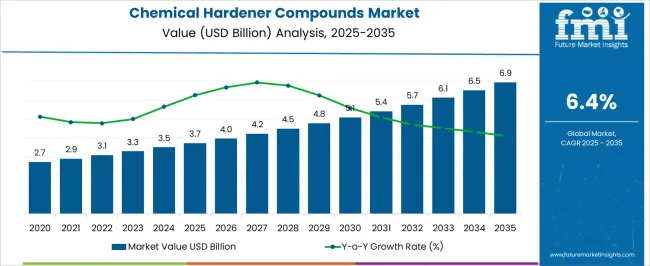

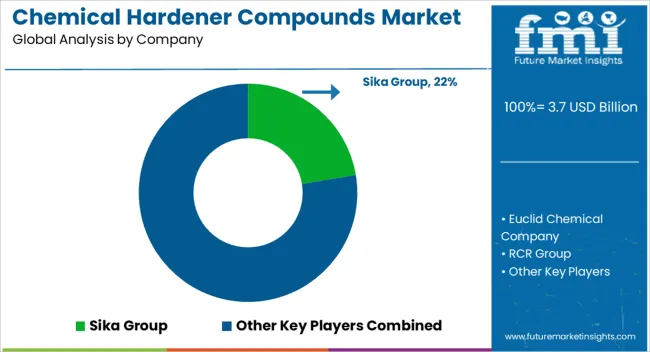

The Chemical Hardener Compounds Market is estimated to be valued at USD 3.7 billion in 2025 and is projected to reach USD 6.9 billion by 2035, registering a compound annual growth rate (CAGR) of 6.4% over the forecast period.

| Metric | Value |

|---|---|

| Chemical Hardener Compounds Market Estimated Value in (2025 E) | USD 3.7 billion |

| Chemical Hardener Compounds Market Forecast Value in (2035 F) | USD 6.9 billion |

| Forecast CAGR (2025 to 2035) | 6.4% |

The Chemical Hardener Compounds market is experiencing steady growth driven by the rising demand for high-performance construction materials, industrial adhesives, and composite manufacturing. The market is benefiting from increasing adoption of durable and fast-setting compounds across construction, automotive, aerospace, and industrial applications.

Growth is further supported by the need for improved mechanical strength, resistance to environmental factors, and faster production cycles in modern manufacturing processes. Innovations in chemical formulations have allowed hardeners to enhance curing efficiency and compatibility with a variety of substrates, reducing downtime and operational costs.

The market outlook is positive, with the ongoing focus on sustainable and environmentally friendly compounds creating opportunities for advanced liquid and powder formulations Expansion in emerging economies, alongside technological advancements in material science and automation in production processes, is expected to further drive demand for chemical hardeners over the coming years, supporting long-term market development.

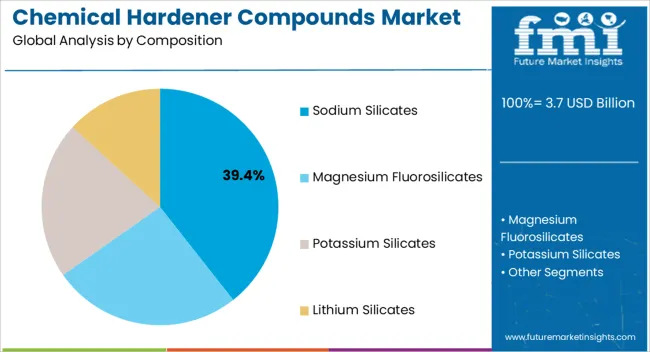

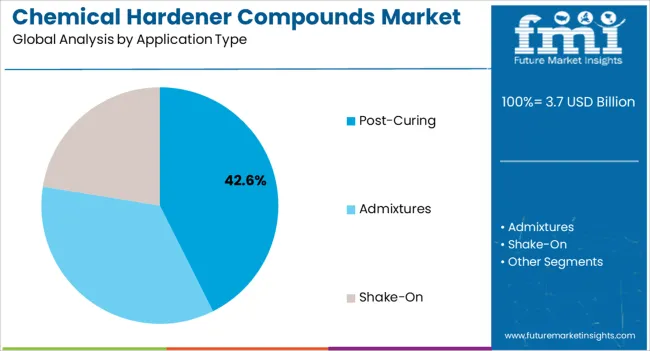

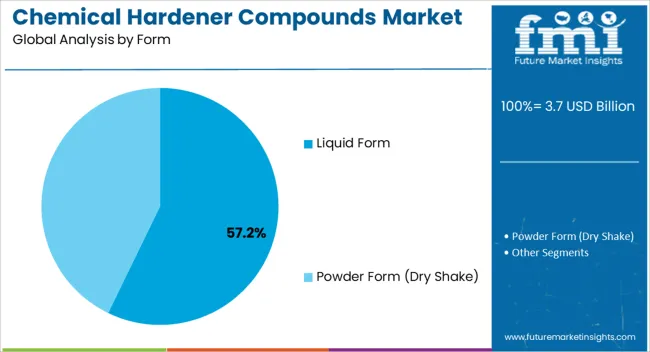

The chemical hardener compounds market is segmented by composition, application type, form, end use, and geographic regions. By composition, chemical hardener compounds market is divided into Sodium Silicates, Magnesium Fluorosilicates, Potassium Silicates, and Lithium Silicates. In terms of application type, chemical hardener compounds market is classified into Post-Curing, Admixtures, and Shake-On. Based on form, chemical hardener compounds market is segmented into Liquid Form and Powder Form (Dry Shake). By end use, chemical hardener compounds market is segmented into Commercial Construction, Residential Construction, Industrial Construction, and Infrastructure Construction. Regionally, the chemical hardener compounds industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Sodium Silicates composition segment is projected to hold 39.40% of the overall Chemical Hardener Compounds market revenue in 2025, making it the leading composition type. This dominance is attributed to the high binding capacity, water solubility, and chemical stability of sodium silicates, which allow them to perform effectively across a variety of applications.

Widespread use in industrial adhesives, concrete stabilization, and refractory products has reinforced its adoption. The growth of this segment has been further supported by the ease of formulation adjustments, enabling manufacturers to tailor performance characteristics for specific requirements such as thermal resistance and mechanical strength.

Additionally, the ability to combine sodium silicates with other compounds to enhance curing efficiency and reduce energy consumption has promoted its preference Long-term reliance on established industrial processes and the compatibility of sodium silicates with both automated and manual mixing systems has ensured steady market growth, positioning this composition as a cornerstone of chemical hardener applications.

The Post-Curing application type segment is expected to account for 42.60% of the Chemical Hardener Compounds market revenue in 2025, emerging as the leading application type. This predominance is being driven by its critical role in enhancing mechanical and thermal properties of cured products, particularly in industrial and construction contexts. Post-curing allows chemical hardeners to complete cross-linking reactions effectively, improving the durability, strength, and resistance of materials.

The adoption of post-curing processes has increased in applications where long-term stability and structural integrity are critical, such as composite panels, precast concrete elements, and specialty coatings. The segment’s growth has been further supported by manufacturers’ focus on minimizing production defects and optimizing energy efficiency during the curing process.

Additionally, post-curing offers flexibility in integrating automated heat or moisture curing systems, which aligns with modern industrial production standards These factors collectively contribute to the segment’s leading share and sustained growth in the chemical hardeners market.

The Liquid Form segment is projected to hold 57.20% of the Chemical Hardener Compounds market revenue in 2025, making it the leading form type. The growth of this segment is being driven by the ease of application, uniform mixing, and enhanced reaction control offered by liquid formulations. Liquid chemical hardeners enable precise dosing and rapid distribution throughout substrates, ensuring consistent curing and high-quality outcomes.

Industries such as construction, adhesives, and composites favor liquid forms due to their adaptability to automated dispensing systems and compatibility with large-scale production processes. The segment has also benefited from the increasing preference for formulations that reduce dust and handling risks compared to powders, thereby improving workplace safety and efficiency.

Additionally, liquid forms allow for faster penetration and reaction in complex or dense materials, enhancing overall performance The combination of operational efficiency, safety, and superior material properties has reinforced the segment’s market dominance and is expected to sustain its leading position in the coming years.

Chemical hardener compounds are used to increase the density and hardness of concrete surfaces. They are usually inorganic in nature and available in dry or liquid forms for application on cured or uncured concrete surfaces. Chemical hardener compounds, when applied to a concrete surface, react with the free lime in concrete, which results in a mixture consisting of dicalcium and tricalcium silicate compounds. These dicalcium and tricalcium silicate compounds further react with the excess water present in concrete to produce calcium silicate hydrate, which is also known as tobermorite gel.

The end result of this entire sequence is that the empty pores of the concrete surface are filled with the by-products, thus increasing the density of the concrete surface. Also, the crystalline structure of the mixture is further strengthened with enhanced bonding, which increases the surface hardness of concrete. The application of chemical hardener compounds reduces the pitting and dusting of concrete. Chemical hardener compounds are available in various chemical compositions, depending on the manufacturer. However, all of the compounds are composed of silicate ions, which ultimately react with the free lime in concrete.

Considering these aspects of chemical hardener compounds, the study of the trends and forecasts of the chemical hardener compounds market becomes an important read.

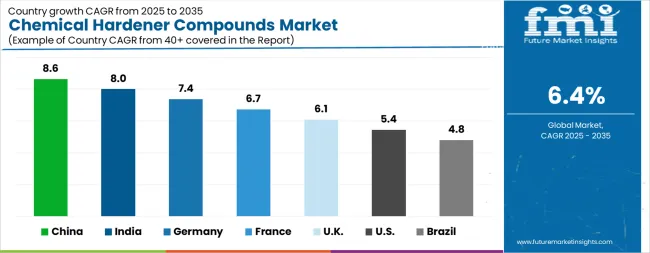

| Country | CAGR |

|---|---|

| China | 8.6% |

| India | 8.0% |

| Germany | 7.4% |

| France | 6.7% |

| UK | 6.1% |

| USA | 5.4% |

| Brazil | 4.8% |

The Chemical Hardener Compounds Market is expected to register a CAGR of 6.4% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 8.6%, followed by India at 8.0%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 4.8%, yet still underscores a broadly positive trajectory for the global Chemical Hardener Compounds Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.4%. The USA Chemical Hardener Compounds Market is estimated to be valued at USD 1.4 billion in 2025 and is anticipated to reach a valuation of USD 2.4 billion by 2035. Sales are projected to rise at a CAGR of 5.4% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 178.0 million and USD 93.8 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 3.7 Billion |

| Composition | Sodium Silicates, Magnesium Fluorosilicates, Potassium Silicates, and Lithium Silicates |

| Application Type | Post-Curing, Admixtures, and Shake-On |

| Form | Liquid Form and Powder Form (Dry Shake) |

| End Use | Commercial Construction, Residential Construction, Industrial Construction, and Infrastructure Construction |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Sika Group, Euclid Chemical Company, RCR Group, Flowcrete, Dribond Construction Chemicals, Laticrete International, W. R. Meadows, Boyer Industries Corporation (Prosoco), Convergent Concrete Technologies LLC, Fescon Oy, and Construction Material Chemical Industries |

The global chemical hardener compounds market is estimated to be valued at USD 3.7 billion in 2025.

The market size for the chemical hardener compounds market is projected to reach USD 6.9 billion by 2035.

The chemical hardener compounds market is expected to grow at a 6.4% CAGR between 2025 and 2035.

The key product types in chemical hardener compounds market are sodium silicates, magnesium fluorosilicates, potassium silicates and lithium silicates.

In terms of application type, post-curing segment to command 42.6% share in the chemical hardener compounds market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Chemical Hydraulic Valves Market Size and Share Forecast Outlook 2025 to 2035

Chemical Vapor Deposition Market Forecast Outlook 2025 to 2035

Chemical Recycling Service Market Forecast Outlook 2025 to 2035

Chemical Dosing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Chemical Filling System Market Size and Share Forecast Outlook 2025 to 2035

Chemical Absorbent Pads Market Size and Share Forecast Outlook 2025 to 2035

Chemical Indicator Inks Market Size and Share Forecast Outlook 2025 to 2035

Chemical Boiler Market Size and Share Forecast Outlook 2025 to 2035

Chemical Anchors Market Size and Share Forecast Outlook 2025 to 2035

Chemical Peel Market Size and Share Forecast Outlook 2025 to 2035

Chemical Protective Gloves Market Size and Share Forecast Outlook 2025 to 2035

Chemical Injection Pump Market Size and Share Forecast Outlook 2025 to 2035

Chemical Liquid Hydrogen Market Size and Share Forecast Outlook 2025 to 2035

Chemical Sensors Market Size and Share Forecast Outlook 2025 to 2035

Chemical Resistant EVA Film Market Size and Share Forecast Outlook 2025 to 2035

Chemical Resistant Fabrics Market Size and Share Forecast Outlook 2025 to 2035

Chemical Resistant Coating Market Size and Share Forecast Outlook 2025 to 2035

Chemical Distribution Market Size and Share Forecast Outlook 2025 to 2035

Chemical & Petrochemical IECS Market Size and Share Forecast Outlook 2025 to 2035

Chemical Air Separation Unit Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA