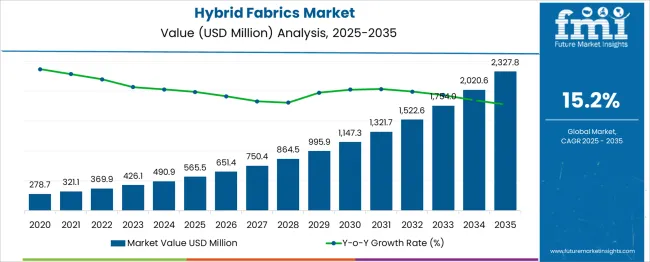

The Hybrid Fabrics Market is estimated to be valued at USD 565.5 million in 2025 and is projected to reach USD 2327.8 million by 2035, registering a compound annual growth rate (CAGR) of 15.2% over the forecast period. A saturation point analysis reveals that the market experiences a phase of rapid growth followed by signs of stabilization as it matures. Between 2025 and 2030, the market grows from USD 565.5 million to USD 1,147.3 million, contributing USD 581.8 million in growth, with a CAGR of 14.8%. This early-stage expansion is driven by increasing demand for hybrid fabrics in automotive, aerospace, and construction sectors, where lightweight, high-strength, and multifunctional materials are essential. The rapid adoption is fueled by innovations in fabric technology, performance benefits, and cost efficiency.

The first peak occurs at USD 1,147.3 million in 2030, followed by a slight deceleration between 2030 and 2032, where the market grows from USD 1,147.3 million to USD 1,321.7 million, adding USD 174.4 million with a CAGR of 7.5%. This deceleration indicates the market nearing its saturation point as adoption becomes widespread. From 2032 to 2035, the market grows from USD 1,321.7 million to USD 2,327.8 million, contributing USD 1,006.1 million in growth, with a CAGR of 15.2%. This final acceleration reflects continued innovation and demand, particularly in emerging markets and industries looking for advanced material solutions. The analysis shows initial sharp growth followed by stabilization and a final burst of expansion as new applications drive demand.

| Metric | Value |

|---|---|

| Hybrid Fabrics Market Estimated Value in (2025 E) | USD 565.5 million |

| Hybrid Fabrics Market Forecast Value in (2035 F) | USD 2327.8 million |

| Forecast CAGR (2025 to 2035) | 15.2% |

As industries prioritize energy efficiency and structural performance, hybrid fabrics have become a strategic material choice due to their ability to blend the distinct advantages of different fiber types, such as glass, carbon, and aramid.

The rising adoption of automation in manufacturing, coupled with advancements in composite processing technologies, is further accelerating the integration of hybrid fabrics in aerospace, automotive, wind energy, and construction sectors. Stringent emission norms and fuel efficiency regulations in the automotive and aviation industries have reinforced the need for high-strength, low-weight components where hybrid fabrics are increasingly being utilized.

Furthermore, collaborations between material science companies and end-use industries are fostering innovation in fabric weaves and resin compatibility, paving the way for cost-efficient and scalable production. The market outlook remains strong as global emphasis on sustainable and high-strength materials continues to shape investment and R&D in hybrid composites.

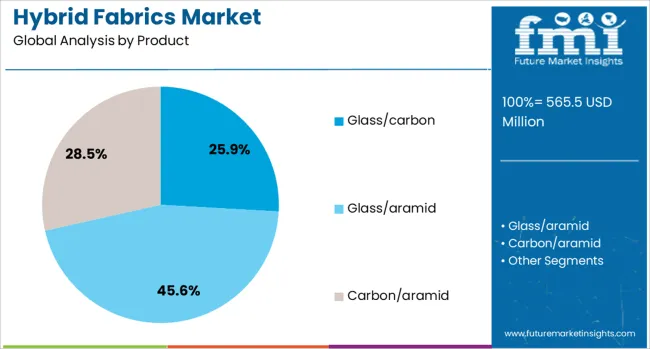

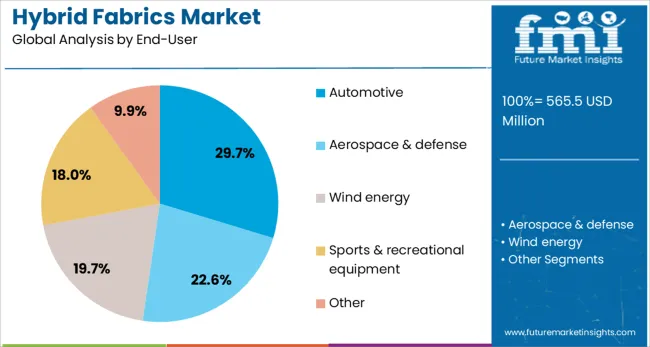

The hybrid fabrics market is segmented by product, end-user, and geographic regions. By product, the hybrid fabrics market is divided into Glass/carbon, Glass/aramid, Carbon/aramid, and others. In terms of end-users of the hybrid fabrics market, it is classified into Automotive, aerospace and defense, Wind energy, sports and recreational equipment, and others. Regionally, the hybrid fabrics industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Glass carbon hybrid fabrics are projected to account for 25.9% of the total product segment revenue in the hybrid fabrics market by 2025. This leading position is attributed to their exceptional balance between stiffness, impact resistance, and cost-effectiveness, which makes them suitable for applications requiring both structural integrity and weight reduction. These hybrid fabrics are being increasingly preferred in performance-critical applications where the mechanical limitations of individual fibers need to be compensated through hybridization.

The segment’s growth is also being supported by enhanced compatibility with various resin systems and improved fatigue performance in composite structures. Manufacturing flexibility and ease of processing using existing composite infrastructure have made glass carbon combinations viable for both low and high-volume production runs.

The growing emphasis on electric vehicle components, sporting goods, and marine structures is further strengthening demand, particularly where thermal resistance and flexural strength are crucial. Industry interest in recyclable and sustainable materials has also contributed to the segment’s expansion as hybrid configurations continue to evolve with circular design objectives.

The automotive segment is anticipated to hold 29.7% of the total end-user revenue share in the hybrid fabrics market in 2025, establishing its leadership among application areas. This dominance is driven by the escalating demand for lightweight materials to enhance fuel efficiency, vehicle performance, and battery range in electric and hybrid vehicles.

Hybrid fabrics are being increasingly used in structural and semi-structural automotive components including chassis parts, underbody shields, and interior elements due to their high strength-to-weight ratio and crash absorption capabilities. Regulatory pressures to meet carbon emission targets have compelled OEMs to replace traditional metals with fiber-reinforced composites that offer both durability and design flexibility.

The adaptability of hybrid fabrics in molding complex shapes, combined with their compatibility with existing thermoset and thermoplastic processes, has accelerated their use across both premium and volume segments. Additionally, advancements in joining techniques and material simulation tools are enabling seamless integration of hybrid fabrics into mainstream automotive platforms, further supporting the growth of this segment during the forecast period.

The hybrid fabrics market is growing as industries seek versatile, high-performance materials that offer a balance of strength, durability, and lightweight properties. Hybrid fabrics, made from a combination of natural and synthetic fibers, are increasingly being used in applications such as automotive, aerospace, and sports equipment. The demand for these fabrics is driven by the need for cost-effective and sustainable solutions that provide enhanced performance without compromising on quality. Despite challenges related to manufacturing complexities, technological innovations continue to drive market growth and expansion.

The primary driver of the hybrid fabrics market is the increasing demand for lightweight yet durable materials in industries such as automotive, aerospace, and construction. Hybrid fabrics offer a combination of natural and synthetic fibers, providing a balance of strength, flexibility, and low weight. In the automotive industry, hybrid fabrics are used to reduce vehicle weight, improving fuel efficiency without compromising on safety or performance. In aerospace, these fabrics are crucial for reducing the weight of aircraft components while maintaining structural integrity. The need for performance-driven, cost-effective, and energy-efficient materials across various industries is further driving the adoption of hybrid fabrics.

A significant challenge in the hybrid fabrics market is the complexity involved in the manufacturing process. The production of hybrid fabrics requires advanced techniques to combine natural and synthetic fibers effectively. Achieving the desired balance of properties such as strength, flexibility, and durability while maintaining cost-efficiency can be difficult. The cost of raw materials and the manufacturing processes involved in creating hybrid fabrics can make them more expensive than conventional fabrics, which may limit adoption in cost-sensitive industries. Additionally, the complexity of hybrid fabric production may pose challenges for smaller manufacturers without the required technical expertise or infrastructure.

Considerable growth opportunities exist in the hybrid fabrics market, driven by technological advancements and expanding applications across various industries. Innovations in fiber technology are improving manufacturing processes, enhancing quality, and reducing production costs. The increased use of hybrid fabrics in industries such as automotive, aerospace, and sports equipment, where high-performance materials are in demand, offers substantial growth potential. The ongoing shift toward more eco-friendly manufacturing practices, combined with the rising demand for sustainable materials in textiles, presents additional opportunities for hybrid fabrics as a preferred solution for the industry.

A major trend in the hybrid fabrics market is the growing demand for eco-friendly products, with more companies looking to incorporate eco-friendly materials into their products. Hybrid fabrics that combine natural fibers with synthetic alternatives are gaining traction as a sustainable option, as they offer performance benefits without relying entirely on synthetic materials. Customization is another emerging trend, as industries demand fabrics tailored to specific applications. For example, automotive manufacturers are increasingly using hybrid fabrics in vehicle interiors, requiring customized textures, durability, and aesthetics. The focus on creating more durable, efficient, and sustainable materials is driving innovation and expanding the range of applications for hybrid fabrics across multiple sectors.

| Country | CAGR |

|---|---|

| China | 20.5% |

| India | 19.0% |

| Germany | 17.5% |

| France | 16.0% |

| UK | 14.4% |

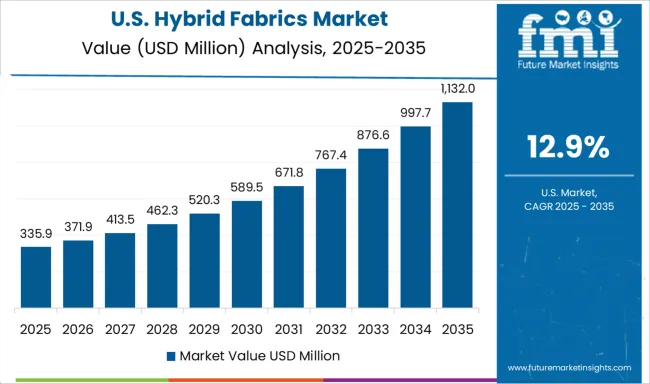

| USA | 12.9% |

| Brazil | 11.4% |

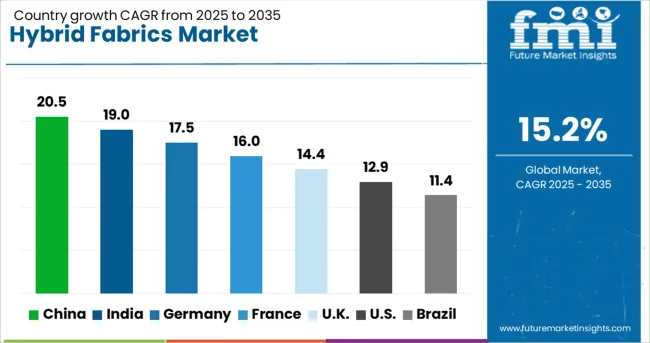

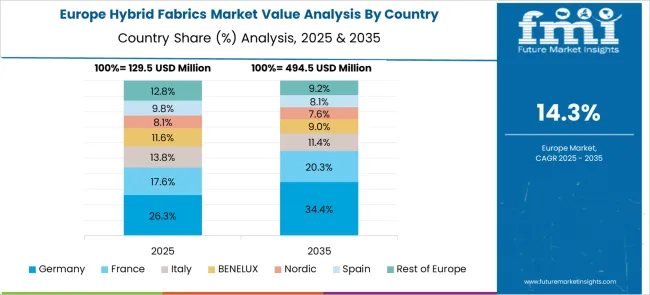

The global hybrid fabrics market is expected to grow at a CAGR of 15.2% from 2025 to 2035. China leads the market with a growth rate of 20.5%, followed by India at 19.0%. Germany is also experiencing strong growth with a CAGR of 17.5%, while the UK and USA show moderate growth rates of 14.4% and 12.9%, respectively. The increasing demand for high-performance fabrics in industries such as automotive, aerospace, and construction is driving the market. The rise in demand for hybrid materials that combine the benefits of different fibers is further contributing to the market’s growth across regions. The analysis includes over 40 countries, with the top markets detailed below.

The hybrid fabrics market in China is projected to grow at a CAGR of 7.7%, driven by the country’s expanding industrial base and increasing investments in sectors like automotive, aerospace, and energy. Hybrid fabrics, combining different fiber types for enhanced performance, are increasingly used to meet the demand for lighter, stronger, and more durable materials in various applications. China’s rapidly growing electric vehicle (EV) and renewable energy sectors are significant contributors to the adoption of hybrid fabrics. Furthermore, the country’s focus on technological advancements in manufacturing processes continues to drive market growth.

The hybrid fabrics market is India growing at a CAGR of 6.8%, driven by strong growth in the automotive, textiles, and infrastructure sectors. Hybrid fabrics are becoming increasingly popular in India due to their cost-effectiveness and superior performance in various industrial applications. The country’s push towards modernizing its automotive sector and expanding electric vehicle production is contributing to the rising demand for hybrid fabrics. The growing construction and industrial sectors, particularly in urban areas, continue to drive the need for durable and efficient materials, further boosting market growth.

The hybrid fabrics market in Germany is expected to grow at a CAGR of 6.2%. As a leading manufacturer of automotive and aerospace products, Germany’s demand for hybrid fabrics is driven by the need for lightweight, high-strength materials. The country’s focus on improving energy efficiency and reducing emissions in the automotive sector is accelerating the use of advanced materials in vehicle manufacturing. Furthermore, Germany’s commitment to renewable energy and infrastructure development is creating new opportunities for hybrid fabrics in sectors like wind and solar energy production.

The UK ’s hybrid fabrics market is projected to grow at a moderate CAGR of 5.4%. The adoption of hybrid fabrics is being driven by industries such as automotive, construction, and healthcare, where there is an increasing demand for advanced materials that provide superior strength, flexibility, and durability. The UK focus on smart manufacturing and energy-efficient production technologies is contributing to the use of hybrid fabrics, particularly in the automotive and construction sectors. The demand for hybrid fabrics in high-performance applications such as protective clothing and industrial filtration is also contributing to the market’s growth.

The USA hybrid fabrics market is projected to grow at a CAGR of 4.8%, with demand driven by the automotive, aerospace, and consumer goods sectors. As industries shift towards more energy-efficient and lightweight solutions, the adoption of hybrid fabrics in vehicle manufacturing and industrial applications is accelerating. The USA market is seeing increasing demand for high-performance fabrics in construction, medical, and consumer electronics industries. The rise of electric vehicles, along with growing demand for advanced textiles in the medical and healthcare sectors, is also contributing to the growth of hybrid fabrics in the USA

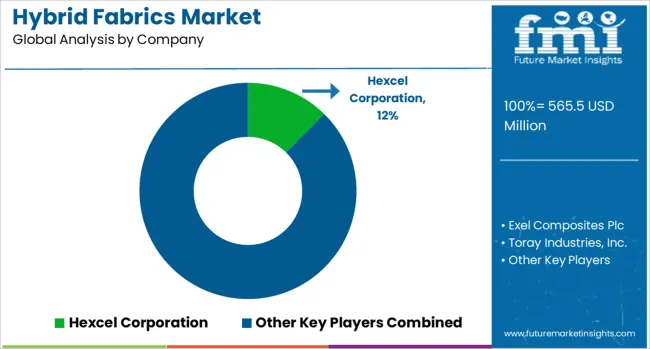

The hybrid fabrics market is dominated by Toray Industries, which leads with a broad portfolio of advanced hybrid textile materials combining synthetic and natural fibers for applications in automotive, aerospace, apparel, and industrial sectors. Toray’s dominance is underpinned by its strong R&D capabilities, global distribution network, and focus on producing high-performance, lightweight, and durable fabrics. Key players such as Teijin Limited, DuPont, and Hyosung Corporation maintain significant market shares by offering hybrid fabrics optimized for strength, flexibility, thermal resistance, and comfort across multiple applications. These companies focus on integrating advanced fiber technologies, functional coatings, and fabric blends to meet evolving industry needs.

Emerging players like Ahlstrom-Munksjö, Glen Raven, and Parkdale Mills are expanding their market presence by providing niche hybrid fabric solutions tailored for sportswear, protective clothing, and industrial applications. Their strategies include enhancing performance properties such as moisture management, abrasion resistance, and dimensional stability, while improving manufacturing efficiency and offering customizable solutions for specific client requirements. Market growth is driven by the rising demand for lightweight, multifunctional fabrics, increased adoption of protective and technical textiles, and the integration of eco-friendly fibers. Innovations in fiber blending, smart textiles, and durable functional coatings are expected to continue shaping competitive dynamics and contribute to expansion in the global hybrid fabrics market.

| Item | Value |

|---|---|

| Quantitative Units | USD 565.5 Million |

| Product | Glass/carbon, Glass/aramid, Carbon/aramid, and Others |

| End-User | Automotive, Aerospace & defense, Wind energy, Sports & recreational equipment, and Other |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Hexcel Corporation, Exel Composites Plc, Toray Industries, Inc., SGL Carbon, Mitsubishi Chemical Corporation, Solvay S.A., Teijin Limited, Axiom Materials Inc., and Zoltek Companies, Inc. |

| Additional Attributes | Dollar sales by fabric type (carbon/glass hybrid fabrics, aramid/carbon hybrid fabrics, glass/aramid hybrid fabrics) and end-use segments (automotive, aerospace, construction, sports). Demand dynamics are driven by the increasing need for lightweight, high-strength materials in automotive and aerospace industries, as well as the rising demand for durable and energy-efficient construction materials. Regional trends show strong growth in North America and Europe, driven by advancements in aerospace and automotive manufacturing, while Asia-Pacific is expanding due to increasing industrialization and infrastructure development. |

The global hybrid fabrics market is estimated to be valued at USD 565.5 million in 2025.

The market size for the hybrid fabrics market is projected to reach USD 2,327.8 million by 2035.

The hybrid fabrics market is expected to grow at a 15.2% CAGR between 2025 and 2035.

The key product types in hybrid fabrics market are glass/carbon, _aerospace & defense, _wind energy, _sports & recreational equipment, _others, glass/aramid, _automotive, _aerospace & defense, _wind energy, _sports & recreational equipment, _others, carbon/aramid, _automotive, _aerospace & defense, _wind energy, _sports & recreational equipment, _others, others, _automotive, _aerospace & defense, _wind energy, _sports & recreational equipment and _others.

In terms of end-user, automotive segment to command 29.7% share in the hybrid fabrics market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Hybrid Sleeve Cartridges Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Hybrid Reactive Power and Harmonic Compensation Device Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Vision Sensor Chips Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Printing Market Forecast Outlook 2025 to 2035

Hybrid Boat Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Metal-Paper Seamers Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Sealing-Cut Machines Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Hybrid Powertrain Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Additive Manufacturing Machines Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Integration Platform Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Marine Gensets Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Meat Products Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Generator Sets Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Rice Seeds Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Memory Cube Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Aircraft Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Solar Wind Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Cutters Market Analysis Size and Share Forecast Outlook 2025 to 2035

Hybrid Train Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA