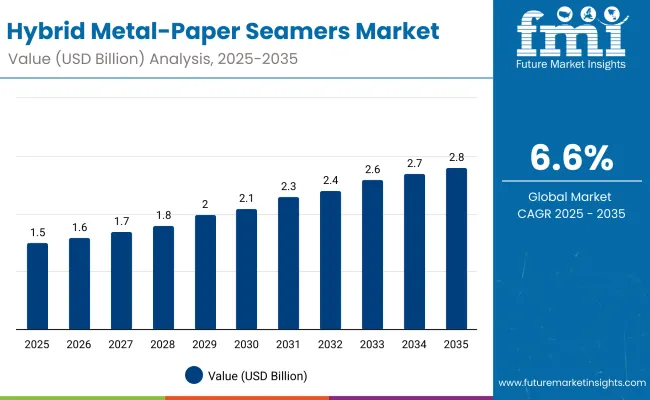

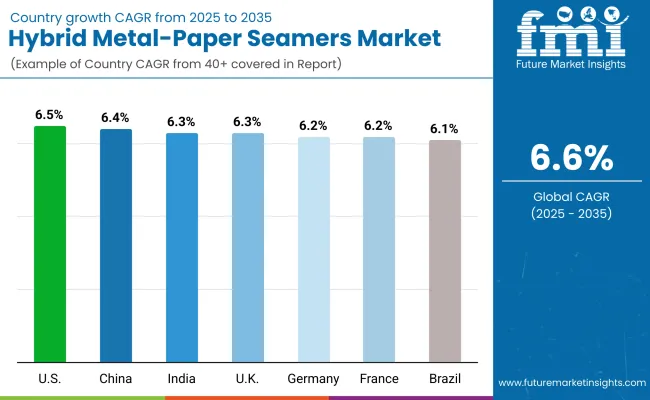

The global Hybrid Metal-Paper Seamers Market will expand from USD 1.5 billion in 2025 to USD 2.8 billion by 2035, at a CAGR of 6.6%. Market growth is supported by surging demand for hybrid packaging combining metal durability with paper sustainability. Fully automatic seamers are preferred for precision sealing and high-speed operations. Between 2025 and 2030, investments in sustainable packaging for beverage cans and food cartons will accelerate market value by USD 0.8 billion. By 2035, automation, modular integration, and recyclable hybrid materials will transform packaging lines globally.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1.5 billion |

| Forecast Value in (2035F) | USD 2.8 billion |

| Forecast CAGR (2025 to 2035) | 6.6% |

From 2020 to 2024, hybrid metal-paper seaming gained prominence as sustainability targets encouraged lightweight yet strong packaging. Aluminum-paper laminates emerged as the preferred alternative to pure metal sealing. By 2035, the market will reach USD 2.8 billion, fueled by automation and eco-compliant sealing materials. Asia-Pacific leads global output with investments in hybrid canning lines, while Europe focuses on performance and recyclability. Technological advancement in ultrasonic and adhesive hybrid sealing will further expand the sector.

Growth is driven by the packaging sector’s transition to hybrid materials that balance recyclability, durability, and aesthetics. The demand for premium beverage and food cartons encourages adoption of efficient, automated sealing systems. Increasing consumer awareness of sustainable packaging and global regulatory mandates on recyclable materials further accelerate technology deployment.

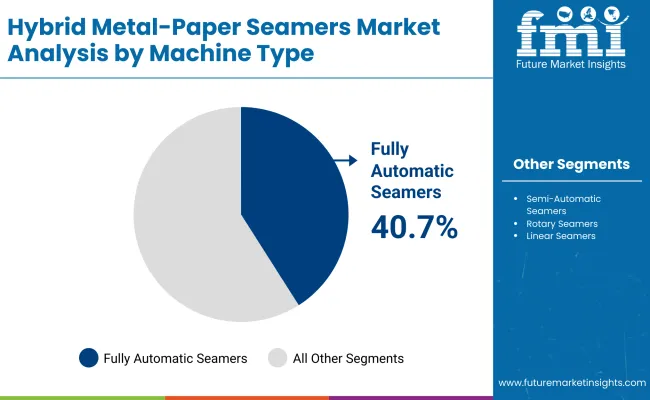

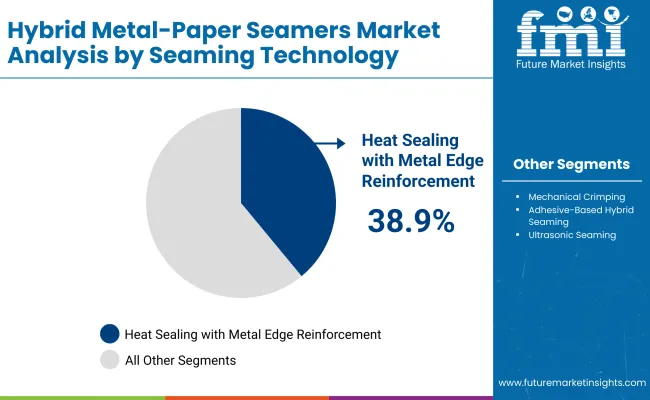

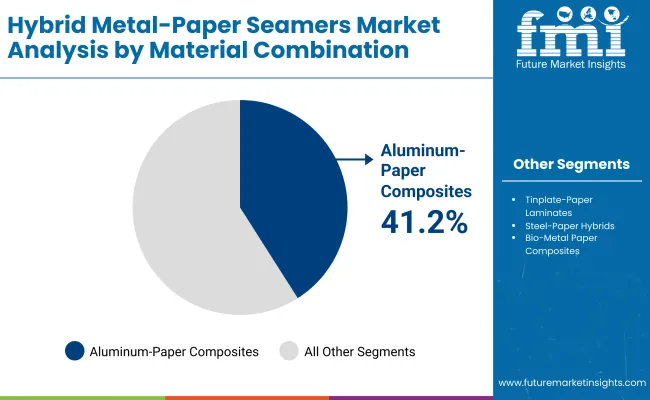

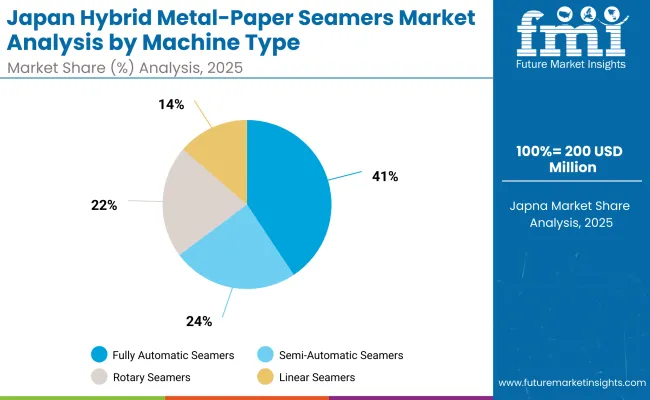

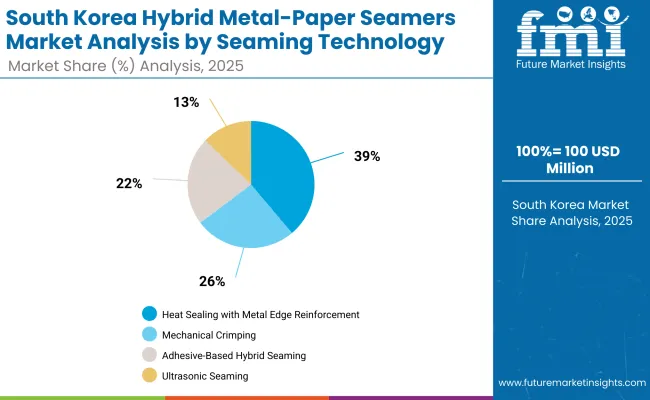

The market is segmented by machine type, seaming technology, material combination, application, end-use industry, and region. Machine type includes semi-automatic seamers, fully automatic seamers, rotary seamers, and linear seamers, offering flexibility in production scale and automation. Seaming technology covers mechanical crimping, heat sealing with metal edge reinforcement, adhesive-based hybrid seaming, and ultrasonic seaming, ensuring durable and leak-proof closures. Material combination includes aluminum-paper composites, tinplate-paper laminates, steel-paper hybrids, and bio-metal paper composites, enhancing recyclability and lightweight performance. Applications span beverage cans and containers, food cartons, cosmetic tins, and specialty industrial packaging, supporting sustainable alternatives to conventional metal packaging. End-use industries include food and beverages, cosmetics and personal care, industrial goods, and specialty retail packaging. Regionally, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Fully automatic seamers are forecast to capture 40.7% of the market in 2025, driven by their ability to deliver consistent seaming performance in high-speed packaging environments. These systems combine precision controls with automated feeding and sealing mechanisms, ensuring reliability across mass-production lines. Their reduced reliance on manual labor improves operational efficiency and throughput.

Adoption is reinforced by growing demand for automation in food and beverage packaging. Integration with vision inspection and quality assurance systems enhances sealing accuracy and minimizes waste. As manufacturers prioritize speed and consistency, fully automatic seamers remain the preferred technology for hybrid closure operations.

Heat sealing with metal edge reinforcement is expected to represent 38.9% of the market in 2025, valued for its ability to ensure durable, tamper-resistant closures. The technology provides a strong bond between metal and paper layers, maintaining barrier integrity against moisture and oxygen.

Its adoption is widespread in food and beverage packaging, where leak prevention and product preservation are critical. Heat sealing also supports recyclability by eliminating the need for chemical adhesives. As packaging transitions toward hybrid materials, this technology remains the cornerstone of sustainable seaming solutions.

Aluminum-paper composites are projected to hold 41.2% of the market in 2025, offering a balance between structural strength, light weight, and environmental performance. These composites combine the barrier properties of aluminum with the renewability of paper, enhancing protection while supporting recyclability.

They are extensively used in beverage cans, premium food cartons, and specialty tins requiring both functionality and shelf appeal. Their compatibility with hybrid seaming systems reinforces adoption across multiple packaging categories. As sustainability becomes central to packaging innovation, aluminum-paper composites continue to dominate.

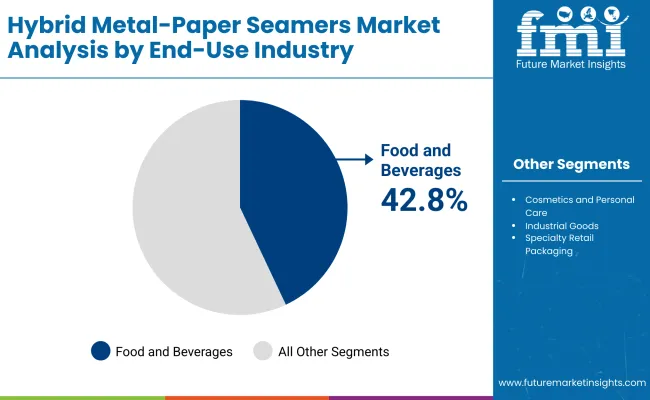

The food and beverages segment is projected to account for 42.8% of the market in 2025, driven by growing demand for eco-friendly closures and high-speed production systems. Hybrid seamers enable efficient sealing of composite materials used in ready-to-drink beverages, canned foods, and dairy products.

Global shifts toward recyclable and lightweight packaging further support adoption. Manufacturers are investing in hybrid materials to reduce carbon footprints while maintaining product safety. As consumption of packaged foods expands, the food and beverage industry remains the anchor for market growth.

Sustainable packaging demand and automated sealing innovations are driving adoption across food, beverage, and cosmetic sectors. High initial setup costs for automated hybrid sealing equipment hinder uptake among small-scale producers. Emergence of bio-based metal laminates and modular seaming solutions create expansion potential. Smart sealing systems, laser-assisted hybrid joining, and digital quality inspection technologies are shaping next-generation packaging machinery.

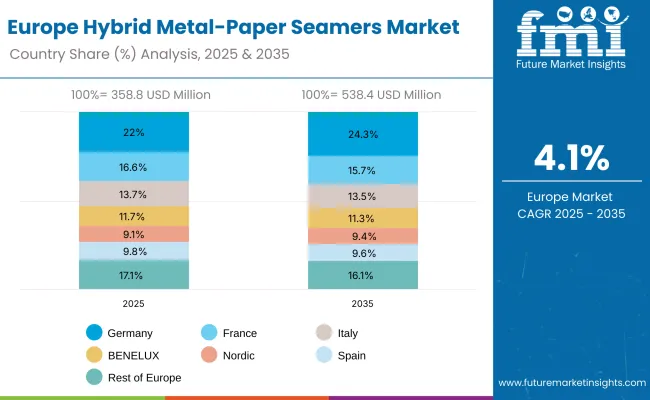

The global hybrid metal-paper seamers market is growing rapidly as sustainability and material innovation reshape modern packaging systems. Asia-Pacific leads in automation and large-scale hybrid material integration, while Europe and North America focus on recyclable composite designs and circular economy compliance. The shift toward hybrid seaming solutions reflects a broader industry transition toward lightweight, eco-friendly, and digitally optimized packaging technologies, with applications spanning beverages, food, and personal care sectors worldwide.

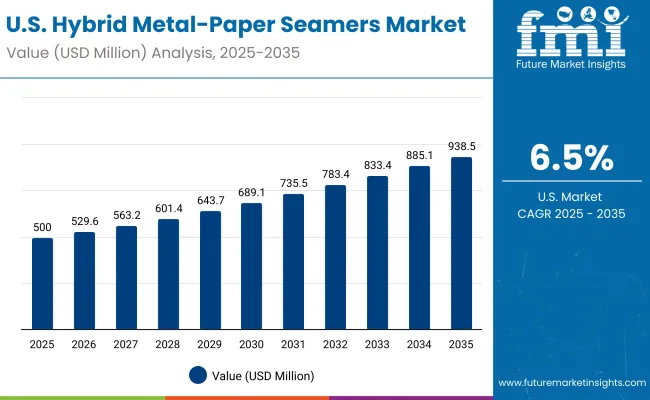

The USA will grow at 6.5% CAGR, driven by modern packaging automation and expanding sustainability mandates. Smart hybrid seaming systems are being adopted across beverage, food, and personal care packaging facilities. Growing compliance with green labeling standards is accelerating investment in recyclable hybrid materials. Continuous innovation in intelligent seaming technology is enhancing production speed and precision, reinforcing the USA market’s leadership in sustainable packaging modernization.

Germany will expand at 6.2% CAGR, emphasizing precision sealing and hybrid material optimization. Automation technologies are improving production efficiency and throughput in industrial packaging lines. Material optimization strategies are reducing waste and enhancing sustainability compliance under EU packaging directives. The replacement of legacy systems with hybrid laminates is strengthening Germany’s competitiveness in high-performance sealing equipment exports.

The UK will grow at 6.3% CAGR, focusing on sustainability-driven innovation and compact hybrid sealing systems. Small and medium enterprises are increasingly adopting automated seamers for recyclable composite packaging. Premium food and beverage brands are leading adoption of hybrid metal-paper containers to align with eco-packaging goals. Ongoing advancements in adhesive-based hybrid sealing are improving sealing durability and recyclability in consumer packaging applications.

China will grow at 6.4% CAGR, leading in hybrid packaging production through large-scale automation and infrastructure expansion. Beverage exports are spurring major investments in hybrid metal-paper seaming technologies. Rapid automation in seaming plants is improving productivity and reducing manual labor dependency. Government-driven eco-regulations and national sustainability policies are propelling widespread adoption of recyclable and biodegradable hybrid packaging formats.

India will grow at 6.3% CAGR, driven by growing demand for affordable hybrid sealing systems across FMCG, food, and beverage sectors. Local manufacturers are embracing hybrid packaging to improve product appeal and export competitiveness. Industrial modernization initiatives are fostering the transition from traditional sealing methods to hybrid, automated lines. Export-oriented producers are increasing capacity to serve sustainable packaging requirements across global markets.

Japan will grow at 6.9% CAGR, leading in compact, energy-efficient, and high-speed hybrid seaming technologies. Automation and robotics partnerships are improving precision sealing for food and beverage manufacturers. Energy-efficient systems are gaining adoption to meet carbon neutrality goals. Japan’s continued R&D investment in hybrid material bonding and smart maintenance systems is ensuring global competitiveness in advanced seaming solutions.

South Korea will lead with 7.0% CAGR, driven by technological innovation and R&D in hybrid material applications. High-speed automation and AI integration are defining the next generation of smart seaming systems. Domestic manufacturers are scaling exports across Asia and Europe, supported by regional demand for hybrid, recyclable packaging. Ongoing advancements in material science and digital manufacturing are strengthening South Korea’s leadership in sustainable packaging technologies.

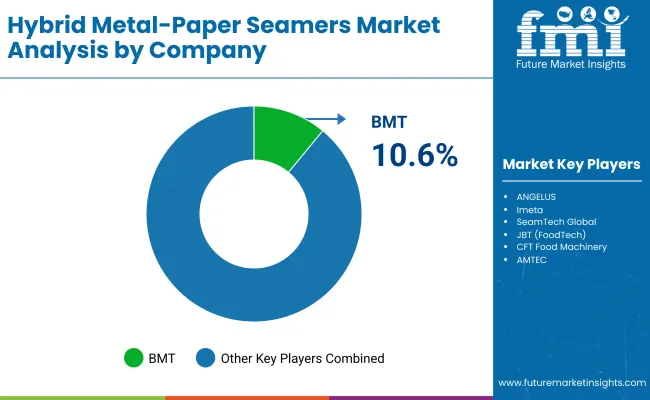

The market is moderately consolidated, with BMT, ANGELUS, Imeta, SeamTech Global, JBT (FoodTech), CFT Food Machinery, AMTEC, Ferrum Packaging, Innovus Engineering, and MEM/Dutchpacks as major players. Companies focus on sustainability-compliant equipment, high-speed operations, and real-time monitoring to ensure consistent seaming quality in hybrid packaging systems.

Key Developments

| Item | Value |

|---|---|

| Quantitative Units | USD 1.5 Billion |

| By Machine Type | Semi-Automatic, Fully Automatic, Rotary, Linear |

| By Seaming Technology | Heat Sealing, Mechanical Crimping, Adhesive Hybrid, Ultrasonic |

| By Material Combination | Aluminum -Paper, Tinplate-Paper, Steel-Paper, Bio-Metal Composites |

| By Application | Beverage Cans, Food Cartons, Cosmetic Tins, Specialty Packaging |

| By End-Use Industry | Food & Beverages, Cosmetics, Industrial, Retail |

| Key Companies Profiled | BMT, ANGELUS, Imeta , SeamTech Global, JBT (FoodTech), CFT Food Machinery, AMTEC, Ferrum Packaging, Innovus Engineering, MEM/ Dutchpacks |

| Additional Attributes | Market driven by eco-packaging, precision automation, and recyclable hybrid material integration. |

The Hybrid Metal-Paper Seamers Market is valued at USD 1.5 billion in 2025.

The Hybrid Metal-Paper Seamers Market is projected to reach USD 2.8 billion by 2035.

The market will grow at a CAGR of 6.6%.

Heat sealing with metal edge reinforcement leads with a 38.9% share.

Aluminum-paper composites hold the top position with 41.2% share.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Hybrid Boat Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Sealing-Cut Machines Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Hybrid Powertrain Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Additive Manufacturing Machines Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Integration Platform Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Marine Gensets Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Meat Products Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Generator Sets Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Rice Seeds Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Memory Cube Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Aircraft Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Solar Wind Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Cutters Market Analysis Size and Share Forecast Outlook 2025 to 2035

Hybrid Fabrics Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Train Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Hybrid Solar Wind Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Drivetrain Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Emulsifier Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Cloud Storage Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA