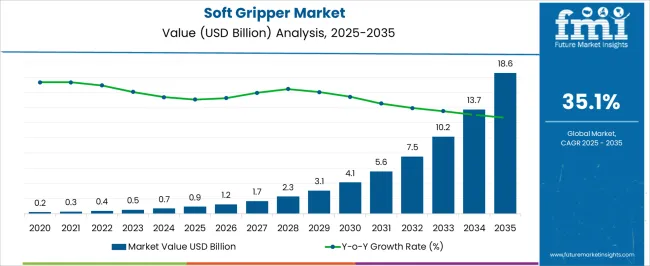

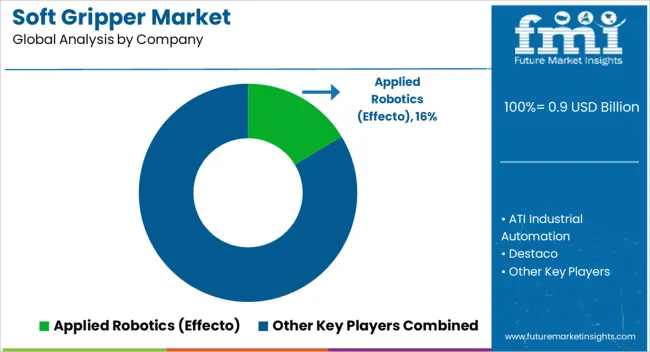

The soft gripper market is estimated to be valued at USD 0.9 billion in 2025 and is projected to reach USD 18.6 billion by 2035, registering a compound annual growth rate (CAGR) of 35.1% over the forecast period. This growth translates into a substantial absolute dollar opportunity for businesses and investors, highlighting the increasing adoption of soft grippers across various industries.

Starting at USD 0.2 billion in the initial years, the market shows steady expansion, reaching USD 5.6 billion by 2030. By capturing even a small share of this rapidly growing market, companies can leverage significant revenue potential, particularly as demand accelerates in the latter half of the decade. Between 2025 and 2035, the soft gripper market offers an absolute dollar opportunity of USD 17.7 billion, calculated as the difference between the market size in 2035 (USD 18.6 billion) and 2025 (USD 0.9 billion).

The growth trajectory shows a gradual climb in the early years, moving from USD 1.2 billion in 2026 to USD 7.5 billion in 2031, before surging to USD 18.6 billion by 2035. This substantial increase highlights the potential for market entrants and existing players to generate high returns, emphasizing the importance of strategic positioning and timely investments in this sector.

| Metric | Value |

|---|---|

| Soft Gripper Market Estimated Value in (2025 E) | USD 0.9 billion |

| Soft Gripper Market Forecast Value in (2035 F) | USD 18.6 billion |

| Forecast CAGR (2025 to 2035) | 35.1% |

A breakpoint analysis of the soft gripper market highlights critical periods where growth accelerates or investment returns become more significant. From 2025 to 2028, the market grows from USD 0.9 billion to USD 1.7 billion, representing early-stage adoption where businesses can establish a presence with moderate investment risk. During this period, incremental gains are smaller, ranging from USD 0.2 to 0.5 billion annually, allowing companies to test strategies, refine product offerings, and understand end-user requirements.

The next breakpoint occurs between 2030 and 2035, where the market expands sharply from USD 4.1 billion to USD 18.6 billion. This stage represents mass adoption and higher revenue potential, with annual increments exceeding USD 3 billion in the later years. Strategic positioning during this phase is critical, as market share captured here translates into significant absolute dollar gains. Companies entering or scaling operations at this point benefit from strong demand and a robust CAGR of 35.1%.

The soft gripper market is expanding steadily, supported by the growing adoption of robotics in industries requiring delicate and precise handling capabilities. Advances in automation technology, combined with rising demand for adaptive gripping solutions, have positioned soft grippers as a preferred choice in sectors where traditional rigid grippers pose risks of product damage.

Industry developments have emphasized the role of soft grippers in improving efficiency in food processing, electronics assembly, and healthcare applications. The market has also benefited from material innovations that enhance flexibility, durability, and tactile sensitivity. Investments in collaborative robotics and integration of soft grippers with AI-driven control systems have increased operational versatility, enabling their use across varied environments.

Additionally, the rising emphasis on automation in healthcare and service industries is accelerating adoption. Growth will be shaped by advancements in actuator design, biodegradable material development, and expanding applications in high-precision and safety-critical operations.

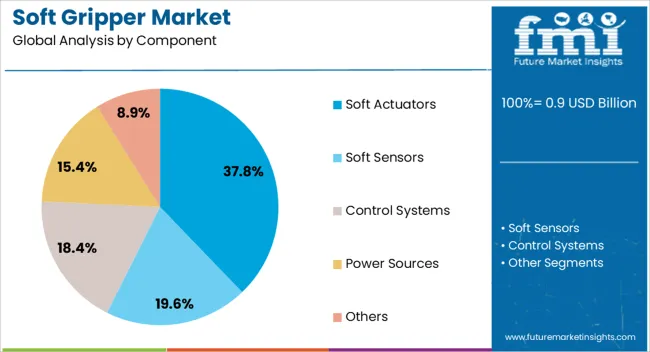

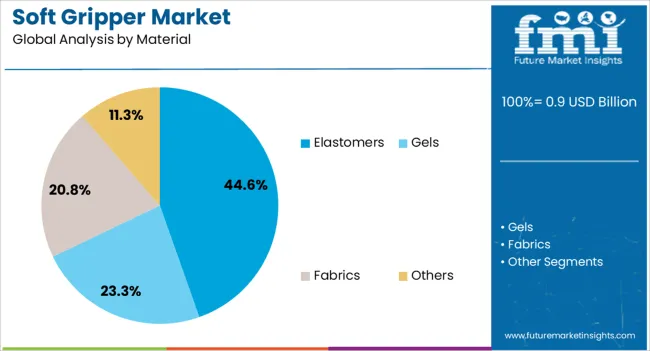

The soft gripper market is segmented by component, material, application, and geographic regions. By component, soft gripper market is divided into Soft Actuators, Soft Sensors, Control Systems, Power Sources, and Others. In terms of material, soft gripper market is classified into Elastomers, Gels, Fabrics, and Others.

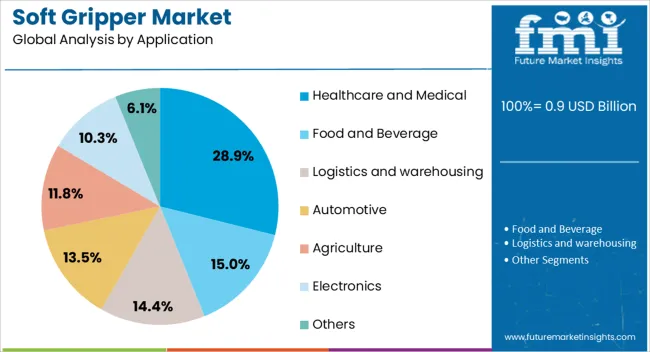

Based on application, soft gripper market is segmented into Healthcare and Medical, Food and Beverage, Logistics and warehousing, Automotive, Agriculture, Electronics, and Others. Regionally, the soft gripper industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The soft actuators segment is projected to account for 37.8% of the soft gripper market revenue in 2025, maintaining its leading position due to its central role in enabling flexible and adaptive gripping functions. This growth has been driven by advancements in pneumatic, hydraulic, and electroactive polymer-based actuator designs, which have improved force control, repeatability, and responsiveness.

Manufacturers have focused on developing lightweight and energy-efficient actuator systems that can adapt to a wide range of shapes and sizes without damaging the gripped object. Additionally, soft actuators offer compatibility with collaborative robots, enhancing safety in human-robot interaction scenarios.

The increasing need for precision in automated assembly lines, packaging operations, and delicate handling in medical device manufacturing has supported the segment’s adoption. Continuous research into soft robotics has also expanded performance capabilities, reinforcing the segment’s dominance in the overall market.

The Elastomers segment is projected to contribute 44.6% of the soft gripper market revenue in 2025, securing its position as the dominant material type. Growth in this segment has been driven by the inherent flexibility, durability, and deformation resilience of elastomers, which make them ideal for creating adaptive gripping surfaces.

Advances in material science have led to the development of elastomers with enhanced chemical resistance, temperature tolerance, and biocompatibility, broadening their application scope. Elastomers also allow for customizable stiffness levels, enabling grippers to handle objects of varying fragility with precision.

In industries such as food processing and healthcare, the hygienic properties and ease of cleaning associated with elastomer-based grippers have been key adoption drivers. The combination of material adaptability and long operational life has ensured the continued preference for elastomers in high-performance soft gripper designs.

The Healthcare and Medical segment is projected to hold 28.9% of the soft gripper market revenue in 2025, reflecting its leading role in application adoption. This growth has been supported by the increasing integration of robotics in medical device handling, surgical assistance, and patient care applications.

Soft grippers offer distinct advantages in these settings, including gentle contact, adaptability to irregular shapes, and reduced risk of tissue or equipment damage. Healthcare facilities have embraced soft gripper technology for tasks such as handling laboratory samples, aiding rehabilitation devices, and assisting in minimally invasive procedures.

Regulatory approval for medical-grade materials and sterilizable designs has further boosted their adoption in clinical environments. Additionally, as healthcare systems worldwide continue to adopt automation to improve efficiency and patient outcomes, the demand for precision, safety, and hygiene-focused gripping solutions is expected to keep the Healthcare and Medical segment at the forefront of market growth.

The soft gripper market is expanding as industries increasingly adopt advanced robotics for automated handling of delicate, irregular, or fragile objects. Soft grippers, typically made from silicone, elastomers, or pneumatic materials, provide adaptive and gentle grasping capabilities in applications such as food processing, electronics assembly, medical devices, and packaging.

Rising demand for flexible automation, collaborative robots (cobots), and Industry 4.0 integration drives adoption. Manufacturers offering customizable, lightweight, and durable soft grippers with embedded sensors and force-feedback capabilities gain competitive advantages. Additionally, growth in e-commerce, logistics automation, and precision manufacturing supports market expansion. The trend toward automation in small-scale, high-mix production environments further reinforces the need for adaptive, soft robotic end-effectors globally.

Market growth is restrained by material limitations and integration challenges associated with soft grippers. Soft materials, while adaptive, have lower load-bearing capacity and limited durability compared to rigid end-effectors, which can restrict application in heavy-duty operations. Customization for specific object shapes and sizes may require additional design and manufacturing time, increasing costs. Integration with existing robotic arms and automation systems can be complex, especially when force control and sensor feedback need calibration. Maintenance, cleaning, and wear-and-tear management of soft materials are additional operational considerations. Until material performance, durability, and integration solutions improve, adoption may remain concentrated in sectors handling lightweight, delicate, or irregular objects rather than high-volume, heavy-duty industrial applications.

Market trends are driven by technological advancements in soft robotics, sensor integration, and actuation systems. Pneumatic, hydraulic, and electroactive polymer-based soft grippers are being enhanced with embedded tactile sensors, force-feedback systems, and machine learning algorithms for precise manipulation. Modular designs enable adaptability to a wide range of objects and tasks. Advances in 3D printing and elastomer fabrication allow rapid prototyping and customization of soft grippers. Integration with collaborative robots and autonomous systems improves operational efficiency, safety, and flexibility in production environments. These trends highlight the growing importance of combining material science, robotics, and digital intelligence to expand soft gripper applications across manufacturing, food processing, logistics, and healthcare sectors globally.

Opportunities in the soft gripper market are driven by rising automation in industries requiring delicate or irregular object handling. Sectors such as food and beverage, consumer electronics, medical devices, pharmaceuticals, and packaging increasingly demand end-effectors that minimize product damage while maintaining throughput. Collaborative robots and lightweight automation systems provide a favorable platform for soft gripper adoption. Expansion in e-commerce and fulfillment centers also drives demand for adaptive robotic handling solutions. Manufacturers offering customizable, durable, and sensor-equipped soft grippers can capitalize on these opportunities. The shift toward high-mix, low-volume production and precision handling environments reinforces long-term market growth, particularly in emerging economies investing in advanced manufacturing and automation technologies.

Market growth is restrained by intense competition, cost considerations, and lack of standardization in soft gripper designs. Numerous global and regional suppliers compete on price, customization, and technological capabilities, impacting margins. High R&D and production costs for advanced materials, sensors, and actuators can limit adoption by smaller manufacturers. Standardization challenges arise due to variations in gripper size, material properties, and integration requirements for different robotic platforms. Inconsistent performance metrics across suppliers can hinder confidence and scalability. Until manufacturers provide cost-effective, durable, and interoperable soft grippers with reliable performance metrics, adoption may remain concentrated in industries prioritizing delicate handling and precision operations over high-volume, heavy-duty automation globally.

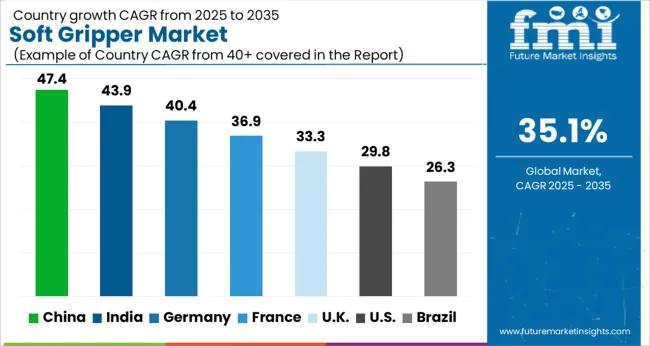

| Country | CAGR |

|---|---|

| China | 47.4% |

| India | 43.9% |

| Germany | 40.4% |

| France | 36.9% |

| UK | 33.3% |

| USA | 29.8% |

| Brazil | 26.3% |

The global soft gripper market was projected to grow at a 35.1% CAGR through 2035, driven by demand in robotics, automation, and material handling applications. Among BRICS nations, China recorded 47.4% growth as large-scale manufacturing facilities were established and compliance with industrial and safety standards was enforced, while India at 43.9% growth saw commissioning of new production units to support rising regional adoption in automation sectors. In the OECD region, Germany at 40.4% maintained substantial output under strict industrial regulations, while the United Kingdom at 33.3% relied on moderate-scale operations for robotics and manufacturing applications. The USA, expanding at 29.8%, remained a mature market with steady demand in industrial automation and research, supported by adherence to federal and state-level safety and manufacturing standards. This report includes insights on 40+ countries; the top five markets are shown here for reference.

Soft gripper market in China is expanding at a CAGR of 47.4%, driven by rapid adoption of automation and robotics in manufacturing and e-commerce sectors. Industrial automation in electronics, food processing, and packaging industries is creating strong demand for soft robotic grippers that handle delicate and irregular objects. Local robotics manufacturers are investing in research and development to produce cost effective and high performance solutions. The market is also supported by government incentives for smart factories and intelligent manufacturing. Integration with collaborative robots is increasing, enabling safer human machine interaction. E-commerce fulfillment centers are implementing soft grippers to improve efficiency and reduce product damage. The combination of technological innovation, industrial demand, and government support positions China as a leading market for soft gripper adoption in Asia.

Soft gripper market in India is growing at a CAGR of 43.9%, supported by rising industrial automation and e-commerce expansion. Food processing, packaging, and electronics manufacturing sectors are adopting soft grippers to handle delicate products efficiently. Domestic robotics firms are developing solutions tailored to local manufacturing requirements and cost considerations. The market benefits from government initiatives promoting smart manufacturing and Industry 4.0 adoption. Startups are introducing innovative designs that combine lightweight construction with precision handling. Integration of soft grippers with collaborative robots is gaining traction to ensure safe human machine interaction. The combination of industrial growth, technological innovation, and affordable solutions is propelling India as a major emerging market for soft gripper applications.

Soft gripper market in Germany is growing at a CAGR of 40.4%, driven by advanced industrial automation and strong robotics adoption. Automotive, electronics, and pharmaceutical industries are using soft grippers for precise handling of fragile and irregularly shaped components. Research institutions and manufacturing companies are investing in materials innovation to improve gripper flexibility, durability, and performance. Collaborative robots integrated with soft grippers are increasingly deployed in production lines to enhance safety and efficiency. Germany’s emphasis on high quality manufacturing and Industry 4.0 standards ensures the adoption of innovative robotic solutions. The market growth reflects a combination of industrial sophistication, innovation in soft robotics, and increasing demand for human safe automation.

Soft gripper market in the United Kingdom is expanding at a CAGR of 33.3%, supported by growth in industrial automation and logistics sectors. Food handling, e-commerce fulfillment, and packaging industries are adopting soft grippers for careful product manipulation. Research and development activities are focusing on lightweight, energy efficient designs with high adaptability. Collaborative robotics integration is growing, allowing soft grippers to operate safely alongside human workers. Government programs promoting automation and smart manufacturing are creating additional incentives for adoption. Market trends show rising demand for multifunctional grippers that can handle a variety of materials and shapes. The United Kingdom market reflects a balance between technological advancement, workplace safety, and industrial productivity improvement.

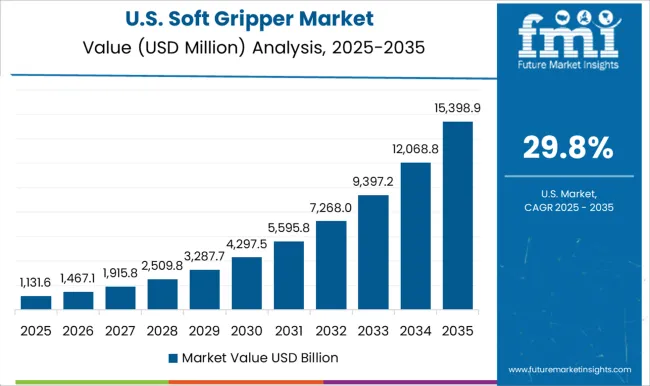

Soft gripper market in the United States is growing at a CAGR of 29.8%, fueled by automation in e-commerce, food, and electronics manufacturing. Manufacturers are adopting soft grippers to reduce product damage and improve handling of irregular shapes. Collaborative robots are increasingly integrated with soft grippers to support human machine interaction safely. Research in materials science and robotics is enhancing flexibility, precision, and durability of soft grippers. Startups and established firms are focusing on modular and adaptable designs suitable for multiple industrial applications. Investment in intelligent robotic systems and fulfillment automation is further boosting market growth. The combination of technological innovation, industrial demand, and safety considerations makes the United States a key player in the global soft gripper market.

The soft gripper market is supplied by Applied Robotics (Effecto), ATI Industrial Automation, Destaco, Festo AG, Gimatic, and KUKA Robotics, with competition driven by gripping precision, adaptability, and integration with robotic systems. Applied Robotics and Festo brochures highlight pneumatically actuated soft fingers, detailing maximum payload, stroke range, and force distribution. ATI Industrial Automation and KUKA emphasize force-torque sensing and end-of-arm tooling compatibility, with datasheets specifying load capacity, response time, and material compliance. Destaco and Gimatic focus on modular gripper designs, providing technical sheets on gripping profiles, surface contact area, and durability under repetitive operations. Observed industry patterns indicate increasing adoption of soft robotics for delicate objects in manufacturing, food handling, and packaging applications.

Market strategies are oriented toward differentiation through adaptability, modularity, and system integration. Applied Robotics and Festo invest in high-compliance materials and actuator designs to maximize object conformity and reduce damage risk. ATI Industrial Automation and KUKA provide integrated solutions combining sensors, grippers, and robotic arms for automated inspection and assembly lines.

| Item | Value |

|---|---|

| Quantitative Units | USD 0.9 Billion |

| Component | Soft Actuators, Soft Sensors, Control Systems, Power Sources, and Others |

| Material | Elastomers, Gels, Fabrics, and Others |

| Application | Healthcare and Medical, Food and Beverage, Logistics and warehousing, Automotive, Agriculture, Electronics, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Applied Robotics (Effecto), ATI Industrial Automation, Destaco, Festo AG, Gimatic, and KUKA Robotics |

| Additional Attributes | Dollar sales vary by gripper type, including pneumatic, electric, and hybrid soft grippers; by application, such as packaging, food handling, electronics assembly, and healthcare; by end-use industry, spanning manufacturing, logistics, food & beverage, and pharmaceuticals; by region, led by North America, Europe, and Asia-Pacific. Growth is driven by rising automation, demand for delicate object handling, and advancements in robotic end-effectors. |

The global soft gripper market is estimated to be valued at USD 0.9 billion in 2025.

The market size for the soft gripper market is projected to reach USD 18.6 billion by 2035.

The soft gripper market is expected to grow at a 35.1% CAGR between 2025 and 2035.

The key product types in soft gripper market are soft actuators, soft sensors, control systems, power sources and others.

In terms of material, elastomers segment to command 44.6% share in the soft gripper market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Software-Defined Wide Area Network Market Size and Share Forecast Outlook 2025 to 2035

Soft Start Resistor Market Size and Share Forecast Outlook 2025 to 2035

Soft Touch Lamination Film Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Networking (SDN) And Network Function Virtualization (NFV) Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Perimeter (SDP) Market Size and Share Forecast Outlook 2025 to 2035

Soft Ferrite Core Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Wide Area Network SD-WAN Market Size and Share Forecast Outlook 2025 to 2035

Soft Magnetic Composite Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Softwood Veneer and Plywood Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Radio (SDR) Market Size and Share Forecast Outlook 2025 to 2035

Software License Management (SLM) Market Size and Share Forecast Outlook 2025 to 2035

Soft Wall Military Shelter Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Networking SDN Market Size and Share Forecast Outlook 2025 to 2035

Soft Drinks Packaging Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Anything (SDx) Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Data Center Market Size and Share Forecast Outlook 2025 to 2035

Software Containers Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Application And Infrastructure Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Networking Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA