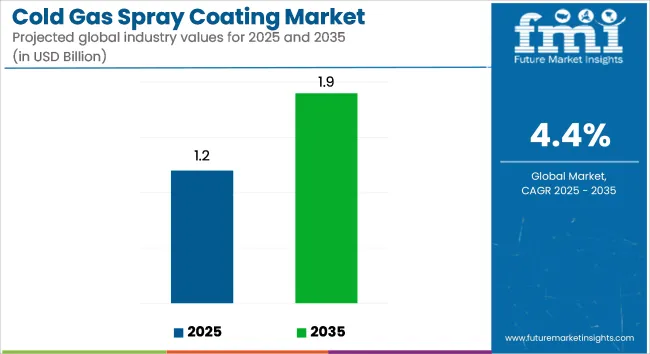

The global cold gas spray coating market is projected to grow from USD 1.2 billion in 2025 to USD 1.9 billion by 2035, reflecting a CAGR of 4.4% over the forecast period. Market expansion is being supported by increasing use in aerospace, automotive, medical, and energy sectors, where high-performance surface restoration and protection are essential.

Cold gas spray coating is being adopted for its ability to apply metal coatings without exposing base materials to high temperatures. This characteristic is enabling the preservation of substrate integrity, especially for lightweight alloys and sensitive components. Aerospace and defense sectors are incorporating cold spray processes for component repair, corrosion resistance, and dimensional restoration. In the automotive industry, drivetrain and engine components are being treated to improve wear resistance and prolong service life.

Advanced materials including titanium, aluminum, and nickel-based powders are being utilized in cold spray systems to deliver coatings with improved hardness, thermal conductivity, and electrical properties. Healthcare equipment manufacturers are using cold spray to deposit biocompatible coatings on implants and surgical tools, with minimal oxidation and thermal degradation.

Growth in the market is being further reinforced by ongoing R&D focused on portable cold spray systems, robotic integration, and new powder formulations. Investments are being made by equipment manufacturers and research institutions to improve deposition rates, layer adhesion, and geometrical precision.

Repair and re-manufacturing applications are contributing significantly to market expansion. Components in aviation and energy industries are being refurbished with minimal material removal, enabling cost savings and reduced turnaround times. Cold gas spray is being selected for its ability to restore dimensional tolerances without compromising component strength.

Environmental considerations are influencing the adoption of cold spray coatings. The absence of toxic fumes and minimal thermal distortion are being viewed favorably in industrial sustainability programs. Efforts to reduce reliance on traditional thermal spray and electroplating techniques are accelerating market adoption.

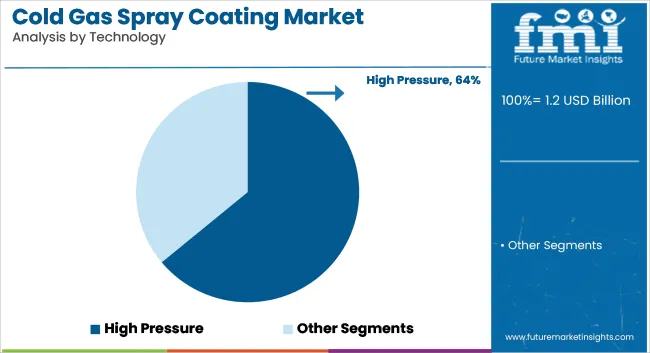

High-pressure cold gas spray systems are estimated to account for approximately 64% of the global cold gas spray coating market share in 2025 and are projected to grow at a CAGR of 4.5% through 2035. This technology enables accelerated deposition of metallic powders such as aluminum, titanium, copper, and their alloys at supersonic velocities, resulting in coatings with superior mechanical strength, low porosity, and excellent corrosion resistance.

High-pressure systems are preferred in aerospace, defense, and high-performance industrial applications where component restoration, dimensional correction, and electrical conductivity are critical. Advancements in nozzle design and powder feeding systems are further enhancing coating precision, driving adoption in both OEM and MRO segments globally.

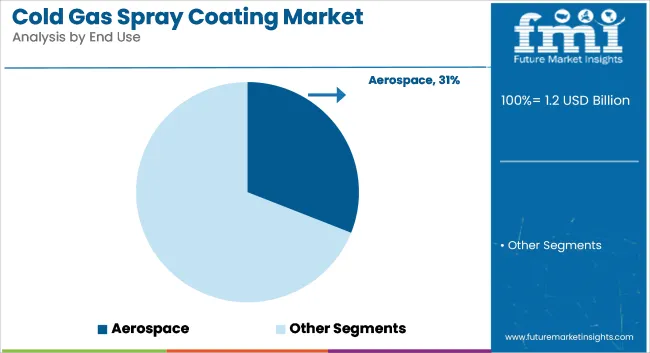

The aerospace segment is projected to hold approximately 31% of the global cold gas spray coating market share in 2025 and is expected to grow at a CAGR of 4.6% through 2035. Cold spray coatings are extensively used for repairing landing gear components, turbine casings, and structural airframe elements.

Their ability to restore worn or corroded surfaces without inducing thermal stress makes them ideal for high-value aerospace components that cannot tolerate distortion or metallurgical changes. As the aviation industry prioritizes fleet efficiency, component longevity, and reduced maintenance turnaround times, cold spray technologies are being integrated into OEM processes and in-field MRO operations. The segment continues to benefit from rising aircraft production, defense modernization, and broader acceptance of additive repair solutions across global aviation hubs.

| Key Drivers | Key Restraints |

|---|---|

| Increasing demand for high-performance coatings in the aerospace and automotive industries | High initial investment and operational costs |

| Growing adoption of cold spray technology for component repair and restoration | Limited awareness and technical expertise in emerging markets |

| Advancements in 3D printing and additive manufacturing | Challenges in coating complex geometries with uniform thickness |

| Rising emphasis on sustainability and eco-friendly coating solutions | Limited availability of specialized feedstock materials |

| Expanding applications in the medical and electronics sectors | Regulatory challenges and stringent industry standards |

| Reduced thermal stress and minimal oxidation during the coating process | Slower adoption in traditional manufacturing industries |

Impact of Key Drivers

| Key Drivers | Impact |

|---|---|

| Increasing demand for lightweight and durable coatings in the aerospace and automotive industries | High |

| Advancements in additive manufacturing and 3D printing technologies | High |

| Superior coating properties, including corrosion resistance and thermal protection | High |

| Growing emphasis on eco-friendly and sustainable coating solutions | Medium |

| Expanding applications in healthcare, electronics, and defense sectors | Medium |

| Ability to repair and restore high-value components with minimal heat impact | High |

Impact of Key Restraints

| Key Restraints | Impact |

|---|---|

| High initial setup and operational costs | High |

| Limited awareness and adoption in small-scale industries | Medium |

| Challenges in achieving uniform coating on complex geometries | Medium |

| High dependency on specialized powder materials | High |

| Regulatory challenges and stringent industry standards | Medium |

| Slower integration in conventional manufacturing processes | Medium |

Strong growth of the cold gas spray coating market in aerospace, defense, and the automotive industry will be responsible for the growth of the cold gas spray coating market in the USA Demand will also be driven by ongoing investments into advanced manufacturing and repair technologies, as industries increasingly concentrate on lightweight and corrosion-resistant coatings. The defense sector continues to be a key driver, employing cold gas spray in the maintenance of aircraft and the enhancement of weapon systems.

The rise of end-user preference & sustainability will drive industries towards eco-friendly coating solutions. Research institutes and companies will continue to innovate, improving the efficiency and performance of coatings. The growing demand for refurbishment of components in industrial machinery will again propel supplementary market growth.

The cold gas spray coating market in Canada will grow steadily owing to its robust aerospace and oil & gas sectors. The increasing need for high-performance coatings to extend the life of important gear will provide an impetus for adoption. The automotive industry will also be a contributing factor, as manufacturers search for ways to combat corrosion in extreme weather conditions.

These government initiatives supporting innovation and sustainability would lead businesses to invest in advanced coating technologies. Innovation will be further accelerated through collaboration between sectors, including universities and industries. As industrial activities increase, more and more cold gas spray coatings will be used for the repair and restoration of equipment.

Their use for cold gas spray coating will also grow in the UK, especially in industries such as aerospace, defense, and transportation. The growing requirement of lightweight coatings, especially in the automotive sector, will supplement the demand by offering sustainability and emissions reduction. The defense contract will continue the work with a focus on advancing repair and maintenance solutions, as well as legacy military aircraft and other aging naval equipment.

New opportunities are likely to emerge as renewable energy capacity is expanded, especially as components are coated for wind turbine construction. Manufacturers will narrow down on increasing efficiency and cost-effectiveness with improving R&D activities. Cold spray coatings will also find application in the medical industry for implants and surgical instruments.

As the aerospace and automotive sectors expand in France, the French cold gas spray coating market will expand. Companies will turn to this technology to become more fuel-efficient and spend less on maintenance. Defense is expected to invest in advanced coating solutions because these solutions improve overall aircraft and military equipment performance. The transition to electric vehicles will also drive demand for lightweight and highly wear-resistant coatings.

Research institutions will work with manufacturers to come up with sustainable solutions, in accordance with the sustainability goals of France. Moreover, cold spray coatings in the medical and electronics sectors will also be used for high-precision applications that demand biocompatibility and durability, which will drive the growth of the market.

Germany will experience significant growth in the cold gas spray coating market in Germany owing to its established industrial base that encompasses automotive and engineering. The shift to electric mobility will make automated electric battery and motor components drive the demand for advanced coatings. Cold spray coatings will remain important to the aerospace manufacturing sector in increasing durability and lowering repair costs.

The electronics industry will also expand as businesses implement coatings in semiconductor production. Eco-friendly coating materials will drive R&D for sustainable manufacturing practices. Cold gas spray will be more widely used in industrial machinery and heavy equipment manufacturing to restore and prolong component life and help reduce operational costs.

One of the most important industries in South Korea is the high-tech electronics industry, and this is expected to create increased demand for cold gas spray coatings. Semiconductor makers will lead the way, leveraging coatings to boost durability and conductivity. In particular, the aerospace sector will continue investing in these cold spray solutions for both aircraft maintenance and lightweight materials.

The transition of the automotive sector towards electric vehicles will additionally support market development with coatings, whereas improving battery and structural efficiency. Environmentally friendly coating solutions are also driven by government-backed R&D initiatives. Cold-gas spray coatings will be key to improving systems longevity and efficiency as industrial automation increases.

There will be a huge demand for cold gas spray coating in Japan as the industries are looking towards high-tech manufacturing and need advanced materials. In the aerospace domain, adoption will grow to increase asset longevity and minimize maintenance actions. Demand for coatings in semiconductor and circuit board manufacturing will be driven by electronics sales. Automakers, spurred by the electric vehicle push, will adopt cold gas spray coatings to optimize battery and motor performance.

There will be benefits for robotics and automation, using coatings for wear-resistant components. In this new era, the need for state-of-the-art storage systems will take precedence, leading the way to the combination of sustainable technologies, in which cold spray coatings will be key to developing new material waste reduction systems and improving the conservation of components.

Industrial sector growth and infrastructure developments are driving the growth of China's cold gas spray coating market along with increasing applications in the aerospace and automotive sectors. The shift towards electric vehicles will increase demand for advanced coatings that have the potential to enhance the efficiency of batteries and other critical components. These include the defense and aviation industries, which will invest heavily in cold spray technology to make aircraft and military equipment more durable.

The consequence will be more adoption, spurred by China’s focus on semiconductor and electronics manufacturing. It will also promote the adoption of eco-friendly coatings in various industries. Growing government initiatives to promote green technology and sustainable manufacturing will further give a boost to the market. The medical sector will also be an important supplier, using coatings for implants.

The cold gas spray coating market in India is expected to record steady growth as a result of fast industrialization and rising adoption of these coatings in aerospace and automotive industries. Cold spray coatings will be used for maintaining aircraft and weapon systems. The auto industry's shift toward electric mobility will, along with other coatings improvements, mobile battery efficiency, and corrosion resistance, drive market growth.

Coatings such as these will become more prevalent in the electronics and semiconductor industries to strengthen component durability. The initiatives by the government to promote Make in India and sustainability will serve as a propeller for domestic manufacturing and technology for cold gas spray. Rental of heavy machinery will create new opportunities in infrastructure development.

Key players are concentrating on enhancing coating technologies to provide improved adhesion, durability, and cost-efficiency. There is growing investment in specialized coatings tailored for industries like aerospace, automotive, and electronics, meeting the demand for high-performance, wear-resistant solutions.

Linde provides advanced cold gas spray solutions as part of its thermal spraying portfolio for the metal fabrication and surface engineering industries. The company offers tailored process gases and equipment support to enable high-performance cold spraying of metals, alloys, and composite materials at supersonic velocities without significant heat input. This technique is used to repair, reinforce, or enhance components across aerospace, automotive, and heavy industry sectors. Linde’s solutions are engineered to deliver dense, oxide-free coatings while minimizing thermal distortion and residual stress, making them ideal for temperature-sensitive substrates and precision parts.

It is segmented into High Pressure, Low Pressure

It is segmented into Transportation, Aerospace, Automotive, Electrical & Electronics, Oil & Gas, Utility, Medical, and Others

The market is analyzed across North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia and Pacific, and Middle East and Africa

Cold gas spray coating is popular because it coats without causing heat damage, thus suitable for aerospace, automotive, and electronics applications.

Aerospace, automotive, oil & gas, electronics, and medical sectors apply cold gas spray coatings for increasing durability, corrosion protection, and thermal protection.

Cold gas spray has improved adhesion, zero thermal effect, and the capacity to refurbish worn parts, which makes it better than most conventional coatings.

The market will continue to grow with the development in additive manufacturing, growing use in electric vehicles, and increased demand for green coatings.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Cold Forging Machine Market Size and Share Forecast Outlook 2025 to 2035

Cold-Pressed Oil Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Packaging Market Size and Share Forecast Outlook 2025 to 2035

Cold Plates Market Size and Share Forecast Outlook 2025 to 2035

Cold-Chain Sensor Encapsulators Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Cold-Pressed Fruit Extracts Market Size and Share Forecast Outlook 2025 to 2035

Cold Heading Wire Market Size and Share Forecast Outlook 2025 to 2035

Cold Water Swelling Starch Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Cold Insulation Materials Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Cold Finished Iron and Steel Bars and Bar Size Shapes Market Size and Share Forecast Outlook 2025 to 2035

Cold Storage Equipment Market Size and Share Forecast Outlook 2025 to 2035

Cold Laser Therapy Market Analysis - Size, Share & Forecast 2025 to 2035

Cold Mix Asphalt Market Size and Share Forecast Outlook 2025 to 2035

Cold Cuts Market Analysis - Size, Share, and Forecast 2025 to 2035

Cold Seal Paper Market Size and Share Forecast Outlook 2025 to 2035

Cold Pain Therapy Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Equipment Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Logistics Market Size and Share Forecast Outlook 2025 to 2035

Cold Formed Blister Foil Market Growth - Demand & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA