The membrane switch market is estimated to be valued at USD 4.6 billion in 2025 and is projected to reach USD 7.5 billion by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

This steady expansion highlights the enduring importance of membrane switches as reliable, cost-effective human–machine interface solutions across sectors such as medical devices, consumer electronics, automotive, and industrial equipment. From 2025 to 2030, the market will be driven by rising adoption in compact electronics and medical instruments, where thin, lightweight, and durable switches enhance device usability and design flexibility.

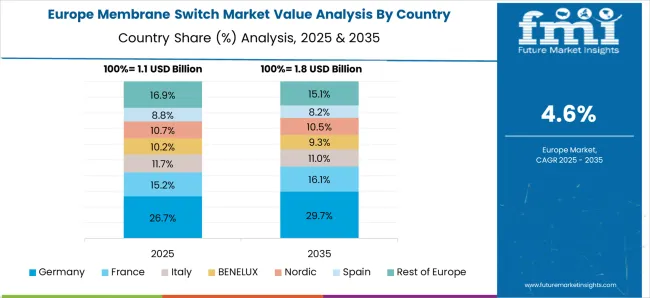

During 2030 to 2035, growth will be reinforced by advancements in tactile feedback, printed electronics integration, and antimicrobial coatings, pushing the market to USD 7.5 billion. The incremental opportunity of USD 2.9 billion over ten years emphasizes continuous demand despite increasing competition from touchscreens. Competitive differentiation will depend on material innovation, extended product lifespans, and application-specific customization. Regional growth will be prominent in Asia-Pacific due to electronics manufacturing clusters, while North America and Europe will see demand from medical and automotive sectors.

Custom fabrication operations experience workflow challenges as membrane switch orders often involve unique graphic overlays, circuit patterns, and connector configurations that require coordination between customer design teams and internal engineering departments. Design engineers work with manufacturing planning groups to evaluate feasibility of customer specifications while managing prototype development cycles that must balance design validation against production scheduling commitments for existing customer orders.

Quality control departments implement testing procedures that verify both electrical performance and mechanical durability characteristics across operating temperature ranges and environmental conditions. Testing laboratories include stations for contact resistance measurement, actuation life cycling, and environmental stress testing alongside standard electrical continuity verification. These validation requirements affect production throughput as durability testing often requires extended test cycles and specialized environmental chambers that create capacity constraints during peak demand periods.

Cross-functional coordination between sales engineering teams and manufacturing departments creates ongoing dialogue about lead times and customization capabilities as customer applications span medical devices, industrial controls, and consumer electronics with varying performance requirements. Applications engineers coordinate with production scheduling departments to evaluate custom tooling requirements and material sourcing timelines while managing customer expectations about prototype development and production ramp-up schedules.

Supply chain operations encounter material sourcing complexity as membrane switch production requires coordination between multiple specialty suppliers for flexible circuits, pressure-sensitive adhesives, and overlay materials that may have different lead times and minimum order quantities. Procurement teams work with inventory management departments to balance material availability against customer forecast accuracy while managing shelf life considerations for adhesive materials and environmental storage requirements.

| Metric | Value |

|---|---|

| Membrane Switch Market Estimated Value in (2025 E) | USD 4.6 billion |

| Membrane Switch Market Forecast Value in (2035 F) | USD 7.5 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

The membrane switch market is witnessing robust growth due to its increasing relevance in compact electronic interface applications where space optimization, durability, and tactile feedback are essential. The demand for user-centric, low-profile switching mechanisms has expanded across sectors such as healthcare devices, industrial machinery, consumer appliances, and automotive controls. Technological innovations that enhance circuit responsiveness, graphic overlay durability, and long-term environmental resistance have further supported the market's evolution.

The growing adoption of touch interfaces in embedded systems, along with the need for sealed, dustproof, and moisture-resistant control panels, is favoring membrane switch configurations. Additionally, supply chain localization and improvements in material sourcing are enabling manufacturers to offer more customized and cost-competitive products.

With rising automation in end-use sectors and increasing preference for human-machine interfaces that are easy to sanitize and operate in harsh environments, the membrane switch market is poised for continued expansion Future demand is expected to be shaped by advancements in flexible circuitry and hybrid tactile-electronic systems.

The membrane switch market is segmented by type, material, technology, construction type, end-use, distribution channel, and geographic region. By type, the membrane switch market is divided into Standard membrane switches, PCB membrane switches, Graphic membrane switches, and Others (illuminated membrane switches, etc.). In terms of material, the membrane switch market is classified into Polyester, Polycarbonate, Acrylic, and Others (silicone, etc.).

Based on technology, the membrane switch market is segmented into Resistive membrane switches, Capacitive membrane switches, and Force-sensitive resistor (FSR) membrane switches. By construction type, the membrane switch market is segmented into Tactile and Non-tactile. By end use, the membrane switch market is segmented into Manufacturers (OEMs), Individual consumers, Healthcare providers, Automotive companies, Industrial enterprises, and Others (retailers, etc.).

By distribution channel, the membrane switch market is segmented into Direct and Indirect. Regionally, the membrane switch industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Standard membrane switches are projected to hold 39.6% of the membrane switch market revenue share in 2025, reflecting their significant contribution to overall market growth. This segment's leading position is being influenced by its widespread usage in equipment that requires simple, cost-efficient control mechanisms. Their structured design, which combines multiple layers including circuit, spacer, and overlay, allows effective functioning in a wide range of environmental conditions.

These switches are favored for their thin profile, ease of integration, and tactile responsiveness, making them suitable for applications such as industrial control panels, home appliances, and medical instrumentation. Their consistent performance under varying temperatures, alongside moisture and chemical resistance, has increased their adoption in regulated environments.

The standard format's compatibility with a broad range of graphic designs and LED integration options has enabled scalable production without compromising on design versatility This has strengthened their presence across mass-produced electronic devices where functional reliability and affordability are critical.

The polyester material segment is expected to account for 47.2% of the total revenue share in the membrane switch market by 2025, owing to its superior durability and cost-performance balance. Polyester-based membrane switches are widely utilized due to their excellent flex life, dimensional stability, and chemical resistance, all of which are crucial for applications that demand long operational life under repeated use. The material's resilience to heat and abrasion, coupled with its compatibility with different printing methods, supports efficient large-scale production.

Polyester substrates also provide a stable platform for silver or carbon-based conductive inks, enabling precise circuit patterning and long-term conductivity. The preference for polyester has been reinforced by its ability to retain functional integrity even under continuous actuation cycles in mission-critical environments.

Furthermore, its resistance to surface degradation and suitability for outdoor and industrial applications have contributed to its dominant share in the market These attributes have made polyester the material of choice for designers aiming for performance longevity and reliability in human-machine interfaces.

Resistive membrane switches are expected to account for 52.9% of the total market revenue in 2025, driven by their robust utility in sectors requiring precise and cost-effective input control systems. These switches operate through pressure-based actuation, allowing input through various touch methods, including gloved hands or styluses, which is especially useful in industrial, medical, and outdoor environments. The segment's growth has been supported by its strong performance in applications where capacitive alternatives may fail due to moisture, contaminants, or electromagnetic interference.

The resistive technology offers higher operational flexibility and lower susceptibility to false touches, enhancing its utility in equipment that demands stable, interference-free performance. Additionally, its simple layered construction allows for streamlined integration into sealed interfaces, reducing maintenance and enhancing device longevity.

The continued reliance on this technology in devices such as diagnostic equipment, navigation consoles, and rugged industrial panels has ensured a sustained demand. Ease of customization and low production costs further enhance the market position of resistive membrane switches.

The membrane switch market thrives on regulatory compliance, demand for durability, customization, and growth in the medical and industrial sectors. The demand for cost-effective, reliable interfaces continues to drive its development across key industries.

The membrane switch market is heavily influenced by stringent regulatory compliance and industry standards, particularly in sectors like medical devices and automotive. Regulations ensure that membrane switches meet specific safety, quality, and performance standards. In medical applications, switches must comply with ISO and FDA requirements to guarantee reliability and safety. Similarly, in automotive and industrial sectors, compliance with safety regulations ensures that the switches are durable, easy to use, and resistant to harsh environments. Manufacturers must adhere to these standards while maintaining product quality and cost-efficiency. Continuous monitoring and adaptation to regulatory changes are crucial to stay competitive in these highly regulated markets.

Durability remains a key driver of demand in the membrane switch market, especially in industrial and medical applications. Membrane switches are preferred for their robustness in challenging environments such as heavy machinery, medical devices, and outdoor applications. The growing need for long-lasting and reliable interfaces, especially in harsh conditions like extreme temperatures, moisture, and heavy usage, ensures their continued relevance. As industries focus on reducing maintenance costs and improving operational efficiency, the demand for durable membrane switches capable of withstanding prolonged use is expected to rise. This durability is a central aspect of the market’s growth trajectory.

One of the primary drivers of the membrane switch market is cost-efficiency combined with the ability to customize designs. Membrane switches offer manufacturers the ability to develop user-specific interfaces at a lower cost compared to alternatives like capacitive touchscreens. This makes them an attractive option for industries that require affordable yet high-quality interfaces. The customization options available for membrane switches, including unique layouts, colors, and shapes, cater to a wide range of applications, from consumer electronics to industrial equipment. The ability to meet specific customer needs while maintaining a low cost of production continues to drive the growth of the membrane switch market.

The medical and industrial sectors are key drivers of the membrane switch market. In the medical field, membrane switches are used in devices like diagnostic equipment, infusion pumps, and patient monitoring systems due to their ease of cleaning and durability. In industrial settings, they are commonly found in control panels, machinery, and process control systems. The continued expansion of these industries, along with the increasing demand for reliable and easy-to-use control interfaces, will continue to support market growth. As these sectors expand and modernize, the demand for high-performance, durable, and cost-effective membrane switches will remain strong.

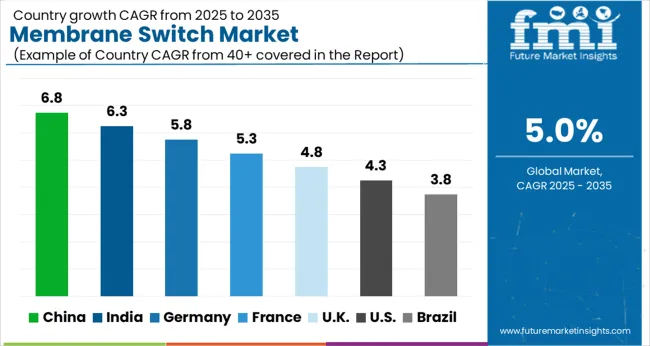

| Countries | CAGR |

|---|---|

| China | 6.8% |

| India | 6.3% |

| Germany | 5.8% |

| France | 5.3% |

| UK | 4.8% |

| USA | 4.3% |

| Brazil | 3.8% |

The membrane switch market is projected to grow globally at a CAGR of 5.0% from 2025 to 2035, fueled by the increasing demand for energy-efficient, durable, and customizable user interfaces in various industries. China leads with a CAGR of 6.8%, driven by rapid industrialization, a growing electronics manufacturing sector, and the increasing use of membrane switches in consumer electronics and industrial controls. India follows with a CAGR of 6.3%, supported by a rising demand for cost-effective, durable switches in sectors like automotive, medical devices, and industrial applications. France shows a growth rate of 5.3%, driven by the increasing adoption of membrane switches in industrial automation and medical sectors. The UK achieves 4.8% growth, fueled by strong demand for membrane switches in industrial control panels and the growing preference for low-maintenance, high-performance solutions. The USA posts a CAGR of 4.3%, supported by the growing trend of automation and the increasing need for reliable, customizable switches in various industrial sectors. This analysis highlights China, India, and Germany as key players in the market, with significant contributions from Europe and North America, supported by industrial growth, technological demand, and increasing focus on energy-efficient solutions.

The UK is expected to post a CAGR of 4.8% during 2025–2035, slightly below the global average of 5.0%. In the 2020–2024 period, the market grew at a rate of 4.3%, driven by increasing demand for durable, energy-efficient switches in industrial automation, medical devices, and automotive sectors. The UK’s transition towards more automated and digitized manufacturing processes has led to a higher adoption of membrane switches, particularly in control panels and industrial machinery. As industries seek more reliable and cost-effective alternatives to traditional switches, membrane switches have gained popularity. The growth for 2025–2035 is expected to rise due to increased automation, smart technology adoption, and greater focus on energy efficiency. Market growth will also be driven by advancements in material technology, which enhance the durability and performance of membrane switches. The push for more sustainable solutions in manufacturing processes is contributing to the increased adoption of these switches, as they are more eco-friendly than other options.

China is projected to achieve a CAGR of 6.8% during 2025–2035, outpacing the global rate of 5.0%. The 2020–2024 period saw growth at a CAGR of 6.2%, largely due to the country's rapid industrial expansion, the increasing automation in manufacturing, and rising demand for efficient and durable user interfaces across multiple industries. China’s emphasis on technological progress, including advancements in smart manufacturing, has led to increased demand for membrane switches, particularly in consumer electronics and automotive industries. For 2025–2035, the market is expected to grow further as industries continue to adopt more automated systems, driving the need for more efficient and robust user interfaces. Government initiatives and investments in renewable energy technologies are contributing to the rising demand for environmentally friendly and energy-efficient membrane switches.

India is expected to post a CAGR of 6.3% during 2025–2035, above the global average. During 2020–2024, the market grew at a CAGR of 5.8%, supported by the increasing adoption of advanced control panels in industries such as manufacturing, automotive, and healthcare. India's growing industrial base, along with the shift towards smart technologies and automation, has driven the demand for membrane switches, particularly in machinery and medical devices. The rise in disposable income and industrial development is contributing to the market’s expansion, as businesses seek more efficient and durable interfaces. Moving forward, the growth rate is expected to accelerate as India focuses on digital transformation, energy efficiency, and smart infrastructure, all of which will increase the demand for advanced HMI solutions like membrane switches.

France is projected to grow at a CAGR of 5.3% during 2025–2035, slightly below the global average of 5.0%. In the 2020–2024 period, the market grew at a rate of 5.1%, supported by the strong demand for durable and efficient membrane switches across various sectors such as automotive, industrial controls, and medical devices. France’s emphasis on smart manufacturing, digitalization, and energy-efficient solutions has led to an increased adoption of membrane switches, which are preferred for their reliability and cost-effectiveness in critical applications. For 2025–2035, growth is expected to accelerate as industries in France increasingly transition towards more automated and eco-friendly solutions. Government policies aimed at promoting clean energy and digital transformation are expected to further drive demand for energy-efficient and customizable interface solutions like membrane switches.

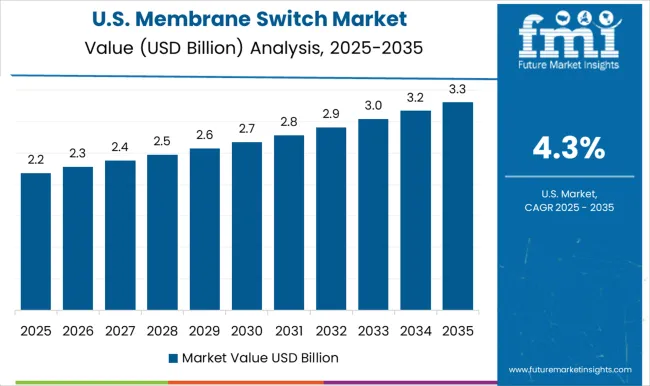

The USA is expected to grow at a CAGR of 4.3% during 2025–2035, below the global average. From 2020 to 2024, the USA market grew at a CAGR of 4.1%, driven by steady demand in key sectors such as automotive, healthcare, and industrial controls. The increasing trend towards automation and smart manufacturing technologies has created strong demand for more durable and efficient membrane switches, especially for use in heavy-duty applications. As the USA continues to focus on digital transformation and the development of smart infrastructure, the demand for energy-efficient and customizable user interfaces like membrane switches is expected to rise. Furthermore, the USA government’s focus on manufacturing innovation and clean energy will continue to boost the adoption of membrane switches in various sectors.

The membrane switch market is driven by leading global and regional manufacturers that provide advanced interface solutions for a broad range of industrial, commercial, medical, and consumer electronics applications. 3M Company leads the market with its high-performance membrane switch materials and assemblies, emphasizing durability, tactile responsiveness, and design flexibility for applications in automotive controls, medical devices, and industrial automation. Schneider Electric SE integrates membrane switches within its energy-efficient control and automation systems, delivering reliable user interfaces for building management and industrial environments.

Eaton Corporation plc contributes with rugged and energy-efficient membrane interfaces designed for industrial automation and power management, prioritizing operator safety and performance. TE Connectivity Ltd. stands out for its custom-engineered membrane switch and connector solutions, used in automotive, medical, and aerospace systems that demand compact, durable interconnects. Zippy Technology Corp. provides cost-effective, high-reliability tactile switches optimized for electronics and instrumentation, while NKK Switches Co., Ltd. is known for its premium mechanical and membrane switch solutions designed for precision control applications in industrial and medical systems.

Membrane Switches, Inc. (MSI) focuses exclusively on custom membrane switch assemblies, offering durable, cost-effective interfaces for electronics and instrumentation. MacDermid Alpha Electronics Solutions (part of Element Solutions Inc.) strengthens the market with advanced conductive ink and printed circuit technologies that enhance performance and production efficiency. Graphic Controls LLC delivers innovative printed electronic interfaces meeting stringent industry standards for reliability and responsiveness. Keypad Guy, Inc. and Switching Solutions Inc. provide customizable membrane and silicone keypad solutions, combining user-centric design with robust functionality for industrial, consumer, and healthcare applications.

BiT Semiconductor, Inc. supports the ecosystem with semiconductor-level switching and sensing components that complement membrane-based control systems. Seaton Switches Ltd. and Elmatica AS (an NCAB Group company) focus on precision membrane and printed circuitry integration, ensuring reliability in specialized and mission-critical applications. Apex Systems, LLC contributes engineering and integration support for customized electronic interface solutions, enabling large-scale design and production partnerships.

Competitive strategies in the membrane switch market center on continuous innovation in materials, tactile response, and electrical performance. Manufacturers are investing in durability enhancement, thin-film conductive technologies, and flexible circuit integration, while pursuing cost optimization and custom design capabilities for niche industries. Collaborations between OEMs, materials suppliers, and electronic design firms continue to strengthen market competitiveness, supporting the growing demand for lightweight, durable, and energy-efficient human–machine interface (HMI) systems across automotive, medical, industrial, and consumer sectors.

| Items | Values |

|---|---|

| Quantitative Units | USD 4.6 Billion |

| Type | Standard membrane switches, PCB membrane switches, Graphic membrane switches, and Others (illuminated membrane switches, etc.) |

| Material | Polyester, Polycarbonate, Acrylic, and Others (silicone, etc.) |

| Technology | Resistive membrane switches, Capacitive membrane switches, and Force-sensitive resistor (FSR) membrane switches |

| Construction Type | Tactile and Non-tactile |

| End Use | Manufacturers (OEMs), Individual consumers, Healthcare providers, Automotive companies, Industrial enterprises, and Others (retailers, etc.) |

| Distribution Channel | Direct and Indirect |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled |

The membrane switch market is driven by leading global and regional manufacturers that provide advanced interface solutions for a broad range of industrial, commercial, medical, and consumer electronics applications. 3M Company leads the market with its high-performance membrane switch materials and assemblies, emphasizing durability, tactile responsiveness, and design flexibility for applications in automotive controls, medical devices, and industrial automation. Schneider Electric SE integrates membrane switches within its energy-efficient control and automation systems, delivering reliable user interfaces for building management and industrial environments. Eaton Corporation plc contributes with rugged and energy-efficient membrane interfaces designed for industrial automation and power management, prioritizing operator safety and performance. TE Connectivity Ltd. stands out for its custom-engineered membrane switch and connector solutions, used in automotive, medical, and aerospace systems that demand compact, durable interconnects. Zippy Technology Corp. provides cost-effective, high-reliability tactile switches optimized for electronics and instrumentation, while NKK Switches Co., Ltd. is known for its premium mechanical and membrane switch solutions designed for precision control applications in industrial and medical systems. Membrane Switches, Inc. (MSI) focuses exclusively on custom membrane switch assemblies, offering durable, cost-effective interfaces for electronics and instrumentation. MacDermid Alpha Electronics Solutions (part of Element Solutions Inc.) strengthens the market with advanced conductive ink and printed circuit technologies that enhance performance and production efficiency. Graphic Controls LLC delivers innovative printed electronic interfaces meeting stringent industry standards for reliability and responsiveness. Keypad Guy, Inc. and Switching Solutions Inc. provide customizable membrane and silicone keypad solutions, combining user-centric design with robust functionality for industrial, consumer, and healthcare applications. BiT Semiconductor, Inc. supports the ecosystem with semiconductor-level switching and sensing components that complement membrane-based control systems. Seaton Switches Ltd. and Elmatica AS (an NCAB Group company) focus on precision membrane and printed circuitry integration, ensuring reliability in specialized and mission-critical applications. Apex Systems, LLC contributes engineering and integration support for customized electronic interface solutions, enabling large-scale design and production partnerships. Competitive strategies in the membrane switch market center on continuous innovation in materials, tactile response, and electrical performance. Manufacturers are investing in durability enhancement, thin-film conductive technologies, and flexible circuit integration, while pursuing cost optimization and custom design capabilities for niche industries. Collaborations between OEMs, materials suppliers, and electronic design firms continue to strengthen market competitiveness—supporting the growing demand for lightweight, durable, and energy-efficient human–machine interface (HMI) systems across automotive, medical, industrial, and consumer sectors. |

| Additional Attributes | Dollar sales and market share of leading competitors, insights on technological trends, consumer preferences, and pricing strategies are also crucial. |

The global membrane switch market is estimated to be valued at USD 4.6 billion in 2025.

The market size for the membrane switch market is projected to reach USD 7.5 billion by 2035.

The membrane switch market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in membrane switch market are standard membrane switches, pcb membrane switches, graphic membrane switches and others (illuminated membrane switches, etc.).

In terms of material, polyester segment to command 47.2% share in the membrane switch market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Membrane Filter Press Solutions Market Size and Share Forecast Outlook 2025 to 2035

Membrane Filter Press Machines Market Size and Share Forecast Outlook 2025 to 2035

Switchgear for Data Centers Market Size and Share Forecast Outlook 2025 to 2035

Membrane Separation Ammonia Cracker Market Size and Share Forecast Outlook 2025 to 2035

Switchrack Assemblies Market Size and Share Forecast Outlook 2025 to 2035

Membrane Separation Technology Market Size and Share Forecast Outlook 2025 to 2035

Switching Residential Voltage Regulator Market Size and Share Forecast Outlook 2025 to 2035

Switching Commercial Voltage Regulator Market Size and Share Forecast Outlook 2025 to 2035

Membrane Filtration Systems Market Size and Share Forecast Outlook 2025 to 2035

Membrane Microfiltration Market Size and Share Forecast Outlook 2025 to 2035

Membrane Filter Cartridge Market Size and Share Forecast Outlook 2025 to 2035

Membrane Boxes Market Size and Share Forecast Outlook 2025 to 2035

Membrane Chemicals Market Growth - Trends & Forecast 2025 to 2035

Switching Mode Power Supply Market - Growth & Forecast 2025 to 2035

Membrane Air Dryers Market Growth - Trends & Forecast 2025 to 2035

Switched Reluctance Motors Market Growth - Trends & Forecast 2025 to 2035

Switchgear Market Growth - Trends & Forecast 2025 to 2035

Market Leaders & Share in Membrane Boxes Manufacturing

AC Switchgear Market Size and Share Forecast Outlook 2025 to 2035

RF Switches Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA