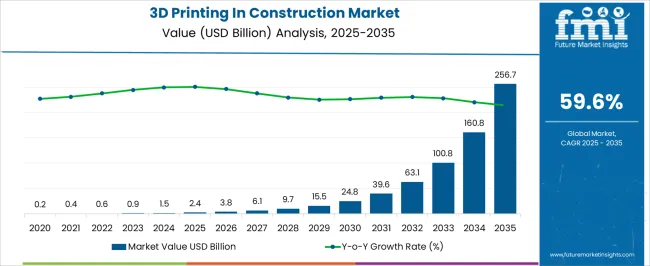

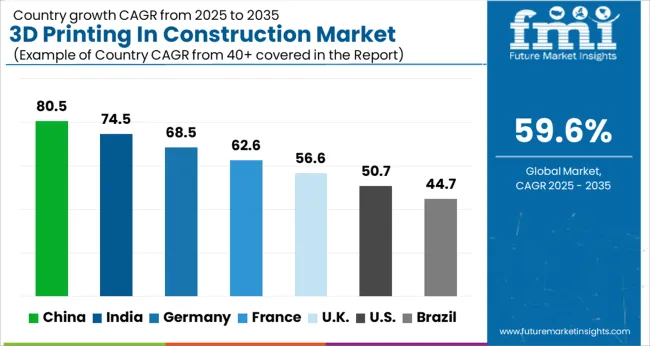

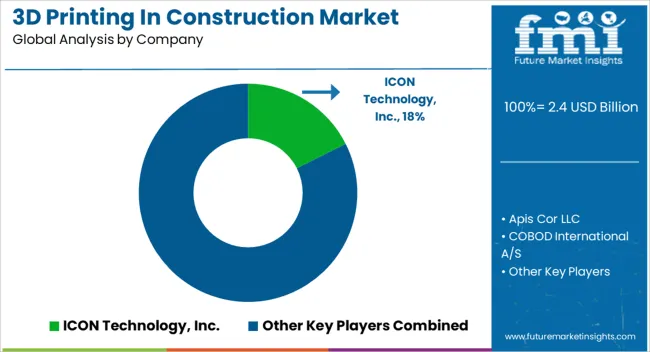

The 3D Printing In Construction Market is estimated to be valued at USD 2.4 billion in 2025 and is projected to reach USD 256.7 billion by 2035, registering a compound annual growth rate (CAGR) of 59.6% over the forecast period. This reflects an absolute dollar opportunity of USD 1.7 billion, signaling steady market momentum. Between 2025 and 2030, the market is projected to grow from USD 1.9 billion to USD 2.5 billion, representing an incremental gain of USD 600 million. The year-over-year (YoY) growth ranges from 5.3% to 6.0%, highlighting consistent performance supported by material innovation and growing demand across multiple sectors.

From 2030 to 2035, the market is expected to continue expanding at a healthy rate, moving from USD 2.5 billion to USD 3.6 billion, driven by increasing adoption in electronics, medical devices, aerospace, and structural applications. The unique properties of metallic glasses, such as high strength, corrosion resistance, and superior elasticity, are attracting industries looking for advanced materials with high performance-to-weight ratios. Moreover, miniaturization trends in electronics and the push for lightweight materials in automotive and aerospace are expected to strengthen the demand curve. The market's upward trajectory indicates a robust future, propelled by continued R&D investment and scaling of production technologies.

| Metric | Value |

|---|---|

| 3D Printing In Construction Market Estimated Value in (2025 E) | USD 2.4 billion |

| 3D Printing In Construction Market Forecast Value in (2035 F) | USD 256.7 billion |

| Forecast CAGR (2025 to 2035) | 59.6% |

The 3D printing in the construction market is expanding steadily as the industry embraces automation, speed, and precision-driven building solutions. Advancements in material science, robotics, and building information modeling (BIM) have created a favorable ecosystem for integrating additive manufacturing into residential, commercial, and infrastructure development.

Rising pressure to reduce labor costs, construction waste, and carbon emissions is pushing stakeholders toward 3D printing technologies that offer faster build times and design flexibility. Governments and private investors are increasingly funding sustainable housing pilots and disaster-resilient structures using 3D techniques.

Regulatory shifts and standardization initiatives around printed structures are also enhancing commercial viability. Moving forward, increased customization, localized production, and eco-friendly material usage are anticipated to accelerate the adoption of 3D printing across diverse construction applications.

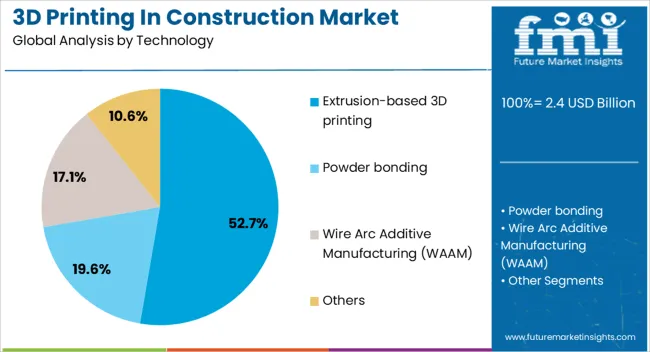

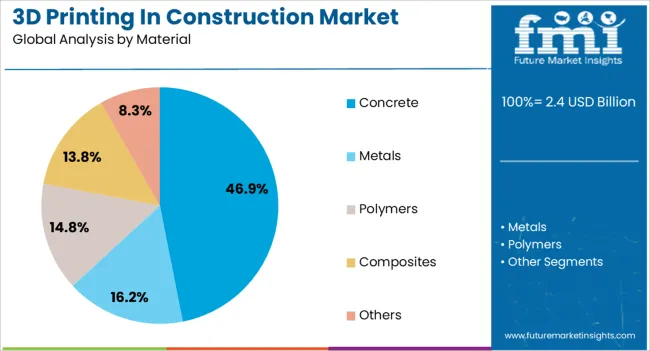

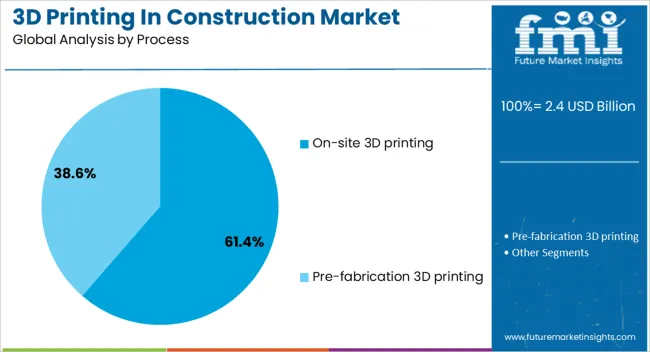

The 3D printing in construction market is segmented by technology, material, process, application, and geographic regions. By technology, the 3D printing in the construction market is divided into Extrusion-based 3D printing, Powder bonding, Wire Arc Additive Manufacturing (WAAM), and Others. In terms of materials, the 3D printing in the construction market is classified into Concrete, Metals, Polymers, Composites, and Others. The process of 3D printing in the construction market is segmented into On-site 3D printing and Pre-fabrication 3D printing. The application of 3D printing in the construction market is segmented into Residential, Commercial, Infrastructure, Industrial, and Others. Regionally, the 3D printing in the construction industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Extrusion-based 3D printing is projected to dominate with 52.70% of the total revenue share in 2025, making it the leading technology in this market. This position is being driven by its adaptability to large-scale construction and compatibility with readily available materials like concrete and geopolymer mixes.

The technology’s layer-by-layer deposition method supports automated, continuous operations, significantly reducing time and manual intervention on job sites. Its ability to construct complex geometries without the need for extensive formwork lowers overall project costs and environmental impact.

The growing popularity of single-story housing, low-rise buildings, and modular components further strengthens the reliance on extrusion-based systems in both emerging and developed markets.

Concrete is expected to contribute 46.90% of the revenue share in 2025, establishing it as the most utilized material in 3D construction printing. This dominance stems from its structural integrity, local availability, and proven performance across diverse climatic and load-bearing conditions.

The ability to adapt concrete mixtures for pumpability, quick setting, and bonding between layers has enhanced its application in automated construction workflows. Additionally, the incorporation of supplementary cementitious materials and admixtures has supported innovation in sustainable and high-strength formulations.

With ongoing R&D efforts aimed at reducing carbon intensity and improving print quality, concrete remains the primary choice for structural and non-structural 3D-printed components.

On-site 3D printing is anticipated to lead with 61.40% of the market share in 2025, emerging as the dominant process type. This leadership is attributed to its ability to minimize logistics, transportation costs, and assembly time by constructing structures directly at the final location.

The process enables large-format printing of full-scale buildings with real-time adjustments, eliminating the need for prefabrication and reducing construction lead times. It has gained momentum in low-cost housing, emergency shelters, and infrastructure development in remote or disaster-prone areas.

Integration with mobile gantry systems and automated mixers has further improved precision and operational scalability. As construction projects increasingly prioritize speed, sustainability, and labor efficiency, on-site 3D printing is expected to remain at the forefront of technological adoption.

The metallic glasses market is gaining momentum due to the growing demand for materials that offer superior strength, high elasticity, and corrosion resistance across electronics, aerospace, biomedical, and defense sectors. These amorphous alloys, often called bulk metallic glasses (BMGs), exhibit unique properties like high hardness and excellent wear resistance, making them suitable for structural and functional components. The absence of crystalline structure enables precise molding and complex geometries. As industries pursue lightweight, high-performance materials, metallic glasses continue to present strong alternatives to conventional metals and ceramics.

The use of metallic glasses in electronic casings, precision sensors, and wearable device components is expanding. Their combination of high strength and aesthetic finish makes them ideal for smartphone frames, bezels, and housings. Unlike traditional metals, they offer superior durability while maintaining slim form factors. Their non-magnetic and corrosion-resistant nature is especially advantageous for miniaturized components and biomedical wearables. Manufacturers benefit from net-shape casting capabilities that reduce machining and post-processing steps, thereby improving production efficiency. As consumer electronics move toward more rugged, lightweight, and stylish designs, demand for metallic glasses in casing and connector applications continues to rise. With growing requirements for both form and function in wearables and mobile technology, metallic glasses enable design freedom without compromising durability or performance. This makes them an attractive material choice in next-generation electronics manufacturing, where material behavior under thermal, electrical, and mechanical stress is critical.

Metallic glasses are gaining traction in biomedical applications such as surgical tools, orthopedic implants, and dental devices. Their biocompatibility, resistance to corrosion in bodily fluids, and high mechanical strength offer clear benefits over conventional stainless steel or titanium. The amorphous structure reduces the risk of bacterial colonization and offers smoother surface finishes, enhancing hygiene and healing outcomes. These materials also allow for precision fabrication of small, complex shapes needed in minimally invasive instruments. As medical devices evolve toward personalized, minimally invasive solutions, manufacturers are looking for materials that support fine geometries and superior wear resistance. Although still limited by cost and availability, metallic glasses are increasingly considered for premium or critical-use components where reliability and patient safety are paramount. Ongoing clinical research and certification efforts are helping open new applications, enabling a slow but steady market penetration in specialized biomedical use cases.

Aerospace and defense sectors value metallic glasses for their exceptional strength-to-weight ratio, impact resistance, and structural stability under extreme conditions. These properties make them suitable for lightweight structural components, vibration-damping parts, and even protective armor systems. The absence of grain boundaries in metallic glasses reduces the chances of crack initiation and propagation, improving fatigue resistance over traditional alloys. Components made from metallic glasses are also less prone to failure due to thermal cycling, which is critical in aerospace systems exposed to fluctuating temperatures. Their ability to undergo precision casting without shrinkage or warping supports the manufacture of high-tolerance parts. While cost and production scale still limit widespread adoption, interest remains high in research and pilot programs for advanced air and space vehicle parts. Continued focus on lightweighting and extreme performance in aerospace missions supports the long-term integration of metallic glasses into these high-value applications.

Despite their performance advantages, metallic glasses face challenges in widespread industrial adoption due to production complexity and high material costs. Manufacturing requires precise thermal control and rapid cooling to prevent crystallization, which limits scalability and increases energy consumption. The availability of only a few commercial-grade metallic glass alloys restricts design flexibility, especially in applications needing specific mechanical or thermal properties. Compared to traditional metals, the tooling and processing equipment needed to mold or shape metallic glasses can be expensive and difficult to integrate into existing lines. Inconsistencies during casting or cooling can also lead to performance defects, making quality assurance more demanding. These limitations are particularly problematic for high-volume, cost-sensitive industries like automotive. Until scalable processing methods and alloy diversification improve, the use of metallic glasses will likely remain confined to high-performance, low-volume applications. Overcoming these constraints is essential for the material to gain broader industrial acceptance.

The global metallic glasses market is projected to grow at a CAGR of 6.5% through 2035, supported by increasing use in electronics, medical devices, and structural applications requiring high strength-to-weight ratios. Among BRICS nations, China leads with 8.8% growth, driven by advancements in alloy casting and integration into consumer electronics. India follows at 8.1%, where research initiatives and limited-scale manufacturing have expanded applications in precision tools and automotive components. In the OECD region, Germany reports 7.5% growth, supported by regulated production methods and high-performance material demand. France, growing at 6.8%, has maintained adoption in instrumentation, aerospace, and micro-component industries. The United Kingdom, at 6.2%, reflects steady use in academic prototyping, wearable technologies, and defense-related materials. Market activity has been shaped by metallurgical standards, processing constraints, and end-use qualification procedures. This report includes insights on 40+ countries; the top five markets are shown here for reference.

Robust deployment of metallic glasses across precision components and industrial tooling has pushed the China market to a CAGR of 8.8%. Strong interest has been observed from electronics firms manufacturing casings and cores requiring high strength-to-weight ratios. Manufacturing clusters have shifted alloy designs toward zirconium- and palladium-based types with improved amorphous structure retention. Usage in robotics and automation tool heads has contributed to specialized batch production. Defense sector suppliers have adopted high-density metallic glasses for shock-resistant parts. Foundries have operated with modified casting chambers to support amorphous material handling. Contract facilities have delivered strip forms and powder variants to magnetic and electronic component assemblers. Local demand has also grown for non-crystalline alloys in thermal barrier and wear-resistant coatings.

India’s metallic glasses market has advanced steadily, maintaining a CAGR of 8.1%, with usage evident in electronics packaging, magnetic shielding, and wear-resistant surfaces. Procurement has been driven by the expansion of domestic foundry operations supporting component hardening and casing applications. Demand from educational research units and metallurgical labs has ensured steady uptake of rod and ribbon forms. Tooling subcontractors have applied metallic glass inserts for dies and molds in low-volume production. Adoption of bulk metallic glasses has grown in the machining sector for precision fittings. Magnetism-sensitive parts have been developed using iron-based amorphous structures. Sheet forms have been distributed to aerospace and automotive R&D centers. Powdered variants have been blended into composites for pilot-scale mechanical testing.

Across Germany, a CAGR of 7.5% has been recorded in the metallic glasses market, with consistent activity in the automotive, optics, and tooling segments. Industrial suppliers have transitioned to amorphous structures for reduced mechanical loss and improved surface wear. High-precision component makers have favored metallic glasses in pump systems and laser mounts. Rod extrusion units have upgraded cooling techniques to retain amorphous consistency. Academic institutes have utilized metallic glass samples in microstructure studies and applied mechanics simulations. Injection mold makers have applied copper-based blends for improved surface performance. Industrial gear manufacturers have sourced metallic glass layers for vibration damping. Small-scale test runs have been carried out in additive manufacturing setups. Specialized casting machines have been installed in southern Germany.

France has exhibited CAGR growth of 6.8% in the metallic glasses sector, with adoption noted in biomedical, industrial machinery, and military components. Biocompatible metallic glasses have been incorporated into orthopedic fasteners and dental implants. Mechanical part fabricators have applied amorphous alloys in load-bearing and precision-critical fixtures. Small-batch producers have relied on copper- and iron-based ribbons for thermal sensors and magnetic couplings. Defense-grade use cases have included blade edges and casings that require fracture toughness. Metal injection molders have integrated metallic glass feedstock in micro-injection units. Research collaborations between public labs and foundries have led to increased alloy variety. Use in fast-response actuators and heat exchangers has shown upward momentum. Applications in customized wear-resistant layering have added niche demand.

Within the United Kingdom, the metallic glasses market has maintained a CAGR of 6.2%, with expanding usage across tooling inserts, electronics, and design prototypes. Rod and strip forms have been supplied to toolmakers for high-stress, low-volume press tools. Precision electronics firms have explored applications in compact magnetic enclosures and transformer cores. Composite researchers have investigated blends with thermoplastics and ceramics for lightweight structural layering. Manufacturers of aerospace fixtures have evaluated metallic glasses for bracketry and thermal isolation. Trial deployments have occurred in creative prototyping where fine surface finish and shape memory are prioritized. Sourcing has been diversified through regional distributors aligned with academic and technical buyers. Alloys with improved corrosion resistance have been favored in marine and lab-based setups.

The metallic glasses market is supported by a specialized group of suppliers producing amorphous alloys known for their exceptional strength, elasticity, and corrosion resistance, widely used in electronics, aerospace, medical devices, and precision tools. Liquidmetal Technologies Inc. leads the market with proprietary bulk metallic glass (BMG) formulations used in high-performance components requiring near-net-shape molding and superior mechanical properties. Amorphology Inc., a spin-off from NASA’s Jet Propulsion Laboratory, offers space-grade amorphous metal parts focused on precision gears and advanced industrial applications. Asian manufacturers such as Antai Technology Co., Ltd., EPSON ATMIX Corporation, and Qingdao Yunlu Advanced Materials Technology Co., Ltd. play a growing role in producing amorphous alloy powders and parts at scale, supplying local electronics and automotive sectors. Hitachi Metals Ltd. and Usha Amorphous Metals Limited are significant regional contributors, focusing on magnetic metallic glasses for power distribution and transformer cores. European suppliers like Exmet AB, Glassimetal Technology, and PX Group SA provide customized BMG products for watches, surgical tools, and consumer electronics, where high strength and precision formability are essential. Heraeus Holding and Materion Corporation bring material science expertise, offering tailored metallic glass solutions for medical implants, semiconductor packaging, and structural components. PrometalTech and RS Alloys contribute to niche market segments with application-specific amorphous alloys. As demand for lightweight, high-performance materials rises, these suppliers continue refining processing methods like injection molding and additive manufacturing to meet expanding needs in advanced manufacturing sectors.

Major collaborations between technology firms and construction companies are helping to accelerate the development of 3D printing in construction. For example, Bouygues Construction, LafargeHolcim, and Samsung C&T have partnered with technology providers to develop 3D-printed construction solutions for a range of projects. These partnerships are paving the way for large-scale adoption of 3D printing in construction across the globe, particularly in commercial, residential, and government projects.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.4 Billion |

| Technology | Extrusion-based 3D printing, Powder bonding, Wire Arc Additive Manufacturing (WAAM), and Others |

| Material | Concrete, Metals, Polymers, Composites, and Others |

| Process | On-site 3D printing and Pre-fabrication 3D printing |

| Application | Residential, Commercial, Infrastructure, Industrial, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | ICON Technology, Inc., Apis Cor LLC, COBOD International A/S, Contour Crafting Corporation, CyBe Construction BV, Peri GmbH, Sika AG, XtreeE SAS, and Yingchuang Building Technique Co., Ltd. |

| Additional Attributes | Dollar sales vary by material type including concrete, composites, and polymers, construction method such as extrusion, powder bonding, and additive welding, application across residential, commercial, and infrastructure projects, and region covering North America, Europe, and Asia-Pacific. Growth is driven by demand for sustainable building solutions, reduced construction time, and advancements in digital fabrication technologies. |

The global 3D printing in construction market is estimated to be valued at USD 2.4 billion in 2025.

The market size for the 3D printing in construction market is projected to reach USD 256.7 billion by 2035.

The 3D printing in construction market is expected to grow at a 59.6% CAGR between 2025 and 2035.

The key product types in 3D printing in construction market are extrusion-based 3D printing, powder bonding, wire arc additive manufacturing (waam) and others.

In terms of material, concrete segment to command 46.9% share in the 3D printing in construction market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

3D Ready Organoid Expansion Service Market Size and Share Forecast Outlook 2025 to 2035

3D NAND Flash Memory Market Size and Share Forecast Outlook 2025 to 2035

3D Audio Market Size and Share Forecast Outlook 2025 to 2035

3D Surgical Microscope Systems Market Size and Share Forecast Outlook 2025 to 2035

3D Display Market Size and Share Forecast Outlook 2025 to 2035

3D Neuroscience Market Size and Share Forecast Outlook 2025 to 2035

3D Glasses Market Size and Share Forecast Outlook 2025 to 2035

3D Laser Scanner Market Growth - Trends & Forecast 2025 to 2035

3D Scanners Market Size and Share Forecast Outlook 2025 to 2035

3D Sensor Market Size and Share Forecast Outlook 2025 to 2035

3D Cell Culture Market - Demand, Size & Industry Trends 2025 to 2035

3D Motion Capture Market by System, Component, Application & Region Forecast till 2035

3D TSV Packages Market Analysis by Process Realization, Application, End Users, and Region through 2035

3D Metrology Market Insights – Growth & Industry Outlook 2025 to 2035

3D Camera Market Growth – Trends & Forecast 2025 to 2035

3D Secure Payment Authentication Market Insights by Components, Application, and Region - 2025 to 2035

3D Mobile Theater Market Demand & Trends 2024 to 2034

3D ICs Market

3D Display Module Market

3D Reconstruction Technology Market Analysis & Forecast by Component, Type, Enterprise Size, Deployment Model, Application, and Region Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA