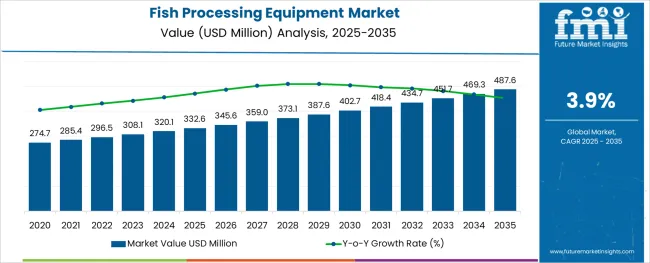

The Fish Processing Equipment Market is estimated to be valued at USD 332.6 million in 2025 and is projected to reach USD 487.6 million by 2035, registering a compound annual growth rate (CAGR) of 3.9% over the forecast period.

The fish processing equipment market is witnessing steady expansion as demand for efficient, hygienic, and sustainable seafood production continues to rise globally. Increasing consumption of processed seafood, coupled with stricter food safety regulations, is driving investments in advanced equipment that can deliver higher throughput with minimal waste.

Automation, precision engineering, and integration of digital monitoring technologies are transforming processing lines, making them more adaptable to varying fish sizes and species. Future growth is expected to be supported by innovation in energy-efficient designs, rising demand from emerging markets, and consolidation among processors seeking economies of scale.

Growing focus on product quality, shelf life extension, and reduction of labor dependency is paving the way for further adoption of specialized fish processing machinery across the value chain.

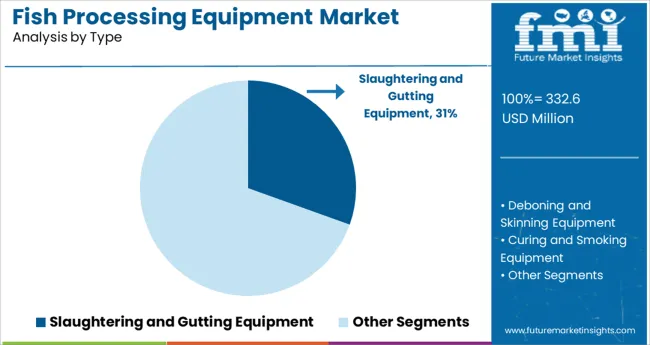

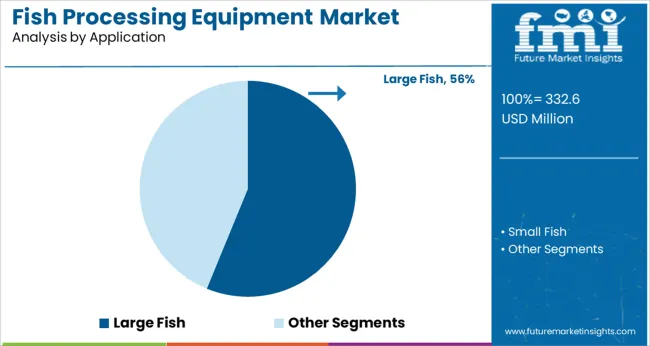

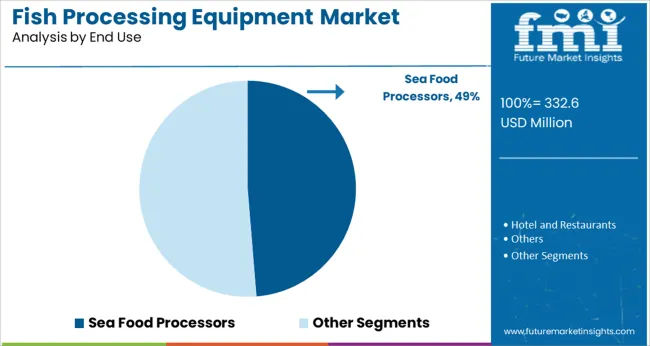

The market is segmented by Type, Application, End Use, and Operating Mechanism and region. By Type, the market is divided into Slaughtering and Gutting Equipment, Deboning and Skinning Equipment, Curing and Smoking Equipment, and Other Types. In terms of Application, the market is classified into Large Fish and Small Fish. Based on End Use, the market is segmented into Sea Food Processors, Hotel and Restaurants, and Others. By Operating Mechanism, the market is divided into Mechanical and Electrical. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The market is segmented by Type, Application, End Use, and Operating Mechanism and region. By Type, the market is divided into Slaughtering and Gutting Equipment, Deboning and Skinning Equipment, Curing and Smoking Equipment, and Other Types. In terms of Application, the market is classified into Large Fish and Small Fish. Based on End Use, the market is segmented into Sea Food Processors, Hotel and Restaurants, and Others. By Operating Mechanism, the market is divided into Mechanical and Electrical. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by type, slaughtering and gutting equipment is expected to hold 30.5% of the total market revenue in 2025, establishing itself as the leading equipment type. This leadership is attributed to its critical role in ensuring hygiene and efficiency at the initial stages of fish processing.

The ability of modern slaughtering and gutting machines to handle high volumes with precision while minimizing damage to the flesh has reinforced their indispensability in both large and medium-scale operations. Advancements in blade technology, ergonomic design, and automated evisceration mechanisms have reduced processing time and improved product yield.

The growing emphasis on maintaining strict sanitary standards and reducing manual handling has further positioned this segment as a cornerstone of modern processing facilities, supporting its continued dominance.

In terms of application, large fish is projected to account for 56.2% of the market revenue share in 2025, making it the top application segment. This prominence is driven by the significant economic value of large fish species, which require robust and specialized equipment to process efficiently.

The ability of advanced machinery to accommodate the size and weight of large fish while ensuring precision cutting and waste reduction has strengthened demand in this segment. Larger species often command higher market prices, incentivizing processors to invest in equipment that maximizes yield and preserves quality.

Additionally, the durability and scalability of equipment tailored for large fish have appealed to processors aiming to improve operational efficiency and meet the growing demand for premium seafood products, solidifying the segment’s leadership.

Segmenting by end use reveals that seafood processors are expected to hold a 48.7% share of the market revenue in 2025, positioning them as the top end users. This dominance arises from their central role in converting raw catch into ready-to-consume or value-added products that meet regulatory and consumer standards.

Investments by seafood processors in modernizing facilities have been propelled by the need to enhance throughput, maintain quality consistency, and reduce operational costs. The segment’s leadership is further supported by their ability to deploy integrated processing lines that combine multiple functions, thereby optimizing space and labor.

As processors cater to both domestic and international markets, the necessity for reliable, high-capacity equipment that ensures compliance with global food safety norms has cemented their position as the primary adopters of fish processing machinery.

Europe is expected to be one of the most significant markets for fish processing equipment.

Europe's fish oil market is valued at USD 332.6 billion as of 332.60332.6332.6. There has been an increasing demand for fish oil in the region owing to its increased application in the pharmaceutical business and animal nutrition, and pet feed market as these are rich sources of omega-3 fatty acids, EPA and DHA.

The fish oil market has depended upon fish processing equipment as they generate products that are high in proteins, lipids, and various other nutrients.

North America is expected to be the second-largest market for fish processing machines during the forecast period.

The North American aquaculture therapeutics market was valued at USD 332.6 million as of 2025, and the region held a massive 35% of the global market share. There were increasing cases of bacterial illness among the aquaculture species, as a result of which the manufacturers wanted to get them treated before putting them into further usage.

As a matter of fact, consumer confidence would further enhance, and this would give the fish processing equipment manufacturers the leeway to seamlessly carry out the activity owing to FDA authorization.

Based on the research conducted by FMI, the Asia Pacific region is expected to be the largest fish processing equipment market during the forecast period.

Asia Pacific is currently the largest seafood market and based on the market analysis, the region occupies nearly 40% of the global market share. As of 2024, the Asia Pacific seafood market was valued at close to USD 74 billion.

A huge seafood market would definitely showcase a huge potential for the surging demand for fish processing equipment. The major players in the seafood market are making use of fish processing equipment to carry out the fish slaughtering process effectively.

On comparing the historical CAGR with the anticipated CAGR, we might get a sense that the market growth is gradual, but the analysts are of the view that the growth would certainly be long-lasting.

While the historical CAGR for the market was 3.2%, the anticipated CAGR is 3.9%. This certainly indicates that an increase in the sales of fish and related products would certainly surge the market growth. It is because the fish processing equipment is versatile in nature and does much more than just fish slaughtering.

| Attributes | Value |

|---|---|

| Fish Processing Equipment Market Value (2025) | USD 297.4 million |

| Fish Processing Equipment Market Value (2025) | USD 308.1 million |

| Fish Processing Equipment Market Forecast Value (2035) | USD 451.6 million |

| Fish Processing Equipment Market Expected CAGR (2025 to 2035) | 3.9% |

Reducing labor cost

The implementation of fish processing equipment ensures that the manpower is put to work on more relevant matters, thereby increasing the efficiency of the operations.

Reduced process errors

The application of fish processing equipment ensures that there are no cases pertaining to unclean cuts, slower work, wasted fish, or reduced product quality.

Owing to a high level of automation in fish processing equipment, the overall activity that is performed in a day is equivalent to the same combined effort put in by the laborers to achieve the same result in a span of at least five days.

Thanks to the consistency offered by these machines, and the ability to work for long hours together, companies operating in this business are able to reap the benefits.

Safe mode of operation

Tasks like cutting, grinding, and canning are performed flawlessly by the fish processing equipment. However, if such tasks are performed manually, it can be extremely dangerous for workers.

Moreover, the usage of the fish processing equipment also ensures that the workers are not exposed to extreme conditions, such as low temperatures, lifting heavy equipment, and exposure to toxins, which might surge the fish processing equipment market share.

Fixed initial investment

In the current times of volatile markets, the impact of inflation can be ruthless at times, which means higher labor charges along with high raw material prices.

Implementation of the fish processing equipment is as good as a one-time investment. Apart from that, the implementation of the latest technology ensures that the equipment performs all the functions with the highest level of accuracy.

Concerns regarding the quality of food

One of the biggest challenges experienced by the market is that there might be differences in the method which is used as a yardstick to check the quality of fish, during import and export activities.

Moreover, the manufacturers hardly have any clue of whether the quality of the fish is good or not, and this can further impede the market growth.

Rising water pollution

Increasing cases of water pollution have led to the deteriorating health of aquatic species across the globe. This might severely impact the health of consumers, as a result of which the demand for fish processing equipment might be impacted.

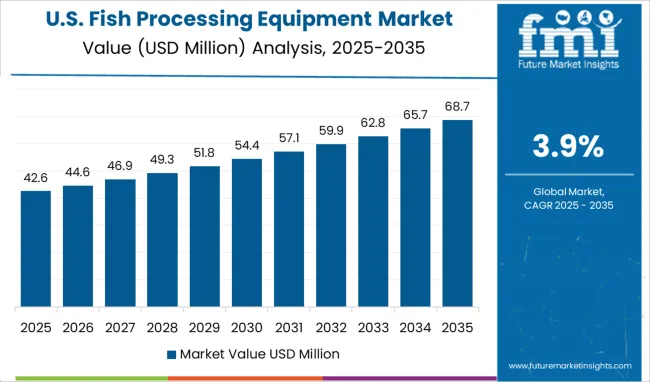

The USA fish processing equipment market is expected to grow at a CAGR of 2.9% during the forecast period. The market is valued at USD 332.6 million as of 2025, and by 2035, the market is expected to reach a valuation of USD 89 million.

The historic CAGR (2020 to 2025) for the market was 2.6%.

The USA is also one of the largest markets for fish sauce. As per the research conducted by FMI, the USA fish sauce market is valued at nearly USD 332.6 billion as of 2025. Being a rich source of Vitamin D and Vitamin B2 is surging the demand for fish sauce in the region.

Manufacturers are increasingly making use of fish processing equipment to ensure that the fish is finely processed and converted to finer forms for the ease of preparation of the fish sauce.

The United Kingdom market is expected to grow at a CAGR of 2.9% during the forecast period. The market is valued at USD 15.2 million as of 2025, and by 2035, the market is expected to hit a valuation of USD 20.3 million.

The historical CAGR of (2020 to 2025) for the market was 2.7%.

the United Kingdom is a prominent fish meal market. The fish meal market in the United Kingdom is expected to reach a valuation of USD 487.6 million by 2035. Fish meal is gradually replacing the likes of soybean meals and corn gluten meals because they are a sustainable form of protein and have higher nutritional benefits.

The implementation of fish processing equipment in the fish meal market makes the process of deriving valuable nutrients from fish much easier.

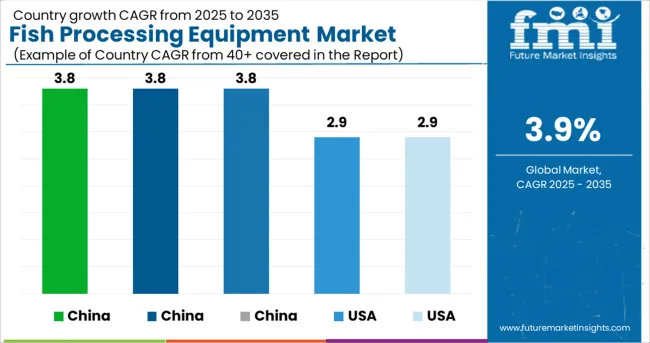

The China fish processing equipment market is valued at USD 29.9 million as of 2025. The market is expected to surge at a CAGR of 3.8% during the forecast period, and by 2035, is projected to reach a valuation of USD 43.5 million.

The historic CAGR (2020 to 2025) for the market was 3.4%.

The China fish collagen market was valued at USD 102.4 million as of 2025, and the market is expected to surge at an above-average CAGR of 6.1%. Fish collagens are being used for strengthening bones and regulating blood sugar. Apart from that, the collagens are also used to improve the condition of tissues as well.

The fish processing equipment is used for deriving the necessary nutrients from the fish so that the fish collagen manufacturers can make use of them to prepare the required products.

The Japan fish processing equipment market is expected to reach a valuation of USD 36.3 million by 2035. The market is anticipated to grow at a CAGR of 3.8%, and as of 2025, the market is valued at USD 25 million.

The historical CAGR (2020 to 2025) for the market was 3.4%.

Japan has a fast-growing fish-based pet food market which was valued at USD 320.1 million as of 2024 and is expected to grow at an anticipated CAGR of around 5%. There is an increasing demand for high-quality pet foods which is expected to surge the demand for fish-based pet food. Apart from that, the increasing scenario of pet humanization is expected to further surge the demand for fish-based pet food.

The fish processing equipment is being utilized mainly to convert the fish into a finer form so that, they can be easily converted to edible form.

The South Korean market is expected to grow at a CAGR of 3.8% during the forecast period. The market is expected to reach a valuation of USD 30.5 million by 2035, and as of 2025, the market is valued at USD 21 million.

The historical CAGR (2020 to 2025) for the market was 3.4%.

The South Korean fish protein market is valued at USD 341 million as of 2024. An increase in the number of health-conscious customers in South Korea is expected to surge the market share. Apart from that, the increasing adoption of fish protein chemicals by pharmaceutical companies is expected to further surge the market growth.

The fish processing equipment helps in converting the fish into a form from which protein and other nutrients can be easily derived. This is something that might surge the demand for fish processing equipment among the fish protein market players.

The slaughtering and gutting equipment segment is expected to grow at a CAGR of 3.5% during the forecast period.

The historical CAGR (2020 to 2025) for the market was 2.7%.

The process of gutting ensures that the nutrients are effectively derived from the fish, as the process essentially involves cutting the species and converting them into finer pieces. Moreover, the usage of stainless steel ensures easy cleaning of the slaughtering and gutting machines, and gives long life to them. ;

The seafood processors are expected to grow at a CAGR of 3.7% during the forecast period.

The historic CAGR (2020 to 2025) for the segment was 2.9%.

The seafood processors perform the core functionality of processing the fish and converting them into finer forms so that they can be further used by the end users. This segment is known to serve other sectors like pharmaceutical, hospitality, wholesale markets, etc.

The start-ups serving the fish processing equipment market are making use of the latest technological developments to provide the best services to the customers. Some of the start-ups are working on seafood traceability using QR tags. This would allow the company to trace the fish’s journey back to its origins and define who caught it.

SmartCatch is providing fishermen with eyes within their nets, which helps capture and organize the data at the point of harvest, controls the net from the wheelhouse, and selectively releases the unwanted catch.

On 9th March 2020, the company managed to raise USD 2.5 million from Sustainable Ocean Alliance.

The key players operating in the fish processing equipment market are on a mission of handling issues pertaining to the labor shortage. For this, the companies are developing automatic in-line cut-ups, which can handle up to 7200 broilers per hour.

Additionally, the key players are also developing systems that can handle both air and water-chilled products.

Some of the recent developments in the fish processing equipment market are:

Marel, Trifisk Manufacturing Inc., and Blois Fish Processing Automation Ltd. have been producing great quality fish processing equipment to serve the niche in the best way possible

Marel is a market leader in transforming the way food is processed. They have been producing high-quality, safe, and affordable food by providing solutions, services, and software to the poultry, meat, and fish processing industries. The business works on the core idea of sustainability.

Employing more than 7,000 who are working around the globe in over 30 countries, the company is willing to provide the best in the world products to its customers. Marel has been laying huge emphasis on innovation. The company is dedicated to surpassing industry standards in providing to development of the highest quality affordable food.

On 2nd November’22, Marel announced that it is refining its operating model to enable customer-centricity, enhancing end-to-end accountability and cross-business collaboration.

Blois Fish Processing Automation Ltd. has been offering quality assured, on-site sales, service, and maintenance to the North American fish processing market. The success of the company is built on integrity and building long-term relationships. The company has been providing top-quality food processing equipment, which coordinates Transport, Export, and Import.

The company has also been providing equipment and parts sourcing, equipment evaluations, consultation design, equipment cleaning services, and Business Supportive Resources. The company has always assisted its clients in innovating, and increasing the quality and quantity of throughput, to attain high-quality ratings.

Trifisk Manufacturing Inc. brings four trusted names together: Simnar, Simor, Fishmore, and Trifisk: all under a single brand. The company is a market leader in commercial fish scalers and continues to produce Simor brand fish de-scaler. The company takes pride in producing excellent fish scaler repairs and service for all its customers.

The company has also been providing machining and CAD Services using the latest 3D software. They accept DWG, DXF, IGES, and other software files.

The global fish processing equipment market is estimated to be valued at USD 332.6 million in 2025.

It is projected to reach USD 487.6 million by 2035.

The market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types are slaughtering and gutting equipment, deboning and skinning equipment, curing and smoking equipment and other types.

large fish segment is expected to dominate with a 56.2% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Fish Pond Circulating Water Pump Filter Market Size and Share Forecast Outlook 2025 to 2035

Fish Hydrolysate Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Isolates Market Size and Share Forecast Outlook 2025 to 2035

Fish Meal Alternative Market Size and Share Forecast Outlook 2025 to 2035

Fish Oil Alternatives Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Concentrate Market Size and Share Forecast Outlook 2025 to 2035

Fish Feed Pellet Making Machine Market Size and Share Forecast Outlook 2025 to 2035

Fish Fermentation Market Size and Share Forecast Outlook 2025 to 2035

Fishing Reels Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Filleting Machine Market Size and Share Forecast Outlook 2025 to 2035

Fish Deboning Machine Market Size and Share Forecast Outlook 2025 to 2035

Fish Cutting Machine Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Hydrolysate Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Hydrolysate For Animal Feed And Pet Food Applications Market Size and Share Forecast Outlook 2025 to 2035

Fishmeal and Fish Oil Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Feed Ingredients Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Collagen Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Bone Minerals Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Peptones Market Size, Growth, and Forecast for 2025 to 2035

Fish Nutrition Market Size, Growth, and Forecast for 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA