are consolidating upstream in high-purity alloy production and downstream in application-specific solutions for semiconductor manufacturing, optical coating applications, and electronics device markets where material consistency, deposition uniformity, and exceptional purity levels command substantial premiums. Value is migrating from basic sputtering target production to specification-driven, electronics-ready materials where alloy composition expertise, precision manufacturing capabilities, and reliable supply chain management create competitive advantages.

Several archetypes define market leadership: established American materials companies defending share through advanced alloy development and comprehensive technical support; German materials suppliers leveraging manufacturing excellence and precision processing capabilities; Japanese technology leaders with electronics expertise and quality manufacturing heritage; and emerging materials manufacturers pursuing cost-effective production while developing advanced alloy capabilities.

Switching costs - material qualification, process validation, equipment compatibility - provide stability for established suppliers, while technological advancement requirements and electronics application growth create opportunities for innovative materials manufacturers. Consolidation continues as companies seek manufacturing scale; direct customer partnerships grow for specialized applications while traditional materials distribution remains relationship-driven. Focus areas: secure semiconductor and electronics market positions with application-specific performance specifications and technical collaboration; develop zinc-tin alloy technology and advanced manufacturing capabilities; explore specialized applications including display technology and optical device manufacturing requirements.

| Stakeholder Type | Primary Advantage | Repeatable Plays |

|---|---|---|

| American Materials Leaders | Advanced alloy development expertise; proven electronics integration; established manufacturer relationships | Precision manufacturing; technical innovation; materials certification support |

| German Materials Suppliers | Manufacturing excellence; comprehensive quality programs; established customer partnerships | Engineering collaboration focus; integrated solutions; technical consultation |

| Japanese Technology Leaders | Electronics system expertise; precision technology leadership; trusted by major electronics programs | Manufacturer partnerships; application-specific specifications; electronics infrastructure collaboration |

| Emerging Materials Producers | Manufacturing efficiency; competitive pricing; rapid technology development | Production scaling; technology advancement; market entry strategies |

| Materials Distributors | Technical distribution networks; electronics service relationships | Electronics expertise; inventory management; technical support services |

| Item | Value |

|---|---|

| Quantitative Units | USD 233.4 million |

| Purity Segments | ≥ 99.99% Purity; ≥ 99.9% Purity; ≥ 99.5% Purity; Others |

| Applications | Electronic Devices; Optical Coating; Decorative Coating; Solar Cells; Others |

| End-Users | Semiconductor Manufacturers; Display Panel Producers; Optical Device Manufacturers; Research Institutions; Others |

| Target Size Segments | Small Targets (< 6 inches); Medium Targets (6-12 inches); Large Targets (> 12 inches); Custom Sizes |

| Distribution Channels | Direct Sales; Authorized Distributors; Online Platforms; Technical Partners |

| Regions Covered | North America; Latin America; Europe; Asia Pacific; Middle East & Africa |

| Key Countries | China; India; Germany; Brazil; United States; United Kingdom; Japan (+35 additional countries) |

| Key Companies Profiled | Advanced Engineering Materials Limited; American Elements; Edgetech Industries; Able Target Limited; XI'AN FUNCTION MATERIAL GROUP CO.,LTD; ALB Materials Inc; QS Advanced Materials; Nanografi; UVTM; JX Nippon; Stanford Advanced Materials; Kurt J. Lesker Company; Materion Corporation; Plansee Group; Tosoh Corporation; Honeywell Electronic Materials; Praxair Surface Technologies; Hitachi Metals Ltd |

| Additional Attributes | Dollar sales by purity and application; Regional demand trends (NA, EU, APAC); Competitive landscape; Direct sales vs. distributor adoption patterns; Semiconductor manufacturing and electronics technology integration; Advanced materials innovations driving purity enhancement, deposition reliability, and electronics manufacturing excellence |

The global zinc-tin alloy sputtering target market is estimated to be valued at USD 233.4 million in 2025.

The market size for the zinc-tin alloy sputtering target market is projected to reach USD 508.6 million by 2035.

The zinc-tin alloy sputtering target market is expected to grow at a 8.1% CAGR between 2025 and 2035.

The key product types in zinc-tin alloy sputtering target market are ≥ 99.9% purity, ≥ 99.99% purity, ≥ 99.5% purity and others.

In terms of application, electronic devices segment to command 47.3% share in the zinc-tin alloy sputtering target market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Halloysite Market Size and Share Forecast Outlook 2025 to 2035

Superalloys Market Size and Share Forecast Outlook 2025 to 2035

Ferroalloy Market Size and Share Forecast Outlook 2025 to 2035

Metal Alloys Market Size and Share Forecast Outlook 2025 to 2035

Braze Alloys Market Growth - Trends & Forecast 2025 to 2035

Nickel Alloy Market

Aluminum Alloys Market Size and Share Forecast Outlook 2025 to 2035

Automotive Alloys Market Size and Share Forecast Outlook 2025 to 2035

Nickel Superalloy Market Size and Share Forecast Outlook 2025 to 2035

High Entropy Alloy Market Size and Share Forecast Outlook 2025 to 2035

Shape Memory Alloy Market Size and Share Forecast Outlook 2025 to 2035

Solar Aluminum Alloy Frame Market Size and Share Forecast Outlook 2025 to 2035

High Temperature Alloys Market Growth - Trends & Forecast 2025 to 2035

Copper and Copper Alloy Scrap and Recycling Market Size and Share Forecast Outlook 2025 to 2035

Aviation Titanium Alloy Market Analysis by Type, Application, Microstructure, and Region: Forecast for 2025 to 2035

Beryllium Aluminum Alloy Market Growth - Trends & Forecast 2025 to 2035

India Shape Memory Alloy Market Analysis by Material Type, Component Type, Application, End Use Industry, and Region Forecast Through 2025 to 2035

Secondary Smelting and Alloying of Aluminium Market Size and Share Forecast Outlook 2025 to 2035

Polyphenylene Ether (PPE) Alloy Market Size and Share Forecast Outlook 2025 to 2035

Hot Rolled Or Cold Finished Alloy Steel Bars Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA