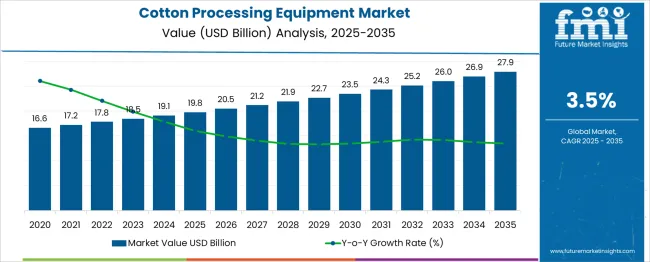

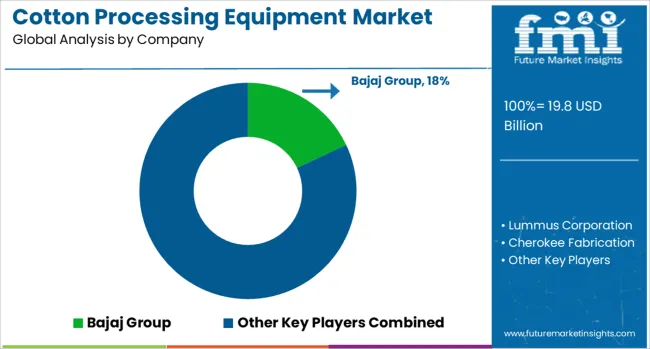

The Cotton Processing Equipment Market is estimated to be valued at USD 19.8 billion in 2025 and is projected to reach USD 27.9 billion by 2035, registering a compound annual growth rate (CAGR) of 3.5% over the forecast period. From 2025 to 2030, the market will grow gradually, reaching USD 23.5 billion. Intermediate yearly values include USD 20.5 billion in 2026, USD 21.2 billion in 2027, USD 21.9 billion in 2028, and USD 22.7 billion in 2029. Market share gains will likely go to manufacturers offering durable, high-capacity, and energy-efficient processing solutions.

Players that cater to demand from both large-scale ginneries and smallholder co-operatives, especially in Asia and Africa, will have an edge. On the other hand, companies dependent on legacy machines or unable to meet throughput and lint quality requirements may lose relevance. Inconsistent after-sales support and delayed spare part supply chains could contribute to share erosion, particularly in regions with seasonal harvest cycles. Between 2025 and 2030, equipment makers who focus on affordability, ease of maintenance, and scalable integration with existing systems will outperform. The market will favor those who can support operational efficiency and minimize downtime across diverse cotton-producing regions.

| Metric | Value |

|---|---|

| Cotton Processing Equipment Market Estimated Value in (2025 E) | USD 19.8 billion |

| Cotton Processing Equipment Market Forecast Value in (2035 F) | USD 27.9 billion |

| Forecast CAGR (2025 to 2035) | 3.5% |

The Long-Term Value Accumulation Curve for the Cotton Processing Equipment Market from 2025 to 2035 illustrates a stable, gradual growth path, reflecting steady adoption and modernization in cotton-producing regions. Starting at USD 19.8 billion in 2025, the market increases to USD 27.9 billion by 2035, with an average annual increment of approximately USD 0.8 billion. This results in a cumulative value gain of USD 8.1 billion over the forecast period, driven by the increasing need for efficient processing solutions in ginning, lint cleaning, and pressing systems.

From 2025 to 2030, the market rises from USD 19.8 billion to 23.5 billion, indicating the early growth phase characterized by equipment upgrades and mechanization, especially in developing economies. The second half, from 2030 to 2035, sees the market reaching USD 27.9 billion, reflecting continued investments, equipment replacement cycles, and capacity expansion by textile manufacturers. The curve’s gentle but steady upward slope signals consistent demand and low volatility, ideal for long-term capital deployment. Its structure also highlights the absence of sharp cyclical behavior, making it attractive for OEMs, component suppliers, and investors seeking reliable value accumulation. Overall, the market’s maturity and moderate CAGR of 3.5 % suggest long-range predictability in return generation.

The Cotton Processing Equipment market is experiencing consistent growth as global demand for processed cotton intensifies, driven by the expanding textile and apparel industries. Technological evolution in ginning, spinning, and cleaning equipment has allowed manufacturers to deliver more efficient and cost-effective solutions. The integration of automation and smart monitoring systems is improving productivity while reducing operational costs, which remains a key concern for mill operators.

Market growth is further supported by government initiatives in cotton-producing countries that aim to modernize outdated infrastructure and promote exports. Investments in agricultural mechanization and rural industrialization are also enhancing adoption, particularly in emerging economies where cotton remains a primary cash crop.

Additionally, shifting consumer preference toward natural fibers is boosting cotton demand, creating a ripple effect on equipment modernization. As environmental compliance becomes more critical, energy-efficient and low-emission processing systems are gaining traction, paving the way for sustainable innovation across the value chain..

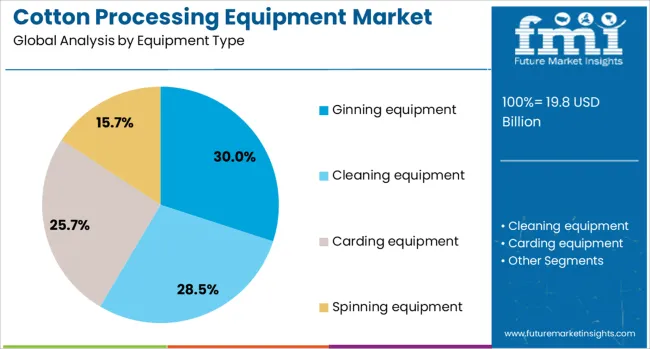

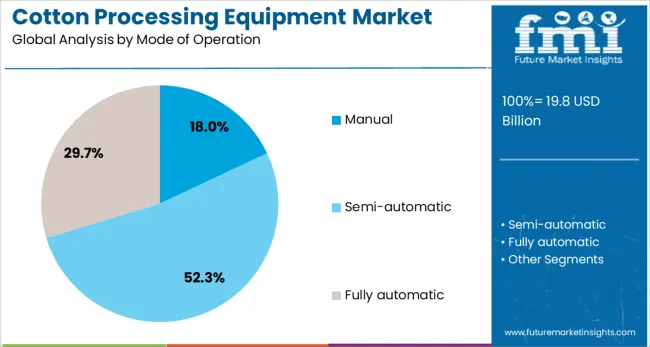

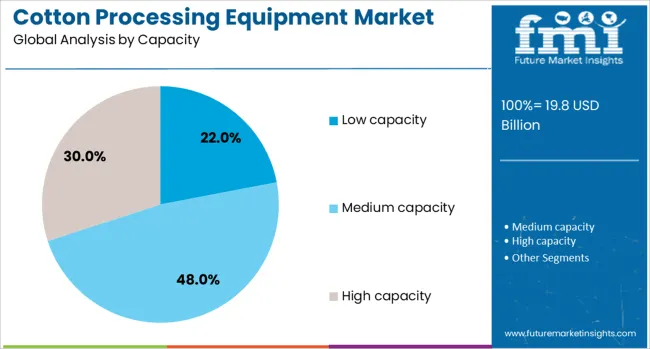

The cotton processing equipment market is segmented by equipment type, mode of operation, capacity, application, distribution channel, and geographic regions. The cotton processing equipment market is divided into Ginning equipment, Cleaning equipment, Carding equipment, Spinning equipment, Weaving equipment, finishing machines, and Others (sorting, etc.). In terms of mode of operation, the cotton processing equipment market is classified into Manual, Semi-automatic, and fully automatic. The cotton processing equipment market is segmented into low-capacity, medium-capacity, and high-capacity. The cotton processing equipment market is segmented into the Textile industry, Medical & surgical, and Others. The distribution channel of the cotton processing equipment market is segmented into Direct sales and Indirect sales. Regionally, the cotton processing equipment industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The ginning equipment segment is projected to account for 30% of the Cotton Processing Equipment market revenue share in 2025, making it the leading equipment type. Growth in this segment has been influenced by the essential role ginning plays in separating cotton fibers from seeds, a foundational process in the textile production chain. High adoption has been observed due to the increasing need for fast and efficient fiber extraction, particularly in large-scale cotton-producing regions.

Technological improvements in ginning systems have enabled greater throughput, fiber quality retention, and reduced wastage. Additionally, many countries have launched modernization programs to replace legacy ginning units with high-capacity automated alternatives.

The demand for cleaner and contamination-free cotton has also made advanced ginning machinery more attractive to manufacturers. As textile manufacturers demand consistent raw material quality, investments in ginning equipment continue to rise, securing its dominance within the overall equipment type segment.

The manual mode of operation segment is expected to contribute 18% of the Cotton Processing Equipment market revenue share in 2025. This segment has remained relevant primarily in small to medium-scale cotton processing units, particularly in developing countries where labor costs are lower and automation infrastructure remains limited. The preference for manual systems is often driven by cost considerations, ease of maintenance, and operator familiarity with traditional workflows.

Despite the industry’s gradual shift toward automation, manual equipment continues to serve vital roles in regions with fragmented supply chains and limited access to capital. Flexibility in handling various cotton grades and adaptability to inconsistent power supply environments have also favored manual operations.

Continued use in community-based processing clusters and cooperatives has sustained its demand. However, integration with semi-automated tools is increasingly being explored to enhance output without sacrificing the hands-on control these systems offer.

The low capacity segment is projected to hold 22% of the Cotton Processing Equipment market revenue share in 2025, leading the capacity-based segmentation. This dominance has been shaped by its suitability for smallholder farms, micro-processing units, and localized cotton production clusters. Low capacity equipment has been widely adopted where throughput requirements are modest, but consistent processing quality is essential.

The affordability and space efficiency of these machines have made them an ideal choice for rural operators and startups in the cotton supply chain. Operational simplicity, low maintenance needs, and minimal energy consumption have contributed to their sustained popularity.

Additionally, public and private initiatives promoting micro-industrialization in agrarian economies have boosted investments in low capacity systems. As regional governments continue to fund small-scale cotton value addition projects, this segment is likely to maintain its momentum, offering practical solutions in cost-sensitive production environments..

The cotton processing equipment market is expanding steadily as global demand grows for cotton textiles, yarns, and industrial materials. Machines such as ginning units, balers, carding machines, and spinning equipment enable efficient removal of impurities and fiber preparation. Key demand sectors include textile manufacturing, garment production, and cottonseed utilization. Growth is strongest in regions with large agricultural and textile output such as Asia‑Pacific, Africa, and South Asia. Manufacturers are enhancing automation, fiber quality control, and energy efficiency in modern machinery. Sustainability expectations and labor savings support technology adoption across processing lines.

Cotton processing equipment supply chain fragmentation increases operational challenges for both machinery providers and processors. Raw tool suppliers, fiber line integrators, and equipment manufacturers must coordinate delivery schedules, compatibility standards, and maintenance routines. Small scale mills or coop operations may lack centralized procurement systems and require customized solutions. Equipment delivery depends on infrastructure such as port access, customs clearance, and local service networks. Delays in spare part availability or configuration mismatches can interrupt production cycles. Coordination among multiple stakeholders, including local engineering firms and international OEMs, requires clear communication. Machinery commissioning and operator training across dispersed processing regions add complexity. Ensuring compatibility with existing ginning and spinning lines at the site level demands both logistical planning and technical alignment. Suppliers that support turnkey setups, field training, and localized spare inventory reduce disruption risk. Addressing this fragmentation through structured partnerships and service networks enables smoother equipment adoption.

Automation innovations are transforming the cotton processing equipment market by improving throughput, fiber purity, and operational safety. Modern ginning and bale pressing machines incorporate sensor-based monitoring for humidity, trash content, and fiber breakage rates. Automated bale weighing, packaging, and module tracking reduce manual handling. Carding lines now use optical detection of foreign matter and motor controls to stabilize sliver consistency. Integration of PLC systems and human‑machine interfaces enables predictive maintenance and reduces downtime. These automation enhancements also reduce labor requirements and improve workplace safety. As processors scale up to meet textile demand, automated lines deliver reliable, repeatable output quality. Vendors offering modular systems with remote diagnostics and consistency benchmarking win favor among processors seeking to improve efficiency and reduce waste. Automation further supports compliance with quality certification standards in international textile supply chains.

Variability in raw cotton quality presents a key operational challenge for cotton processing equipment users. Differences in staple length, moisture, botanical impurities, and fiber maturity impact ginning efficiency and end-product performance. Equipment settings such as rotor speed, lint cleaning intensity, and carder adjustment must be calibrated to raw input conditions. Inconsistent inputs can lead to increased fiber breakage, neps formation, or damaged cotton fibers risking yarn strength and textile quality. This requires processor teams to conduct frequent quality testing and machine fine‑tuning. Lack of consistent local cotton quality complicates machine adoption in emerging regions. Suppliers may provide guidance on fiber pre-sorting, moisture control, and pre-cleaning modules. Without reliable material preparation protocols, even advanced machinery fails to deliver consistent output. Developing calibration frameworks and providing technical training on raw quality influence empowers processors to adapt equipment to real-world conditions and sustain consistent fiber quality.

Increasing emphasis on energy consumption and environmental impact is shifting cotton equipment selection toward efficient designs. Modern machines incorporate energy-saving motors, waste heat recovery systems, and optimized hydraulic circuits. Low-noise, low-vibration models reduce environmental burden near processing facilities. Dust collection and lint control systems minimize emissions and improve air quality. Sustainable certifications or credible energy usage reporting support processor acceptance in environmentally conscious textile supply chains. Renewable power integration for equipment such as solar-assisted blowers or drying units helps reduce operating cost and carbon footprint. Equipment providers that highlight lifecycle efficiency and reduced maintenance burdens gain preference. As sustainability criteria become integral to textile brand sourcing, cotton processing machinery that aligns with green manufacturing goals becomes increasingly valuable. Suppliers demonstrating both operational efficiency and environmental responsibility are better positioned for long-term market relevance in the modern textile ecosystem.

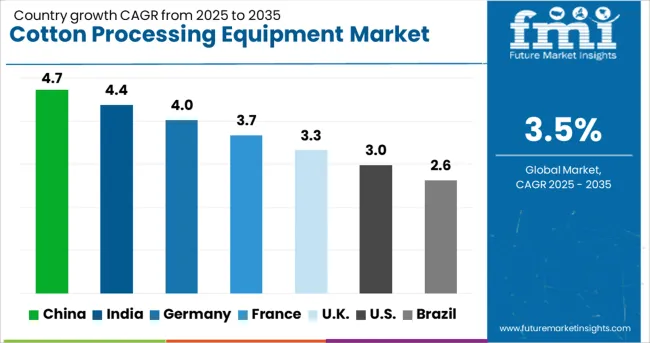

| Country | CAGR |

|---|---|

| China | 4.7% |

| India | 4.4% |

| Germany | 4.0% |

| France | 3.7% |

| UK | 3.3% |

| USA | 3.0% |

| Brazil | 2.6% |

The Cotton Processing Equipment Market is projected to grow at a CAGR of 3.5% through 2035, due to mechanization in agriculture and increasing demand for high-efficiency cotton handling systems. China leads with a growth rate of 4.7%, fueled by automation in textile production and upgrades in ginning technologies. India follows at 4.4%, where commercial adoption is expanding rapidly across its vast cotton-growing regions. Germany, growing at 4.0%, is standardizing modern cotton processing systems with a focus on energy-efficient, precision-based equipment. The UK, with a 3.3% growth rate, is modernizing its small-scale textile manufacturing by integrating advanced ginning and lint cleaning machinery. In the USA, growing at 3.0%, the market reflects steady innovation in post-harvest handling systems, particularly in sustainable cotton processing and export-ready packaging. This report includes insights on 40+ countries; the top five markets are shown here for reference.

China recorded a CAGR of 4.7% in the cotton processing equipment market, driven by large-scale cotton farming regions transitioning to automated systems. Processing hubs across Xinjiang and Shandong prioritized throughput improvement, prompting widespread deployment of ginning and pressing equipment equipped with monitoring tools. Government-led programs incentivized producers to replace aging systems to meet high-volume demands. The push for machine upgrades helped maintain export competitiveness, especially in key textile clusters. Cross-border machine purchases from Europe contributed to improved output quality. Factory owners prioritized output consistency, cost reduction, and low maintenance cycles. Training programs helped operators adopt new tools quickly. Domestic suppliers also expanded after-sales service networks to ensure minimal downtime. While the market saw strong demand in industrial zones, smaller processing units also invested in modular equipment suited for regional-scale cotton volumes. These transitions reflect a broader focus on maximizing yield while reducing inefficiencies in high-output production environments.

India experienced a CAGR of 4.4% in the cotton processing equipment market, led by steady mechanization in Gujarat, Maharashtra, and Tamil Nadu. Ginning and baling equipment upgrades were common among mid-sized firms seeking to reduce contamination and meet global standards. Equipment makers introduced compact, power-efficient machines compatible with local grid conditions. Government schemes like TUFS helped smaller producers access affordable financing to modernize outdated infrastructure. Emphasis was placed on labor-saving models to reduce dependence on manual sorting and pressing. Exporters targeted premium cotton markets, encouraging investment in better fiber handling. Software-based control systems allowed operators to track processing accuracy, and maintenance requirements were built into machine dashboards. Regional suppliers focused on durability and cost-effectiveness, boosting adoption among first-time buyers. Increasing demand for uniform fiber bundles pushed processors to select machines with precise lint separation and impurity removal features, helping them meet international buyer expectations.

Germany posted a CAGR of 4.0% in the cotton processing equipment market, although domestic cotton is not grown at scale. Firms relied on imported raw cotton for specialized textile applications, including medical and high-thread-count fabrics. These businesses installed equipment built for precision and repeatability in cleaning and ginning processes. Many machines included real-time monitoring features and automatic calibration, enabling small batch runs without affecting consistency. Processing sites operated within tight quality parameters, often requiring third-party certification. German producers also exported cotton equipment to Asia and Africa, focusing on models built for long operation cycles and low fault tolerance. Domestic use cases were typically confined to niche manufacturers, often supplying European garment makers. Training in equipment handling and performance tracking was incorporated into operator workflows. Cross-sector partnerships ensured feedback loops for improving reliability across export and domestic markets, where equipment lifespan and processing uniformity were priorities.

The United Kingdom recorded a CAGR of 3.3% in the cotton processing equipment market, largely due to the rise in demand for locally processed cotton by boutique brands. Though cotton is not cultivated domestically, textile firms imported raw materials and upgraded older ginning and cleaning systems. Many buyers sought batch-scale equipment built for flexibility and minimal operator intervention. Equipment providers customized machines to support smaller production volumes while maintaining output control. Post-installation support was a key factor in purchasing decisions. Local manufacturers preferred machines that could integrate easily with legacy infrastructure. Compliance with processing standards was emphasized by brands supplying to major retailers. Cross-collaboration with universities allowed pilot runs for fabric testing before full-scale deployment. Financing options and equipment leasing became popular, allowing smaller players to enter the market without large upfront costs. Port cities offered logistical advantages in raw cotton imports and outbound textile shipments.

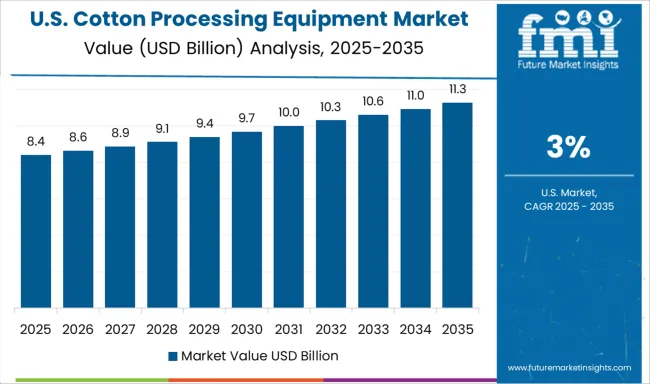

The United States observed a CAGR of 3.0% in the cotton processing equipment market, driven by upgrades across southern states such as Texas and Mississippi. Large-scale farms invested in new ginning systems to meet rising demand for cleaner, uniform fiber output. Equipment suppliers introduced models equipped with remote diagnostics, RFID tracking, and automated impurity control. The push for cleaner cotton helped farmers secure better contracts with apparel brands. Federal support under farm modernization programs subsidized equipment purchases, accelerating adoption among small and mid-size ginners. Regional workshops provided training on machine maintenance and performance monitoring. The shift toward efficient systems reduced dependence on seasonal labor and improved daily throughput. Processing facilities were designed to handle large cotton volumes with minimal waste. Producers exporting to Europe and Asia adopted advanced quality grading features to meet buyer requirements. The presence of local equipment manufacturers helped maintain service reliability.

The cotton processing equipment market is essential to the global textile value chain, facilitating efficient ginning, cleaning, baling, and lint conditioning. The market is shaped by rising global cotton demand, automation trends in agriculture, and the push for fiber quality preservation during post-harvest handling. As climate resilience and operational scalability become increasingly important, manufacturers are focusing on energy-efficient, low-lint-loss, and high-capacity solutions tailored to both smallholder and industrial cotton operations. Bajaj Group, one of the largest manufacturers globally, dominates in terms of product variety and installed base, particularly across Asia and Africa. Its portfolio includes automatic double roller (DR) gins, pre-cleaners, and baling presses, with a strong emphasis on rugged, field-tested machinery that supports decentralized cotton processing.

Lummus Corporation, a historic USA-based innovator, leads in saw ginning and delinting systems, known for their high throughput and quality preservation in long-staple cotton markets like the USA and Australia. Cherokee Fabrication specializes in custom-built cotton ginning systems for large-scale operations, focusing on modular design, airflow optimization, and minimal fiber damage. Nipha Group and Jadhao Gears Pvt. Ltd. offer advanced components and systems with a focus on precision engineering, noise reduction, and maintenance efficiency ideal for modernizing legacy ginneries. Shandong Swan Cotton Machinery, a major Chinese supplier, is rapidly scaling exports with competitively priced, automation-ready equipment suited for fast-growing cotton economies. As digital integration and sustainability rise in importance, suppliers investing in IoT-enabled gins, dust suppression, and adaptive power consumption are poised to shape the next generation of cotton processing infrastructure.

As mentioned in the Times of India article dated May 20, 2025, researchers from ICAR‑CIRCOT (Central Institute for Research on Cotton Technology) and Bajaj Steel Industries publicly launched a pre‑grooved roller system for double‑roller cotton gins. This engineering innovation significantly reduces labor and energy costs (by 10%), boosts lint yield from 63 kg to 70 kg per hour per gin, eliminates the need for frequent re-grooving, has been adopted in over 1,000 ginning units, and was officially recognized by India's Union Agriculture Minister.

| Item | Value |

|---|---|

| Quantitative Units | USD 19.8 Billion |

| Equipment Type | Ginning equipment, Cleaning equipment, Carding equipment, Spinning equipment, Weaving equipment, Finishing machines, and Others (sorting etc.) |

| Mode of Operation | Manual, Semi-automatic, and Fully automatic |

| Capacity | Low capacity, Medium capacity, and High capacity |

| Application | Textile industry, Medical & surgical, and Others |

| Distribution Channel | Direct sales and Indirect sales |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Bajaj Group, Lummus Corporation, Cherokee Fabrication, Nipha Group, Jadhao Gears Pvt. Ltd., and Shandong Swan Cotton Machinery |

| Additional Attributes | Dollar sales by cotton processing equipment type including ginning machines, cleaning units, carding, spinning, weaving, and finishing systems, by application in textile manufacturing and cottonseed processing, and by geographic region including North America, Europe, and Asia‑Pacific; demand driven by rising cotton production and apparel/textile demand; innovation in IoT-enabled automated gins, AI monitoring, and energy-efficient systems; costs influenced by steel and component prices, machine sophistication, and automation overhead; and emerging use cases in mobile ginning units and real-time predictive maintenance across small and large-scale operations. |

The global cotton processing equipment market is estimated to be valued at USD 19.8 billion in 2025.

The market size for the cotton processing equipment market is projected to reach USD 27.9 billion by 2035.

The cotton processing equipment market is expected to grow at a 3.5% CAGR between 2025 and 2035.

The key product types in cotton processing equipment market are ginning equipment, _knife roller gin, _macarty gin, _saw gin, cleaning equipment, _raw cotton cleaning machine, _cotton lint cleaner machines, carding equipment, _flat carding machines, _roller carding machines, _high-production carding machines, spinning equipment, _ring spinning, _rotor spinning, _compact spinning, _air jet spinning, weaving equipment, finishing machines and others (sorting etc.).

In terms of mode of operation, manual segment to command 18.0% share in the cotton processing equipment market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Tea Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Seed Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Meat Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Sand Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Wine Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Fish Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Food Processing Equipment Market - Size, Share, and Forecast Outlook 2025 to 2035

Wafer Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Fruit Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Dairy Processing Equipment Market Outlook – Growth, Demand & Forecast 2023-2033

Bakery Processing Equipment Market Analysis by Product Type, End User, Application & Region: A Forecast for 2025 and 2035

Mineral Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Bioprocessing Analytics Equipment Market Size and Share Forecast Outlook 2025 to 2035

Poultry Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Beverage Processing Equipment Market Size, Growth, and Forecast 2025 to 2035

Chocolate Processing Equipment Market Size, Growth, and Forecast 2025 to 2035

Ice Cream Processing Equipment Market Growth - Trends, Demand & Innovations 2025 to 2035

Shale Gas Processing Equipment Market

Upstream Bioprocessing Equipment Market - Growth, Trends & Forecast 2025 to 2035

Animal Feed Processing Equipment Market Analysis & Forecast by Function, Feed Type, End-User, Automation, and Region through 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA