Flexible silos are the most common industrial packaging product used for the packaging applications in the food, plastics, chemical, and pharmaceutical industry. These bags are available in the variety of sizes with capacity ranging from 1 tonnes to 50 tonnes for bulk storage of the goods and products. They are supplied as the flat packs to the customers and erected on site. Flexible silos, also known as fabric silos, are manufactured from high tenacity, anti-static, woven polymeric material.

Flexible silos have high rigidity and load carrying capacities with a 7:1 safety factor for seams and fabric. Standard flexible silos are breathable bags and remove any air generated during the filling process. According to the packaging requirement, different types of flexible silos are available in the market which includes coated fabric silos, etc. which are also approved by FDA and ATEX. From the design perspective of flexible silos, they could be incorporated with the same features as of steel silos such as access doors, sight glasses, explosion relief panels, etc.

These silos could be filled manually by hand or by blowing system, road tanker, screw conveyor, bucket elevator, vacuum conveying, and other mechanical conveying machines. Flexible silos are available in square and rectangular shapes in the market. Also, it is very convenient to discharge flexible silos within a fraction of minutes. Also, some of the discharge options available in the market are vacuum take-off box, belt conveyor, bin activator, air pads, screw conveyor, stirring agitator discharger, etc. Some of the key products which are stored in the flexible silos are flake material, fillers such as chalk, salt, sugar, starch, EPS, polymer powder, etc.

The flexible silos market is expected to increase at a growth rate of 6%-7% annually in the next 4-5 years. Companies in this market are continuously innovating their existing product lines to offer wider options to its consumers for application-specific packaging application. The brand owners are shifting their packaging requirement to more sustainable and cheaper packaging alternatives. Growth in this market will be further fuelled by the increase in the number of food & beverages and petrochemical companies etc. in the developing regions.

Furthermore, flexible silos have witnessed moderate growth in the developed countries due to the high penetration of the other packaging formats for the similar applications. Although, the demand for flexible silos will increase at an impressive growth rate in the next 4-5 years and may outgrow other formats. Some of the companies provide vertically integrated solutions in the flexible silos market. One such company is Maguire Products Inc., a US-based material handling systems Manufacturer Company which offers flexible silos of capacity up to 50 tonnes and different types of silo systems.

Earlier, most of the industrial silos were made up of aluminum and steel material but the trend is changing from the metallic material to flexible fabric materials. For eg. - ABS silo and conveyor systems GmbH, a Germany based company has installed more than 70,000 silos worldwide which are made up of the high-strength, high-tech polyester fabric. One of the recent acquisitions in the flexible silos market is –

Flexible silos are prominently used for the packaging of the food & beverages and chemical products. Both of these industries comprises of around 50% of the global flexible silos market.

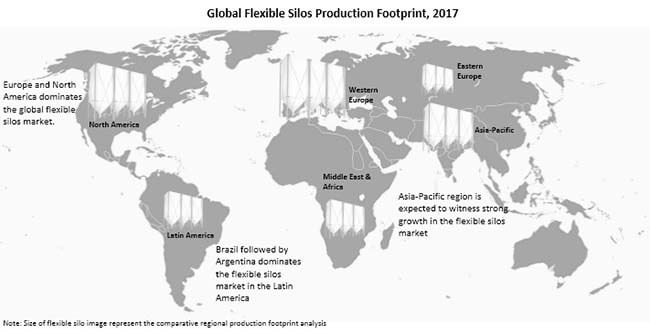

On the basis of region, the Flexible Silos market is segmented into seven regions which include North America, Latin America, Eastern Europe, Western Europe, Asia-Pacific, Middle East & Africa, and Japan. Flexible silos are more popular in the developed countries such as the U.S., Germany, Italy, etc. There is high penetration of the flexible silos in these regions due to a large number of manufacturers offering the product and lack of other alternatives available for similar packaging applications in the region.

The demand for flexible silos is expected to increase in the Asia-Pacific region due to increase in the number of food & beverages and chemical manufacturers in the region. Western Europe and North America are expected to show an almost similar trend with respect to demand in the flexible silos market. The MEA and Latin America region also offer untapped growth opportunities in the flexible silos market.

Some of the key players in the Flexible Silos market are Remae Industria e Comercio Ltda., Siloanlagen Achberg GmbH & Co. KG, Summit Systems, Inc., R.R.S.-INTERNATIONAL GmbH, ABS silo and conveyor systems GmbH, Spiroflow Systems, Inc., Maguire Products Inc., CS Plastics bvba, Contemar Silo Systems Inc., Zimmermann Verfahrenstechnik AG, Prillwitz y CIA SRL.

Tier 1 Companies: ABS silo and conveyor systems GmbH, Summit Systems, Inc., Siloanlagen Achberg GmbH & Co. KG

Tier 2 Companies: Siloanlagen Achberg GmbH & Co. KG, R.R.S.-INTERNATIONAL GmbH, Spiroflow Systems, Inc.

Tier 3 Companies: Maguire Products Inc., CS Plastics bvba, Contemar Silo Systems Inc., Zimmermann Verfahrenstechnik AG, Prillwitz y CIA SRL.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

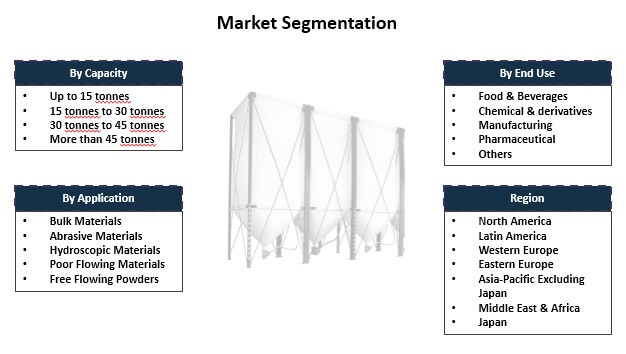

By Capacity

By Application

By End Use

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Flexible Plastic Pouch Market Size and Share Forecast Outlook 2025 to 2035

Flexible Packaging Paper Market Size and Share Forecast Outlook 2025 to 2035

Flexible Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible Rubber Sheets Market Size and Share Forecast Outlook 2025 to 2035

Flexible Printed Circuit Boards Market Size and Share Forecast Outlook 2025 to 2035

Flexible Packaging Machinery Market Size and Share Forecast Outlook 2025 to 2035

Flexible Electronic Market Size and Share Forecast Outlook 2025 to 2035

Flexible Foam Market Size and Share Forecast Outlook 2025 to 2035

Flexible Plastic Packaging Industry Analysis in United States Size and Share Forecast Outlook 2025 to 2035

Flexible Protective Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible AC Current Transmission System Market Size and Share Forecast Outlook 2025 to 2035

Flexible End-Load Cartoner Market Size and Share Forecast Outlook 2025 to 2035

Flexible Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible Screens Market Size and Share Forecast Outlook 2025 to 2035

Flexible Metallic Conduit Market Size and Share Forecast Outlook 2025 to 2035

Flexible Electrical Conduit Market Size and Share Forecast Outlook 2025 to 2035

Flexible Display Market Size and Share Forecast Outlook 2025 to 2035

Flexible Substrate Market Size and Share Forecast Outlook 2025 to 2035

Flexible Paper Battery Market Size and Share Forecast Outlook 2025 to 2035

Flexible Metallic Tubing Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA