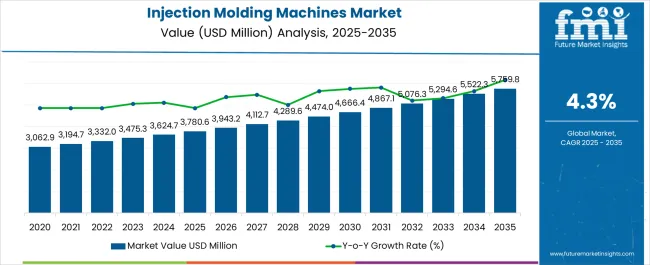

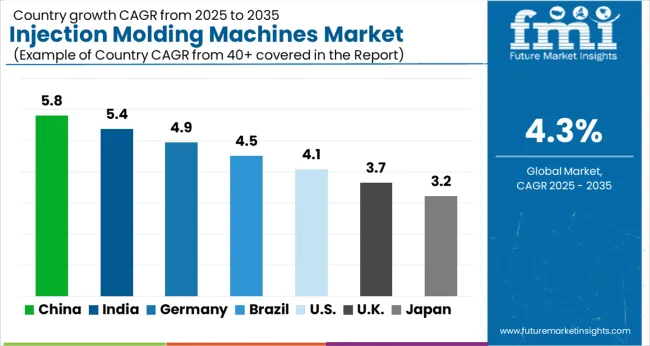

The Europe Injection Molding Machines Market is estimated to be valued at USD 3780.6 million in 2025 and is projected to reach USD 5759.8 million by 2035, registering a compound annual growth rate (CAGR) of 4.3% over the forecast period.

| Metric | Value |

|---|---|

| Europe Injection Molding Machines Market Estimated Value in (2025 E) | USD 3780.6 million |

| Europe Injection Molding Machines Market Forecast Value in (2035 F) | USD 5759.8 million |

| Forecast CAGR (2025 to 2035) | 4.3% |

The Europe injection molding machines market is advancing steadily due to strong demand across automotive, packaging, healthcare, and consumer goods sectors. The shift toward lightweight materials, precision engineering, and energy efficiency has fueled the adoption of advanced molding technologies.

Regulatory emphasis on sustainability and the need for recyclable packaging solutions are further shaping investment trends. Industry players are increasingly prioritizing automation, digital control systems, and energy efficient machine designs to enhance productivity and reduce operational costs.

The market outlook remains positive as European manufacturers continue to adopt smart manufacturing technologies, integrate Industry 4.0 solutions, and respond to the growing requirement for high performance machines that support both mass production and specialized applications.

The all electric automation segment is expected to account for 48.60% of the total market revenue by 2025, making it the most dominant automation type. Its leadership is attributed to superior energy efficiency, high precision, and faster cycle times compared to traditional hydraulic systems.

Reduced maintenance requirements and environmentally friendly operation have further supported adoption in regions with strict energy regulations. Manufacturers have also embraced all electric systems for their reliability in producing complex parts with minimal defects, especially in industries requiring accuracy and repeatability.

As sustainability initiatives gain momentum across Europe, this segment continues to drive growth within the automation category.

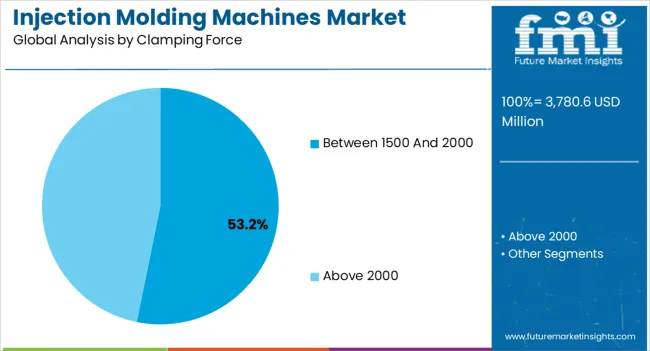

The clamping force category between 1500 and 2000 is projected to hold 53.20% of the market revenue by 2025, positioning it as the leading force range. This dominance stems from its versatility in catering to a wide range of applications, from automotive components to consumer products.

The machines in this range provide an optimal balance between energy consumption, part size, and production efficiency. Their suitability for both medium and large scale production has made them a preferred choice for manufacturers seeking flexibility without compromising performance.

Growing demand for durable and lightweight components in European automotive and packaging industries has further strengthened the position of this segment.

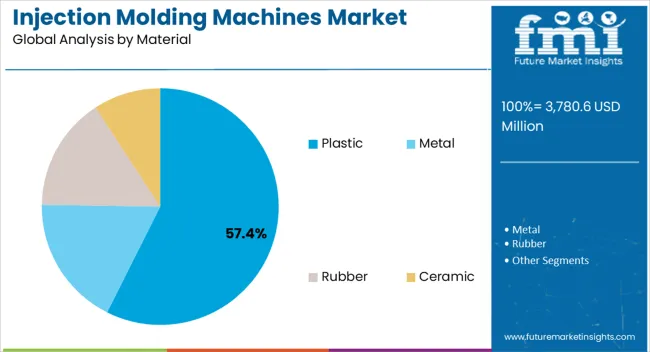

The plastic material category is anticipated to account for 57.40% of the overall market revenue by 2025, establishing it as the leading material segment. This growth is driven by increasing reliance on plastics for packaging, medical devices, automotive components, and consumer products.

The adaptability of plastics, combined with advancements in bio based and recyclable variants, has accelerated their application across industries. European environmental regulations promoting recyclability and sustainable material usage have further reinforced this segment’s growth.

Manufacturers are leveraging injection molding to deliver lightweight, durable, and cost effective plastic solutions, thereby sustaining the material’s dominance in the regional market.

Europe injection molding machines market showcased a CAGR of 2.4% during the historical period. It reached a market value of USD 3,339.4 million in 2025 from USD 2,961.9 million in 2020.

Manufacturing sector in Europe has traditionally been strong, with a focus on producing high-quality products across various sectors. Injection molding machines are essential for mass production of plastic components and products, allowing manufacturers to meet the increasing demand for consumer goods.

Expansion of sectors such as automotive, packaging, and electronics has also contributed to increased demand for injection molding machines. These sectors heavily rely on plastic components for their products.

Injection molding provides a cost-effective and efficient method of production. As countries in the region experienced economic growth and an increased demand for these products, need for injection molding machines naturally followed suit.

Demand for injection molding machines has further increased as manufacturers seek to introduce innovative and complex products to the market. Injection molding allows for the production of intricate shapes, precise details, and multi-component parts.

It enables designers to push the boundaries of product development. Ability to create sophisticated designs with injection molding has led to a surging demand for machines that can meet these requirements.

Injection molding offers significant cost advantages over other manufacturing processes. It enables high-volume production with shorter cycle times, reducing labor costs and increasing overall efficiency.

Manufacturers in Europe have recognized the cost-effectiveness of injection molding machines. Hence, they have increasingly adopted them to streamline their production processes and improve profitability.

Europe's geographical location and proximity to various markets have made it an attractive manufacturing hub. Injection molding machines play a vital role in the regional supply chain, allowing for localized production and faster turnaround times.

Demand for these machines has risen as manufacturers aim to establish or expand their operations in Europe. They are aiming to cater to the local and international markets efficiently.

Europe automobile sector is highly driven by increasing demand for vehicles to facilitate easier commutes. The demand for passenger cars and other vehicles has surged in the region due to rising income levels, urbanization, and improving road infrastructure.

Europe has one of the largest automobile sectors with maximum automobile brands coming from the region. Consequently, this has generated a heightened demand for the production of new automobile parts and equipment.

By minimizing material waste, injection molding can help the automobile sector cut expenses. It can also facilitate the use of lightweight materials, further surging fuel efficiency.

Several car parts, including dashboard components, door panels, seat components, electrical components, and engine components are produced through injection molding. It provides a practical and economical alternative for the production of these parts, which demand high levels of uniformity and precision.

In February 2025, for instance, Marelli, a prominent player in the automotive lighting sector, proactively responded to the evolving demands of the new energy vehicle (NEV) market. As a leader in the sector, Marelli has taken the initiative to acquire multiple YIZUMI 1400T-1850T ‘H-type parallel quartet’ multi-component injection molding machines.

The advanced machines enable efficient mass production of tricolor and run-through taillights, as well as thick-walled light guides. By investing in these cutting-edge machines, Marelli aims to meet the growing market requirements. It also wants to stay at the forefront of innovation in the automotive lighting sector.

Numerous injection molding machines are built with modular parts that can be easily replaced or rearranged to suit different production requirements. This enables clients to modify their equipment for certain applications or product specifications.

Molds and dies that are specially made for a certain part or product can be installed on injection molding machines as custom tooling. Custom tooling enables clients to create parts with specified characteristics, shapes, and sizes.

Numerous injection molding machines are nowadays equipped with advanced controls. These hence enable precise control of the injection molding process by modifying factors such as temperature, pressure, and speed. High demand for customized solutions in Europe is projected to drive injection molding machine sales.

Use of plastics is growing across various sectors such as food & beverage, automobile, electronics, consumer goods, and personal care, among several others. This is attributed to cost-effectiveness, durability, and ease of manufacturing that plastics provide. These factors are leading to a high demand for injection molding machines to manufacture plastic products.

There are multiple applications of injection molding plastics. Availability of numerous types of plastics such as polyamide (PA), polyvinyl chloride (PVC), polypropylene (PP), and thermoplastics in Europe would also propel sales.

Plastic bags, bottles, packaging products, accessories for computers, toys, automobile parts, pipe fittings, and consumer electronics parts can all be manufactured using the injection molding process.

Technology of plastic injection molding can also be used to make easy items such as a fork, as well as complex, life-saving medical items. Increased use of plastic products is further expected to fuel injection molding machine demand in Europe.

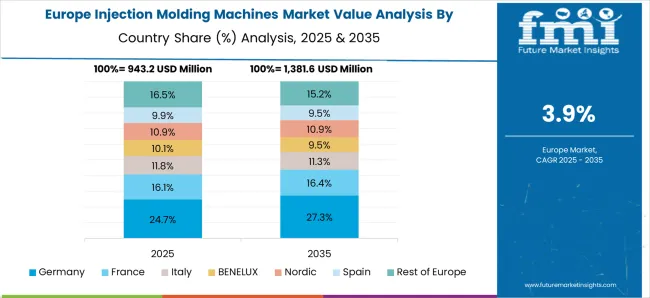

| Country | Germany |

|---|---|

| Market Share (2025) | 26.9% |

| Market Share (2035) | 23.4% |

| BPS Analysis | -350 |

| Country | France |

|---|---|

| Market Share (2025) | 11.0% |

| Market Share (2035) | 9.7% |

| BPS Analysis | -130 |

| Country | Spain |

|---|---|

| Market Share (2025) | 5.5% |

| Market Share (2035) | 5.1% |

| BPS Analysis | -40 |

| Country | Italy |

|---|---|

| Market Share (2025) | 7.3% |

| Market Share (2035) | 6.9% |

| BPS Analysis | -120 |

| Country | United Kingdom |

|---|---|

| Market Share (2025) | 8.3% |

| Market Share (2035) | 7.1% |

| BPS Analysis | -10 |

| Country | BENELUX |

|---|---|

| Market Share (2025) | 3.6% |

| Market Share (2035) | 3.5% |

| BPS Analysis | -20 |

| Country | Poland |

|---|---|

| Market Share (2025) | 3.9% |

| Market Share (2035) | 3.0% |

| BPS Analysis | -90 |

| Country | Hungary |

|---|---|

| Market Share (2025) | 2.8% |

| Market Share (2035) | 2.2% |

| BPS Analysis | -60 |

| Country | Russia |

|---|---|

| Market Share (2025) | 4.0% |

| Market Share (2035) | 3.1% |

| BPS Analysis | -90 |

Demand for Molding Equipment to Surge among Leading Automakers in Germany

The automobile sector in Germany, with a labor force of over 857,336, is one of the largest employers in the world. Germany has been highly recognized all over the world for its extraordinary automotive sector and excellence in engineering.

The country is ranked third in terms of car production in the world and fourth in total motor vehicle production. According to Germany Trade & Invest (GTAI), the country accounted for 25% of all passenger cars manufactured along with 20% of new registrations.

Germany is occupied with 44 original equipment manufacturer (OEM) sites. The Germany OEM market share accounted for 55% in 2024 in Europe. As a result, the country is anticipated to offer an incremental opportunity of USD 573.2 million over the next ten years.

Pharmaceutical Firms in the United Kingdom to Look for Hand Press Molding Machines

The pharmaceutical sector is an important space in the United Kingdom. The sector is investing hugely in research & development for new and innovative medicines.

According to the Association of the British Pharmaceutical Industry, the pharmaceutical sector in the United Kingdom has a turnover of around USD 44 billion, and invests USD 5.4 billion in research & development. Injection molding machines are heavily used in the pharmaceutical sector for producing different packaging products with accuracy and repeatability.

The pharma sector of the United Kingdom is creating numerous opportunities for Europe injection molding machines market. Owing to this, the United Kingdom market accounted for about 8.3% of share in 2025, and is set to exhibit a CAGR of 3.7% in the forecast period.

Demand for Hydraulic Resin Molding Machines to Expand across Europe

Hydraulic molding machines currently hold the dominant injection molding machines market share. These molding machines are suitable for thick-walled parts with longer hold times.

They have better injection rates and high resistance to wear and tear compared to other type of automations. Hydraulic molding machines are low-cost options over electric molding machines.

Easy availability of replacement parts might also result in reduced maintenance costs. Lower initial price of hydraulic molding machines makes them the ideal choice for manufacturers. As a result, the hydraulic segment is anticipated to gain a market share of around 44% in 2025.

Automotive Companies Present Demand for Rubber Injection Molding Machines to Make Lightweight Parts

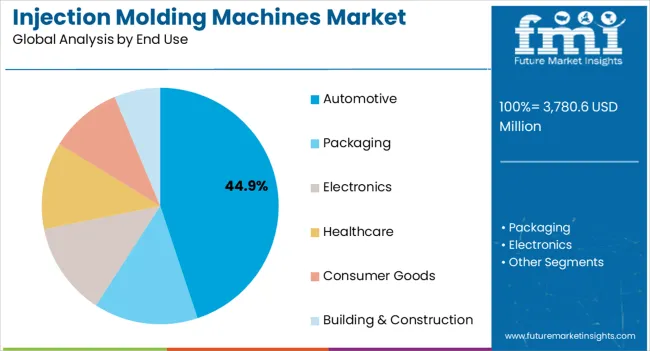

Injection molding machines are widely used in the automotive sector for producing plastic and metal parts. Metal injection molding machines are most commonly used in automotive to produce high strength and high complexity parts for engines and gearboxes. The automotive sector also utilizes plastic injection molding machines to manufacture various lightweight parts such as interior components and engine panels.

Injection molding further offers an unmatched level of versatility when it comes to manufacturing parts for various vehicles. A few of these include classic cars, coupes, sedans, boats, and airplanes.

Injection molding is used in both automotive OEM and aftermarket sectors. Hence, by end use, the automotive sector is set to hold around 29% of the market share in 2025.

Injection molding machine manufacturers in Europe are investing in research & development to introduce innovative features and technologies in their machines. This includes advancements in automation, robotics, control systems, and sensor technologies to enhance productivity, precision, and efficiency.

To cater to the diverse needs of customers, a few others are focusing on offering customizable and flexible solutions. This involves designing machines that can accommodate a wide range of product sizes, materials, and production requirements, allowing customers to optimize their manufacturing processes.

To tap into new opportunities, leading firms are expanding their presence in different geographical regions within Europe. This involves setting up sales & distribution networks, establishing local manufacturing facilities, and strengthening relationships with customers to enhance market reach & responsiveness.

For instance,

| Attribute | Details |

|---|---|

| Estimated Market Size (2025) | USD 3,475.3 million |

| Projected Market Valuation (2035) | USD 5,288.9 million |

| Value-based CAGR (2025 to 2035) | 4.3% |

| Historical Data | 2020 to 2025 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Value (USD million) |

| Segments Covered | Automation, Material, Clamping Force, End Use, Country |

| Key Countries Covered | Germany, Spain, Russia, Italy, United Kingdom, France, BENELUX, Nordic, Poland, Rest of Europe |

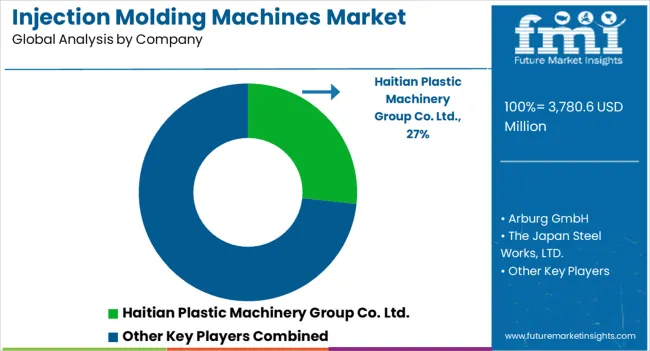

| Key Companies Profiled | Haitian Plastic Machinery Group Co. Ltd.; Arburg GmbH; The Japan Steel Works, LTD.; Husky Injection Molding Systems Ltd.; Engel AUSTRIA GmbH; Chen Hsong Holdings Limited; Milacron; Sumitomo Heavy Industries, Ltd.; KraussMaffei Group; FANUC CORPORATION; Woojin Plaimm GmbH; Tederic |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

The global Europe injection molding machines market is estimated to be valued at USD 3,780.6 million in 2025.

The market size for the Europe injection molding machines market is projected to reach USD 5,759.8 million by 2035.

The Europe injection molding machines market is expected to grow at a 4.3% CAGR between 2025 and 2035.

The key product types in Europe injection molding machines market are all-electric, hydraulic and hybrid.

In terms of clamping force, between 1500 and 2000 segment to command 53.2% share in the Europe injection molding machines market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Europe Cruise Market Forecast and Outlook 2025 to 2035

Europe Massage Therapy Service Market Size and Share Forecast Outlook 2025 to 2035

Europe Cement Market Analysis Size and Share Forecast Outlook 2025 to 2035

European Union Tourism Industry Size and Share Forecast Outlook 2025 to 2035

Europe and MENA Generic Oncology Drug Market Size and Share Forecast Outlook 2025 to 2035

Europe Masking Tapes Market Size and Share Forecast Outlook 2025 to 2035

Europe Liners Market Size and Share Forecast Outlook 2025 to 2035

Europe Dermal Fillers Market Size and Share Forecast Outlook 2025 to 2035

Europe Trolley Bus Market Size and Share Forecast Outlook 2025 to 2035

Europe Protease Market Size and Share Forecast Outlook 2025 to 2035

Europe Luxury Packaging Market Size and Share Forecast Outlook 2025 to 2035

Europe & USA Consumer Electronics Packaging Market Size and Share Forecast Outlook 2025 to 2035

Europe Plant-Based Meal Kit Market Size and Share Forecast Outlook 2025 to 2035

Europe Temperature Controlled Packaging Solutions Market Size and Share Forecast Outlook 2025 to 2035

Europe Rubber Derived Unrefined Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Europe Pet Food Market Analysis by Nature, Product Type, Source, Pet Type, Packaging, Distribution Channel, and Country - Growth, Trends, and Forecast through 2025 to 2035

Europe's Golden Generation Travel Market Size and Share Forecast Outlook 2025 to 2035

Europe Automotive Night Vision System Market Size and Share Forecast Outlook 2025 to 2035

Europe Winter Tourism Market Size and Share Forecast Outlook 2025 to 2035

Europe Bulk Bags Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA