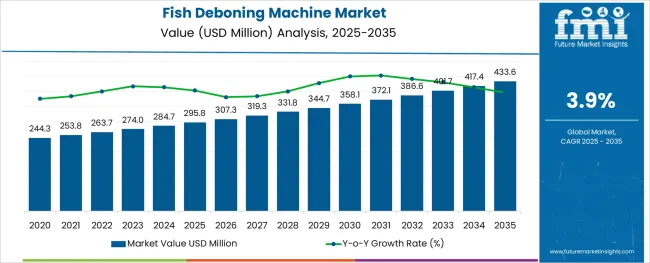

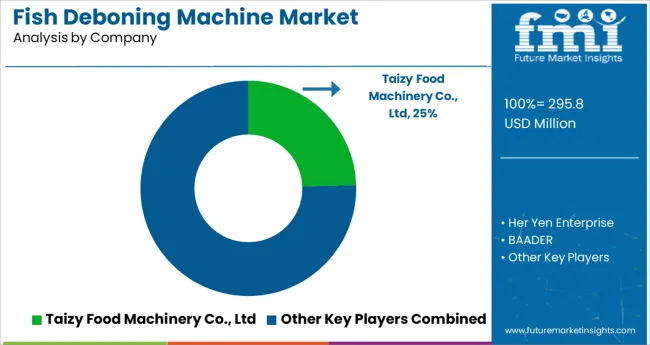

The Fish Deboning Machine Market is estimated to be valued at USD 295.8 million in 2025 and is projected to reach USD 433.6 million by 2035, registering a compound annual growth rate (CAGR) of 3.9% over the forecast period.

The fish deboning machine market is witnessing consistent growth as demand for efficiency, hygiene, and yield optimization rises in seafood processing. Regulatory focus on food safety, coupled with labor shortages and cost pressures, has accelerated the adoption of mechanized deboning solutions in both developed and emerging markets.

The shift from manual to machine-driven processing is being driven by the need to minimize product wastage, ensure consistent quality, and comply with stringent hygiene standards. Innovations in blade technology, ergonomic design, and material durability are enhancing machine performance and reducing maintenance downtime, which is further encouraging investment.

Future market opportunities are expected to be fueled by the growing consumption of processed seafood, the expansion of cold chain logistics, and increasing investments in automation within mid-scale processing facilities. These drivers are shaping a market that is steadily moving toward higher capacity, fully automated systems designed to meet evolving operational and regulatory demands.

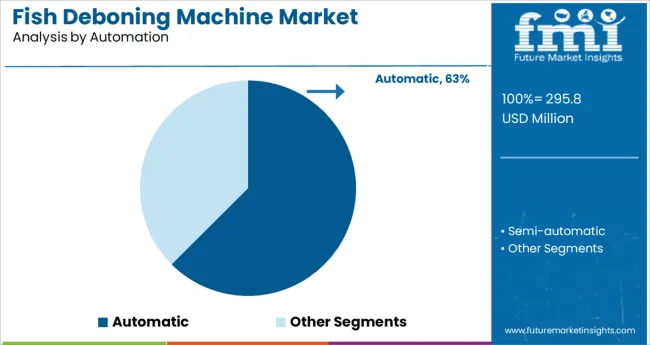

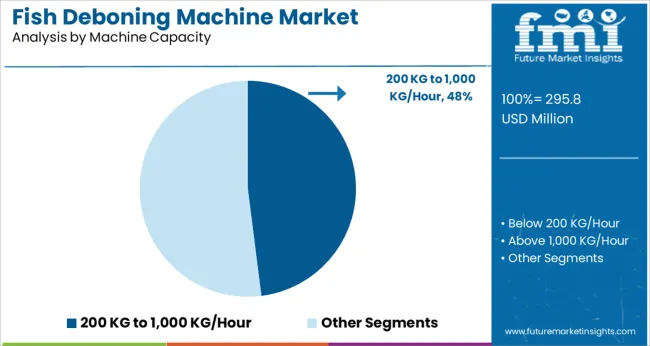

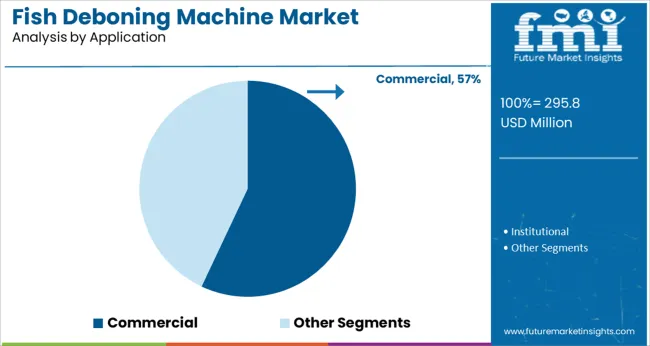

The market is segmented by Automation, Machine Capacity, and Application and region. By Automation, the market is divided into Automatic and Semi-automatic. In terms of Machine Capacity, the market is classified into 200 KG to 1,000 KG/Hour, Below 200 KG/Hour, and Above 1,000 KG/Hour. Based on Application, the market is segmented into Commercial and Institutional. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by automation, the automatic segment is expected to command 62.5% of the total market revenue in 2025, establishing itself as the leading subsegment. This prominence is attributed to the pressing need for consistency and speed in seafood processing operations, which manual or semi-automatic machines struggle to deliver.

Automatic machines have been designed to reduce dependency on skilled labor while enhancing output precision, which is critical in meeting high-volume orders. Their integration with programmable settings, safety mechanisms, and hygiene-compliant materials has allowed processors to maintain operational efficiency and comply with food safety standards.

The reduction of human error and the ability to operate continuously with minimal supervision have further supported the widespread adoption of automatic fish deboning machines, reinforcing their dominance in facilities focused on maximizing throughput and maintaining consistent product quality.

Segmented by machine capacity, units with a throughput of 200 KG to 1,000 KG per hour are projected to hold 48.0% of the market revenue in 2025, making them the preferred capacity range. This leadership is a result of their balanced performance, which caters effectively to medium and large processors who require higher output without the space and energy demands of the largest industrial models.

Machines in this capacity range have been recognized for their flexibility to handle varying fish sizes and species while maintaining efficiency, making them suitable for diverse operational needs. Their optimal footprint, ease of integration into existing processing lines, and competitive cost-performance ratio have made them the choice for facilities looking to upgrade from manual operations without overcapitalizing.

This segment’s sustained growth reflects its ability to meet the needs of processors balancing volume, quality, and operational costs.

When segmented by application, the commercial segment is forecast to capture 57.0% of the market revenue in 2025, solidifying its position as the leading segment. This dominance has been reinforced by the growing demand for deboned fish products in retail, hospitality, and institutional catering channels, which require uniformity, safety, and reliability at scale.

Commercial processors have adopted these machines to meet rising consumer expectations for ready-to-cook and ready-to-eat seafood products. The commercial segment benefits from its capacity to invest in dedicated production lines and its focus on reducing turnaround time while maintaining product quality.

Enhanced machine reliability and hygiene standards have made these solutions integral to commercial operations, allowing processors to respond effectively to bulk orders and seasonal peaks. The increasing prevalence of branded seafood products and the need to ensure consistent supply to supermarkets and foodservice chains have further entrenched the commercial segment at the forefront of the market.

Key players claim that the fish deboning machines can work at temperatures as low as -30 °C and are designed to be waterproof. They take pride in having built a solid reputation for excellent product quality, reliability, and affordability.

Their goal is superior customer service with competitive prices. Their aim is to offer cutting-edge technology to save labor and maximize resources. In addition, they provide advanced high-quality fish deboning machines and solutions to fit all budgets and sectors. These machines provide a high-quality product ready for preparation at a rate of up to 50 Lakh fish per minute.

It is crucial for manufacturers to make sure that these machines are reworked concerning hygiene and that the main parts can be opened or lifted for the better. A quick tightening device for dismantling the transport belt ensures easier cleaning and maintenance. Additionally, one side of the machine grinds fish bone and blood clots, and the other side grinds fish skin. The whole process is extremely fast and beginner-friendly. All these factors are anticipated to generate market opportunities and expand the global fish deboning machine market size.

Processed food and packaged convenience food products have been increasing in demand over the years. These products require minced meat to mould and hence rely on the proper processing of fish meat which includes efficient deboning. This is likely to spark innovations in the fish deboning machines market trends.

15% of the global supply of animal proteins is derived from seafood, as stated according to data published by the Food & Agriculture Organization (FAO). This is likely to encourage producers to scale up their production with the help of efficient equipment and hence is estimated to boost the market growth.

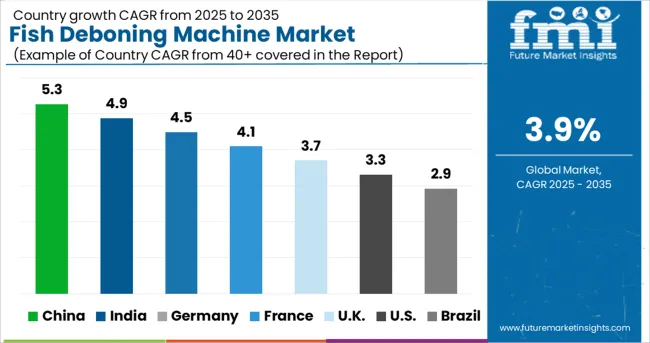

The statistics accumulated by Future Market Insights, reveal the global forum of fish deboning machines which has witnessed an unprecedented surge over the past few years. The manufacturers in the market are in conjunction with the increasing demand for fish deboning machines. There has been a gradual rise from a CAGR of 2.5% registered during the period of 2020 to 2025 and is likely to expand at a steady 3.9% in the forecast period.

The significant growth in the market can be attributed to the high consumption of fish, across the globe. The process of deboning can be a tedious, time-consuming process if done manually using various mechanisms such as a manual method of meat bone separation, where the tool is manually operated by gripping and pulling bones from a fish fillet. Owing to the high demand for fish and seafood, the processing is required to be faster. This increased the deployment of fish deboning machines, as deboned fish has various applications in the commercial sector.

Over the years, fish deboning machines have been growing in demand as huge quantities of comminuted raw meat from fish are utilized in the manufacture of food products such as fish burgers, fish sticks, canned fish, fish sausage, and fish dumplings. The objective of this invention was to develop a hygienic, provision for cleaning-in-place (CIP) that gives cost-effective need and reliability for both large and small scale industries to produce fish meat in turn used for their value-added products. This is estimated to propel the adoption of the fish deboning machine market in the forecast period.

By operating type, the market is segmented into automatic and semi-automatic. It has been observed by the analysts at Future Market Insights that the automatic segment is estimated to hold a major market share, recording a CAGR of 4.9% through the forecast period.

The pivotal elements determining the momentum of this segment are:

By application type, the market is segmented into commercial and institutional. It has been researched by the analysts at Future Market Insights that the commercial segment is likely to hold a major market share, recording a CAGR of 4.2% through the forecast period.

The vital attributes determining the momentum of this segment are:

There is a constant growth in demand for fish deboning machines because of the increasing focus on preventing fish products from deteriorating. Furthermore, the extracted protein from fish has various properties such as gelling activity, oil absorption, foaming capacity, and water-holding capacity.

Fish meat and proteins are used as ingredients in various food products including soups, infant formulas, and bakery substitutes. In addition, leading producers and exporters of fish products rely heavily on advanced fish deboning machines which facilitates the growth of the market share.

Fish meat provides two kinds of omega-3 fatty acids which are eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). Consumers recognize the vital roles these fatty acids play in controlling hypertension, improving brain function, and reducing inflammation. This is estimated to increase demand for fish deboning machines.

Despite the several advantages of fish deboning machines, the high capital investment in these machines can be extremely over the budget for small and mid-range consumers. Additionally, several countries have limited knowledge regarding technological development and advancement in the processing food industry due to a lack of availability of information. These factors are expected to hinder market growth.

On the contrary, seafood producers are encouraged to increase their production with efficient manufacturing processes to maintain production costs owing to the rise in demand for fish. Furthermore, emerging countries have witnessed a growing adoption of fish deboning machines which is a supportive factor for seafood producers. This is anticipated to generate market opportunities in the forecast period.

The presence of major market players in fish deboning machines in Germany makes it a lucrative market with a revenue of 2.9%. Most of the market players are headquartered in rural areas where they work with various niches and have managed to assert themselves over decades. In addition, sales of new machines and spare parts offer installation support for new processing lines and provide service and maintenance on their customers’ fleets.

Owing to the patented technology incorporated into the production of fish deboning machines, German customers have taken advantage of the high-quality meat recovered from these machines. Moreover, the machine further helps small-scale processors extract the meat and help businesses produce structured meat products out of fish. These factors are expected to drive the demand for fish deboning machines.

The players are able to provide a full range of technically advanced fish deboning machines to their customers. Furthermore, research and development (Research and Development) are being extensively carried out by experienced graduate engineers, electronic engineers, technicians, and mechanists who are working in laboratories, design, and research departments to find innovative solutions for manifold tasks. These factors are expected to support the fish deboning machine market growth.

China is expected to hold a significant share with a revenue of 4.4% in the fish deboning machine market. This is attributed to the country being known for its wide range of food processing machines and one-stop intimate services. Moreover, these processing machines are versatile, i.e., they can be applied to both family and commercial use.

End users in China have a high demand for fish deboning machines that adopt the way of mechanical speed and drive regulation with an attractive appearance, long service life, and easy of operation. Furthermore, certain key players are equipped with independent intellectual property rights for their deboning equipment and production techniques, leading to the expansion of the fish deboning machine market size.

Manufacturers in China ensure that these machines are user-friendly with easy disassembling and easy to clean. In addition, China is one of the top fish and seafood-consuming countries. Hence, manufacturers also offer the ability to debone all types of fish. This is expected to contribute to global market growth.

Market players promote the fish deboning machine as a three-piece fish slicer. The replacement of labor is very efficient, and the meat yield is comparable to that of skilled workers. Moreover, it can be used because the mechanical equipment itself is cheap. These factors are expected to drive the sales of fish deboning machines.

India is a significant fish deboning machine market growing at a profit of 5.3%. The market players in the country have years of expertise and experience. Additionally, the key companies have acquired specialization in offering the latest technology in fish deboning machines, with the support of their skilled and competent workforce.

Market players in India who are committed to fulfilling their clients’ demands are counted among the most reliable importers, suppliers, and distributors across the globe. Moreover, they offer a wide product portfolio with products that have been procured from well-established vendors who assure optimum quality products and timely deliveries. This is likely to increase the sales of fish deboning machines, in this region.

Several states in India such as West Bengal, Orissa, Tamil Nadu, Goa, Kerala, and Maharashtra, consume large quantities of fish and fish by-products. Hence, by adopting disruptive modern technologies, key players aim to provide the best fish deboning automation equipment that reduces human labor while increasing processing output with low wastage, amongst small end users like restaurants to large end users like fish farms and fish processing plants.

With a market share of 3.7%, Japan is a notable fish deboning machine market. This is owing to the extremely high consumption of fish and other seafood in this country. Japan is surrounded by water bodies, and 90% of the diet of the major population consists of seafood.

Manufacturers in Japan are determined to adopt disruptive technological innovations such as robots and automation, which are expected to change how business is done. This is because Japan is the birthplace of sushi, which requires deboned, raw fish meat. These factors are estimated to increase the adoption of fish deboning machines in this region, in the forecast period.

Key players in Japan aim to partner with their clientele in which they are able to assist them in acquiring the maximum return on investment by automating their fish deboning processes. Moreover, their primary vision is to provide high-quality fish deboning machines that decrease human labor while improving production output with a minimal amount of wastage. These aspects are likely to boost the global fish deboning machine market growth

Start-up companies are incorporating advanced technologies or creating devices that support the global fish deboning machine market size:

Owing to the presence of several players, the fish deboning machine market share is fragmented. Both developed and emerging markets are increasing the demand for these fish processing units. Hence, the demand for fish deboning machines has surged the number of distributors and suppliers.

The latest developments in the fish deboning machine market are

The global fish deboning machine market is estimated to be valued at USD 295.8 million in 2025.

It is projected to reach USD 433.6 million by 2035.

The market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types are automatic and semi-automatic.

200 kg to 1,000 kg/hour segment is expected to dominate with a 48.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Fish Pond Circulating Water Pump Filter Market Size and Share Forecast Outlook 2025 to 2035

Fish Hydrolysate Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Isolates Market Size and Share Forecast Outlook 2025 to 2035

Fish Meal Alternative Market Size and Share Forecast Outlook 2025 to 2035

Fish Oil Alternatives Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Concentrate Market Size and Share Forecast Outlook 2025 to 2035

Fish Fermentation Market Size and Share Forecast Outlook 2025 to 2035

Fishing Reels Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Processing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Hydrolysate Market Size and Share Forecast Outlook 2025 to 2035

Fish Protein Hydrolysate For Animal Feed And Pet Food Applications Market Size and Share Forecast Outlook 2025 to 2035

Fishmeal and Fish Oil Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Feed Ingredients Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Collagen Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Bone Minerals Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Peptones Market Size, Growth, and Forecast for 2025 to 2035

Fish Nutrition Market Size, Growth, and Forecast for 2025 to 2035

Fish Oil Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Fish Sauce Market Growth - Culinary Trends & Industry Demand 2025 to 2035

Fish Meal Market Analysis – Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA