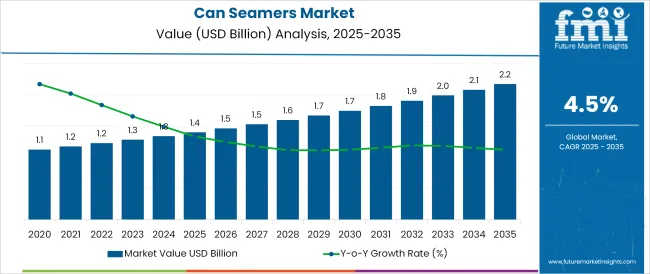

The Can Seamers Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 2.2 billion by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

The can seamers market is undergoing steady growth as manufacturers across food, beverage, and industrial sectors prioritize automation, efficiency, and quality assurance in packaging operations. Rising demand for metal cans driven by sustainability trends, extended shelf life requirements, and brand differentiation is fostering the adoption of advanced seaming machines.

The emphasis on minimizing product loss, ensuring hermetic sealing, and complying with stringent hygiene and safety standards has led companies to invest in reliable seaming technologies. Future growth is expected to benefit from the integration of digital monitoring systems, compact machine designs for space constrained facilities, and the rising penetration of metal packaging in emerging markets.

Enhanced operational throughput, reduced labor dependency, and improvements in energy efficiency are paving the way for wider acceptance of can seamers across diverse end user segments.

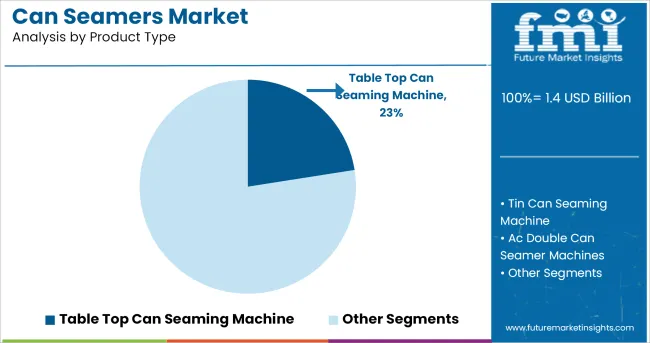

The market is segmented by Product Type, Capacity (Pieces / Minute), Operation, Weight, Power, Phase Type, and Material Type and region. By Product Type, the market is divided into Table Top Can Seaming Machine, Tin Can Seaming Machine, Ac Double Can Seamer Machines, Can Still Type Can Seamer Machine, Pet Can Tin Filler Seamer Machine, Regular (Round) Can Seamer Machine, Irregular (Non-Round) Can Seamer, and Others.

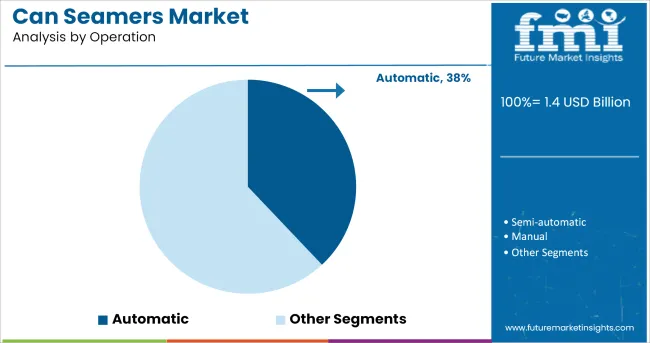

In terms of Capacity (Pieces / Minute), the market is classified into 30-50, < 20, 20-30, 50-80, and >80. Based on Operation, the market is segmented into Automatic, Semi-automatic, and Manual. By Weight, the market is divided into 100-150 Kg, 80-100 Kg, 150-200 Kg, 200-500, and >500 Kg.

By Power, the market is segmented into 6-8 KW, 4-6 KW, 8-10 KW, and >10 KW. By Phase Type, the market is segmented into 3 Phase, Single Phase, and 2 Phase. By Material Type, the market is segmented into Stainless Steel, Mild-Steel, Cast Iron, and Others.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Within the product type category, the table top can seaming machine segment is projected to account for 22.5% of the market revenue in 2025, establishing itself as a significant subsegment. This share is supported by its suitability for small scale production, craft businesses, and pilot lines where flexibility and ease of use are valued over high throughput.

The compact design, lower capital investment, and ability to seam various can sizes without extensive changeovers have made these machines an attractive choice for niche manufacturers. Additionally, their portability and minimal installation requirements have enabled deployment in constrained spaces and on demand production setups.

These advantages have reinforced the adoption of table top machines in operations seeking cost effective, reliable seaming solutions for moderate volumes while maintaining product integrity and quality.

When analyzed by capacity, the 30-50 pieces per minute segment is expected to capture 24.0% of the market revenue in 2025, reflecting its balanced position between efficiency and affordability. This capacity range has been favored by mid sized manufacturers who require higher productivity than manual or low capacity machines but do not yet need high speed industrial systems.

Its adoption has been strengthened by the ability to deliver consistent sealing quality while accommodating a moderate footprint and lower energy consumption. Operators have also recognized this range as optimal for batch production and seasonal demand fluctuations, offering flexibility without compromising throughput.

The alignment of this segment with the needs of growing businesses and its capacity to support expansion plans at a manageable investment level have secured its strong market presence.

In terms of operation type, the automatic segment is forecast to dominate with 38.0% of the market revenue in 2025, driven by widespread adoption in high volume production environments. This leadership has been supported by the ability of automatic machines to deliver superior productivity, consistency, and hygiene with minimal human intervention.

Their integration into fully automated production lines has enabled manufacturers to meet rising demand while ensuring compliance with quality and safety regulations. Enhanced features such as programmable settings, automated lubrication, and self diagnostics have further elevated operational efficiency and reliability.

The reduction in labor costs, minimization of operator errors, and ability to sustain continuous operation have made automatic can seamers the preferred choice for large scale, quality conscious producers aiming to optimize throughput and maintain competitive advantage.

The utilization of can seamers in food and beverages industries for packaging purpose is anticipated to give a positive impact to the production volume. Moreover, rising concerns of packaging related issues are also likely generate significant market demand for can seamers market during the assessment year.

Can seamers are very easy to use and do not required any technical knowledge and expertise. Although, it does not require too much space and huge capital investment. Due to this fact, it is attribute to provide significant opportunities for workshops and small plant. It is projected to create new aspect for manufacturers across the globe.

The utilization of can seamers ensure no leakage to the can and provide a better outlook with cylindrical and rectangular shape. It will lead to attract other end use industries such as pharmaceutical and manufacturing industries.

The rising per capita income, improving lifestyle and population around the world is anticipated to create significant demand for food processing industries. It will directly intensify the utilization of can seamers and likely to give promising stance to the manufacturers.

The utilization of can seamers machine is anticipated to address the rising plastic waste and metal waste challenges throughout the globe. Since, these materials can be recycled in the form of large to small boxes for packaging purpose. It will lead to provide noteworthy sale to the manufactures during the forecast period.

The growing demand for lightweight, high-performance and automatic machines form the end use industries is likely to create abundant aspects for manufacturers.

Asia pacific region accounts for majority of the demand for can seamers machines due to high demand from food & beverages, pharmaceutical, packaging and manufacturing industries. The countries such as India, China, Japan, Australia and Singapore accounts for the foremost utilization of these machines, due to rapid industrialization and urbanization.

In addition to this, the import and exports activities is also associated with the packaging of food and related activities. It is anticipate to surge the utilization of can seamers in Asia Pacific regions during the forecast period.

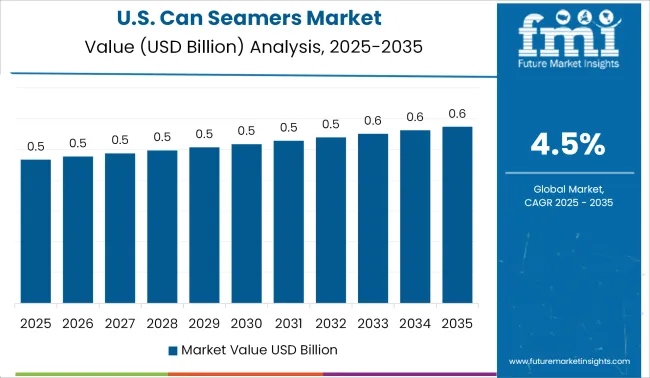

North America is anticipate to lead the global can seamer market during the forecast period. The surging demand from the USA retail sector is attributed to hold the foremost share during the same period. The increasing healthcare infrastructure is projected to account for considerable demand of can seamers for packaging purposes. In addition to this, chemical and paint industries also generates abundant aspect in North America region.

Europe is predicted to account for significant demand during the assessment period. The rising food & beverages industry is the foremost factor which drive the Europe can seamers market. Moreover, the rising hygiene related issues and rising per capita income are attribute to utilizing can based products, it is expected to give a positive impact to the production volume.

The automatic can seamer machine is a lucrative avenue from the end use industries, due to its cheap price and size. Moreover, it does not require any human efforts for product development. Additionally, semi-automatic and manual machines also account for significant demand, but due to adoption of automation and robotics in manufacturing industries automatic machines are likely to witness plethora of opportunities during the forecast period.

Some of the leading manufacturers of can seamer include

Leading manufacturers across the globe are continuously rising their investment to improve the production capacity and reduce the weight. It will lead to rise the utilization for small workshops and other industries. Moreover, key manufacturers are rising momentous amount on R&D for utilizing alternative power source. It will lead to improve the operational flexibility and reduce operational cost.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

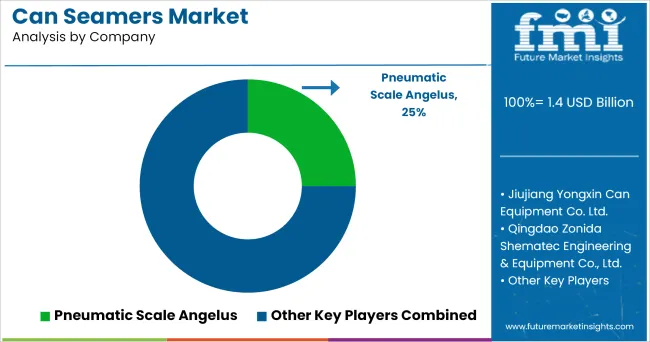

The global can seamers market is estimated to be valued at USD 1.4 billion in 2025.

The market size for the can seamers market is projected to reach USD 2.2 billion by 2035.

The can seamers market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in can seamers market are table top can seaming machine, tin can seaming machine, ac double can seamer machines, can still type can seamer machine, PET can tin filler seamer machine, regular (round) can seamer machine, irregular (non-round) can seamer and others.

In terms of capacity (pieces / minute), 30-50 segment to command 24.0% share in the can seamers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industry Share & Competitive Positioning in Can Seamer Market

Beverage Can Seamers Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Beverage Can Seamers Manufacturers

Canine Cancer Screening Services Market Size and Share Forecast Outlook 2025 to 2035

Candle Filter Cartridges Market Size and Share Forecast Outlook 2025 to 2035

Can Stack Motors Market Size and Share Forecast Outlook 2025 to 2035

Cancer Registry Software Market Size and Share Forecast Outlook 2025 to 2035

Canine Arthritis Treatment Market Forecast and Outlook 2025 to 2035

Can Stack Stepper Motors Market Forecast and Outlook 2025 to 2035

Canned Wet Cat Food Market Size and Share Forecast Outlook 2025 to 2035

Canned Food Packaging Market Size and Share Forecast Outlook 2025 to 2035

Canada Compact Wheel Loader Industry Analysis Size and Share Forecast Outlook 2025 to 2035

Cancer Biological Therapy Market Size and Share Forecast Outlook 2025 to 2035

Canned Wine Market Size and Share Forecast Outlook 2025 to 2035

Canned Pet Food Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Canada Straws Market Size and Share Forecast Outlook 2025 to 2035

Canthaxanthin Market Size and Share Forecast Outlook 2025 to 2035

Canned Food Packaging Industry Analysis in the United Kingdom Size and Share Forecast Outlook 2025 to 2035

Canada Executive Education Program Market Size and Share Forecast Outlook 2025 to 2035

Can Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA