The Automotive Cylinder Liner market is experiencing significant growth driven by increasing demand for durable and high-performance engine components across light-duty and heavy-duty vehicles. The future outlook for this market is shaped by advancements in engine technologies, stricter emission norms, and the growing adoption of fuel-efficient engines. Rising vehicle production and sales, particularly in emerging economies, are further supporting market expansion.

Increasing emphasis on reducing engine wear, improving thermal efficiency, and extending engine life is encouraging manufacturers to invest in advanced cylinder liner materials and designs. Continuous innovation in manufacturing processes, including precision casting and surface coating techniques, is enhancing the performance and reliability of cylinder liners.

Additionally, growing awareness of the role of cylinder liners in improving fuel economy and reducing maintenance costs is driving adoption across both passenger and commercial vehicles As automotive manufacturers focus on optimizing engine performance and meeting regulatory requirements, the demand for high-quality cylinder liners is expected to remain robust, offering sustained growth opportunities in both developed and emerging regions.

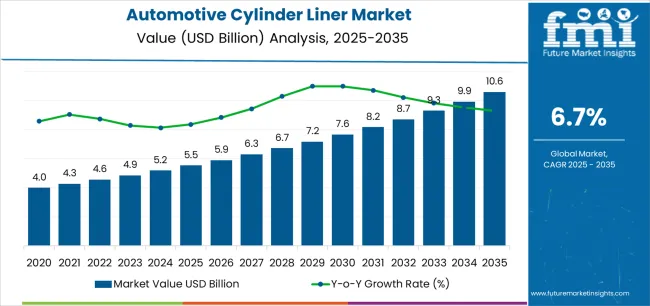

| Metric | Value |

|---|---|

| Automotive Cylinder Liner Market Estimated Value in (2025 E) | USD 5.5 billion |

| Automotive Cylinder Liner Market Forecast Value in (2035 F) | USD 10.6 billion |

| Forecast CAGR (2025 to 2035) | 6.7% |

The market is segmented by Liner Type, Material Type, Vehicle Type, and Application and region. By Liner Type, the market is divided into Wet Liners and Dry Liners. In terms of Material Type, the market is classified into Cast Iron, Aluminum Alloy, Steel, and Titanium Alloy. Based on Vehicle Type, the market is segmented into Light-Duty Vehicles and Heavy-Duty Vehicles. By Application, the market is divided into Diesel Engines and Gasoline Engines. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

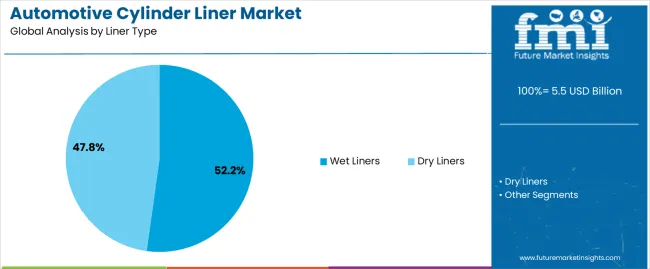

The wet liners segment is projected to hold 52.20% of the Automotive Cylinder Liner market revenue share in 2025, establishing it as the leading liner type. This growth has been driven by the superior cooling efficiency and enhanced thermal conductivity offered by wet liners, which help improve engine performance and longevity.

Their design allows direct contact with engine coolant, enabling effective heat dissipation and reducing the risk of overheating. Wet liners also support easier maintenance and replacement compared to dry liners, which is particularly beneficial for high-performance and heavy-duty applications.

The increasing demand for reliable and durable engines in light-duty and commercial vehicles has further strengthened the adoption of wet liners Additionally, the focus on reducing wear and tear and improving fuel efficiency has contributed to the segment’s continued dominance in the market.

The cast iron material type segment is expected to capture 73.40% of the Automotive Cylinder Liner market revenue share in 2025, making it the leading material. This preference is attributed to cast iron’s excellent wear resistance, high strength, and ability to withstand high operating temperatures, which are critical for engine longevity.

The material’s durability and stability under varying thermal and mechanical loads make it suitable for a wide range of vehicle applications. Cast iron cylinder liners also provide effective lubrication retention, reducing friction and enhancing engine efficiency.

The widespread availability and cost-effectiveness of cast iron have further reinforced its dominance in the market As automotive engines continue to evolve for higher performance and lower emissions, the demand for cast iron liners is expected to maintain its leading position in the market.

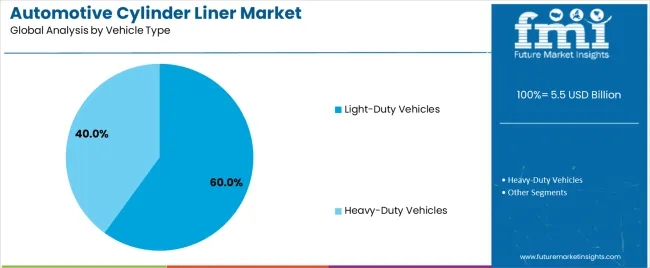

The light-duty vehicles segment is anticipated to account for 60.00% of the Automotive Cylinder Liner market revenue in 2025, establishing it as the leading vehicle type. This growth is driven by the rising production and sales of passenger vehicles globally, fueled by increasing urbanization, rising disposable incomes, and enhanced mobility needs.

Cylinder liners for light-duty vehicles are required to provide superior engine performance, fuel efficiency, and reliability, which aligns with the adoption of advanced engine technologies. The preference for low-maintenance, durable, and thermally efficient liners has further reinforced their adoption in this segment.

Additionally, regulatory standards for emissions and fuel economy in passenger vehicles are accelerating the demand for high-quality cylinder liners The emphasis on reducing operational costs and improving vehicle performance continues to support the dominance of light-duty vehicles in the cylinder liner market.

The table below exhibits the anticipated CAGR for the global automotive cylinder liner industry over semi-annual periods ranging between 2025 and 2025. The examination provides organizations with a better understanding of the growth over the year by divulging critical shifts in performance and growth patterns. The first half (H1) of 2025 spans from January to June. The second half or H2 includes July to December.

Figures presented in the table below exhibit the growth rate for each half between 2025 and 2025. The industry is predicted to rise at a CAGR of 6.5% in the first half (H1) of 2025. The second half of the same year is projected to showcase a surge in the growth rate at a CAGR of 6.9%.

| Particular | Value CAGR |

|---|---|

| H1 | 6.5% (2025 to 2035) |

| H2 | 6.9% (2025 to 2035) |

| H1 | 6.6% (2025 to 2035) |

| H2 | 6.8% (2025 to 2035) |

Preceding in the subsequent period, from H1 2025 to H2 2035, the CAGR is set to witness a drop to 6.6% in the first half (H1) and then rise to 6.8% in the second half (H2).

Innovations in Material Technologies to Boost Engine Performance and Sustainability

Manufacturers of cylinder liners for automotive applications are utilizing unique materials, such as aluminum alloys and silicon carbide composites, for maximum durability and improved thermal efficiency. BMW’s TwinPower Turbo technology utilizes high-strength coatings to reduce friction and extend cylinder liner life, optimizing engine performance.

Porsche also integrates specialized composites in its high-performance engines to withstand extreme conditions, ensuring better thermal conductivity and durability.

General Motors is bolstering its engine platforms by developing liners with innovative materials that support high-performance metrics, contributing to improved fuel efficiency and reduced environmental impact. These innovations underscore the industry's commitment to pushing the boundaries of engine performance and sustainability.

Rising Demand for Lightweight Cylinder Liners to Enhance Fuel Efficiency

Automotive manufacturers are innovating lightweight cylinder liners to achieve reduced vehicle weight, improved fuel efficiency, and address the industry's focus on sustainability. These innovations involve using materials like silicon-aluminum alloy composites that offer enhanced wear resistance and thermal conductivity over traditional cast iron. The move toward light designs conforms to stringent emission standards and the need for better vehicle handling.

For instance, Federal-Mogul Powertrain announced the release of its new silicon-aluminum alloy composite cylinder liner in January 2025. The new material was developed to deliver lightweight strategies with excellent performance. It perfectly aligns with the industry’s commitment to developing lightweight and efficient engines.

Surging Global Vehicle Production to Create New Opportunities

The continuous rise in global vehicle production is a key driver for growth in the automotive cylinder liner industry. The global vehicle production reached 5.5 million units in 2025, signaling a strong growth momentum driven by the automotive industry’s aim to meet the growing consumer demand. This increasing production directly impacts the demand for cylinder liners as they are essential for enhanced engine performance and durability.

Countries, including China and India, have witnessed significant expansion in vehicle production, with China producing over 26 million vehicles, accounting for around 30% of the global output. Automotive manufacturers are investing in unique manufacturing technologies to ensure the development of high-quality cylinder liners that align with performance and regulatory standards, further supporting growth.

Enhanced Emission Standards Augmenting Innovation Worldwide

The introduction of stringent emission regulations is anticipated to significantly influence demand for cutting-edge cylinder liners. Regulatory frameworks like the Euro 7 standards, set to take effect in 2025, aim to considerably cut nitrogen oxide (NOx) emissions. These regulations are pushing manufacturers to innovate and enhance cylinder liners to improve engine performance and emissions control.

The Bharat Stage VI (BS6) standards implemented in India have driven a 30% reduction in NOx emissions in diesel engines. This regulatory pressure is accelerating the development of cylinder liners with superior thermal management and durability, aligning with the need for compliance and enhanced vehicle efficiency.

Rising Adoption of Electric Vehicles to Impact Demand

The growing popularity of electric vehicles (EVs) is transforming the automotive industry while impacting demand for automotive cylinder liners. As EVs gain traction, the need for conventional internal combustion engine (ICE) components, including cylinder liners, is decreasing.

Industry data shows a 40% increase in global EV sales in 2025, fueled by government incentives and a shift toward sustainable transport solutions. This trend is set to accelerate, likely reducing demand for ICE parts.

For instance, prominent automotive players, such as General Motors and Ford are shifting their focus toward electric and hybrid vehicles, which directly influences demand for cylinder liners used in traditional engines. This shift presents a significant challenge for manufacturers reliant on ICE technology.

The global automotive cylinder liner market was valued at USD 4,390.9 million in 2020. It grew at a CAGR of 2.7% during the historical period ranging between 2020 and 2025. It attained a value of USD 4,890.6 million in 2025.

The growth of the industry during the historical period experienced notable volatility. This was owing to the cyclical nature of the automotive industry and the disruptions caused by the COVID-19 pandemic. The pandemic LED to a sharp decline in vehicle production and sales, with global automotive sales falling from 90.3 million units in 2020 to 5.2 million units in 2025.

The statistics directly impacted the demand for cylinder liners as these components are critical in internal combustion engines (ICEs). The recovery phase for the market began in 2025 with key regions, including the United States, China, and Europe seeing gradual improvements in demand.

The industry is anticipated to reach USD 5,182.9 million by 2025 and is projected to rise at a CAGR of 6.7% during the forecast period. It is estimated to reach USD 9,884.3 million by 2035.

The industry is set to witness steady growth throughout the forecast period supported by ongoing innovations in engine technologies and a resurgence in vehicle production. The push for better fuel efficiency, emissions reduction, and enhanced engine performance is projected to continue to augment demand for cylinder liners, especially those made with cutting-edge materials that can withstand high temperatures and pressures.

The anticipated transition toward alternative fuel vehicles, including hybrids, is also set to shape the demand for automotive cylinder liners. Despite a potential decline in ICE vehicle demand, the need for high-performance liners in hybrid and performance-oriented ICE engines is likely to remain strong.

Manufacturers are anticipated to focus on developing cylinder liners that meet the evolving requirements of modern engines, ensuring they align with new technologies and designs. This focus on innovation will likely be a key driving factor over the forecast period.

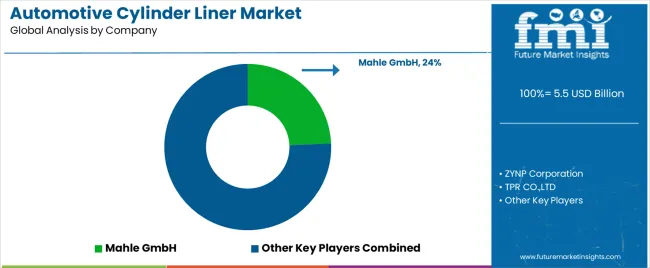

Tier 1 consists of organizations with a revenue above USD 100 million. These businesses capture a significant share ranging between 32% to 36% in the global market. They are categorized by high production capacity and an extensive product portfolio.

The organizations are distinguished by their expertise in manufacturing and a broad geographical reach that is underpinned by a robust consumer base. Renowned companies within Tier 1 include ZYNP Corporation, TPR CO., LTD., Tenneco, Mahle GmbH, and NIPPON PISTON RING Co., Ltd.

Tier 2 is made up of mid-sized players with a revenue below USD 100 million. These companies have a presence in specific regions and have a huge impact on the local industry. Businesses in Tier 2 are characterized by a strong presence overseas and robust industry knowledge.

The companies may not have cutting-edge technology and a wide global reach like organizations in Tier 1. However, they have access to good technology and ensure regulatory compliance. Zhongyuan Cylinder Liner Company Limited GKNZ, Liners India Limited, and Melling Cylinder Sleeves are prominent companies in Tier 2.

The section provides companies with an overview of the industry. It consists of a detailed analysis of the emerging trends and opportunities on a country-by-country basis. This country-specific examination of the dynamics is anticipated to help companies understand the complex nature of the business.

The examination comprises key factors, potential challenges, and forecasts influencing the demand, production, and consumption of the product within each country. This section aims to help companies make informed decisions and develop effective strategies tailored to individual countries.

The United States is projected to dominate in terms of country-wise growth during the assessment period with an estimated CAGR of 6.2%. Japan, Germany, and India are set to follow behind to become the leading countries with projected CAGRs of 6%, 5.6%, and 5.4%, respectively.

| Countries | CAGR 2025 to 2035 |

|---|---|

| United States | 6.2% |

| Japan | 6% |

| Germany | 5.6% |

| India | 5.4% |

| China | 5.3% |

Sales of automotive cylinder liners in China are projected to reach USD 1,682.6 million with an estimated CAGR of 5.3% by 2035. The country’s booming automobile industry is positioned to be a prominent driver of growth in the automotive cylinder liner market.

The automotive industry in China, in 2025, exhibited strong growth, with passenger car production surpassing 30.16 million units and total sales exceeding 30.09 million units. The industry achieved a year-on-year growth of 11.6% and 12%, as reported by the China Association of Automobile Manufacturers (CAAM).

China's emergence as the world’s most significant car exporter is set to be another key trend. The country overtook Japan with 5.5 million units exported in the first 11 months of 2025, marking a year-on-year increase of 58%.

The country’s ability to produce high-quality automotive cylinder liners with efficiency and cost-effectiveness reinforces its global standing. Innovations in automotive technology in China are also set to increase the demand for unique and improved automotive cylinder liners.

The United States automotive cylinder liner market is set to rise at a CAGR of 6.2% during the forecast period to reach a size of USD 1,333.2 million by 2035. This growth is primarily driven by rising consumer demand for innovative engine technologies in the country. As a pivotal player in the global automotive landscape, the United States is at the forefront of developing high-performance cylinder liners.

Local automakers are adopting cutting-edge materials and techniques to enhance the durability and efficiency of these components. For instance, Ford's use of plasma-transferred wire arc (PTWA) technology in its EcoBoost engines has LED to the innovation of light and durable cylinder liners that boost fuel efficiency and lower emissions.

The push for innovation aligns with consumer expectations for engines that deliver better performance, low emissions, and high longevity. It helps in solidifying the position of the United States as a prominent country for unique cylinder liners.

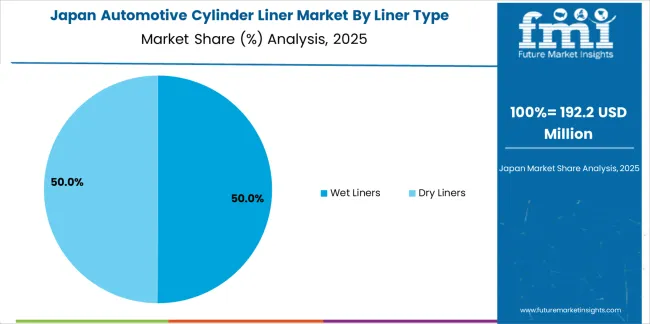

Japan is projected to showcase a CAGR of 6% during the assessment period in the automotive cylinder liner market, taking its value to USD 375.5 million by 2035. The country, driven by its robust automotive industry and commitment to technological innovation, provides substantial opportunities for automotive cylinder liner manufacturers.

The country’s automotive industry, home to leading automakers, including Toyota, Honda, and Nissan, has consistently pushed the boundaries of engine efficiency and performance.

These companies are focusing on developing unique engine designs that require high-quality cylinder liners to meet the rising demands for durability, heat resistance, and lightweight properties. As Japan continues to lead in automotive innovations, manufacturers of cylinder liners stand to benefit from this progressive environment, fostering growth.

The section provides companies with insightful data and analysis of the two leading segments. Segmentation of these categories assists organizations in understanding the dynamics and investing in the beneficial zones.

Examination of the growth helps businesses gain a thorough understanding of the trends, opportunities, and challenges present in the market. This analysis is anticipated to help companies navigate the complex environment of the business world and make informed decisions.

Wet liner is set to lead in terms of liner type with a value share of 52.2% in 2025. In terms of material type, cast iron is estimated to dominate with a value share of 73.4% in the same year.

| Segment | Wet Liner (Liner Type) |

|---|---|

| Value Share (2025) | 52.2% |

Wet-type cylinder liners are anticipated to lead in terms of liner type with a value share of 52.2% in 2025. This growth is attributed to their exceptional performance and longevity in engine applications. These liners are widely preferred for their ability to provide superior cooling, which enhances engine efficiency and extends component lifespan.

Leading automotive manufacturers like BMW have adopted wet-type liners in their latest engine designs to improve thermal management and reduce engine wear. This choice supports the engine's high-performance requirements while meeting stringent emission standards. The integration of wet liners in BMW's high-output engines highlights their critical role in achieving durability and operational reliability under demanding conditions.

| Segment | Cast Iron (Material Type) |

|---|---|

| Value Share (2025) | 73.4% |

Cast iron is anticipated to emerge as the dominating material type with a predicted value share of 73.4% in 2025. Its cost-effectiveness and ease of machining are the key factors driving demand. This material allows manufacturers to efficiently produce liners with complex geometries, thereby reducing manufacturing costs.

For instance, Volkswagen has used cast iron cylinder liners in its 1.0 TSI engines. This choice is pushed by the materials’ ability to provide reliable performance while maintaining affordability. The material's machinability also supports the precise tolerances required for high-efficiency engines, making it a preferred choice in both standard and performance applications.

Key players in the industry include ZYNP Corporation, TPR CO., LTD, Tenneco, Mahle GmbH, NIPPON PISTON RING Co., Ltd, and Cooper Corp. Key companies manufacturing automotive cylinder liners moderately consolidate the market with 32% to 36% share. They are progressively prioritizing technological innovations, integrating sustainable practices, and broadening their footprints in several regions.

Customer satisfaction remains paramount. Prominent companies are actively fostering collaborations to stay at the forefront of innovation, ensuring their automotive cylinder liners align with the evolving demands and maintain superior standards of quality and adaptability.

Companies are adopting a proactive approach to mitigate the risks associated with the procurement of raw materials. This strategy ensures a consistent and uninterrupted supply of materials that are necessary for the production of cylinder liners.

The market is showcasing an increased consumer demand for the use of lightweight materials in the production of automotive cylinder liners. Manufacturers are hence adopting lightweight materials, including aluminum and composite alloys to improve fuel efficiency, decrease emissions, and fulfill consumer requirements.

The industry experiences stiff competition from aftermarket suppliers that offer relatively low-cost alternatives to cylinder liners. Original equipment manufacturers (OEMs) will hence be required to focus on product differentiation while appending value-added services to stay competitive in the industry.

Industry Updates

In terms of liner type, the industry is segregated into dry liners and wet liners.

Cast iron, aluminum alloy, steel, and titanium alloy are the material types.

Light-duty vehicles and heavy-duty vehicles are the two vehicle types.

Automotive cylinder liners have applications in diesel engines and gasoline engines.

The sector is spread across North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia and Pacific, and the Middle East and Africa.

The global automotive cylinder liner market is estimated to be valued at USD 5.5 billion in 2025.

The market size for the automotive cylinder liner market is projected to reach USD 10.6 billion by 2035.

The automotive cylinder liner market is expected to grow at a 6.7% CAGR between 2025 and 2035.

The key product types in automotive cylinder liner market are wet liners and dry liners.

In terms of material type, cast iron segment to command 73.4% share in the automotive cylinder liner market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Automotive Cylinder Block Market

Automotive Headliners Market Size and Share Forecast Outlook 2025 to 2035

Automotive Gas Cylinder Market Growth - Trends & Forecast 2025 to 2035

Automotive Headliner Market Growth - Trends & Forecast 2025 to 2035

Automotive Roof Liners Market Size and Share Forecast Outlook 2025 to 2035

Automotive Cast Iron Cylinder Head Market - Growth & Demand 2025 to 2035

Engine Cylinder Liners Market Size and Share Forecast Outlook 2025 to 2035

Automotive Clutch Slave Cylinder Market Growth – Trends & Forecast 2024-2034

Automotive Brake Booster and Master Cylinder Market Size and Share Forecast Outlook 2025 to 2035

Automotive Direct Liquid Cooling IGBT Module Market Size and Share Forecast Outlook 2025 to 2035

Automotive Hoses and Assemblies Market Size and Share Forecast Outlook 2025 to 2035

Automotive Network Testing Market Size and Share Forecast Outlook 2025 to 2035

Automotive Performance Part Market Size and Share Forecast Outlook 2025 to 2035

Automotive Carbon Ceramic Brake Market Size and Share Forecast Outlook 2025 to 2035

Automotive Camshaft Market Size and Share Forecast Outlook 2025 to 2035

Automotive Stamping Industry Analysis in India Size and Share Forecast Outlook 2025 to 2035

Automotive Microcontroller Market Size and Share Forecast Outlook 2025 to 2035

Automotive Roof Rails Market Size and Share Forecast Outlook 2025 to 2035

Cylinder Boring Machine Market Size and Share Forecast Outlook 2025 to 2035

Automotive Active Safety System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA