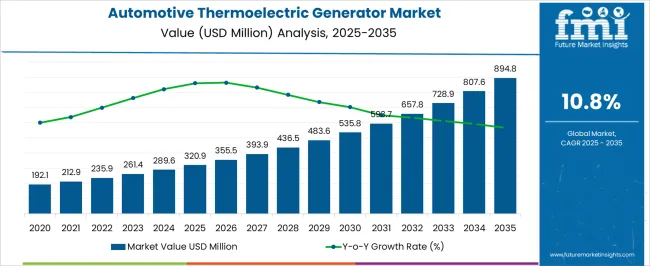

The automotive thermoelectric generator market is projected to grow from USD 320.9 million in 2025 to USD 894.8 million in 2035, reflecting a CAGR of 10.8%. During the early adoption phase (2020–2024), growth was moderate, rising from USD 192.1 million to USD 320.9 million as manufacturers began exploring waste heat recovery systems and testing prototype installations. This period focused on demonstrating efficiency gains, reducing fuel consumption, and proving feasibility in different vehicle models.

By 2025, the market will achieve a critical size, signaling readiness for broader deployment and increasing interest from automotive OEMs seeking complementary power solutions for internal combustion and hybrid vehicles. From 2025 to 2035, the market enters a scaling phase (2025–2030) and later consolidation (2030–2035). By 2030, the market will surpass USD 483.6 million, driven by wider integration across passenger and commercial vehicles and improved production capabilities. During the consolidation phase, growth is expected to continue toward USD 894.8 million by 2035, as leading suppliers dominate the segment and smaller players align with established networks. The 10.8% CAGR underscores steady, long-term growth, reflecting the market’s shift from experimental adoption to a more structured and widely implemented technology across the automotive sector.

| Metric | Value |

|---|---|

| Automotive Thermoelectric Generator Market Estimated Value in (2025 E) | USD 320.9 million |

| Automotive Thermoelectric Generator Market Forecast Value in (2035 F) | USD 894.8 million |

| Forecast CAGR (2025 to 2035) | 10.8% |

The automotive thermoelectric generator market is shaped by several related sectors, each influencing its growth. The global automotive industry drives about 35%, as the scale of vehicle production directly determines potential adoption. Automotive powertrain systems account for 20%, providing the core platforms for integrating thermoelectric solutions. Vehicle energy management and battery systems contribute 15%, enabling efficient use of recovered heat. Automotive component manufacturing represents 10%, supporting the production and supply of thermoelectric modules. Aftermarket automotive services influence roughly 7%, facilitating retrofits and maintenance of installed generators. Transportation and logistics make up 5%, as fleet operators evaluate fuel efficiency gains and operational cost reduction. Electronics and semiconductor industries contribute 5%, providing the sensors and control units necessary for system optimization. Finally, software and monitoring platforms account for 3%, enabling real-time performance tracking and diagnostics. Together, these parent markets create a comprehensive ecosystem supporting the adoption of thermoelectric generators in vehicles. Understanding the relative contributions of each sector helps stakeholders prioritize investments, form strategic partnerships, and scale manufacturing and deployment effectively. This multi-dimensional approach ensures that the market grows steadily while addressing both technical and operational considerations, supporting broader integration across passenger and commercial vehicles.

The Automotive Thermoelectric Generator market is experiencing steady growth, driven by increasing demand for energy-efficient and environmentally friendly power solutions in the automotive industry. The current market scenario reflects a strong emphasis on reducing fuel consumption and emissions, with thermoelectric generators being leveraged for converting vehicle waste heat into electrical energy. Technological advancements in materials and system integration are enabling higher conversion efficiency, making these solutions more viable for mainstream automotive adoption.

Rising regulatory pressures for emission reduction and growing consumer preference for eco-friendly vehicles are shaping the future market outlook. Additionally, improvements in vehicle design and thermal management systems are supporting the adoption of thermoelectric technologies.

Strategic investments by automakers to incorporate these generators in passenger cars and commercial vehicles are expected to further drive market expansion As automotive electrification trends continue to evolve, the market for thermoelectric generators is projected to grow steadily, offering opportunities for innovation in materials, applications, and integration with hybrid and conventional engine systems.

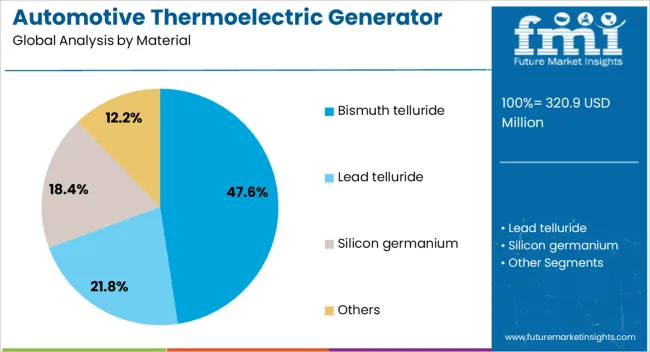

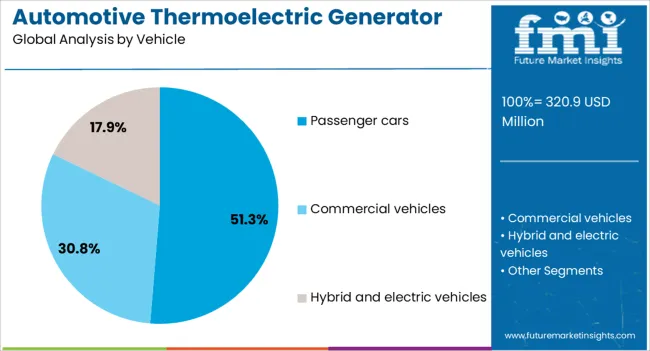

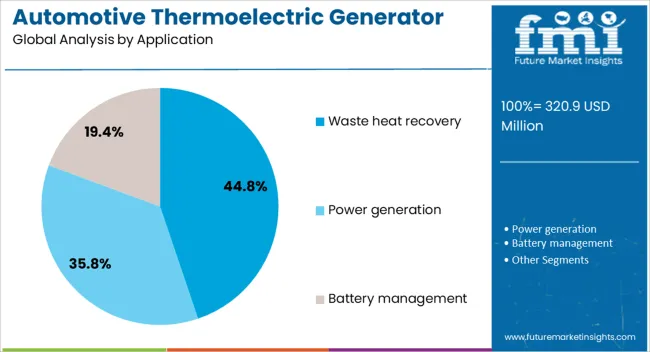

The automotive thermoelectric generator market is segmented by material, vehicle, application, sales channel, and geographic regions. By material, automotive thermoelectric generator market is divided into Bismuth telluride, Lead telluride, Silicon germanium, and Others. In terms of vehicle, automotive thermoelectric generator market is classified into Passenger cars, Commercial vehicles, and Hybrid and electric vehicles. Based on application, automotive thermoelectric generator market is segmented into Waste heat recovery, Power generation, and Battery management. By sales channel, automotive thermoelectric generator market is segmented into OEM and Aftermarket. Regionally, the automotive thermoelectric generator industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Bismuth Telluride material segment is projected to hold 47.6% of the Automotive Thermoelectric Generator market revenue in 2025, making it the leading material type. This dominance is attributed to its high thermoelectric efficiency and stability under automotive operating conditions.

The material is extensively adopted because it enables effective conversion of heat into electrical energy, supporting energy recovery in both passenger and commercial vehicles. Bismuth Telluride offers reliable performance across a wide range of temperatures, allowing consistent power generation without compromising vehicle system safety.

Growth in this segment is further supported by ongoing advancements in material processing and cost-effective manufacturing techniques, which have reduced production costs while maintaining high performance. As automotive manufacturers prioritize waste heat recovery and fuel efficiency, the use of Bismuth Telluride-based thermoelectric modules is expected to expand, reinforcing its leadership position in the market.

The Passenger Car segment is expected to account for 51.3% of the market revenue in 2025, establishing it as the dominant vehicle type. This leading position is being driven by the growing adoption of energy recovery solutions in private vehicles to improve fuel efficiency and reduce carbon emissions.

Passenger cars offer an ideal platform for the integration of thermoelectric generators due to standardized engine layouts, available exhaust heat, and space for module installation. The market growth has been accelerated by rising consumer demand for eco-friendly vehicles and regulatory initiatives targeting emission reduction in urban mobility.

The ability to retrofit thermoelectric generators in passenger cars without major engine modifications has also facilitated adoption. As manufacturers seek to enhance vehicle efficiency and offer advanced eco-technology features, the passenger car segment is anticipated to remain the largest end-use category for automotive thermoelectric generators, supported by increasing awareness and incentives for sustainable transportation solutions.

The Waste Heat Recovery application segment is projected to hold 44.8% of the market revenue in 2025, positioning it as the largest application type. This leadership is being driven by the critical role of thermoelectric generators in capturing otherwise lost energy from vehicle exhaust systems and converting it into usable electrical power.

Adoption is being accelerated by the dual benefits of fuel efficiency improvement and emission reduction, which are central to modern automotive design and sustainability goals. Advancements in thermoelectric module efficiency, lightweight design, and integration with vehicle electronic systems further support the segment’s growth.

Increasing emphasis on reducing the environmental footprint of internal combustion engines has made waste heat recovery a strategic application for both passenger and commercial vehicles. As regulatory pressures and energy efficiency standards continue to rise globally, the deployment of thermoelectric generators for waste heat recovery is expected to expand, solidifying its position as the leading application segment in the automotive thermoelectric generator market.

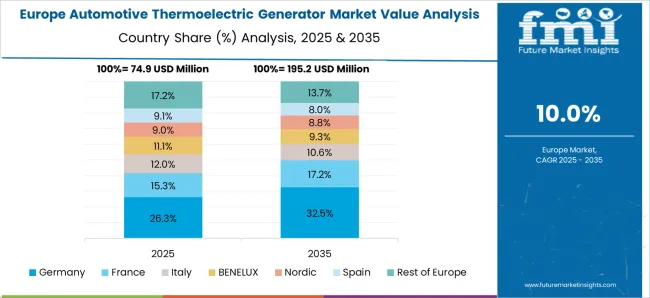

The automotive thermoelectric generator (TEG) market is growing due to increasing demand for energy recovery, fuel efficiency improvement, and reduced vehicular emissions. North America and Europe lead with advanced TEG systems integrated into hybrid and luxury vehicles, driven by stringent fuel economy regulations. Asia-Pacific shows rapid adoption in emerging automotive sectors and electric vehicle fleets. Manufacturers differentiate through conversion efficiency, compact design, thermal stability, and integration with existing exhaust systems. Regional variations in vehicle types, emission norms, and technological readiness influence adoption, development strategies, and competitive positioning globally.

Thermoelectric generator adoption is heavily influenced by conversion efficiency and thermal management performance. North America and Europe focus on high-efficiency TEGs capable of converting exhaust heat into electricity for hybrid and luxury vehicles, optimizing fuel consumption and minimizing environmental impact. Asia-Pacific markets often prioritize cost-effective TEG systems for conventional vehicles and mid-range hybrids, balancing efficiency with affordability. Differences in conversion rates and thermal resilience affect energy output, operational stability, and system lifespan. Leading manufacturers invest in high-performance thermoelectric materials and heat exchanger designs for premium applications, while regional producers focus on practical, budget-conscious solutions. Efficiency and thermal management contrasts shape adoption patterns, fuel savings, and competitiveness across global automotive markets.

TEG performance depends on seamless integration with vehicle exhaust, battery, and electrical systems. North America and Europe emphasize integration with hybrid and EV platforms to maximize energy recovery, ensure stable power supply, and support auxiliary vehicle systems. In Asia-Pacific, integration often targets mid-sized internal combustion engines or smaller hybrid vehicles with simplified connection systems. Differences in integration complexity affect installation timelines, maintenance, and overall system efficiency. Suppliers providing plug-and-play or OEM-integrated TEG solutions gain higher adoption in advanced markets, while regional producers focus on adaptable, retrofit-friendly systems. Integration contrasts drive adoption, operational effectiveness, and market differentiation across luxury, hybrid, and commercial vehicle segments globally.

Regulatory frameworks and fuel efficiency mandates directly influence TEG deployment. Europe and North America enforce stringent CO2 emission limits and fuel consumption standards, incentivizing adoption of energy recovery technologies. Asia-Pacific policies vary; high-income nations implement strict norms, while emerging markets emphasize cost-effective compliance with gradual adoption. Differences in regulations affect vehicle design, R&D investment, and production priorities. Suppliers offering TEGs compliant with global emission standards gain premium contracts, while regional producers supply affordable solutions for local emission requirements. Regulatory contrasts shape market penetration, adoption timelines, and long-term growth potential across passenger vehicles, commercial fleets, and hybrid platforms worldwide.

Thermoelectric generator materials, including bismuth telluride and skutterudite alloys, impact conversion efficiency, thermal stability, and lifespan. North America and Europe prioritize high-performance, durable materials for long-term reliability in high-end vehicles and hybrid fleets. Asia-Pacific markets often rely on cost-effective alloys for mass-market vehicle integration, balancing durability with affordability. Differences in material properties affect operational longevity, maintenance requirements, and energy output. Leading suppliers focus on advanced thermoelectric materials and robust packaging for premium applications, while regional manufacturers emphasize low-cost, practical options. Material and durability contrasts influence adoption, system performance, and competitive positioning in the global automotive TEG market.

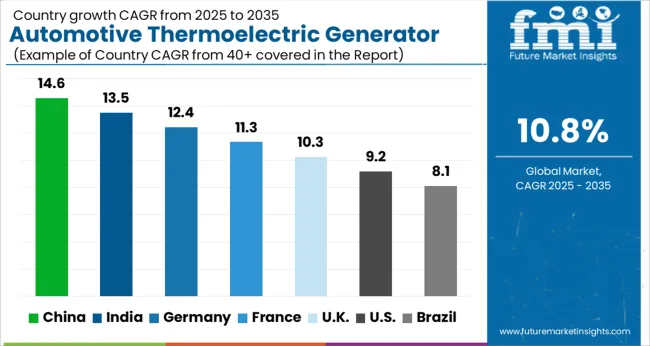

| Country | CAGR |

|---|---|

| China | 14.6% |

| India | 13.5% |

| Germany | 12.4% |

| France | 11.3% |

| UK | 10.3% |

| USA | 9.2% |

| Brazil | 8.1% |

The global automotive thermoelectric generator market was projected to grow at a 10.8% CAGR through 2035, driven by demand in energy recovery, vehicle efficiency, and emission reduction applications. Among BRICS nations, China recorded 14.6% growth as large-scale manufacturing and integration facilities were commissioned and compliance with automotive and safety standards was enforced, while India at 13.5% growth saw expansion of production units to meet rising regional demand. In the OECD region, Germany at 12.4% maintained substantial output under strict industrial and regulatory frameworks, while the United Kingdom at 10.3% relied on moderate-scale operations for vehicle and industrial applications. The USA, expanding at 9.2%, remained a mature market with steady demand across automotive efficiency and energy recovery segments, supported by adherence to federal and state-level quality and safety standards. This report includes insights on 40+ countries; the top five markets are shown here for reference.

The automotive thermoelectric generator market in China is growing at a CAGR of 14.6% driven by increasing adoption of fuel efficient and hybrid vehicles. Thermoelectric generators are being used to convert vehicle waste heat into electrical energy, improving energy efficiency and reducing emissions. Manufacturers are focusing on lightweight, high performance modules compatible with both passenger and commercial vehicles. Growth is supported by government incentives for energy efficient automotive technologies and emission reduction targets. Research and development in thermoelectric materials and integration with automotive systems are accelerating innovation. Distribution through automotive OEMs and aftermarket suppliers ensures wide accessibility. Rising awareness about environmental sustainability and operational efficiency is encouraging adoption. China is emerging as a key market globally due to high vehicle production and growing interest in advanced energy recovery technologies.

Automotive thermoelectric generator market in India is expanding at a CAGR of 13.5% with rising demand for energy efficient vehicles and emission control technologies. Vehicle manufacturers are integrating thermoelectric generators to recover waste heat and generate electricity for onboard systems, improving fuel efficiency. Government initiatives promoting clean energy vehicles and stricter emission norms are driving adoption. Research in advanced thermoelectric materials and modular designs is enhancing efficiency and performance. Distribution through automotive OEMs and aftermarket suppliers ensures accessibility across passenger and commercial vehicle segments. Consumers and fleet operators are increasingly prioritizing fuel savings, operational efficiency, and sustainability. India’s growing automotive sector and interest in energy recovery technologies are key factors supporting market growth.

Germany’s automotive thermoelectric generator market is growing at a CAGR of 12.4% supported by high adoption of hybrid and electric vehicles and strict emission standards. Manufacturers are developing high efficiency thermoelectric modules that convert exhaust heat into electricity, improving overall vehicle efficiency. Integration of these systems with vehicle energy management platforms is gaining traction. Germany’s automotive industry emphasizes innovation, operational efficiency, and environmental compliance. Distribution through OEMs and automotive component suppliers ensures market reach. Growing awareness among consumers and fleet operators about fuel savings, sustainability, and advanced technology adoption is driving demand. Germany remains a key European market due to its strong automotive sector, focus on emissions reduction, and early adoption of energy recovery technologies.

The United Kingdom market is expanding at a CAGR of 10.3% driven by increasing use of fuel efficient vehicles and adoption of energy recovery technologies. Thermoelectric generators are being implemented to convert exhaust heat into electrical energy, enhancing vehicle performance and reducing fuel consumption. Manufacturers are offering modular, lightweight, and high performance solutions compatible with passenger and commercial vehicles. Government policies promoting clean and low emission vehicles support market growth. Distribution through OEMs and aftermarket suppliers ensures wide availability. Fleet operators and individual consumers are prioritizing operational efficiency, sustainability, and fuel savings. The United Kingdom is gradually adopting advanced thermoelectric technology as part of broader efforts to reduce carbon footprint in the automotive sector.

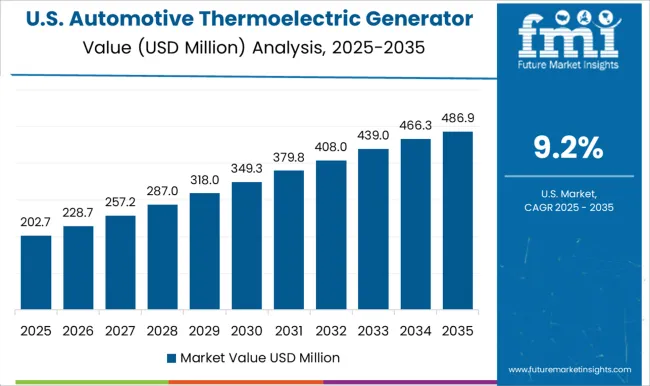

The United States market is growing at a CAGR of 9.2% supported by rising adoption of hybrid and energy efficient vehicles. Automotive thermoelectric generators are being used to recover waste heat from exhaust systems and convert it into electrical energy, improving fuel efficiency. Manufacturers are focusing on high performance, lightweight, and modular designs compatible with various vehicle types. Distribution through OEMs and aftermarket suppliers ensures product availability. Federal incentives and stricter emission standards are encouraging adoption of advanced energy recovery solutions. Fleet operators and consumers increasingly prioritize operational efficiency, fuel savings, and environmentally responsible technologies. The United States remains a significant market for thermoelectric generators due to growing vehicle electrification trends and demand for energy efficient automotive solutions.

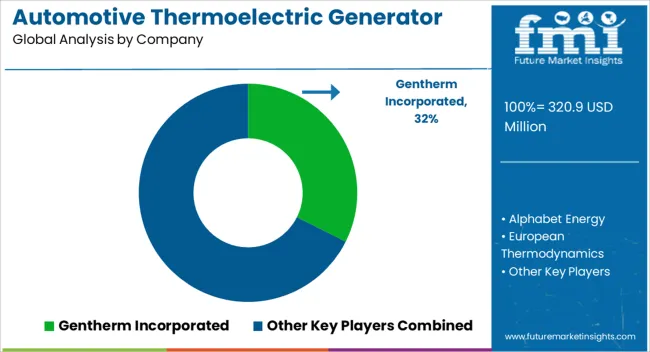

The automotive thermoelectric generator (ATEG) market is witnessing significant growth as automakers and suppliers increasingly focus on energy recovery, fuel efficiency, and reduced greenhouse gas emissions. Key suppliers in this market include Gentherm Incorporated, Alphabet Energy, European Thermodynamics, Faurecia, II-VI Marlow, KELK Ltd., Laird Thermal Systems, and Valeo, all of which are at the forefront of developing innovative thermoelectric solutions for the automotive sector. These companies provide technologies that convert waste heat from vehicle exhaust systems into usable electrical energy, improving overall energy efficiency and supporting the global push toward sustainable mobility. Gentherm Incorporated is a leading player offering automotive energy management systems and thermoelectric generators that capture exhaust heat and convert it into electrical energy for vehicle components. Alphabet Energy specializes in thermoelectric modules and systems designed to recover waste heat from internal combustion engines, enhancing fuel economy and reducing carbon footprint. European Thermodynamics and Faurecia focus on integrating ATEGs into vehicle exhaust systems, providing scalable solutions compatible with both hybrid and conventional powertrains. Companies such as II-VI Marlow and KELK Ltd. provide high-performance thermoelectric materials and modules that optimize the conversion of thermal energy into electricity, ensuring higher efficiency and reliability under varying operating conditions. Laird Thermal Systems delivers customized thermal management solutions for the automotive industry, combining thermoelectric technology with advanced heat exchangers to maximize energy recovery. Valeo, a global automotive supplier, integrates ATEG technologies with advanced vehicle energy management systems, improving efficiency across multiple platforms. The adoption of automotive thermoelectric generators is driven by increasing regulatory pressure to reduce fuel consumption and emissions, rising demand for hybrid and electric vehicles, and the automotive industry’s focus on innovative energy recovery solutions. ATEGs not only improve fuel efficiency but also enhance battery charging, reduce alternator load, and support auxiliary systems, making them increasingly valuable in modern vehicles. As the automotive sector transitions toward greener and more efficient solutions, these leading suppliers are paving the way for widespread adoption of thermoelectric technology, enabling vehicles to recover wasted energy, enhance performance, and meet global sustainability goals. Their innovations continue to define the future of energy-efficient automotive systems, positioning the ATEG market for long-term growth and technological advancement.

| Item | Value |

|---|---|

| Quantitative Units | USD 320.9 Million |

| Material | Bismuth telluride, Lead telluride, Silicon germanium, and Others |

| Vehicle | Passenger cars, Commercial vehicles, and Hybrid and electric vehicles |

| Application | Waste heat recovery, Power generation, and Battery management |

| Sales Channel | OEM and Aftermarket |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Gentherm Incorporated, Alphabet Energy, European Thermodynamics, Faurecia, II-VI Marlow, KELK Ltd., Laird Thermal Systems, and Valeo |

| Additional Attributes | Dollar sales vary by generator type, including waste heat recovery, hybrid, and standalone thermoelectric generators; by vehicle type, spanning passenger cars, commercial vehicles, and electric/hybrid vehicles; by application, such as exhaust heat recovery, battery charging, and auxiliary power; by region, led by North America, Europe, and Asia-Pacific. Growth is driven by rising fuel efficiency standards, emission reduction initiatives, and adoption of energy recovery technologies. |

The global automotive thermoelectric generator market is estimated to be valued at USD 320.9 million in 2025.

The market size for the automotive thermoelectric generator market is projected to reach USD 894.8 million by 2035.

The automotive thermoelectric generator market is expected to grow at a 10.8% CAGR between 2025 and 2035.

The key product types in automotive thermoelectric generator market are bismuth telluride, lead telluride, silicon germanium and others.

In terms of vehicle, passenger cars segment to command 51.3% share in the automotive thermoelectric generator market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thermoelectric Generator Market

Automotive Integrated Starter Generator Units Market Size and Share Forecast Outlook 2025 to 2035

Automotive Direct Liquid Cooling IGBT Module Market Size and Share Forecast Outlook 2025 to 2035

Automotive Hoses and Assemblies Market Size and Share Forecast Outlook 2025 to 2035

Generator Bushing Market Size and Share Forecast Outlook 2025 to 2035

Automotive Network Testing Market Size and Share Forecast Outlook 2025 to 2035

Automotive Performance Part Market Size and Share Forecast Outlook 2025 to 2035

Automotive Carbon Ceramic Brake Market Size and Share Forecast Outlook 2025 to 2035

Automotive Camshaft Market Size and Share Forecast Outlook 2025 to 2035

Automotive Stamping Industry Analysis in India Size and Share Forecast Outlook 2025 to 2035

Automotive Cylinder Liner Market Size and Share Forecast Outlook 2025 to 2035

Automotive Microcontroller Market Size and Share Forecast Outlook 2025 to 2035

Automotive Roof Rails Market Size and Share Forecast Outlook 2025 to 2035

Automotive Active Safety System Market Size and Share Forecast Outlook 2025 to 2035

Automotive Diagnostic Scan Tool Market Size and Share Forecast Outlook 2025 to 2035

Automotive Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Automotive Dynamic Map Data Market Size and Share Forecast Outlook 2025 to 2035

Automotive Green Tires Market Size and Share Forecast Outlook 2025 to 2035

Automotive E-Tailing Market Size and Share Forecast Outlook 2025 to 2035

Automotive Interior Market Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA