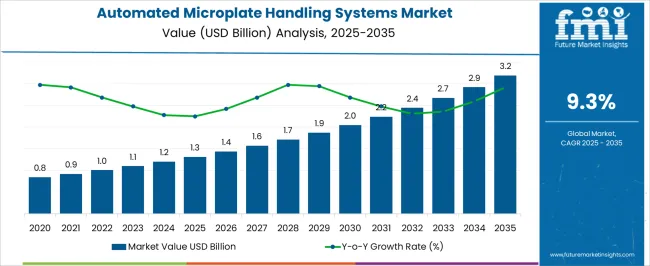

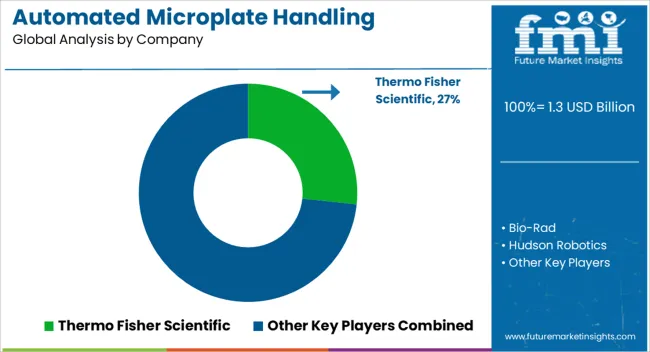

The Automated Microplate Handling Systems Market is estimated to be valued at USD 1.3 billion in 2025 and is projected to reach USD 3.2 billion by 2035, registering a compound annual growth rate (CAGR) of 9.3% over the forecast period.

| Metric | Value |

|---|---|

| Automated Microplate Handling Systems Market Estimated Value in (2025 E) | USD 1.3 billion |

| Automated Microplate Handling Systems Market Forecast Value in (2035 F) | USD 3.2 billion |

| Forecast CAGR (2025 to 2035) | 9.3% |

The Automated Microplate Handling Systems market is experiencing steady growth, driven by increasing demand for high-throughput laboratory automation and the growing need for efficiency in sample processing. The current market scenario reflects the adoption of automated systems across research laboratories, diagnostic centers, and pharmaceutical companies to accelerate testing workflows and minimize human error.

These systems enable seamless integration with downstream laboratory instruments, reducing turnaround time and enhancing reproducibility of results. The market is being further supported by advancements in robotics, software integration, and the miniaturization of microplate-based assays.

Growing investment in genomics, proteomics, and drug discovery has reinforced the need for automated handling solutions, while the push towards precision medicine and personalized diagnostics is driving demand for scalable and reliable laboratory automation The future outlook is shaped by increasing adoption of intelligent automation, including AI-enabled microplate systems capable of adaptive sample handling, which is expected to further enhance throughput and operational efficiency across laboratories globally.

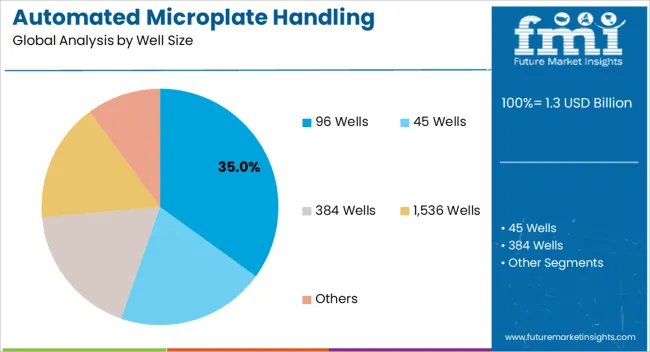

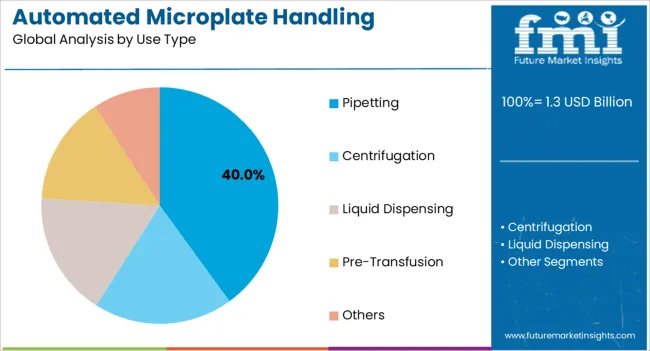

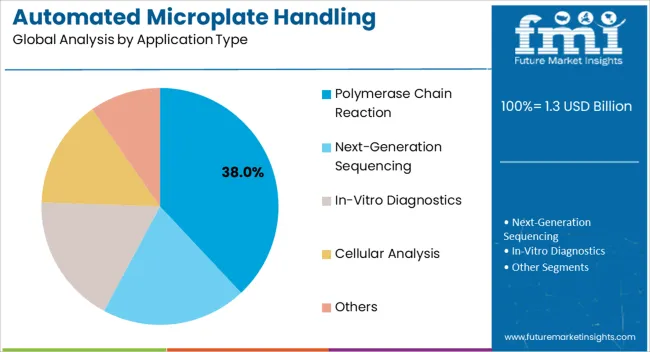

The automated microplate handling systems market is segmented by well size, use type, application type, end users, and geographic regions. By well size, automated microplate handling systems market is divided into 96 Wells, 45 Wells, 384 Wells, 1,536 Wells, and Others. In terms of use type, automated microplate handling systems market is classified into Pipetting, Centrifugation, Liquid Dispensing, Pre-Transfusion, and Others. Based on application type, automated microplate handling systems market is segmented into Polymerase Chain Reaction, Next-Generation Sequencing, In-Vitro Diagnostics, Cellular Analysis, and Others. By end users, automated microplate handling systems market is segmented into Hospitals, Research Institutes, Diagnostic Centers, and Others. Regionally, the automated microplate handling systems industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The 96 Wells well size segment is projected to hold 35.00% of the Automated Microplate Handling Systems market revenue in 2025, making it the leading well size in the market. This dominance is being attributed to its standardization across multiple laboratory assays and compatibility with a wide range of analytical instruments.

The prevalence of 96 well microplates in both academic and industrial laboratories has facilitated rapid integration with automated handling systems, supporting high-throughput screening and reproducible results. Adoption has been reinforced by the ability to perform multiple parallel reactions efficiently while maintaining assay consistency and precision.

As laboratories increasingly prioritize workflow automation to reduce human intervention and error, the 96 Wells segment has benefited from scalability and ease of adaptation in existing setups The established presence of 96 well formats in global laboratory protocols ensures ongoing demand, while the segment continues to serve as a cost-effective and flexible solution for diverse experimental needs, further reinforcing its leading position.

The Pipetting use type segment is expected to account for 40.00% of the Automated Microplate Handling Systems market revenue in 2025, emerging as the most prominent application type. This position is being driven by the critical role pipetting plays in ensuring precise and accurate liquid handling across diverse assays.

Automated pipetting reduces variability in sample volumes, increases reproducibility, and minimizes cross-contamination, which is essential for high-throughput research and diagnostic workflows. Laboratories are increasingly relying on automated pipetting to manage complex protocols with high precision, improving productivity while maintaining data integrity.

The adoption of robotic pipetting systems has been further enhanced by their compatibility with multiple microplate formats and their ability to integrate seamlessly with downstream analytical instruments As research and diagnostic laboratories continue to seek efficiency and reliability in sample processing, automated pipetting is expected to remain the dominant use type, providing measurable improvements in workflow efficiency and operational scalability.

The Polymerase Chain Reaction application type segment is projected to hold 38.00% of the Automated Microplate Handling Systems market revenue in 2025, making it the leading application segment. This dominance is being attributed to the widespread adoption of PCR for molecular diagnostics, genetic research, and drug discovery workflows.

Automated microplate handling in PCR processes ensures accurate sample distribution, reduces human error, and enables high-throughput amplification, which is critical for laboratories handling large volumes of samples. The segment’s growth has been reinforced by the increasing demand for rapid and reliable detection of pathogens, including in clinical diagnostics and epidemiological monitoring.

Integration with automated thermocyclers and liquid handling systems has further accelerated adoption by improving consistency, reproducibility, and laboratory efficiency As PCR-based applications continue to expand in genomics, diagnostics, and research, automated microplate systems supporting this workflow are expected to sustain market leadership, driven by the need for precision, speed, and scalability in molecular biology laboratories.

A Microplate is a flat plate that has many wells on it. These wells serve as small test tubes in clinical and analytical diagnostic testing laboratories. Automated microplate handling systems are used to handle these microplates during any medical diagnostic or analytical procedure.

Automated microplate handling systems are extensively used in enzyme-linked immunosorbent assay procedures also known as ELISA. Manual microplate handling systems are more prone to human-induced errors and are labour intensive.

These handling systems are used in high-throughput protocols in which the microtiter plates are designed to move around a work cell, place or remove them from microplate nests and microplate stacks of other devices like, incubators, microplate readers and liquid handlers.

Automated microplate handling systems work seamlessly with different molecular devices for higher throughput and improved process flow.

These systems allow analysts to speed up and control range of processes. These are also tremendously used in cellular analysis, next generation sequencing, serial dilution, PCR set-up, plate labelling, toxicology etc.

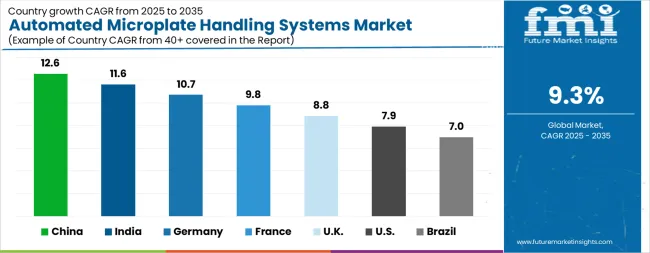

| Country | CAGR |

|---|---|

| China | 12.6% |

| India | 11.6% |

| Germany | 10.7% |

| France | 9.8% |

| UK | 8.8% |

| USA | 7.9% |

| Brazil | 7.0% |

The Automated Microplate Handling Systems Market is expected to register a CAGR of 9.3% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 12.6%, followed by India at 11.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 7.0%, yet still underscores a broadly positive trajectory for the global Automated Microplate Handling Systems Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 10.7%. The USA Automated Microplate Handling Systems Market is estimated to be valued at USD 473.1 million in 2025 and is anticipated to reach a valuation of USD 1.0 billion by 2035. Sales are projected to rise at a CAGR of 7.9% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 61.9 million and USD 37.1 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.3 Billion |

| Well Size | 96 Wells, 45 Wells, 384 Wells, 1,536 Wells, and Others |

| Use Type | Pipetting, Centrifugation, Liquid Dispensing, Pre-Transfusion, and Others |

| Application Type | Polymerase Chain Reaction, Next-Generation Sequencing, In-Vitro Diagnostics, Cellular Analysis, and Others |

| End Users | Hospitals, Research Institutes, Diagnostic Centers, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Thermo Fisher Scientific, Bio-Rad, Hudson Robotics, Avantor, Keysight, Danaher, PerkinElmer, Corning, Mindray Medical International, and Lonza |

The global automated microplate handling systems market is estimated to be valued at USD 1.3 billion in 2025.

The market size for the automated microplate handling systems market is projected to reach USD 3.2 billion by 2035.

The automated microplate handling systems market is expected to grow at a 9.3% CAGR between 2025 and 2035.

The key product types in automated microplate handling systems market are 96 wells, 45 wells, 384 wells, 1,536 wells and others.

In terms of use type, pipetting segment to command 40.0% share in the automated microplate handling systems market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Automated Radionuclide Dispenser Market Size and Share Forecast Outlook 2025 to 2035

Automated Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Automated Machine Learning Market Forecast Outlook 2025 to 2035

Automated CPR Device Market Size and Share Forecast Outlook 2025 to 2035

Automated Compound Storage and Retrieval (ACSR) Market Size and Share Forecast Outlook 2025 to 2035

Automated People Mover Market Size and Share Forecast Outlook 2025 to 2035

Automated Truck Loading System Market Size and Share Forecast Outlook 2025 to 2035

Automated Infrastructure Management Solution Market Size and Share Forecast Outlook 2025 to 2035

Automated Mineralogy Solution Market Size and Share Forecast Outlook 2025 to 2035

Automated Labeling Machines Market Size and Share Forecast Outlook 2025 to 2035

Automated Solar Panel Cleaning Market Size and Share Forecast Outlook 2025 to 2035

Automated Molecular Diagnostics Testing System Market Size and Share Forecast Outlook 2025 to 2035

Automated Infrastructure Management (AIM) Solutions Market Size and Share Forecast Outlook 2025 to 2035

Automated Window Blinds Market Size and Share Forecast Outlook 2025 to 2035

Automated Fingerprint Identification System (AFIS) Market Size and Share Forecast Outlook 2025 to 2035

Automated Cannabis Testing Market Size and Share Forecast Outlook 2025 to 2035

Automated Algo Trading Market Size and Share Forecast Outlook 2025 to 2035

Automated Centrifuge System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Automated Number Plate Recognition (ANPR) and Detection Sensors Market Size and Share Forecast Outlook 2025 to 2035

Automated Tray Fill and Seal Machines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA