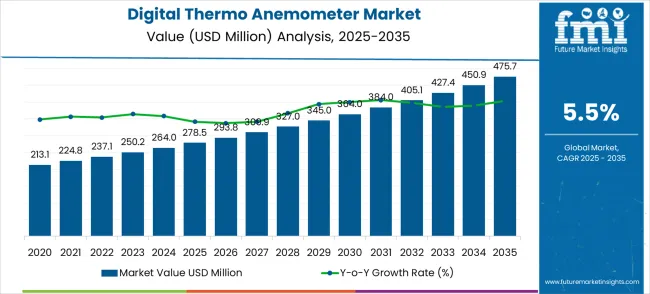

The digital thermo anemometer market reaches USD 278.5 million in 2025 and is estimated to grow to USD 475.7 million by 2035, reflecting a CAGR of 5.5%. Year-on-year (YoY) growth from 2021 to 2025 shows steady progress, with the market starting at USD 213.1 million in 2021. In 2022, the market expands by 5.5%, reaching USD 224.8 million, followed by another 5.5% increase in 2023 to USD 237.1 million. In 2024, the market continues its growth, reaching USD 250.2 million, driven by the increasing demand for accurate air flow measurement tools across HVAC systems, industrial environments, and health & safety sectors. By 2025, the market hits USD 264.0 million, supported by rising global adoption of energy-efficient systems and environmental monitoring solutions.

From 2026 to 2030, the market's growth remains steady, expanding from USD 278.5 million in 2025 to USD 345.0 million in 2030. During this period, the demand for smart sensors, automated industrial processes, and energy efficiency solutions drives market expansion. The growing focus on climate control, indoor air quality, and energy conservation further boosts the need for digital thermo anemometers. Between 2031 and 2035, the market accelerates to USD 475.7 million, as increasing industrialization, urbanization, and advancements in sensor technologies push the market forward. The market’s consistent YoY growth pattern underscores the expanding role of these instruments in multiple sectors, from manufacturing to environmental monitoring.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 278.5 million |

| Forecast Value in (2035F) | USD 475.7 million |

| Forecast CAGR (2025 to 2035) | 5.5% |

The environmental monitoring market contributes around 15–18%, where these devices are used to measure airflow, temperature, and air quality in atmospheric and environmental studies. The test and measurement equipment market accounts for 12–15%, as digital thermo anemometers play a critical role in precision testing for industries like HVAC, manufacturing, and laboratories. The building automation and control systems market contributes approximately 10–12%, where these instruments are essential for optimizing HVAC systems and ensuring energy efficiency in smart buildings. The HVAC equipment market also plays a significant role, contributing about 8–10%, as thermo anemometers are used to monitor air velocity and temperature in ventilation systems. The industrial process control market, contributing 7–9%, utilizes these tools in manufacturing and chemical processing environments to maintain optimal conditions and improve operational efficiency.

Market expansion is being supported by the increasing emphasis on energy efficiency optimization in commercial and industrial buildings, where accurate airflow and temperature measurements are essential for HVAC system performance and operational cost control. Modern building management systems require precise environmental monitoring capabilities that can detect airflow variations and temperature fluctuations to maintain optimal indoor conditions while minimizing energy consumption. Digital thermo anemometers provide the accuracy and data integration features necessary for advanced building automation and energy management applications.

The growing focus on workplace safety and environmental compliance is driving demand for reliable measurement instruments that can monitor air quality parameters and ensure adherence to occupational health standards. Industrial facilities require continuous monitoring of ventilation systems to prevent the accumulation of hazardous gases and maintain safe working conditions. The expansion of cleanroom manufacturing in pharmaceutical, semiconductor, and biotechnology industries creates significant opportunities for specialized digital thermo anemometers that can operate in controlled environments while providing precise measurements for process validation and quality assurance.

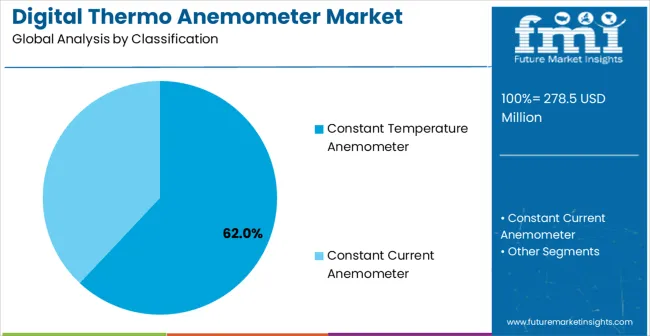

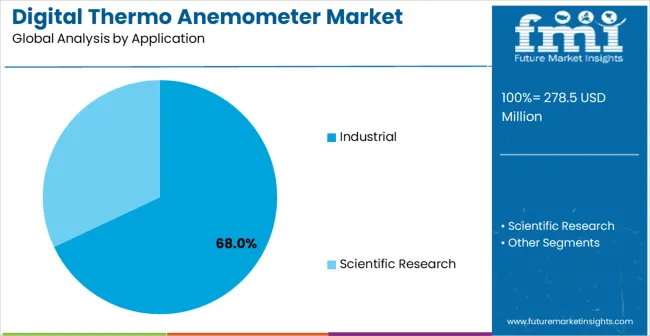

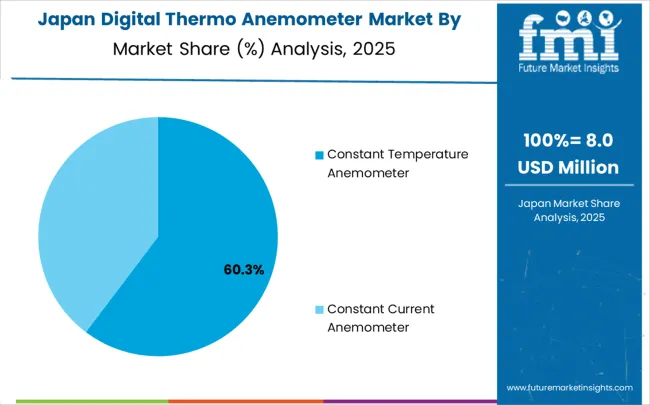

The market is segmented by product type, application, and region. By product type, the market is divided into constant temperature anemometer and constant current anemometer. By application, the market is categorized into industrial and scientific research. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

The constant temperature anemometer (CTA) segment is projected to account for 62% of the digital thermo anemometer market in 2025, establishing itself as the preferred solution for precise airflow measurement across industrial, research, and environmental monitoring applications. CTA technology offers superior sensitivity and accuracy, particularly in low-velocity and turbulent airflow conditions, where precise data is crucial for process optimization, energy efficiency, and equipment validation. The system maintains a near-constant wire temperature by automatically adjusting current, ensuring rapid response and minimal measurement lag even under fluctuating environmental conditions. This enables highly accurate monitoring in HVAC commissioning, cleanroom airflow validation, indoor air quality assessment, and industrial process control.

CTA instruments also provide significant advantages in calibration stability, drift compensation, and temperature correction, which reduce the frequency of maintenance and ensure consistent data quality over prolonged usage. Industries such as pharmaceuticals, aerospace, chemical processing, and electronics manufacturing rely on CTA systems to comply with stringent regulatory and quality standards. Their proven performance, reliability, and ability to integrate with automated monitoring systems drive widespread adoption in environments where airflow precision directly affects safety, operational efficiency, and product quality.

Industrial applications are expected to represent 68% of digital thermo anemometer demand in 2025, reflecting the critical need for precise airflow measurement in manufacturing, facility management, and process optimization. Industrial facilities require accurate airflow monitoring to ensure ventilation system efficiency, product quality, and adherence to workplace safety regulations. Digital thermo anemometers support HVAC system commissioning, ventilation verification, and process control across chemical, pharmaceutical, automotive, electronics, and food processing industries. Their real-time data capabilities enable monitoring of air velocity, temperature, and flow patterns to optimize energy consumption, reduce operational risks, and maintain regulatory compliance.

The growing adoption of automation and Industry 4.0 practices further accelerates demand for digital anemometers in industrial setups. Continuous environmental monitoring allows industrial operations to prevent contamination, minimize energy losses, and maintain consistent process parameters. Applications extend to validating paint booths, dust collection systems, and fume hoods, as well as ensuring controlled airflow in production lines where precision is essential. Energy efficiency and environmental compliance requirements further drive investment in advanced digital airflow measurement systems.

The digital thermo anemometer market is advancing steadily due to increasing demand for precise environmental monitoring and growing emphasis on energy efficiency optimization in building management systems. The market faces challenges including competition from alternative measurement technologies, calibration maintenance requirements for precision instruments, and cost sensitivity in price-conscious market segments. Innovation in wireless connectivity and data integration capabilities continue to influence product development and market expansion patterns.

The growing deployment of smart building technologies is creating significant demand for connected measurement instruments that can integrate with automated control systems and provide continuous monitoring data. IoT-enabled anemometers offer remote monitoring capabilities, automated data logging, and predictive maintenance features that enhance operational efficiency while reducing manual inspection requirements. These systems enable building managers to optimize HVAC performance based on real-time airflow and temperature data, improving energy efficiency and occupant comfort while reducing operational costs.

Modern digital thermo anemometer manufacturers are incorporating advanced sensor technologies including MEMS-based flow sensors, wireless communication modules, and cloud-based data analytics platforms to enhance measurement accuracy and user experience. These technologies improve instrument responsiveness while extending battery life and providing better integration with existing building management systems. Advanced data processing capabilities enable trend analysis, automated reporting, and predictive maintenance scheduling that adds value beyond basic measurement functionality.

Specialized applications in pharmaceutical, semiconductor, and aerospace industries are driving development of digital thermo anemometers with enhanced accuracy specifications and regulatory compliance features. Cleanroom monitoring applications require instruments that meet stringent contamination control standards while providing traceable calibration documentation for regulatory validation. These specialized markets support premium pricing while creating opportunities for manufacturers who can provide industry-specific certification and technical support services.

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.4% |

| India | 6.9% |

| Germany | 6.3% |

| Brazil | 5.8% |

| USA | 5.2% |

| UK | 4.7% |

| Japan | 4.1% |

The digital thermo anemometer market is experiencing steady growth globally, with China leading at 7.4% CAGR through 2035, driven by massive construction activity, industrial expansion, and increasing emphasis on energy efficiency in building operations. India follows at 6.9%, supported by infrastructure development, manufacturing sector growth, and rising awareness of indoor air quality management. Germany records 6.3% growth, emphasizing precision measurement, quality standards, and advanced industrial applications. Brazil shows 5.8% expansion, driven by industrial development and building efficiency improvements.

The report covers an in-depth analysis of 40+ countries, with top-performing countries highlighted below.

China is projected to experience the highest growth in digital thermo anemometer revenue, exhibiting a CAGR of 7.4% through 2035. This growth is driven by massive construction activity, rapid industrialization, and a growing focus on energy efficiency in both commercial and residential buildings. Expanding manufacturing sectors and increased awareness of indoor air quality standards are creating substantial demand for precise airflow measurement instruments. Major construction projects and industrial facility developments are integrating comprehensive environmental monitoring systems to ensure optimal HVAC performance and regulatory compliance.

Government regulations mandating accurate airflow measurements during system commissioning and periodic verification further fuel demand for certified measurement instruments. Industrial modernization initiatives and upgrades to manufacturing facilities are fostering the adoption of digital measurement systems that integrate with automated control platforms, offering real-time monitoring and enabling process optimization and quality assurance. The synergy between construction, industrial growth, and regulatory requirements ensures market expansion, particularly in metropolitan regions such as Shanghai, Shenzhen, and Guangzhou.

The digital thermo anemometer market in China is expanding at a CAGR of 6.9%, driven by rapid industrial and infrastructure development, modernization of manufacturing facilities, and the growth of pharmaceutical and biotechnology industries. Increasing adoption of advanced HVAC systems in commercial and industrial buildings is creating demand for precise airflow monitoring solutions that ensure energy efficiency and process optimization. Pharmaceutical cleanrooms and biotechnology manufacturing require high-accuracy airflow measurement instruments for regulatory compliance, product quality, and contamination prevention.

Industrial facilities are deploying environmental monitoring systems to improve workplace safety, reduce operational costs, and optimize energy consumption. Expansion of infrastructure projects in major cities such as Mumbai, Bangalore, and Hyderabad, coupled with investments in industrial automation, is fueling market growth. The increasing industrialization, strict regulatory compliance in pharmaceutical manufacturing, and modernization of building management systems are creating a growth environment for digital thermo anemometer adoption.

Germany’s market for digital thermo anemometers is projected to grow at a CAGR of 6.3%, reflecting the country’s strong focus on precision manufacturing, advanced industrial automation, and high-quality engineering standards. Industrial facilities in Germany require reliable and highly accurate instruments for environmental monitoring, HVAC system validation, and process optimization to maintain regulatory compliance and operational efficiency. German manufacturers emphasize the importance of measurement stability, calibration precision, and integration with automated control systems to support energy management and productivity improvements.

Key industrial hubs, including Munich, Stuttgart, and Hamburg, are adopting advanced measurement technologies for automotive production, chemical processing, and electronics manufacturing. Environmental monitoring is critical for maintaining workplace safety, controlling airflow in cleanroom applications, and optimizing ventilation systems. The country’s expertise in precision instrumentation, engineering excellence, and robust calibration infrastructure ensures consistent adoption of high-performance digital thermo anemometers, making Germany a benchmark market for technological reliability and industrial quality.

Brazil’s digital thermo anemometer market is growing at a CAGR of 5.8%, fueled by ongoing industrial development, infrastructure modernization, and rising awareness of energy efficiency in commercial and industrial buildings. The country’s established manufacturing sector, coupled with expanding construction activities, is driving the adoption of environmental monitoring equipment to support process optimization, compliance with safety regulations, and operational efficiency. Industrial facilities are increasingly integrating digital measurement systems into HVAC and process control applications to ensure accurate airflow monitoring, reduce maintenance costs, and enhance worker safety.

Construction and renovation projects in key cities such as São Paulo, Rio de Janeiro, and Porto Alegre are incorporating sophisticated HVAC systems, creating demand for precise testing and commissioning instruments. Despite challenges from economic fluctuations affecting capital investment cycles, Brazil’s industrial modernization programs and focus on energy-efficient facility operations continue to drive demand for high-accuracy digital thermo anemometers across multiple sectors.

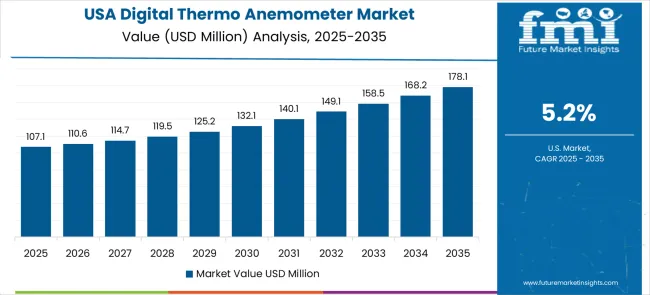

The USA digital thermo anemometer market is expanding at a CAGR of 5.2%, propelled by strict regulatory requirements, technological advancements, and growing focus on energy efficiency in commercial and industrial sectors. Facilities across the country prioritize measurement accuracy, data integration, and traceability to meet building management and process control needs. Pharmaceutical manufacturing, biotechnology, and cleanroom facilities require high-precision instruments to ensure compliance with FDA, GMP, and HACCP standards while maintaining product quality and contamination prevention.

Industrial operators implement environmental monitoring systems to optimize energy usage, enhance operational efficiency, and maintain workplace safety standards. Advanced automation and predictive maintenance initiatives further increase demand for digital measurement instruments that provide real-time airflow and temperature data. The USA market reflects a combination of regulatory-driven adoption, technology-led innovation, and industrial modernization, creating strong opportunities for growth in digital thermo anemometer deployment across various critical applications.

The UK digital thermo anemometer market is projected to grow at a CAGR of 4.7% through 2035, driven by building energy efficiency regulations, heightened indoor air quality awareness, and adoption of smart building technologies. Facility managers in commercial and industrial sectors are investing in digital airflow measurement systems to optimize HVAC performance, ensure occupant comfort, and comply with stringent regulatory standards. Smart building systems increasingly rely on real-time monitoring and data-driven analytics, creating demand for precise instruments capable of integration with automated control systems.

Industrial facilities implement digital thermo anemometers to monitor workplace safety, enhance process control, and support energy management initiatives. The market’s medium growth potential is also supported by periodic equipment upgrades in existing buildings and commercial facilities, along with specialized monitoring requirements for pharmaceutical and healthcare-related environments. The UK combines regulatory compliance with technological adoption to a steady market expansion for high-accuracy airflow measurement solutions.

The digital thermo anemometer market is expected to grow at a CAGR of 4.1%, underpinned by advanced industrial applications, precision manufacturing, and high-quality control standards. Japanese manufacturers prioritize ultra-accurate measurement instruments for cleanrooms, semiconductor fabrication, pharmaceutical production, and electronics assembly. These applications demand instruments that maintain calibration stability, perform reliably under fluctuating environmental conditions, and provide traceable documentation for regulatory compliance. Industrial automation systems in Japan incorporate digital thermo anemometers for process optimization, predictive maintenance, and energy efficiency enhancement.

Major industrial regions such as Tokyo, Osaka, and Nagoya are leading adoption due to their concentration of precision manufacturing facilities. Continuous technological innovation, combined with rigorous quality control protocols, ensures Japan maintains its leadership in deploying high-performance environmental monitoring instruments. Companies also emphasize integration of measurement data with automated control systems, enabling real-time decision-making and improved operational efficiency across industrial and cleanroom applications.

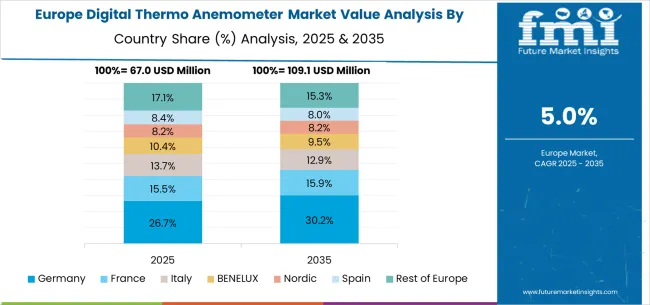

The digital thermo anemometer market in Europe demonstrates strong development across major industrial economies with Germany showing leadership through its advanced manufacturing sector and emphasis on precision measurement technologies. German industrial facilities leverage comprehensive environmental monitoring systems that require accurate airflow and temperature measurement for process optimization and regulatory compliance. The country benefits from established expertise in precision instrumentation and strong demand from automotive, pharmaceutical, and chemical processing industries that utilize sophisticated HVAC and process control systems.

France represents a significant market driven by its nuclear power industry and aerospace manufacturing sector, both requiring specialized environmental monitoring equipment for safety and quality control applications. French companies have developed expertise in cleanroom technologies and controlled environment applications where precise airflow measurement is essential for process validation and regulatory compliance. The UK exhibits considerable growth through its focus on building energy efficiency and smart building technologies, with companies investing in advanced measurement systems for HVAC optimization and indoor air quality management.

Italy and Spain show expanding interest in energy efficiency monitoring for commercial buildings and industrial facilities, particularly in applications requiring compliance with European energy performance standards. BENELUX countries contribute through their focus on high-tech industrial applications and advanced manufacturing facilities that require precision environmental monitoring. Eastern Europe and Nordic regions display growing potential driven by infrastructure modernization and industrial development projects that demand reliable measurement technologies for facility management and process control applications.

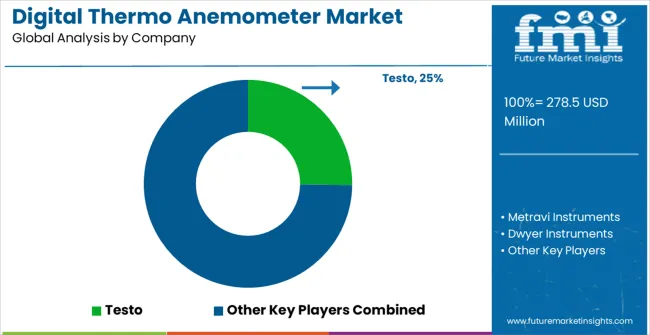

The digital thermo anemometer market is characterized by competition among established measurement instrument manufacturers, specialized environmental monitoring companies, and emerging technology providers. Companies are investing in sensor technology advancement, wireless connectivity development, software integration capabilities, and customer support services to deliver accurate, reliable, and user-friendly measurement solutions. Technical innovation, product quality, and application expertise are central to strengthening product portfolios and market presence in this precision instrument segment.

Testo, Germany-based, leads the market with comprehensive digital anemometer product lines and established customer relationships in HVAC and industrial applications, leveraging advanced sensor technologies and data integration capabilities. Metravi Instruments, India-based, provides cost-effective measurement solutions with focus on emerging market penetration and technical support services. Dwyer Instruments, USA-based, offers reliable industrial measurement equipment with emphasis on application-specific solutions and long-term customer relationships.

Schiltknecht Messtechnik, Germany-based, specializes in precision measurement technologies for demanding industrial applications. Ahlborn Mess- und Regelungstechnik, Germany-based, provides advanced measurement systems with comprehensive data logging and analysis capabilities. Line Seiki, Japan-based, offers precision instruments with emphasis on quality and reliability for industrial applications. HT Italia, Miltronics Manufacturing, TSI, Teledyne FLIR, Brannan, Major Tech, Pyle USA, PCE Instruments, REED Instruments, and Emco Group represent diverse regional suppliers serving specific market segments with specialized product offerings and customer support services.

Digital thermo anemometers represent a critical measurement technology combining airflow velocity and temperature sensing for applications spanning industrial HVAC optimization, environmental monitoring, scientific research, and occupational safety compliance. With the global market valued at $278.5 million in 2024 and projected to reach $475.7 million by 2030 (5.5% CAGR), this precision instrumentation sector is driven by increasing regulatory requirements for indoor air quality, energy efficiency mandates, and growing sophistication in environmental control systems. The market features established German precision instrument manufacturers (Testo, Schiltknecht, Ahlborn) competing with diversified measurement companies and emerging Asian suppliers, while technology variants (constant temperature vs. constant current sensing) serve different accuracy and application requirements.

How Governments Could Accelerate Adoption and Technical Standards?

Regulatory Framework Development: Establish mandatory air quality monitoring requirements for commercial buildings, industrial facilities, and educational institutions, creating consistent demand for calibrated measurement instruments. Include specific performance standards for airflow measurement accuracy and data logging capabilities in building codes and occupational safety regulations.

Energy Efficiency Mandates: Implement building performance standards that require continuous monitoring of HVAC system efficiency, ventilation effectiveness, and indoor environmental quality. Provide tax incentives for facility upgrades that include comprehensive airflow monitoring systems tied to automated building controls.

Scientific Research Infrastructure: Fund meteorological stations, environmental monitoring networks, and research facilities with standardized anemometer specifications, creating anchor demand for high-precision instruments while supporting climate research and environmental compliance monitoring.

Calibration and Metrology Support: Establish national calibration laboratories and certification programs that ensure measurement traceability and instrument accuracy, particularly important for regulatory compliance and scientific applications requiring documented measurement uncertainty.

Public Health and Safety Programs: Integrate airflow monitoring into occupational safety protocols for industries with airborne contaminant risks, including pharmaceutical manufacturing, chemical processing, and food production facilities where air movement patterns affect worker safety and product quality.

How Industry Bodies Could Enhance Measurement Standards and Market Development?

Metrological Standards Harmonization: Develop unified international standards for anemometer accuracy classes, calibration procedures, and measurement uncertainty specifications that enable consistent performance comparison across manufacturers and applications.

Application-Specific Guidelines: Create technical standards for different use cases - HVAC commissioning procedures, cleanroom validation protocols, environmental monitoring network specifications, and industrial ventilation assessment methods - that standardize measurement practices and instrument requirements.

Interoperability and Data Integration: Establish communication protocols and data formats that enable seamless integration of anemometer measurements with building management systems, environmental monitoring networks, and industrial control platforms.

Professional Certification Programs: Develop certification courses for HVAC technicians, environmental consultants, and industrial hygienists that include proper anemometer selection, calibration maintenance, and measurement technique training to ensure reliable field applications.

Technology Roadmap Development: Coordinate industry research priorities around next-generation sensing technologies, including wireless connectivity, multi-parameter environmental sensing, and integration with IoT platforms for predictive maintenance and automated compliance reporting.

How OEMs and Technology Providers Could Strengthen the Ecosystem?

Multi-Parameter Integration: Develop comprehensive environmental monitoring platforms that combine airflow measurement with temperature, humidity, particulate detection, and gas sensing capabilities, providing complete indoor air quality assessment in single instruments.

Wireless and IoT Connectivity: Integrate advanced communication capabilities including Wi-Fi, cellular, and LoRaWAN connectivity for remote monitoring, automated data collection, and integration with cloud-based analytics platforms that support predictive maintenance and compliance reporting.

Ruggedization and Specialization: Engineer application-specific variants optimized for harsh industrial environments, cleanroom applications, outdoor meteorological use, and explosive atmosphere classifications (ATEX/IECEx) that expand addressable market segments.

Smart Calibration and Maintenance: Implement self-diagnostic capabilities, automated calibration reminders, and predictive maintenance algorithms that reduce total cost of ownership while ensuring measurement reliability throughout instrument lifecycle.

User Interface Innovation: Develop intuitive software interfaces and mobile applications that simplify complex measurements, provide real-time data visualization, and generate automated compliance reports for regulatory submissions and facility management.

How Suppliers and Distributors Could Navigate Market Evolution?

Technical Sales and Application Support: Build specialized technical sales teams with deep expertise in airflow measurement principles, regulatory requirements, and application engineering to support customers in proper instrument selection and implementation.

Calibration Service Networks: Establish comprehensive calibration and repair service networks that provide traceable calibration, rapid turnaround times, and on-site service capabilities to minimize measurement downtime for critical applications.

Vertical Market Specialization: Develop focused expertise in specific application sectors - pharmaceutical validation, HVAC commissioning, environmental consulting, industrial hygiene - with specialized product configurations and service offerings tailored to each market's requirements.

Training and Education Programs: Provide comprehensive training programs for end users covering measurement principles, proper technique, data interpretation, and regulatory compliance requirements that improve measurement quality and customer satisfaction.

Inventory Management and Rapid Deployment: Maintain strategic inventory of calibrated instruments and consumables that enable rapid deployment for emergency response, compliance deadlines, and seasonal demand fluctuations in HVAC and environmental monitoring applications.

How Investors and Financial Enablers Could Unlock Market Potential?

Sensor Technology Innovation: Finance development of next-generation sensing technologies including MEMS-based sensors, optical measurement techniques, and multi-point array systems that offer improved accuracy, reduced maintenance requirements, and expanded measurement capabilities.

IoT Platform Development: Support creation of comprehensive environmental monitoring platforms that combine hardware, software, and cloud analytics services, enabling subscription-based business models and recurring revenue streams from data services and predictive analytics.

Geographic Market Expansion: Fund establishment of manufacturing and service capabilities in emerging markets where industrial development and environmental regulations are driving demand for precision measurement instruments, particularly in Asia-Pacific and Latin American markets.

Acquisition and Technology Integration: Finance strategic acquisitions that combine complementary measurement technologies, expand geographic reach, or integrate vertical capabilities from sensor manufacturing through data analytics and compliance reporting services.

Regulatory Compliance Solutions: Invest in development of comprehensive compliance management platforms that automate measurement data collection, generate regulatory reports, and provide predictive analytics for facility management and environmental compliance across multiple jurisdictions.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 278.5 million |

| Product Type | Constant Temperature Anemometer, Constant Current Anemometer |

| Application | Industrial, Scientific Research |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Testo, Metravi Instruments, Dwyer Instruments, Schiltknecht Messtechnik, Ahlborn Mess- und Regelungstechnik, Line Seiki, HT Italia, Miltronics Manufacturing, TSI, Teledyne FLIR, Brannan, Major Tech, Pyle USA, PCE Instruments, REED Instruments, Emco Group |

| Additional Attributes | Dollar sales by measurement range and connectivity type, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established measurement instrument manufacturers and emerging technology providers, buyer preferences for accuracy versus cost optimization, integration with building management systems and IoT platforms, innovations in wireless connectivity and data analytics capabilities, and adoption of specialized applications with enhanced calibration services and regulatory compliance features. |

The global digital thermo anemometer market is estimated to be valued at USD 278.5 million in 2025.

The market size for the digital thermo anemometer market is projected to reach USD 475.7 million by 2035.

The digital thermo anemometer market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in digital thermo anemometer market are constant temperature anemometer and constant current anemometer.

In terms of application, industrial segment to command 68.0% share in the digital thermo anemometer market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Digital Hall Effect Gaussmeter Market Size and Share Forecast Outlook 2025 to 2035

Digital Group Dining Service Market Size and Share Forecast Outlook 2025 to 2035

Digital Pathology Displays Market Size and Share Forecast Outlook 2025 to 2035

Digital Rights Management Market Size and Share Forecast Outlook 2025 to 2035

Digital Liquid Filling Systems Market Size and Share Forecast Outlook 2025 to 2035

Digital Transformation Industry Analysis in MENA Size and Share Forecast Outlook 2025 to 2035

Digital X-Ray Equipment Market Size and Share Forecast Outlook 2025 to 2035

Digital Marketing Analytics Industry Analysis in Latin America Forecast Outlook 2025 to 2035

Digital Health Market Forecast and Outlook 2025 to 2035

Digital Pen Market Forecast and Outlook 2025 to 2035

Digital X-ray Market Size and Share Forecast Outlook 2025 to 2035

Digital Elevation Model Market Size and Share Forecast Outlook 2025 to 2035

Digital Pump Controller Market Size and Share Forecast Outlook 2025 to 2035

Digital Textile Printing Market Size and Share Forecast Outlook 2025 to 2035

Digital Printing Paper Market Size and Share Forecast Outlook 2025 to 2035

Digital Battlefield Market Size and Share Forecast Outlook 2025 to 2035

Digital Product Passport Software Market Size and Share Forecast Outlook 2025 to 2035

Digital Lending Platform Market Size and Share Forecast Outlook 2025 to 2035

Digital Shipyard Market Size and Share Forecast Outlook 2025 to 2035

Digital Freight Matching Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA