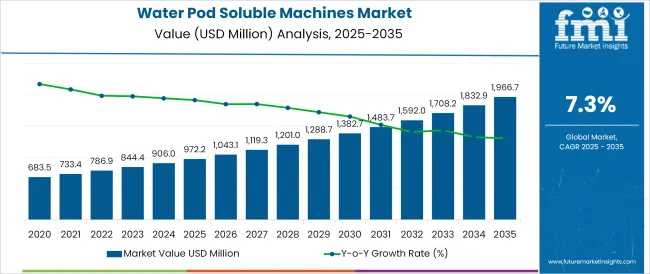

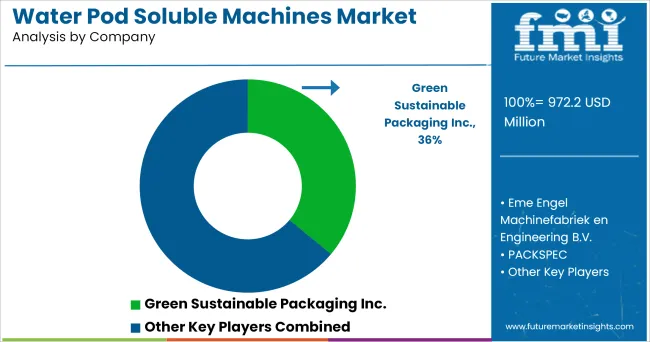

The Water Pod Soluble Machines Market is estimated to be valued at USD 972.2 million in 2025 and is projected to reach USD 1966.7 million by 2035, registering a compound annual growth rate (CAGR) of 7.3% over the forecast period.

The water pod soluble machines market is undergoing dynamic expansion, influenced by heightened demand for unit-dose packaging across household and industrial cleaning sectors. The shift toward single-use, pre-measured pods is being propelled by consumer preference for convenience, sustainability, and precision in dosing.

Manufacturers are aligning with eco conscious goals by adopting water-soluble films that minimize plastic use and reduce environmental waste. Simultaneously, regulatory pressure around accurate chemical handling, worker safety, and zero-waste packaging is compelling brand owners to invest in advanced pod-forming machinery.

The integration of automation, modularity, and servo driven systems is enabling flexibility across various pod designs and sizes. Demand is particularly strong from FMCG brands, chemical manufacturers, and contract packagers aiming to streamline production, lower material costs, and reduce human intervention. As the personal care, detergent, and agrochemical sectors scale up pod-based product lines, market expansion is expected to accelerate through innovation in sealing technologies and biodegradable film compatibility.

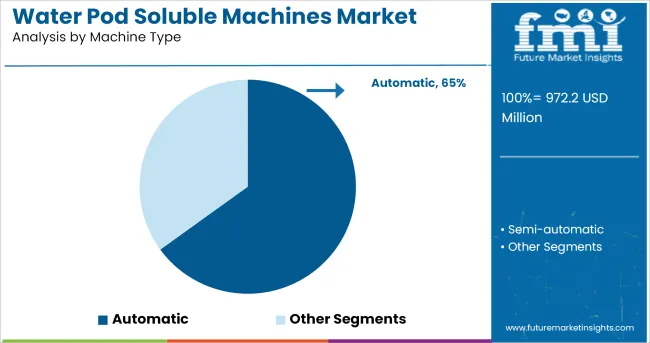

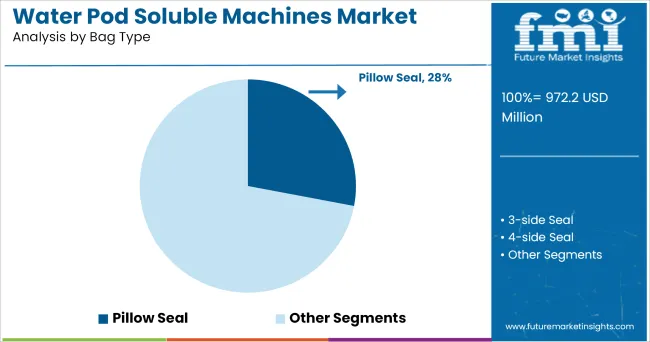

The market is segmented by Machine Type, Bag Type, and Application and region. By Machine Type, the market is divided into Automatic and Semi-automatic. In terms of Bag Type, the market is classified into Pillow Seal, 3-side Seal, 4-side Seal, Gusset Seal, and Pyramid Seal.

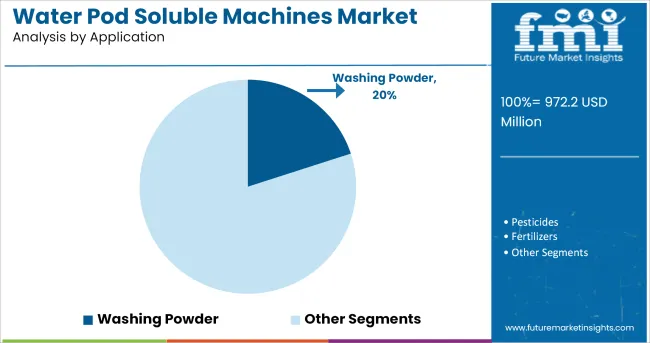

Based on Application, the market is segmented into Washing Powder, Pesticides, Fertilizers, Laundry Detergent Packs, Building Chemicals (Concrete Filaments), Dissolving Bath Salts, Pouched Soap Products, and Insect Repellent. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Automatic machines are projected to account for 65.0% of the total revenue in 2025 within the machine type segment, establishing themselves as the dominant category. This leadership is attributed to the superior efficiency, precision, and scalability automatic machines offer in forming, filling, and sealing water-soluble pods.

Fully automated lines enable high-throughput production while minimizing human error and ensuring consistent pod integrity Their ability to integrate with real-time monitoring systems, perform multiple operations in a compact footprint, and accommodate variable film types has driven preference among large manufacturers.

In response to labor cost pressures and the need for hygiene compliance, automatic machinery is increasingly being adopted in detergent, agrochemical, and pharmaceutical pod manufacturing. The trend toward lights out manufacturing and fully integrated production environments further cements the automatic category’s leadership in this market.

The pillow seal sub segment is projected to contribute 28.0% of the revenue share in 2025 under the bag type category, positioning it as the leading format. This growth is being supported by the design’s compatibility with high-speed sealing systems and its ability to efficiently enclose liquid, powder, or gel-based formulations.

Pillow seal bags offer superior film utilization, lower material waste, and enhanced sealing integrity, making them ideal for cost-sensitive and volume-driven product lines. The format’s adaptability to single and multi cavity molds allows manufacturers to diversify SKUs while maintaining uniform packaging standards.

Additionally, their simple construction facilitates faster machine changeovers and reduced downtime during production runs. These advantages have made pillow seal formats particularly popular in detergent and industrial chemical applications, contributing to their leading share in the bag type segment.

Washing powder is anticipated to hold a 20.0% revenue share in 2025 within the application category, marking it as a key driver of market adoption. This leadership has been driven by the strong consumer shift toward pre-measured pod formulations that offer dosing convenience, prevent product waste, and reduce direct contact with harsh chemicals.

Manufacturers have increasingly aligned their product lines with unit-dose formats for powdered detergents, particularly in regions emphasizing water conservation and product efficiency. The use of water-soluble films in this segment ensures rapid dissolution, improving cleaning efficacy without residue.

Additionally, automated packaging systems tailored to powder density and flow characteristics have enabled accurate fill and seal operations, supporting scale and consistency. As washing powder pods become mainstream in household cleaning and institutional laundry sectors, demand for specialized pod-forming machinery catering to this application continues to grow steadily.

Water-soluble pods are the fastest growing Fast Moving Consumer Goods (FMCG) or Consumer Packaged Goods (CPG) products. The laundry detergent pods are water-soluble pouches having high concentrated laundry detergent.

The water pod soluble machine is a rotary drum type machine for form-fill-seal and cutting equipment for the single unit liquid capsule. It is primarily used and designed for packaging water-soluble liquid or powder laundry detergent pods.

Its rotary drum-type liquid filling ensures precise control of production consistency and flexibility. It has a plunger-type single measuring filling system having great features like corrosion-resistant and high reliability.

The machine has a self-designed water cool sealing structure, which reduces the sealing temperature and safely protects the water solubility of PVA film. It has a unique horizontal or vertically integrated cutting system and the roller moving to keep the drum's consistency rate, which provides good production consistency.

It is an automatic electrical high-capacity heating, sealing, and packing machine specially used for highly concentrated laundry detergent pods, laundry powder pods, oil chemical agents, and missible oil pesticides. It has excellent adaptability of water-soluble PVA film and liquid detergents.

Therefore, ease of operation, high production capacity, highly automatic, less manual intervention and cost-effectiveness will generate massive demand for the water pod soluble machine market.

Water-soluble pods are used for packaging laundry detergents and dish wash products packaged in PVA films in small size packs that are water-soluble. The water-soluble pods having a fixed quantity of packaged detergents in the pods, such as for single wash or one unit size; therefore, the chances of over or less detergent used in washing the product is minimized.

The standardization of quantity depending upon the amount of detergent required for washing will help the customers. The water-soluble pods reduced the wastage of detergents as the chances of spillage and leakage of liquid detergent are reduced.

Therefore the consumers have embraced the water-soluble pods, single-use pouches over the traditional bottled liquids and powder boxes and bags due to its easy-to-use and safe packaging. All these factors will propel the demand for the water-soluble pod machine market in recent years.

Consumers' trends and demands are constantly changing, and modern life is incredibly hectic and fast-paced. Therefore, considering the fast and busy lifestyle, the consumers prefer convenient, single-use, and standardized products, reducing time and energy.

The water-soluble pods are pre-measured, standardized products packaged neatly in dissolvable one-time single-use pouches. Nowadays, the customers have become more health-conscious, and the trend to use more convenient and safe packaging is also proliferating.

The water-soluble laundry detergents allow the customers to use the detergent easily without touching and measuring, which helps in minimizes any potential health and safety risks of the consumers. The growing demand for safe, convenient, and single-use water-soluble pods will undoubtedly increase the demand for water-soluble pods machine, which is automatic with high volume production capacity and computerized temperature, speed, and pressure control parameters.

The water-soluble pods are extensively used in packages of laundry detergents and dish wash liquids. With the growing demand for beauty and spas, water-soluble pods are now being used in cosmetics and beauty care as shaving creams. Consumers have become more accustomed to using water-soluble single-unit dose pods on dishwashing and laundry detergents; now, they also find single-serve mini pods of shaving creams as stand-up pouches.

Therefore the growing demand for single-dose packaging, considering the less wastage, perfectly measured standardized packaging, and the increasing demand for sustainable packaging will enhance the demand for the water-soluble pods market. The water-soluble pod's machines are highly automatic, which reduces labour costs and saves maintenance costs. The water-soluble pod machines will have a significant market demand due to their high efficiency and productivity.

Water soluble pods such as detergents pods. They come with the plastic container which may or may not be recyclable. These pods contain a very damaging chemical cocktail. Due to this, the pods will have a negative impact on the environment and will also contribute to aquatic toxicity. Thus the consumers will refrain themselves from buying these water soluble pods. This will impact the water pod soluble machines market negatively.

Key players such as

are actively involved in water pod soluble machines market for different applications. Key Asian players such as Foshan Polyva Materials Co., Ltd, Foshan Jingliang Daily Chemicals Co., Ltd, Ka Packing Tech Co., Ltd., Furis Group Co., Ltd, HengYuan Machinery Equipment Co., Ltd., and others are actively involved in water pod soluble machines market for different applications.

The manufacturers involved in manufacturing water pod soluble machines market adopt various strategies such as innovation and product launch, to serve the increasing demand for the water pod soluble machines market.

In May 2020, Cloud Packaging Solutions LLC produced Hydroforma 165 water-soluble pod machine. The machine holds the capacity to produce 2,200 pods per minute, and the machine has 165 features new cavity designs and expanded dry and liquid material handling. The company also manufactured a Hydroforma 330 water-soluble pod packaging machine that produces 1,200 pods and 540 pouches for powder and liquid applications.

Water-soluble pods are the fastest FMCG category product for household applications. It is now proliferating in the personal care and beauty packaging industry. Consumers have become more aware of the convenience, one-time usability, and performance benefits of water-soluble pods.

The rising disposable income of the consumers and the trend for eco-friendly sustainable packaging will generate high demand. Many Chinese manufacturers dominate the market for globally designing unique, high-quality, customer-centric water pod soluble machines. Therefore, the growing consumer’s preference is driven by consistency, waste reduction, and excellent quality will expand the water-soluble pod machine market.

The global water pod soluble machines market is estimated to be valued at USD 972.2 million in 2025.

The market size for the water pod soluble machines market is projected to reach USD 1,966.7 million by 2035.

The water pod soluble machines market is expected to grow at a 7.3% CAGR between 2025 and 2035.

The key product types in water pod soluble machines market are automatic and semi-automatic.

In terms of bag type, pillow seal segment to command 28.0% share in the water pod soluble machines market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Water Soluble Pods and Capsules Packaging Market Size and Share Forecast Outlook 2025 to 2035

Water Soluble Pods Packaging Market Analysis by Material Type, Product Type, End Use, Thickness Type, and Region Forecast Through 2035

Water Soluble Detergent Pods Market Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in the Water Soluble Detergent Pods Sector

Water Soluble Bag Market Size and Share Forecast Outlook 2025 to 2035

Water-soluble Packaging Market Size and Share Forecast Outlook 2025 to 2035

Water-Soluble Retinol Market Size and Share Forecast Outlook 2025 to 2035

Water Soluble Polymer Market Size and Share Forecast Outlook 2025 to 2035

Water Soluble Fertilizers Market Trends 2025 to 2035

Competitive Breakdown of Water-Soluble Packaging Companies

Water Soluble Vitamins Market

Water-Soluble Flavors Market

Cold Water Soluble Creamer Market Growth - Base & Function Trends

Edible Water Pods Market Size and Share Forecast Outlook 2025 to 2035

Water Cooled Cube Ice Machines Market - Growth Forecast & Industry Demand 2025 to 2035

Demand for Water Soluble Fertilizers in USA Size and Share Forecast Outlook 2025 to 2035

Demand for Water Soluble Fertilizers in Japan Size and Share Forecast Outlook 2025 to 2035

Demand for Cold Water Soluble Starch in EU Size and Share Forecast Outlook 2025 to 2035

Water Vapor Permeability Analyzers Market Size and Share Forecast Outlook 2025 to 2035

Water and Waste Water Treatment Chemical Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA