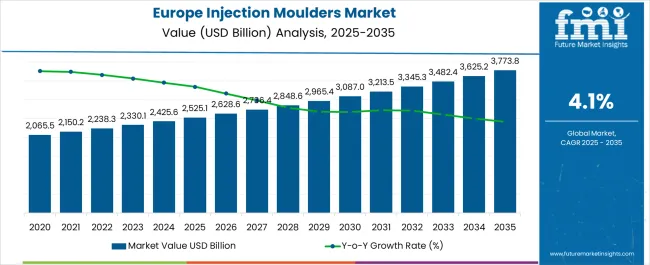

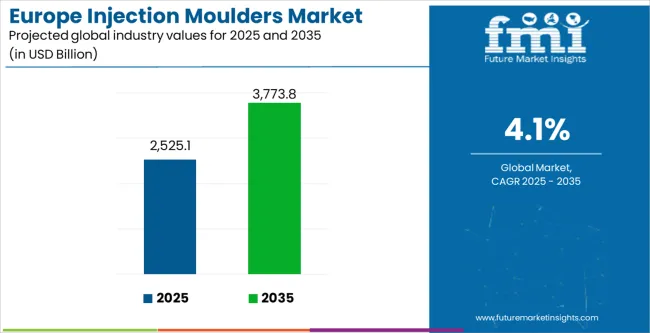

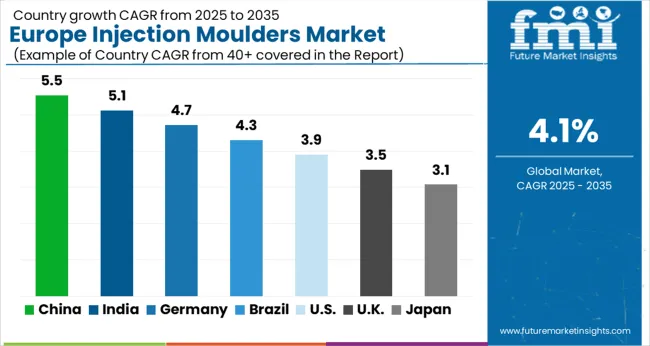

The Europe Injection Moulders Market is estimated to be valued at USD 2525.1 billion in 2025 and is projected to reach USD 3773.8 billion by 2035, registering a compound annual growth rate (CAGR) of 4.1% over the forecast period.

| Metric | Value |

|---|---|

| Europe Injection Moulders Market Estimated Value in (2025 E) | USD 2525.1 billion |

| Europe Injection Moulders Market Forecast Value in (2035 F) | USD 3773.8 billion |

| Forecast CAGR (2025 to 2035) | 4.1% |

The Europe injection moulders market is experiencing strong momentum as manufacturers across multiple industries adopt advanced moulding technologies to achieve higher precision, reduced cycle times, and enhanced material efficiency. Stringent sustainability regulations in the region are accelerating the use of recyclable plastics and innovative moulding techniques to minimize waste and energy consumption.

Growing demand from the automotive sector for lightweight components, coupled with increasing applications in packaging, healthcare, and consumer goods, is supporting steady expansion. Investments in automation, robotics, and digital moulding solutions are also improving production flexibility and reducing operational costs.

With Europe’s strong focus on circular economy initiatives and high-quality manufacturing standards, the market outlook remains positive, presenting opportunities for companies that align with both innovation and sustainability priorities.

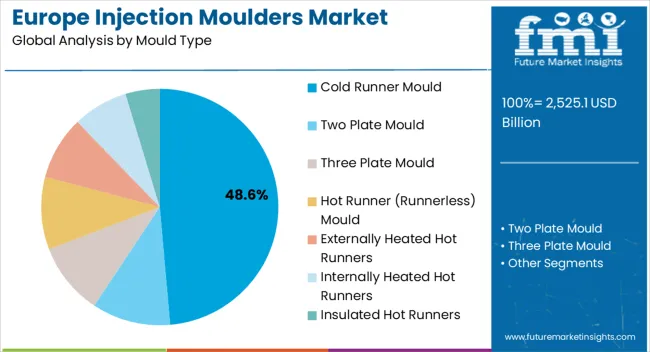

The cold runner mould segment is expected to represent 48.60% of the total market by 2025 within the mould type category, making it the dominant choice. Its strong position is supported by lower initial tooling costs, easier maintenance, and versatility across different production volumes.

Manufacturers favor this segment for its ability to handle a variety of polymers while ensuring consistent quality output. Additionally, cold runner systems are widely utilized in traditional moulding setups, making them more accessible to small and medium sized enterprises.

The balance of cost efficiency and production flexibility has reinforced the continued preference for cold runner moulds across Europe’s injection moulding industry.

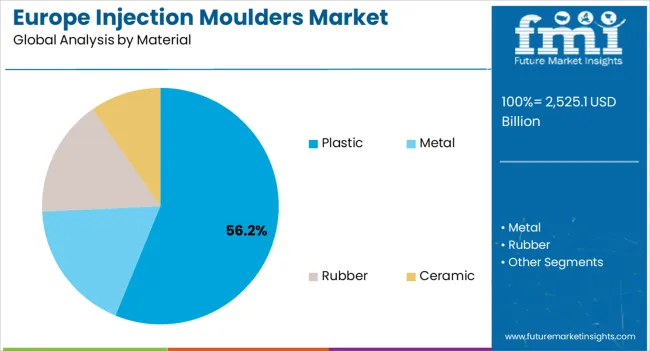

The plastic material segment is projected to account for 56.20% of market revenue by 2025 within the material category, positioning it as the leading choice. Demand for lightweight, durable, and cost effective materials has accelerated adoption in key sectors including automotive, consumer goods, and healthcare.

Plastics are preferred for their ease of moulding, recyclability advancements, and compatibility with high-volume manufacturing processes. Regulatory emphasis on sustainable packaging and lightweight vehicle components has further strengthened their application.

The segment continues to grow as innovations in bio-based and recyclable plastics address environmental concerns while meeting performance standards.

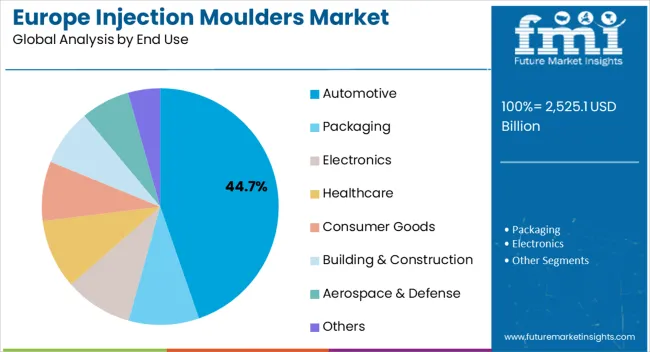

The automotive end use segment is projected to capture 44.70% of total market revenue by 2025, making it the largest industry vertical. This dominance is driven by the region’s strong automotive manufacturing base, which prioritizes light weighting, cost efficiency, and precision in component production.

Injection moulding is extensively used in producing dashboards, bumpers, interior trims, and under the hood components that meet both performance and aesthetic requirements. The shift toward electric vehicles has further amplified demand for injection moulded plastics that enhance efficiency and reduce vehicle weight.

Continuous innovation in design flexibility and integration with advanced materials has positioned automotive as the most influential sector in shaping the growth trajectory of Europe’s injection moulders market.

As per Future Market Insights (FMI), the Europe injection moulders market witnessed a CAGR of 2.6% during the historic period. Total market value at the end of 2025 reached around USD 2,233.5 million.

Looking forwards, the target market is forecast to expand at 4.1% CAGR during the assessment period. By 2035, total market size is anticipated to reach USD 3,481.2 million.

Rising usage of injection moulding across sectors such as automotive, packaging, electronics, and healthcare is a key factor driving Europe injection moulders industry.

Injection moulders have become essential tools for large scale production of components and parts across various sectors. They are being widely used to manufacture automotive parts, electronic components, etc.

Growing automotive manufacturing sector across Europe is expected to boost the injection moulders industry during the assessment period.

Automotive manufacturing is a crucial sector in Europe, producing nearly 20 million vehicles annually. It is one of the leading industries on the continent. With the EU being one of the leading producers of motor vehicles in the world, the sector represents a significant private investor in research and development (R&D).

Injection moulding is among the many manufacturing methods used to keep up with the demand for automotive parts with intricate designs.

Injection moulding is particularly suitable for creating parts with thin walls, sharp cutbacks, tight corners, and protruding edges, especially in flexible materials such as resins, plastics, and rubbers. Therefore, when precision is critical for automotive parts, injection moulding is worth the investment to produce the most advanced designs.

To meet rising demand from automotive sector, leading companies are using strategies such as mergers and collaborations. For instance, recently injection molding software provider Moldex3D and injection molding machine manufacturer ENGEL collaborated to develop simulation software for automotive lightweighting.

High Adoption of In-Mold Process Monitoring and Demand for Eco-Friendly & Sustainable Materials to Boost the Market:

Acquiring a great deal of data for manufacturing process control is a recent trend in plastic production created by evolving industry demands. A study has been going on in-mold process monitoring tools and methods for injection moulding process control.

The most relevant data of the manufacturing process comes from mold cavity. There have been recent developments of standard sensors for the measurement of in-mold process parameters.

Various attempts are being made for solving certain research and industrial problems of injection moulding process monitoring. For instance,

Bio resins are becoming increasingly popular as a viable alternative to traditional resins, as they are made from plant extracts and other renewable sources. They enable green practices by reducing toxic emissions, ensuring safe disposal, and utilizing energy-efficient processes.

Manufacturing companies are now using biodegradable, thermoplastics as well as degradant concentrates such as manganese stearate and cobalt separate as additives to promote disintegration and oxidation. This will support expansion of the target market during the assessment period.

Growth of Electric Vehicle Sector to Propel Demand for Injection Moulding Tools:

The advent of battery technology and innovative engine design has transformed the automobile sector, leading to the development of electric cars that are gaining traction in the market.

As demand for electric cars continues to surge, manufacturers have invested significantly in creating supply chains capable of meeting this demand. Injection moulding plays a crucial role in this supply chain, particularly in the production of plastic components for electric cars.

Although automobiles are typically associated with metal, plastic injection moulding has emerged as a growing trend in the sector, driven largely by the rise of electric vehicles. While metal remains the primary material for the exterior of a car, manufacturers are increasingly turning to plastic for internal components.

Plastic injection moulding offers an affordable, lightweight, and versatile solution for producing high-precision components with consistent quality. This is making it an ideal manufacturing process for the electric car sector. As a result, injection moulder manufacturers are targeting the electric vehicle market to tap into this growing opportunity.

Advantages of Hot Runner Moulds Making them Popular Among Manufacturers

A hot runner mould is an injection moulding tool in which the runners that feed molten plastic to the mould cavities are heated, allowing for more control over the moulding process.

In a hot runner mould, the plastic is injected into the mould via a heated manifold system, which keeps the plastic molten until it reaches the cavity. This enables moulding that is more efficient because less waste is generated during the process, and it can help to cut cycle times and enhance part quality.

Hot runner moulds can be used for a variety of materials and applications. They are frequently employed for high-volume production runs where precision and repeatability are crucial.

Usage of hot runner moulds helps end users increase overall moulding efficiency by reducing cycle time and energy costs. As a result, hot runner systems are becoming ideal choice for moulding thermoplastics.

Growing adoption of hot runner systems across various sectors is expected to play a key role in boosting the Europe injection moulders industry.

According to Future Market Insights, hot runner mould segment is anticipated to gain a market share of more than 82% in the estimated year. Further, it is likely to exhibit a CAGR of 4.4% through 2035.

Plastics Segment Holds a Dominant Market Share

Plastic mould manufacturers are adopting reinforced plastics, which have high growth prospects in the market. The automotive sector is replacing metal with glass, carbon, metal, and graphite plastics due to their design flexibility, durability and lightweight.

The use of reinforced plastics is also gaining popularity in defense and medical applications. In the automotive sector, lightweight & slim tools and parts made of reinforced plastics aim to improve mileage and extend battery life.

The medical sector is shifting towards special medical-grade plastics for joint replacement, stents, and mesh scaffolds. There is an increasing demand for injection moulded equipment and tools to enhance mobility, reduce costs, and maximize outcomes.

Thus, the plastic segment is expected to hold 59.4% of the market in the forecast year. It is projected to create an incremental opportunity worth USD 602.1 million during the forecast period.

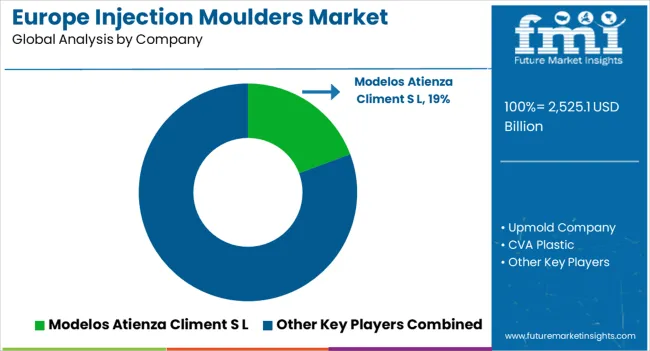

Key injection moulder manufacturers are focusing on developing innovations to meet end user demand across Europe. They are also using strategies such as mergers, facility expansions, partnerships, collaborations, acquisitions, and agreements to strengthen their presence and increase revenues.

Recent developments:

| Attribute | Details |

|---|---|

| Estimated Market Value (2025) | USD 2,330.1 million |

| Projected Market Value (2035) | USD 3,481.2 million |

| Anticipated Growth Rate (2025 to 2035) | 4.1% CAGR |

| Historical Data | 2020 to 2025 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD Million, Volume in Units and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered | Mould Type, Material, End Use, Country |

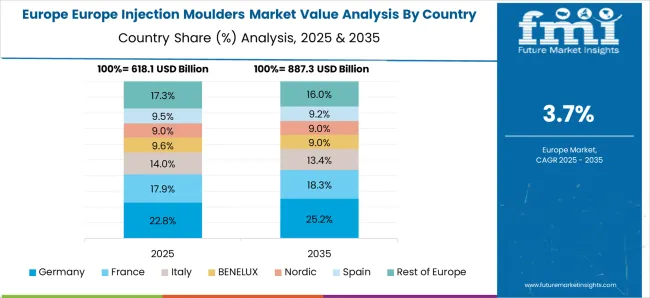

| Key Countries Covered | Germany, Spain, Russia, Italy, United Kingdom, France, BENELUX, Nordic, Poland, Hungary, Romania, Czech Republic, Rest of Europe |

| Key Companies Profiled | Modelos Atienza Climent S L; Upmold Company; CVA Plastic; Dino Brunelli S.a.s. di Giampaolo Brunelli & C.; Nolato AB (Nolato); Erreka Group; WIT MOLD LIMITED; GEOCAD Group; VEM TOOLING (I) PVT LTD; Aco Mold Co Limited; INPLASTIC; TAIZHOU HUANGYAN JMT MOULD CO., LTD.; HASCO Hasenclever GmbH + Co KG; Plastisud SAS; Entech Group UAB |

The global Europe injection moulders market is estimated to be valued at USD 2,525.1 billion in 2025.

The market size for the Europe injection moulders market is projected to reach USD 3,773.8 billion by 2035.

The Europe injection moulders market is expected to grow at a 4.1% CAGR between 2025 and 2035.

The key product types in Europe injection moulders market are cold runner mould, two plate mould, three plate mould, hot runner (runnerless) mould, externally heated hot runners, internally heated hot runners and insulated hot runners.

In terms of material, plastic segment to command 56.2% share in the Europe injection moulders market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Europe Polyvinyl Alcohol Industry Analysis Size and Share Forecast Outlook 2025 to 2035

Europe Cruise Market Forecast and Outlook 2025 to 2035

Europe Massage Therapy Service Market Size and Share Forecast Outlook 2025 to 2035

Europe Cement Market Analysis Size and Share Forecast Outlook 2025 to 2035

European Union Tourism Industry Size and Share Forecast Outlook 2025 to 2035

Europe and MENA Generic Oncology Drug Market Size and Share Forecast Outlook 2025 to 2035

Europe Masking Tapes Market Size and Share Forecast Outlook 2025 to 2035

Europe Liners Market Size and Share Forecast Outlook 2025 to 2035

Europe Dermal Fillers Market Size and Share Forecast Outlook 2025 to 2035

Europe Trolley Bus Market Size and Share Forecast Outlook 2025 to 2035

Europe Protease Market Size and Share Forecast Outlook 2025 to 2035

Europe Luxury Packaging Market Size and Share Forecast Outlook 2025 to 2035

Europe & USA Consumer Electronics Packaging Market Size and Share Forecast Outlook 2025 to 2035

Europe Plant-Based Meal Kit Market Size and Share Forecast Outlook 2025 to 2035

Europe Temperature Controlled Packaging Solutions Market Size and Share Forecast Outlook 2025 to 2035

Europe Rubber Derived Unrefined Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Europe Pet Food Market Analysis by Nature, Product Type, Source, Pet Type, Packaging, Distribution Channel, and Country - Growth, Trends, and Forecast through 2025 to 2035

Europe's Golden Generation Travel Market Size and Share Forecast Outlook 2025 to 2035

Europe Automotive Night Vision System Market Size and Share Forecast Outlook 2025 to 2035

Europe Winter Tourism Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA