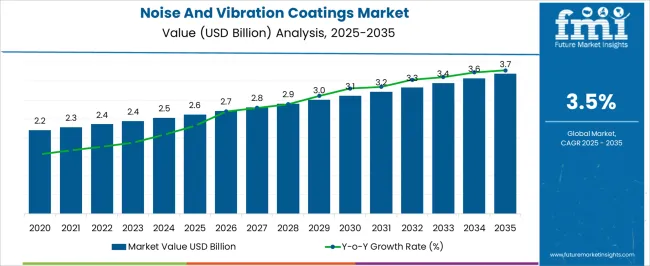

The Noise And Vibration Coatings Market is estimated to be valued at USD 2.6 billion in 2025 and is projected to reach USD 3.7 billion by 2035, registering a compound annual growth rate (CAGR) of 3.5% over the forecast period.

| Metric | Value |

|---|---|

| Noise And Vibration Coatings Market Estimated Value in (2025 E) | USD 2.6 billion |

| Noise And Vibration Coatings Market Forecast Value in (2035 F) | USD 3.7 billion |

| Forecast CAGR (2025 to 2035) | 3.5% |

The noise and vibration coatings market is experiencing notable growth, driven by the increasing demand for solutions that improve acoustic comfort, structural performance, and durability across multiple industries. The rising emphasis on environmental noise reduction regulations, coupled with consumer expectations for enhanced comfort and reduced vibration levels, is supporting wider adoption.

Automotive, construction, aerospace, and industrial machinery sectors are investing in advanced coatings that not only dampen noise and vibrations but also provide protective and functional benefits such as corrosion resistance and longer service life. Continuous innovation in coating formulations, including polymer and resin advancements, is enabling manufacturers to deliver lightweight yet effective solutions that align with sustainability objectives and performance standards.

With industrial growth and urbanization increasing globally, the requirement for noise control and vibration management is expected to intensify, particularly in transportation and heavy machinery applications This growing awareness of health, safety, and environmental standards is further influencing manufacturers to adopt coatings that deliver both performance efficiency and regulatory compliance, positioning the market for long-term expansion.

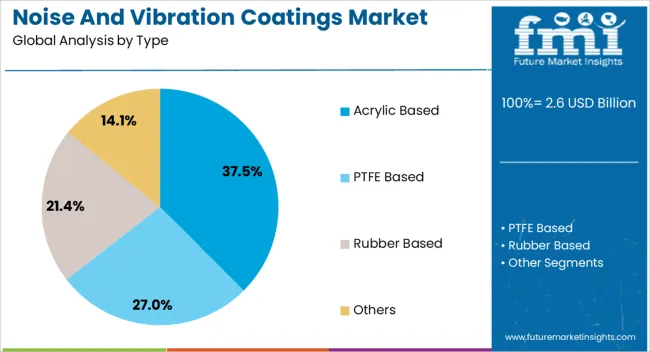

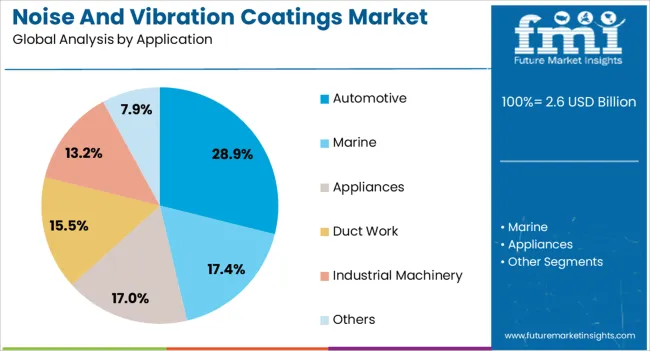

The noise and vibration coatings market is segmented by type, application, and geographic regions. By type, noise and vibration coatings market is divided into Acrylic Based, PTFE Based, Rubber Based, and Others. In terms of application, noise and vibration coatings market is classified into Automotive, Marine, Appliances, Duct Work, Industrial Machinery, and Others. Regionally, the noise and vibration coatings industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The acrylic based segment is projected to account for 37.5% of the noise and vibration coatings market revenue share in 2025, making it the leading product type. Its dominance is being reinforced by its excellent adhesion, durability, and cost-effectiveness, which make it highly suitable for a wide range of industrial and automotive applications. Acrylic based coatings are valued for their ability to provide effective damping of noise and vibrations while maintaining lightweight properties, an essential factor in industries prioritizing fuel efficiency and performance.

Their resistance to environmental factors such as moisture and UV exposure further enhances reliability, ensuring long service life under demanding conditions. The ease of application and compatibility with different substrates are also supporting their widespread use.

In addition, advances in waterborne acrylic formulations are aligning the segment with environmental regulations, enabling reduced volatile organic compound emissions The balance of performance, affordability, and sustainability benefits has positioned acrylic based coatings as the preferred choice, driving consistent demand and reinforcing its leading market share.

The automotive segment is anticipated to represent 28.9% of the noise and vibration coatings market revenue share in 2025, establishing it as the dominant application area. Its leadership is being driven by the increasing focus on passenger comfort, vehicle safety, and regulatory compliance with noise emission standards. The adoption of noise and vibration coatings in vehicles helps minimize road noise, structural vibrations, and engine-induced acoustic disturbances, resulting in a quieter and smoother driving experience.

With the rapid expansion of electric vehicles, the need for advanced coatings has intensified, as the absence of engine noise highlights secondary vibrations and other sound sources. Manufacturers are integrating specialized coatings to meet these new acoustic challenges while maintaining lightweight design requirements for improved energy efficiency.

Additionally, stringent global noise reduction regulations in the automotive sector are compelling automakers to adopt coatings that meet both performance and compliance standards As consumer demand for high comfort levels continues to grow, the automotive sector is expected to remain the leading application for noise and vibration coatings.

Noise and vibration coatings are water based coatings containing noise reducing pigments and are VOC compliant, it is used to reduce noise and vibrations from machinery's and automotive. It is non-flammable and contains and non-toxic in nature and possess highly thixotropic properties along with good temperature resistance up to 350 degrees Fahrenheit and acts as corrosion resistance for machines.

Moreover, once applied on the surface it can be washed and the coatings does not peel off or cracks. The noise and vibrations coatings are manufactured in spray and paste form. There are norms, which allows only a permissible decibel of sound to be emitted from the machinery's or industries thus providing safety to worker operating under harsh noises.

The noise and vibration coatings are used in different applications such as motors and transformers, metal ducts, HVAC systems, grinders, and door panels of car among others. The global noise and vibration coatings market is expected to show considerable growth by the end of forecast period due to its wide range of applications in the end use industries from automotive to marine.

The global noise and vibration coatings market is primarily driven by the increasing demand from the industries to reduce the noise and vibrations from the rotating equipment in order to comply with the regulations for noise emission.

The noise and vibration coatings also protects the surface from corrosion thus having a multipurpose use, which can reduce the additional costs for corrosion prevention coatings. Moreover, the noise and vibrations coatings being water based and VOC free is contributing to the growth of noise and vibrations coatings globally.

Some of the big players in the coatings market are developing technologies to enhance the existing noise and vibration coatings in the market. For instance, DOW coating materials has developed a new a technology Liquid-Applied Sound Damping (LASD) that can be used to mitigate noise and vibrations in cars and home appliances among others.

The global market for noise and vibration coatings is segmented based on resin types, applications, end use industries and regions. Based on the resin types the global noise and vibration coatings market can be segmented into epoxy resins, epoxy PE resins and thermoplastics.

Based on applications, the global noise and vibration coatings market can be segmented into car door panels, motors, metal ducts, grinders and tanks among others. Based on end use industries the global noise and vibration coatings can be segmented into automotive, marine, aerospace, home appliances among others.

Based on the geographic regions, global noise and vibration coatings market is segmented into seven key market segments namely North America, Latin America, Western Europe, Eastern Europe, Asia Pacific, Japan, and Middle East & Africa.

The North America market for noise and vibration coatings market currently holds the largest market share for the noise and vibration coatings market among the aforementioned regions. The Western Europe market trails behind the North American market in terms of market share.

The stringent regulations for noise emission in these regions as well as adaption of new technologies for noise and vibrations coating in the region attributes to the growth of noise and vibrations coatings market in these regions. However, by the end of forecast period the Asia-Pacific market for noise and vibration coatings market is expected to grow significantly due to the growth in automotive industry and other industries in the region.

Some of the major players identified in the global global noise and vibration coatings market includes The Dow Chemical Company, Mascoat, LORD Corporation., Silent Running, Daubert Chemical Company and The Decc Company among others.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, types, technology and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

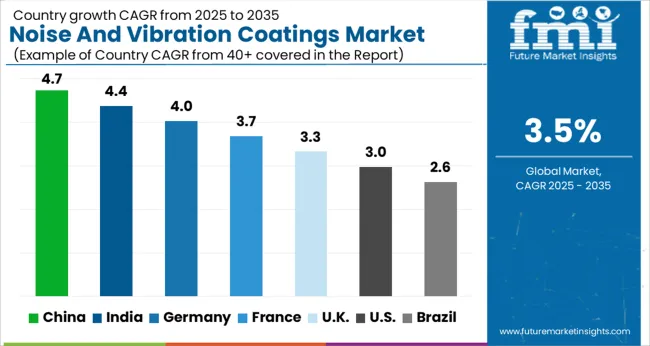

| Country | CAGR |

|---|---|

| China | 4.7% |

| India | 4.4% |

| Germany | 4.0% |

| France | 3.7% |

| UK | 3.3% |

| USA | 3.0% |

| Brazil | 2.6% |

The Noise And Vibration Coatings Market is expected to register a CAGR of 3.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 4.7%, followed by India at 4.4%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 2.6%, yet still underscores a broadly positive trajectory for the global Noise And Vibration Coatings Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 4.0%. The USA Noise And Vibration Coatings Market is estimated to be valued at USD 990.6 million in 2025 and is anticipated to reach a valuation of USD 1.3 billion by 2035. Sales are projected to rise at a CAGR of 3.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 132.8 million and USD 67.4 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.6 Billion |

| Type | Acrylic Based, PTFE Based, Rubber Based, and Others |

| Application | Automotive, Marine, Appliances, Duct Work, Industrial Machinery, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

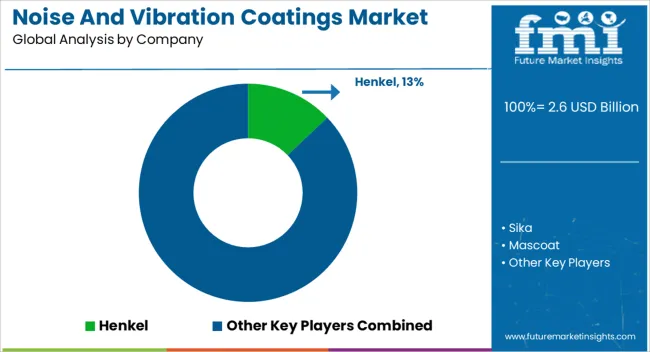

| Key Companies Profiled | Henkel, Sika, Mascoat, 3M, BASF, Lord, Dow, PPG, Miba, Daubert Chem, PABCO Gypsum, Whitford, Auson, Verotek, and Feilu |

The global noise and vibration coatings market is estimated to be valued at USD 2.6 billion in 2025.

The market size for the noise and vibration coatings market is projected to reach USD 3.7 billion by 2035.

The noise and vibration coatings market is expected to grow at a 3.5% CAGR between 2025 and 2035.

The key product types in noise and vibration coatings market are acrylic based, ptfe based, rubber based and others.

In terms of application, automotive segment to command 28.9% share in the noise and vibration coatings market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Noise Vibration Harshness (NVH) Testing Market

Coatings and Application Technologies for Robotics Market Outlook – Trends & Innovations 2025-2035

Demand for Vibration Control Systems in Japan Size and Share Forecast Outlook 2025 to 2035

Demand for Vibration Control Systems in USA Size and Share Forecast Outlook 2025 to 2035

Demand for Coil Coatings in EU Size and Share Forecast Outlook 2025 to 2035

Batters and Coatings Market Analysis – Size, Share, & Forecast Outlook 2025 to 2035

Faux Paints And Coatings Market Size and Share Forecast Outlook 2025 to 2035

Edible Films and Coatings Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Edible Films and Coatings

Stealth Materials and Coatings Market Size and Share Forecast Outlook 2025 to 2035

Insulating Paints And Coatings Market

Road Marking Paints and Coatings Market Size and Share Forecast Outlook 2025 to 2035

Oxygen Barrier Films And Coatings For Dry Food Market Size and Share Forecast Outlook 2025 to 2035

Functional Additives And Barrier Coatings Market from 2025 to 2035

Amine Additives in Paints and Coatings Market

Polyurethane Resins Paints & Coatings Market Growth – Trends & Forecast 2025 to 2035

Corrosion Protection Rubber Linings Market 2022 to 2032

Noise Reduction Tactical Headset Market Size and Share Forecast Outlook 2025 to 2035

Vibration Screening Machine Market Size and Share Forecast Outlook 2025 to 2035

Android Automotive OS (AAOS) Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA