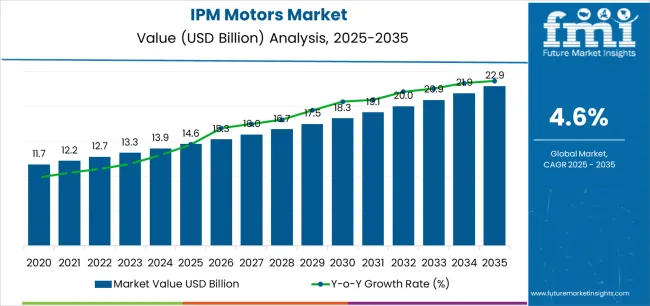

The global IPM (Interior Permanent Magnet) motors market is valued at USD 14,591.6 million in 2025 and is set to reach USD 22,878.1 million by 2035, growing at a CAGR of 4.6%. The market stands at the forefront of a transformative decade that promises to redefine electric motor technologies and energy-efficient drive systems across automotive applications, HVAC operations, and industrial automation systems. The market's journey from USD 14,591.6 million in 2025 to USD 22,878.1 million by 2035 represents substantial growth, demonstrating the accelerating adoption of high-efficiency motor technologies and advanced permanent magnet solutions across automotive applications, industrial projects, and critical power transmission operations.

Electric vehicle sector modernization continues to accelerate adoption of IPM motors, with industries ranging from automotive manufacturing to HVAC systems implementing these motors as critical components in energy-efficient systems. The growing emphasis on energy efficiency, precision control, and performance optimization creates continued demand for motor solutions that deliver consistent performance while reducing energy consumption and operational complexity. IPM motors address these needs through advanced magnetic technologies, enhanced torque capabilities, and robust construction that withstand demanding automotive and industrial applications while providing superior efficiency and motor life performance.

Regional market dynamics reveal distinct growth patterns influenced by electric vehicle development levels, manufacturing capabilities, and energy efficiency adoption rates. Developed markets in North America and Europe demonstrate steady growth driven by equipment modernization, replacement cycles, and advanced automotive processes that prioritize high-efficiency motor systems. Emerging markets in Asia-Pacific show accelerated expansion supported by rapid industrialization, automotive development, and increasing adoption of energy-efficient motor technologies. The competitive landscape encompasses established motor manufacturers alongside specialized permanent magnet solution providers, creating a diverse ecosystem that serves various market segments with tailored solutions.

The first half of the decade (2025-2030) will witness the market climbing from USD 14,591.6 million to approximately USD 17,467.5 million, adding USD 2,875.9 million in value, which constitutes 35% of the total forecast growth period. This phase will be characterized by the rapid adoption of advanced IPM motor technologies, driven by increasing demand for energy-efficient drive solutions and enhanced automotive capabilities worldwide. Superior torque performance and energy efficiency will become standard expectations rather than premium options.

The latter half (2030-2035) will witness continued growth from USD 17,467.5 million to USD 22,878.1 million, representing an addition of USD 5,410.6 million or 65% of the decade's expansion. This period will be defined by mass market penetration of specialized motor systems, integration with comprehensive automotive platforms, and seamless compatibility with existing industrial infrastructure. The market trajectory signals fundamental shifts in how manufacturing facilities approach motor selection, with participants positioned to benefit from continued demand across multiple application segments.

The IPM motors market demonstrates distinct growth phases with varying market characteristics and competitive dynamics. Between 2025 and 2030, the market progresses through its automotive electrification optimization phase, expanding from USD 14,591.6 million to USD 17,467.5 million with steady annual increments averaging 3.7% growth. This period showcases the transition from traditional motor technologies to advanced IPM motor systems with enhanced efficiency performance and integrated control becoming mainstream features.

The 2025-2030 phase adds USD 2,875.9 million to market value, representing 35% of total decade expansion. Market maturation factors include standardization of motor specifications, declining production costs for IPM motors, and increasing automotive awareness of energy efficiency reaching 85-90% effectiveness in automotive applications. Competitive landscape evolution during this period features established manufacturers like Nidec and Yaskawa expanding their IPM motor portfolios while new entrants focus on specialized permanent magnet solutions and enhanced automotive technology.

From 2030 to 2035, market dynamics shift toward comprehensive automotive integration and multi-application deployment, with growth accelerating from USD 17,467.5 million to USD 22,878.1 million, adding USD 5,410.6 million or 65% of total expansion. This phase transition logic centers on universal IPM motor systems, integration with advanced automotive platforms, and deployment across diverse industrial scenarios, becoming standard rather than specialized motor formats. The competitive environment matures with focus shifting from basic motor performance to comprehensive efficiency excellence and compatibility with modern automotive operations.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 14,591.6 million |

| Market Forecast (2035) | USD 22,878.1 million |

| Growth Rate | 4.6% CAGR |

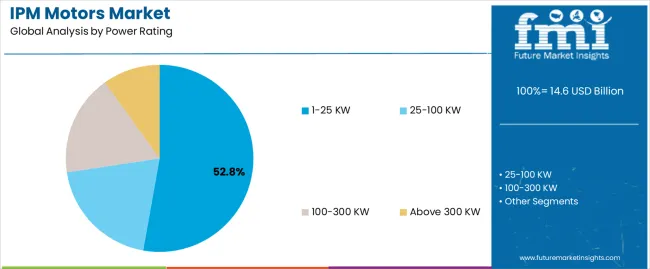

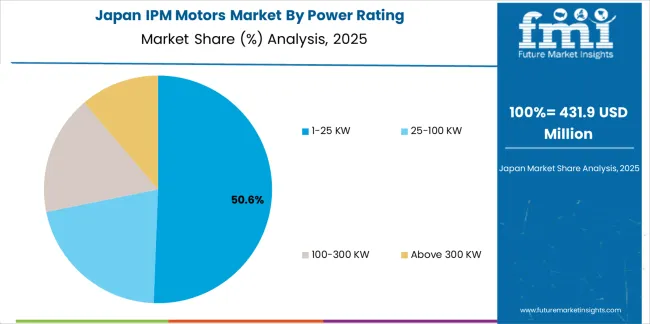

| Leading Power Rating | 1-25 KW |

| Primary Application | Automobile Segment |

The market demonstrates strong fundamentals with 1-25 KW power rating systems capturing a dominant share through superior efficiency characteristics and automotive compatibility. Automobile applications drive primary demand, supported by increasing electrification requirements and enhanced automotive development solutions. Geographic expansion remains concentrated in developed automotive markets with established manufacturing infrastructure, while emerging economies show accelerating adoption rates driven by electric vehicle expansion and rising energy efficiency sophistication.

Market expansion rests on three fundamental shifts driving adoption across automotive and industrial sectors. Automotive electrification growth creates compelling advantages through IPM motor systems that provide comprehensive efficiency properties with operational compatibility, enabling manufacturers to manage increasing performance requirements and maintain quality standards while ensuring energy-efficient operations and justifying investment over traditional motor methods. Advanced efficiency modernization accelerates as companies worldwide seek reliable motors that deliver superior performance directly to automotive systems, enabling energy reduction that aligns with operational expectations and maximizes automotive productivity. Electric vehicle transformation drives adoption from automotive operators requiring specialized motors that maximize performance while maintaining high-quality reliability during automotive and industrial operations.

Growth faces headwinds from rare earth material cost variations that differ across motor suppliers regarding pricing stability and supply chain reliability, potentially limiting margin consistency in price-sensitive automotive categories. Manufacturing complexity also persists regarding motor specifications and automotive requirements that may increase production costs in facilities with demanding quality standards.

The IPM motors market represents a compelling intersection of automotive innovation, energy efficiency advancement, and industrial optimization management. With robust growth projected from USD 14,591.6 million in 2025 to USD 22,878.1 million by 2035 at a 4.6% CAGR, this market is driven by increasing automotive electrification expansion trends, advanced efficiency requirements, and demand for high-performance motor formats.

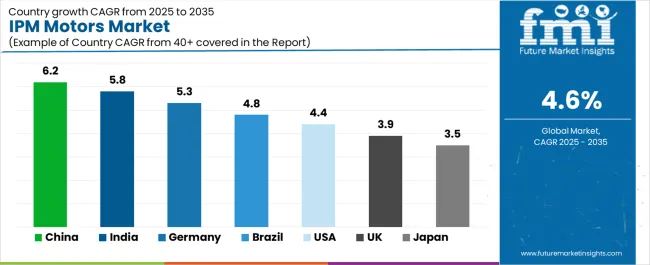

The market's expansion reflects a fundamental shift in how automotive facilities and industrial operators approach motor infrastructure. Strong growth opportunities exist across diverse applications, from automobile operations requiring high-efficiency motors to HVAC systems demanding reliable drive components. Geographic expansion is particularly pronounced in Asia-Pacific markets, led by China (6.2% CAGR) and India (5.8% CAGR), while established markets in North America and Europe drive innovation and specialized segment development.

The dominance of 1-25 KW systems and automobile applications underscores the importance of proven motor technology and automotive reliability in driving adoption. Motor standardization and performance complexity remain key challenges, creating opportunities for companies that can deliver seamless motor performance while maintaining energy efficiency.

What is the segmental analysis of the IPM motors market?

Primary Classification: The market segments by power rating into 1-25 KW, 25-100 KW, 100-300 KW, and above 300 KW categories, representing the evolution from small-scale applications to high-power industrial and automotive systems for comprehensive operations.

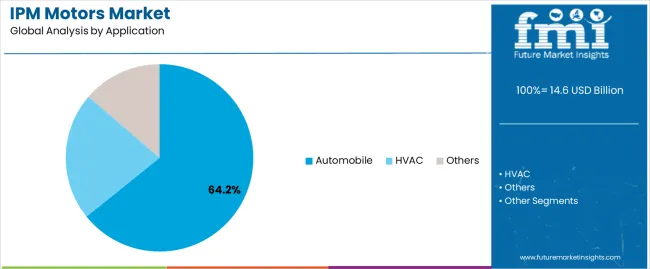

Secondary Breakdown: Application segmentation divides the market into automobile, HVAC, and others sectors, reflecting distinct requirements for efficiency characteristics, power specifications, and operational performance.

Tertiary Classification: End-use industry segmentation covers automotive, industrial manufacturing, construction, energy applications, transportation, and precision machinery, representing diverse requirements for motor specifications and application performance.

Regional Classification: Geographic distribution covers North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, with developed automotive markets leading innovation while emerging economies show accelerating growth patterns driven by electrification programs.

The segmentation structure reveals technology progression from standard motor systems toward integrated high-performance platforms with enhanced efficiency capabilities and precision performance, while application diversity spans from automobile systems to HVAC requiring comprehensive motor properties and intelligent drive solutions.

1-25 KW segment is estimated to account for 52.8% of the IPM motors market share in 2025. The segment's leading position stems from its fundamental role as a critical component in modern automotive applications and its extensive use across multiple automotive and industrial sectors. The 1-25 KW range's dominance is attributed to its superior efficiency properties, including excellent controllability, torque density, and balanced cost-effectiveness that make it indispensable for automotive operations.

Market Position: 1-25 KW systems command the leading position in the IPM motors market through advanced motor technologies, including comprehensive magnetic properties, uniform performance, and reliable efficiency characteristics that enable operators to deploy motors across diverse automotive environments.

Value Drivers: The segment benefits from automotive preference for proven motor interfaces that provide exceptional efficiency performance without requiring ultra-premium power costs. Efficient power implementation enables deployment in automotive, industrial, and HVAC applications where motor reliability and efficiency compatibility represent critical selection requirements.

Competitive Advantages: 1-25 KW systems differentiate through excellent motor capacity, proven automotive reliability, and compatibility with standard industrial processes that enhance motor capabilities while maintaining economical power profiles suitable for diverse automotive applications.

Key market characteristics:

Automobile segment is projected to hold 64.2% of the IPM motors market share in 2025. The segment's market leadership is driven by the extensive use of IPM motors in electric vehicles, hybrid systems, automotive manufacturing, and transportation infrastructure, where motors serve as both a propulsion component and efficiency solution. The automotive sector's consistent demand for reliable motor systems supports the segment's dominant position.

Market Context: Automobile applications dominate the market due to widespread adoption of efficient motor solutions and increasing focus on automotive electrification, performance optimization, and operational management that support automotive operations while maintaining quality standards.

Appeal Factors: Automotive consumers prioritize motor durability, efficiency performance, and integration with standard automotive systems that enable coordinated deployment across multiple automotive needs. The segment benefits from substantial electric vehicle growth and automotive development that emphasize reliable motors for automobile applications.

Growth Drivers: Automotive programs incorporate IPM motors as standard components for propulsion systems and automotive programs. At the same time, automotive compliance initiatives are increasing demand for advanced features that comply with automotive standards and enhance system performance.

Market Challenges: Motor cost fluctuations and standardization requirements may limit deployment flexibility in ultra-price-sensitive markets or regions with varying automotive requirements.

Application dynamics include:

Automotive segment is anticipated to capture 48.7% of the IPM motors market share in 2025. The segment's growth is driven by increasing electric vehicle demand, automotive manufacturing initiatives, and sophisticated motor requirements that require high-quality efficiency systems. The automotive industry's expansion and focus on electrification efficiency support this segment's robust performance.

Market Position: Automotive applications leverage IPM motors for propulsion systems in electric vehicles, automotive manufacturing, assembly operations, and component integration where motor quality and efficiency precision are critical performance factors.

Growth Catalysts: Rising electric vehicle production, automotive development trends, and expanding electrification capabilities drive demand for specialized motors that deliver consistent performance across diverse automotive applications.

Growth Accelerators: Automotive electrification expansion drives primary adoption as IPM motor systems provide exceptional efficiency properties that enable automotive development without performance compromise, supporting electrification advancement and operational efficiency that require reliable motor formats. Advanced efficiency growth accelerates market expansion as companies seek specialized motors that maintain performance during operation while enhancing automotive convenience through standardized specifications and compatibility. Electric vehicle awareness increases worldwide, creating continued demand for IPM motor systems that complement automotive routines and provide operational advantages in efficiency performance.

Growth Inhibitors: Rare earth material cost volatility challenges differ across motor markets regarding price stability and supply chain consistency, which may limit margin predictability and cost planning in price-sensitive automotive categories with demanding affordability requirements. Manufacturing complexity persists regarding motor specifications and automotive standards that may increase production costs in facilities with complex quality protocols. Market fragmentation across multiple motor specifications and application standards creates compatibility concerns between different motor systems and existing automotive infrastructure.

Market Evolution Patterns: Adoption accelerates in automotive and industrial sectors where motor benefits justify equipment investments, with geographic concentration in developed markets transitioning toward mainstream adoption in emerging economies driven by electrification and automotive expansion. Technology advancement focuses on enhanced efficiency properties, improved automotive performance, and integration with automated systems that optimize industrial performance and quality control. The market could face disruption if alternative motor technologies or automotive changes significantly challenge traditional IPM motor advantages in automotive applications.

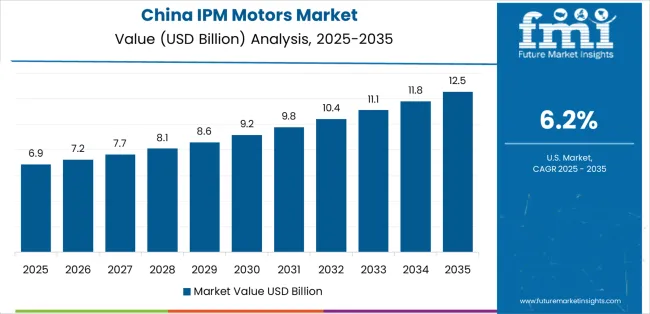

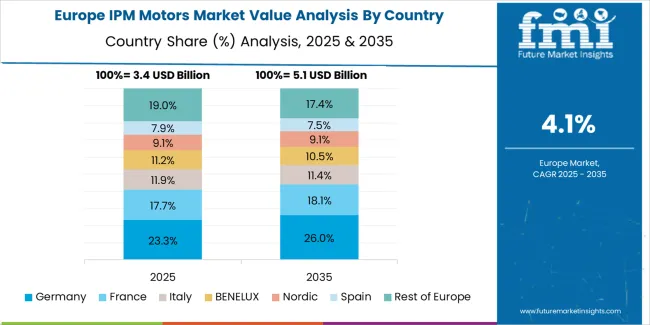

The IPM motors market demonstrates varied regional dynamics with growth leaders including China (6.2% CAGR) and India (5.8% CAGR) driving expansion through automotive manufacturing growth and electrification modernization. Steady Performers encompass Germany (5.3% CAGR), Brazil (4.8% CAGR), and the USA (4.4% CAGR), benefiting from established automotive systems and advanced electrification adoption.

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.2% |

| India | 5.8% |

| Germany | 5.3% |

| Brazil | 4.8% |

| USA | 4.4% |

| UK | 3.9% |

| Japan | 3.5% |

Regional synthesis reveals Asia-Pacific markets leading growth through automotive expansion and electrification development, while European countries maintain steady expansion supported by specialized applications and precision motor requirements. North American markets show strong growth driven by automotive demand and industrial facility upgrades.

Why is China driving automotive manufacturing leadership in the IPM motors market?

China establishes regional leadership through rapid automotive development and comprehensive electric vehicle modernization, integrating advanced IPM motor systems as standard components in automobile manufacturing and transportation operations. The country's 6.2% CAGR through 2035 reflects automotive growth promoting manufacturing density and electrification infrastructure development that mandate the use of reliable motor systems in automotive operations. Growth concentrates in major automotive centers, including Beijing, Shanghai, and Shenzhen, where automotive networks showcase integrated motor systems that appeal to manufacturers seeking enhanced production efficiency and international quality standards.

Chinese manufacturers are developing innovative IPM motor solutions that combine local production advantages with international automotive specifications, including advanced magnetic compositions and enhanced efficiency capabilities.

Strategic Market Indicators:

How is India demonstrating automotive excellence in the IPM motors market?

The Indian market emphasizes automotive manufacturing applications, including rapid electrification development and comprehensive automotive expansion that increasingly incorporates IPM motors for automotive enhancement and transportation applications. The country is projected to show a 5.8% CAGR through 2035, driven by massive automotive activity under electrification initiatives and demand for standardized, high-quality motor systems. Indian automotive facilities prioritize cost-effectiveness with IPM motors delivering automotive efficiency through economical motor usage and reliable performance capabilities.

Technology deployment channels include major automotive companies, electric vehicle integrators, and automotive institutions that support high-volume usage for automotive and transportation applications.

Performance Metrics:

The German market emphasizes advanced automotive manufacturing features, including innovative motor technologies and integration with comprehensive automotive platforms that manage electric vehicle operations, automotive facilities, and institutional applications through unified motor systems. The country is projected to show a 5.3% CAGR through 2035, driven by automotive expansion under electrification development trends and demand for premium, reliable motor systems. German automotive institutions prioritize precision with IPM motors delivering comprehensive automotive performance through enhanced quality protection and operational innovation.

Technology deployment channels include major automotive companies, automotive institutions, and motor equipment manufacturers that support custom development for premium operations.

Performance Metrics:

In São Paulo, Rio de Janeiro, and Belo Horizonte, Brazilian automotive facilities and transportation operators are implementing advanced IPM motor systems to enhance efficiency capabilities and support operational performance that aligns with automotive protocols and electrification standards. The Brazilian market demonstrates continued growth with a 4.8% CAGR through 2035, driven by automotive compliance programs and electrification investments that emphasize reliable motor systems for automotive and transportation applications. Brazilian automotive facilities are prioritizing IPM motor systems that provide exceptional efficiency properties while maintaining compliance with automotive standards and minimizing operational complexity, particularly important in automotive and transportation facility operations.

Market expansion benefits from automotive programs that mandate enhanced motor compliance in electrification specifications, creating continued demand across Brazil's automotive and transportation sectors, where motor efficiency and system consistency represent critical requirements.

Strategic Market Indicators:

Why does the United States maintain automotive excellence in the IPM motors market?

The USA market emphasizes automotive manufacturing features, including innovative motor technologies and integration with comprehensive automotive platforms that manage electric vehicle operations, automotive facilities, and commercial applications through unified motor systems. The country is projected to show a 4.4% CAGR through 2035, driven by automotive expansion under electrification development trends and industry demand for premium, reliable motor systems. American automotive companies prioritize innovation with IPM motors delivering comprehensive automotive performance through enhanced quality protection and operational advancement.

Technology deployment channels include major automotive companies, automotive institutions, and motor manufacturers that support custom development for automotive operations.

Performance Metrics:

The UK market demonstrates advanced automotive manufacturing deployment, growing at 3.9% CAGR, with documented operational excellence in electric vehicle control and automotive applications through integration with existing automotive systems and quality assurance infrastructure. The country leverages engineering expertise in automotive manufacturing and motor science to maintain market leadership. Automotive centers, including Birmingham, Manchester, and Leeds, showcase advanced installations where IPM motor systems integrate with comprehensive automotive platforms and electric vehicle systems to optimize automotive development and operational efficiency.

British automotive facilities prioritize motor precision and system consistency in product selection, creating demand for premium IPM motor systems with advanced features, including enhanced magnetic compositions and integration with automated automotive systems. The market benefits from established automotive infrastructure and willingness to invest in specialized motor technologies that provide superior quality and automotive compliance.

Market Intelligence Brief:

Japan's advanced automotive market demonstrates meticulous IPM motor deployment, growing at 3.5% CAGR, with documented operational excellence in automotive control and electric vehicle applications through integration with existing automotive systems and quality assurance infrastructure. The country leverages engineering expertise in automotive manufacturing and motor technology to maintain market leadership. Automotive centers, including Tokyo, Osaka, and Nagoya, showcase advanced installations where IPM motor systems integrate with comprehensive automotive platforms and quality systems to optimize automotive development and operational efficiency.

Japanese automotive facilities prioritize motor precision and system consistency in product selection, creating demand for premium IPM motor systems with advanced features, including ultra-high quality and integration with automated automotive protocols. The market benefits from established automotive infrastructure and willingness to invest in specialized motor technologies that provide superior performance and automotive compliance.

Market Intelligence Brief:

The IPM motors market in Europe is projected to grow from USD 5,317.2 million in 2025 to USD 8,467.4 million by 2035, registering a CAGR of 4.8% over the forecast period. Germany is expected to maintain its leadership position with a 42.7% market share in 2025, declining slightly to 42.3% by 2035, supported by its automotive excellence and major automotive centers, including Baden-Württemberg and Bavaria.

France follows with a 23.6% share in 2025, projected to reach 23.9% by 2035, driven by comprehensive automotive programs and manufacturing facility initiatives. The United Kingdom holds a 19.4% share in 2025, expected to maintain 19.8% by 2035 through established automotive sectors and electrification adoption. Italy commands a 9.7% share, while Spain accounts for 2.9% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 1.7% to 1.9% by 2035, attributed to increasing automotive development in Eastern European countries and emerging electrification programs implementing standardized motor systems.

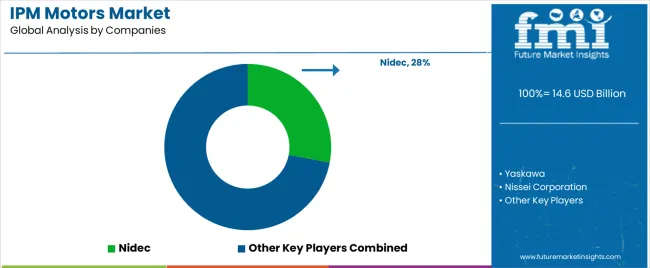

The IPM motors market operates with moderate concentration, featuring approximately 15-22 participants, where leading companies control roughly 58-64% of the global market share through established distribution networks and comprehensive product portfolio capabilities. Competition emphasizes motor performance, automotive reliability, and efficiency optimization rather than premium feature rivalry.

Market leaders encompass Nidec, Yaskawa, and Nissei Corporation, which maintain competitive advantages through extensive automotive manufacturing expertise, regional distribution networks, and comprehensive technical support capabilities that create automotive industry loyalty and support electrification requirements. These companies leverage decades of motor experience and ongoing automotive technology investments to develop advanced IPM motor systems with exceptional quality and automotive features. Nidec leads with 28% share.

Specialty challengers include regional manufacturers and motor specialists, which compete through specialized application innovation focus and efficient production solutions that appeal to automotive buyers seeking reliable performance formats and custom motor flexibility. These companies differentiate through operational efficiency emphasis and specialized market focus.

Market dynamics favor participants that combine consistent motor performance with advanced automotive support, including automated systems and distribution capabilities. Competitive pressure intensifies as traditional motor manufacturers expand into IPM motor systems. At the same time, specialized automotive producers challenge established players through innovative manufacturing methods and cost-effective production targeting emerging automotive segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 14,591.6 million |

| Power Rating | 1-25 KW, 25-100 KW, 100-300 KW, Above 300 KW |

| Application | Automobile, HVAC, Others |

| End-Use Industry | Automotive, Industrial Manufacturing, Construction, Energy Applications, Transportation, Precision Machinery |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, USA, UK, Japan, and 25+ additional countries |

| Key Companies Profiled | Nidec, Yaskawa, Nissei Corporation, VARCHEA |

| Additional Attributes | Dollar sales by power rating and application categories, regional adoption trends across Asia Pacific, North America, and Europe, competitive landscape with motor manufacturers and automotive producers, customer preferences for motor characteristics and automotive performance, integration with automotive equipment and electrification systems, innovations in motor technology and advanced automotive systems, and development of specialized motor solutions with enhanced properties and automotive-grade features |

The global ipm motors market is estimated to be valued at USD 14.6 billion in 2025.

The market size for the ipm motors market is projected to reach USD 22.9 billion by 2035.

The ipm motors market is expected to grow at a 4.6% CAGR between 2025 and 2035.

The key product types in ipm motors market are 1-25 kw, 25-100 kw, 100-300 kw and above 300 kw.

In terms of application, automobile segment to command 64.2% share in the ipm motors market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Equipment Management Software Market Size and Share Forecast Outlook 2025 to 2035

Equipment cases market Size and Share Forecast Outlook 2025 to 2035

Farm Equipment Market Forecast and Outlook 2025 to 2035

Golf Equipment Market Size and Share Forecast Outlook 2025 to 2035

Port Equipment Market Size and Share Forecast Outlook 2025 to 2035

Pouch Equipment Market Growth – Demand, Trends & Outlook 2025 to 2035

VR HMD Shipment Market

Garage Equipment Market Forecast and Outlook 2025 to 2035

Mining Equipment Industry Analysis in Latin America Size and Share Forecast Outlook 2025 to 2035

Subsea Equipment Market Size and Share Forecast Outlook 2025 to 2035

Pavers Equipment Market Size and Share Forecast Outlook 2025 to 2035

Tennis Equipment Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Galley Equipment Market Analysis and Forecast by Fit, Application, and Region through 2035

Sorting Equipment Market Size and Share Forecast Outlook 2025 to 2035

General Equipment Rental Services Market Size and Share Forecast Outlook 2025 to 2035

Bagging Equipment Market Size and Share Forecast Outlook 2025 to 2035

RF Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Medical Equipment Covers Market Size and Share Forecast Outlook 2025 to 2035

Telecom Equipment Market Size and Share Forecast Outlook 2025 to 2035

Welding Equipment And Consumables Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA