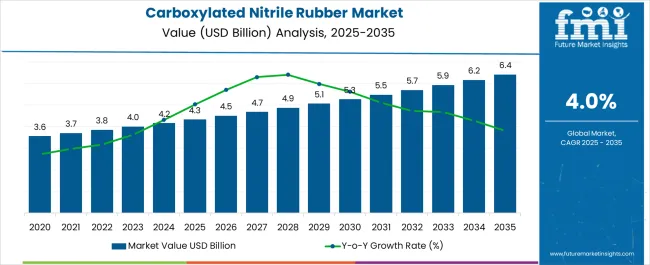

The Carboxylated Nitrile Rubber Market is estimated to be valued at USD 4.3 billion in 2025 and is projected to reach USD 6.4 billion by 2035, registering a compound annual growth rate (CAGR) of 4.0% over the forecast period.

| Metric | Value |

|---|---|

| Carboxylated Nitrile Rubber Market Estimated Value in (2025 E) | USD 4.3 billion |

| Carboxylated Nitrile Rubber Market Forecast Value in (2035 F) | USD 6.4 billion |

| Forecast CAGR (2025 to 2035) | 4.0% |

The carboxylated nitrile rubber market is witnessing consistent growth driven by increasing demand for high performance elastomers in industrial and automotive applications. Rising requirements for oil resistance, durability, and superior mechanical properties are strengthening adoption across multiple end use industries.

Regulatory focus on enhancing product quality and operational safety has encouraged manufacturers to shift toward carboxylated nitrile rubber as a preferred material in applications requiring resistance to abrasion, chemicals, and extreme temperatures. Ongoing innovations in formulation and blending techniques are expanding the versatility of this rubber in sealing, belting, and molding applications.

The market outlook remains positive with automotive, oil and gas, and industrial manufacturing sectors investing in reliable materials that enhance performance, reduce downtime, and extend product lifecycle. These developments are expected to reinforce the position of carboxylated nitrile rubber as a critical material in advanced engineering applications.

The 8 to 18% acrylonitrile content category is projected to hold 47.60% of the total market by 2025, making it the leading acrylonitrile composition segment. This share is supported by its balanced properties of flexibility and resistance to oil and fuel, making it suitable for a wide range of applications.

The moderate acrylonitrile composition enables manufacturers to achieve cost efficiency while maintaining performance standards.

Demand for this content range has been reinforced by its compatibility with industrial requirements, particularly in sealing and belting applications where durability and resilience are essential.

The belts application segment is expected to account for 52.30% of the market share by 2025, positioning it as the most dominant application area. The growth of this segment is being driven by increasing use of carboxylated nitrile rubber in conveyor belts, timing belts, and drive belts across industrial and automotive sectors.

Its superior resistance to wear, oil, and heat supports longer operational life and reduced maintenance costs, which are highly valued in heavy duty environments.

Investments in industrial automation and demand for reliable power transmission systems are also strengthening the dominance of this application segment.

The automotive and transportation end use category is projected to hold 49.80% of the market share by 2025, making it the largest consumer sector. This is attributed to the rising demand for high performance rubber materials that can withstand exposure to oils, fuels, and harsh environmental conditions.

Carboxylated nitrile rubber is increasingly used in seals, gaskets, hoses, and belts across vehicles, enhancing performance and longevity. The expansion of global vehicle production, along with stricter efficiency and safety requirements, is further reinforcing the importance of this material in automotive engineering.

As transportation systems evolve toward higher durability and efficiency, demand from this end use segment continues to drive market growth.

Rapidly growing industrial activities and demand for rubber components across the globe can be identified as the prime driving factor responsible for the carboxylated nitrile rubber market growth. Carboxylated nitrile rubber is mainly used for the manufacturing of the rubber components which are used for industrial purposes in different industries.

Rings and seals manufactured from carboxylated nitrile rubber is mostly used in automotive, marine and aircraft engine systems, and the high oil resistance is making carboxylated nitrile rubber gives it advantage over other products. Thus, growth of automotive, marine and aerospace industry is estimated to escalate the market growth of the carboxylated nitrile rubber market.

Apart from it, increase in automotive aftermarket activities is estimated to have a positive impact on the carboxylated nitrile rubber market. Carboxylated nitrile rubber is used in the manufacturing of printing rolls, hence the growth of printing industry is expected to propel the demand for carboxylated nitrile rubber.

Due to its excellent oil & solvent resistance, the components made from carboxylated nitrile rubber are widely used in oil & gas industry. Recovery of oil & gas industry from slowdown in past year is anticipated to act as a potential driving factor for the growth of carboxylated nitrile rubber market.

Carboxylated nitrile rubber is also used in the making of footwear with high abrasion resistance, thus increasing demand for special purpose footwear is estimated to bolster the carboxylated nitrile rubber market.

Growing population, increased consumer spending and growth of rubber industry are few of the factors which will indirectly affect the growth of carboxylated nitrile rubber market. High product cost and lower awareness amongst the end users might act as restraining factors for the Carboxylated nitrile rubber market.

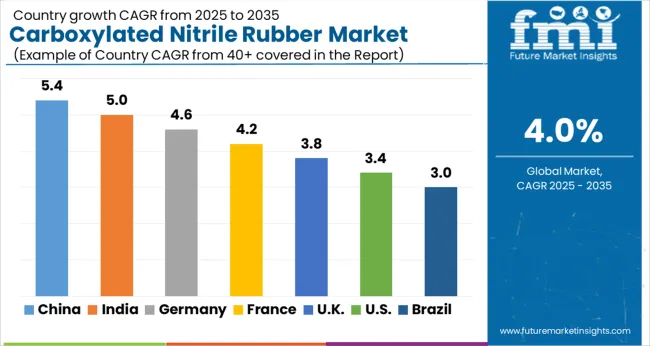

Asia Pacific is considered as one of the prominent market region for carboxylated nitrile rubber, owing to the increasing industrial activities. Due to the lower labor cost and easy availability of raw material, Asia Pacific has witnessed substantial rise in rubber components manufacturing. Apart from it Asia Pacific is the leading region in terms of rubber production.

Regions such as North America and Europe can be attributed as a potential market for carboxylated nitrile rubber, owing to the well-developed industrial landscape.

Industrial production is expected to witness upward trend in Latin America region, therefore Latin America can be considered as promising market for carboxylated nitrile rubber. Middle East & Africa is expected to witness positive growth in the demand for carboxylated nitrile rubber owing to end use industry growth.

Examples of some of the market participants operating in the global carboxylated nitrile rubber market are:

ARLANXEO, Zeon Corporation, Emerald Performance Materials, OMNOVA Solutions Inc., Rahco Rubber, Inc., and Zibo Qilong Chemical Co., Ltd. among others.

The Carboxylated nitrile rubber market report presents a comprehensive assessment of the Carboxylated nitrile rubber market and contains thoughtful insights, facts, and historical data and statistically supported and industry-validated market data.

It also contains projections using a suitable set of assumptions and methodologies. The Carboxylated nitrile rubber market report provides analysis and information according to Carboxylated nitrile rubber market segments such as geographies, application and industry.

The global carboxylated nitrile rubber market is estimated to be valued at USD 4.3 billion in 2025.

The market size for the carboxylated nitrile rubber market is projected to reach USD 6.4 billion by 2035.

The carboxylated nitrile rubber market is expected to grow at a 4.0% CAGR between 2025 and 2035.

The key product types in carboxylated nitrile rubber market are 8-18% acrylonitrile, 18-22% acrylonitrile and 23-27% & above.

In terms of application, belts segment to command 52.3% share in the carboxylated nitrile rubber market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Nitrile Butadiene Rubber (NBR) Latex Market Size and Share Forecast Outlook 2025 to 2035

Acetonitrile Market Growth - Trends & Forecast 2025 to 2035

Pimelonitrile Market Size and Share Forecast Outlook 2025 to 2035

Acrylonitrile Butadiene Styrene Market Size and Share Forecast Outlook 2025 to 2035

Valeronitrile Market Growth - Trends & Forecast 2025 to 2035

Acrylonitrile Market

Specialty Nitriles Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Styrene Acrylonitrile (ASA) Resin Market- Growth & Demand 2025 to 2035

Rubber Molding Market Forecast Outlook 2025 to 2035

Rubber Track for Defense and Security Market Size and Share Forecast Outlook 2025 to 2035

Rubber Frame Monitors Market Size and Share Forecast Outlook 2025 to 2035

Rubber Coating Market Size and Share Forecast Outlook 2025 to 2035

Rubber Anti-Tack Agents Market Size and Share Forecast Outlook 2025 to 2035

Rubber to Metal Bonded Articles Market Analysis Size and Share Forecast Outlook 2025 to 2035

Rubber-to-Metal Adhesion Market Analysis - Size, Share, and Forecast Outlook 2025-2035

Rubber Coatings Market Growth - Trends & Forecast 2025 to 2035

Rubber Conveyor Belt Market Size, Growth, and Forecast 2025 to 2035

Rubber Testing Equipment Market Growth – Trends & Forecast 2025 to 2035

Rubber Tapes Market Trends - Growth & Forecast 2025 to 2035

Rubber Extruder Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA