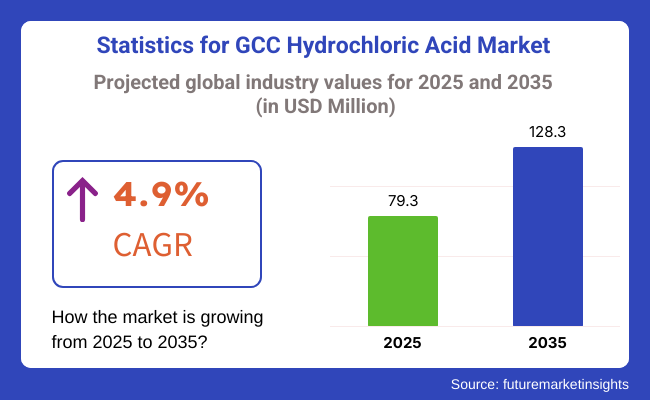

The GCC hydrochloric acid market is projected to reach USD 79.3 million by 2025. The industry is poised to observe USD 128.3 million by 2035, witnessing a 4.9% CAGR from 2025 to 2035.

The main factor behind the growth is the product’s wide application in the industrial field as well as the increasing need from the oil and gas industry and its utilization in water treatment and chemical processing. HCL is a chemical extensively used in oil well acidizing, steel pickling, food processing, pharmaceuticals, and wastewater treatment. The strong oil and gas sector in the GCC bolsters the demand for HCL in petrochemical refining and operation in the EOR (enhanced oil recovery).

Moreover, desalination and industrial water treatment plants have consistently employed the product for the prevention of scale and pH regulation, which, in turn, has led to an increase in industry demand. For instance, Saudi Aramco and ADNOC regularly apply HCL-based solutions during the oil extraction process.

The demand for high-purity acid in the metal industry, construction chemicals, and the electronics sector is increasing due to rapid industrialization, the establishment of new factories, and the booming infrastructure sector.

The GCC’s intention to decrease its reliance on oil has also spilled into HCL's use as a production medium in chemicals and specialty chemicals. Despite these opportunities, challenges remain, especially the corrosivity of the product, which demands special handling requirements like storage, transport, and others.

Further, environmental and workplace safety laws in the GCC are tough. Therefore, manufacturers spend a significant amount of money complying with these regulations, which results in limitations on the disposal of the acid and controlling emissions. Another key barrier is the efficient bulk logistics for shipping the product from the refineries to the industrial clusters. Despite these obstacles, there is enormous potential for growth, particularly in the oil and gas sector. The continued investment in oil exploration and drilling activities within the GCC region is driving demand for the product in well stimulation, acid fracturing, and enhanced oil recovery (EOR).

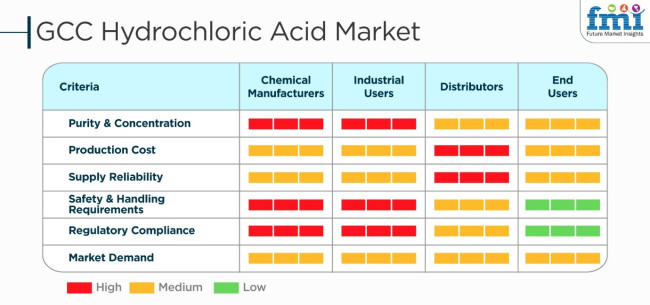

The GCC hydrochloric acid market report also provides glimpse into other market notables such as distribution channels, market performance of companies, and industry related market analysisfor chemical manufactures, industrial users, distributers and end user, which indicates similar nature of priorities.

Distributors, on the other hand, see production cost and supply reliability as must-have criteria (red) since their goal is to procure in a cost-efficient way and keep steady supply chains to meet thedemand. Their role is mainly about controlling distribution efficiency andmaintaining a healthy stock in the market (yellow, medium): purity is somewhat less important to them.

End users (e.g., businesses that use hydrochloric acid in industrial applications) have theirown set of priorities. One of their lowest priorities (green) are regulatory compliance and the safety andhandling requirements of products, meaning that these are concerns handled upstream by manufactures and suppliers. While they care about purity, they place much more weight, in their equation, on market demand, production cost, and supply reliability (medium, yellow) because they need cheap andreadily available hydrochloric acid to help run their facilities.

The GCC hydrochloric acid market between 2020 and 2024 grew steadily due to the increasing demand from industries such as water treatment, chemicals, steel production, and oil & gas. In addition, the increased growth in desalination plants and wastewater treatments has significantly increased consumption, while the use of the product in oil recovery and refining operations has placed it in the oil and gas industry. Nonetheless, industry stability was derailed by supply chain interruptions and volatile raw material prices, leading to investment in domestic manufacturing to mitigate dependence on imports.

Between 2025 and 2035, the industry will be spurred on by advances in acid recovery technology, sustainability trends, and GCC industrial diversification. The hydrogen production and green chemistry influence will affect the use of the product; however, stricter environmental regulations will compel even industries to undertake safer handling and disposal practices. Development of the alternative acid solutions in oil & gas may create a potential impact on the demand, thereby providing a sounder and more resilient industry scenario.

Comparative Industry Shift Analysis (2020 to 2024 vs. 2025 to 2035)

| 2020 to 2024 | 2025 to 2035 |

|---|---|

| Governments enforced environmental guidelines on industrial HCL emissions and chemical handling. Adoption of ISO 14001-certified practices became common in manufacturing facilities. | Stricter environmental policies drive the adoption of carbon-neutral and energy-efficient HCL production. Integration of hydrogen chloride recovery systems and green acid production in industries. |

| HCL was extensively used in well-stimulation, acid fracturing, and crude refining. Rising oil prices increased demand for acidizing fluids in enhanced oil recovery (EOR). | Sustainable drilling technologies and CO₂ reduction mandates encourage alternative acidizing solutions. HCL demand shifts toward lithium refining and green hydrogen production. |

| HCL was of primary importance in pH adjustment, scale removal, and chemical dosing in Saudi Arabian, UAE, and Qatari desalination plants. | Growth in advanced membrane desalination and wastewater recycling enhances the need for ultra-pure acid in water treatment. |

| The product was utilized by the steel pickling and galvanizing industries for purging impurities and surface preparation of metals. Rising infrastructure projects fueled demand. | Smart steel production and low-carbon construction practices promote acid regeneration and HCL recycling systems in steel plants. |

| Adoption of electrochemical HCL synthesis and automation in acid handling and transport improved safety and efficiency. | AI-driven process optimization and blockchain-enabled acid tracking systems improve production efficiency and sustainability. Growth of solid-state acidification technologies. |

| Growth fueled by oil & gas acidizing, desalination, and industrial processing. Expansion of petrochemical and construction projects increased HCL demand. | Industry expansion was driven by sustainable industrial applications, the refining of lithium-ion batteries, and AI-integrated chemical manufacturing. GCC nations strengthen downstream chemical processing hubs. |

The main risk in the Gulf region hydrochloric acid (HCL) market is the dependence on raw materials. The product is often created as a by-product in many industrial processes, such as chlor-alkali production. Essential industries, such as the chlor-alkali, could be disrupted due to supply chain bottlenecks and regulatory changes that would affect HCL availability and pricing.

Regulatory compliance is a major part of this industry. The product is categorized as a hazardous chemical, hence it is subject to strict control over its handling, transport, and storage. This means that any non-compliance with GCC legal frameworks, such as REACH-like requirements in the UAE or Saudi FDA regulations, will result in consequences including fines, operational suspension, or disruption of the supply chain.

The environmental and safety issues are also considerable. HCL is extremely corrosive, posing a risk of leaks, spills, and serious ergonomic hazards. Companies would need to invest in proper containment, personal protective equipment, and emergency response plans in place so as to minimize accidents and ensure business continuity.

Market volatility and demand instability are also the challenges. The product is required in various sectors, including but not limited to the oil and gas industry, water treatment plants, and steel production. Demand can be affected, for example, by economic slowdowns, while other issues, such as geopolitical situations or industry-specific downturns, may result in price instability and oversupply.

Careful evaluation is necessary of the suppliers' financial standing and trustworthiness, as well as their shipping and storage systems. The product is a bulk chemical that needs well-planned transportation and storage logistics. A situation where a company relies on few suppliers or has logistical problems often leads to disruptions in the supply chain. Companies should adopt a multi-sourcing approach and enter into long-term agreements with a diverse range of suppliers.

In the GCC hydrochloric acid market, pricing strategies should take into account production costs, market demand, and regional competition. HCL, being a commodity chemical, its price is largely determined by the cost of raw materials, logistics, and fluctuations in the global chemical industry. A well-thought-out plan will ensure profitability without affecting competitiveness.

Cost-plus pricing is a common plan in this case, where a predetermined profit margin is included in production costs. This way, the company guarantees its consistent profit, more so with the constant fluctuations in raw material prices. On the other hand, in markets where cost is the main target for the customer and suppliers' variations in offer should be cheap, this may be counterproductive.

Dynamic pricing is another option that hinges on real-time industry conditions. For instance, when the rate of sales is driving the oil and gas sectors to a higher standard of living, then the price can be raised to the level that leads to the most profits. In turn, when the economy is not turning down, price adjustments may be needed to counter competition and prevent customers from leaving, thereby maintaining the industry's share.

Competitive pricing is a significant factor in the Gulf, where companies are vying for the business of many industrial users, from a cost standpoint. Selling in bulk with a discount, offering long-term commitments, or providing various additional services like storage that is convenient and adaptable are significant advantages of the pricing method used.

Penetration pricing is a tactic employed when launching new products, targeting new customer segments, or expanding the distribution network. A company will offer lower prices to large industrial customers to enter the new market, thereby gaining a competitive position. However, thoughtful planning is necessary to ensure that the company generates long-term profits and that low-margin sales do not become unsustainable.

Synthetic grade acid is the most commonly used in the GCC region because it has high purity and is widely used in industrial processes, water treatment, and the oil and gas industries. The GCC nations of Saudi Arabia, the UAE, and Qatar emphasize petrochemical refining, metal processing, and chemical production, where synthetic-grade HCl finds vital uses. Its high purity and controlled composition make it critical for acidizing oil wells, a crucial process in the oil and gas production industry in the region.

Due to the GCC region's heavy reliance on the oil and gas industry, oil well acidizing is a key application segment. The product is widely used in well stimulation due to its ability to dissolve carbonate formations, which helps remove obstructions in oil and gas reservoirs, ultimately increasing the productivity of wells. The GCC region, home to several of the world’s largest oil producers, namely Saudi Arabia, UAE and Kuwait, continues to prioritize EOR processes to maximize the extraction of oil from both mature fields and non-conventional reservoirs.

With limited natural freshwater resources, water treatment is a crucial industry that utilizes products in the GCC. HCL is extensively used in desalination plants, which provide a significant portion of the region's drinking water. It is used for pH control, membrane cleaning, and scale removal to ensure the efficiency of reverse osmosis and thermal desalination systems. With increasing population needs, desalination capacity is also increasing, and the application of HCl in water treatment is increasing accordingly.

| Country | CAGR (%) (2025 to 2035) |

|---|---|

| Saudi Arabia | 4.9% |

| U.A.E. | 4.7% |

| Qatar | 4.8% |

| Kuwait, Oman & Bahrain (Rest of GCC) | 4.6% |

The Saudi Arabian industry is experiencing steady growth, driven by increased industrial applications, rising oil and gas production, and growing demand from the chemical and water treatment industries. In the petrochemical and oil refining business, Saudi Arabia widely employs the product in well stimulation, descaling, and refining operations.

Apart from that, growth in the Saudi construction and steel industry is primarily propelling the product demand for pickling and cleaning the steel surface. The nation is among the world's largest proven oil reserves and is a major contributor to enhanced oil recovery (EOR) operations like well acidizing, where the product is an essential ingredient.

FMI states that the Saudi Arabian hydrochloric acid market will be growing at a 4.9% CAGR throughout the study period.

Growth Drivers in Saudi Arabia

| Drivers | Reason |

|---|---|

| Oil & Gas Drilling and Refining Increase | Ride increased demand for the product in oil & gas well acidizing and refinery operations. Saudi Aramco investments in oil & gas projects are fueling industry growth. |

| Expansion in Water Treatment & Desalination Plants | Surging demand for applications in water treatment and pH correction, fueled by Saudi Vision 2030's thrust towards sustainability. |

| Steel & Construction Industry Growth | Surging applications in metal pickling and surface treatment owing to urbanization and infrastructure growth at a fast pace. |

The UAE hydrochloric acid market is progressing steadily, driven by increasing industrialization, the expansion of water treatment facilities, and rising demand for oil refining and chemical manufacturing. The nation's emphasis on sustainable energy and infrastructure development has stimulated demand for hydrochloric acid applications in steel processing, industrial cleaning, and desalination facilities.

With the UAE becoming a regional hub for petrochemicals and manufacturing, the product finds more applications in acidizing oil wells, regenerating catalysts, and adjusting pH levels during chemical synthesis. The UAE's desalination capacity, which accounts for nearly 42% of the GCC's total capacity, is a key driver of hydrochloric acid demand.

The UAE industry is expected to expand at a 4.7% CAGR during the forecast period, according to FMI.

Growth Drivers in the UAE

| Key Drivers | Detail |

|---|---|

| Oil Refining & Petrochemical Industry Growth | Increased demand resulting from the increased use of the product for chemical treatment and catalyst regeneration. ADNOC downstream investment drives demand. |

| Water Desalination & Industrial Waste Treatment | Growing demand for pH balancing and purification, with the UAE relying on 90% of its drinking water to be desalinated. |

| Steel & Metal Processing Industry Growth | Growing applications of acid pickling and surface treatment to facilitate infrastructure and construction activities. |

Desalination and wastewater treatment in Qatar are driving the demand for products used in purification and neutralization. Qatar's energy industry, specifically its natural gas production, utilizes the product in petrochemical refining and well acidizing. Large-scale infrastructure projects are being funded in Qatar, even before the implementation of economic diversification projects outlined in Qatar National Vision 2030. According to FMI, the industry in Qatar is expected to expand at a 4.8% CAGR during the study period.

Growth Drivers in Qatar

| Key Drivers | Detail |

|---|---|

| Expansion of the Oil & Gas Industry | Expansion of the application of the product for acidizing wells and chemical treatment in the world's leading LNG exporter. |

| Expansion of Water Treatment & Desalination | High dependence on desalination to supply freshwater supply, thus pushing the product demand. |

| Expansion of Steel & Manufacturing Industry | Expansion of demand for acid pickling and metal surface treatment in industrial processes. |

| Fertilizer & Chemical Industry Expansion | Application in chemical production and pH balancing in industrial chemicals and fertilizers. |

| Infrastructure Development & Smart City Plans | The product is used in industrial-scale infrastructure development projects for material treatment and industrial cleaning. |

The Omani, Bahraini, and Kuwaiti hydrochloric acid industries are expanding with industrial diversification, increased oil and gas activity, and a rise in desalination projects. With continuous refinery upgradation and expansion in chemical production, hydrochloric acid uses in catalyst rejuvenation, pH balancing, and industrial cleaning are increasing.

The GCC's focus on water sustainability has triggered broad investment in desalination and wastewater treatment, thereby creating a safe and stable demand for softening and treating water. The expansion of development in industrial parks, fertilizer plants, and steel processing facilities is further driving the industry's growth.

Growth Drivers in Kuwait, Oman & Bahrain

| Growth Drivers | Description |

|---|---|

| Oil Refining & Chemicals Production Growth | Increased refining capacity and corresponding hydrochloric acid demand through oil refining, and catalyst regeneration. |

| Faster Desalination & Water Treatment Plants | Strong demand for the product for pH adjustment and purification purposes. |

| Steel & Construction Operations | New applications in metal pickling and surface treatment have emerged due to the development of industrial infrastructure. |

The GCC hydrochloric acid market is witnessing intense competition due to the burgeoning industrial application areas, including oil and gas, water treatment, chemical process development, steel pickling, and food production. Companies in this industry align themselves with the chlorine manufacturing segment, ensuring a stable supply chain and cost efficiency. In addition to this, those leading the industry are inclined towards increasing capacity and strategic distribution networks to meet the growing demand, particularly in Saudi Arabia, the UAE, and Qatar, driven by boosts in petrochemical activities and desalination projects, as well as increasing HCL consumption.

Typically, companies in this space are differentiated by their logistical efficiency, production scalability, or regulatory compliance. Enhanced oil recovery (EOR), industrial pH control, and metallurgy have led to the growing demand for the product, prompting manufacturers to develop a stronger industry for downstream applications. As the race heats up, companies investing in new technology, sustainable production practices as well as supply chain resilience will enjoy the long-term competitive advantage in the GCC region.

Industry Share Analysis by Company

| Company Name | Estimated Industry Share (%) |

|---|---|

| Saudi Basic Industries Corporation (SABIC) | 15-18% |

| Qatar Petrochemical Company (QAPCO) | 12-14% |

| Gulf Chlorine W.L.L. | 8-10% |

| Oman Chlorine S.A.O.G. | 5-7% |

| Unipar LLC (UAE) | 3-5% |

| Other Companies (combined) | 48-57% |

| Company Name | Key Offerings/Activities |

|---|---|

| Saudi Basic Industries Corporation (SABIC) | Produces high-purity acid for the petrochemical, water treatment, and metal processing industries, focusing on integrated chlorine production. |

| Qatar Petrochemical Company (QAPCO) | Manufactures industrial-grade HCL for oil well stimulation, pH control, and chemical processing, serving regional and export markets. |

| Gulf Chlorine W.L.L. | Supplies HCL for industrial applications, including water desalination and petrochemical refining, with a focus on cost-efficient bulk production. |

| Oman Chlorine S.A.O.G. | Develops hydrochloric acid solutions for metal pickling, wastewater treatment, and oilfield services, ensuring high-purity formulations. |

| Unipar LLC (UAE) | Provides products for food processing, pharmaceuticals, and industrial cleaning, complying with stringent GCC regulatory standards. |

Saudi Basic Industries Corporation (SABIC)

SABIC is a regional GCC leader in the product manufacturing high-purity HCL used to refine petrochemicals, treat water, and synthesize chemicals. The firm offers chlor-alkali manufacturing, along with its extensive network of petrochemicals, at optimized cost savings and secure supply.

Qatar Petrochemical Company (QAPCO)

QAPCO is one of the world's largest manufacturers of the product, distributing it primarily for oil well acidizing, pH control, and industrial chemical applications. QAPCO is strategically positioned with excellent export prospects to become the industry leader in the GCC and global markets.

Gulf Chlorine W.L.L.

Gulf Chlorine is a specialist in industrial hydrochloric acid solutions, catering to water desalination plants, industrial processing, and petrochemical refining. The company’s bulk production and competitive pricing strategy make it a preferred supplier for large-scale industrial users.

Oman Chlorine S.A.O.G.

Oman Chlorine manufactures products for metal pickling, water treatment, and oil and gas applications. The company’s focus on high-purity acid production ensures its suitability for specialized industries, including pharmaceuticals and industrial cleaning.

Unipar LLC (UAE)

Unipar LLC supplies the product for food processing, medical, and industrial applications, ensuring compliance with strict safety and quality standards. The firm is focused on sustainable manufacturing and regulatory adherence, serving pharmaceutical and food-grade uses in the GCC region.

Other Key Players

In terms of grade, the industry is divided into synthetic grade and product grade.

Key applications include oil well acidizing, food processing, steel pickling, ore processing, pool sanitation, calcium chloride production, and others.

The industry serves industries such as petroleum, food & beverages, mining, steel, textile, water treatment, chemical industry, and others.

The industry spans the United Arab Emirates, the Kingdom of Saudi Arabia, Kuwait, and the rest of the GCC.

The industry is set to witness USD 79.3 million in 2025.

The industry is predicted to reach a size of USD 128.3 million by 2035.

Key companies include Al Kout Industrial Projects Co., AL Ghaith Industries L.L.C, Union Chlorine LL, BCI Groups, Sachlo, Saudi Basic Industries Corporation (SABIC), Oman Chlorine S.A.O.G., Unipar LLC (UAE), Nama Chemicals, Dub Chem, Muscat Chemical Industry, Gulf Chlorine WLL, Qatar Petrochemical Company, and KLJ Organic Qatar W.L.L.

Synthetic grade is being widely used.

Saudi Arabia, slated to grow at 4.9% CAGR during the study period, is poised for fastest growth.

Table 01: GCC Market Size (US$ million) and Volume (kilo tons) Analysis and Forecast By Grade, 2018 to 2033

Table 02: GCC Market Volume (kilo tons) Analysis and Forecast by Application, 2018 to 2033

Table 03: GCC Market Size (US$ million) Analysis and Forecast by Application, 2018 to 2033

Table 04: GCC Market Volume (kilo tons) Analysis and Forecast by End Use, 2018 to 2033

Table 05: GCC Market Size (US$ million) Analysis and Forecast by End Use, 2018 to 2033

Table 06: GCC Market Size (US$ million) and Volume (kilo tons) Analysis and Forecast by Country, 2018 to 2033

Table 07: Middle East and Africa Market Size (US$ million) and Volume (kilo tons) Analysis and Forecast by Grade, 2018 to 2033

Table 08: Middle East and Africa Market Volume (kilo tons) Analysis and Forecast by Application, 2018 to 2033

Table 09: Middle East and Africa Market Size (US$ million) Analysis and Forecast by Application, 2018 to 2033

Table 10: Middle East and Africa Market Volume (kilo tons) Analysis and Forecast by End Use, 2018 to 2033

Table 11: Middle East and Africa Market Size (US$ million) Analysis and Forecast by End Use, 2018 to 2033

Figure 01: Middle East and Africa Market Historical Volume (kilo tons), 2018 to 2022

Figure 02: Middle East and Africa Market Current and Forecast Volume), 2023 to 2033

Figure 03: Middle East and Africa Market Historical Value (US$ million), 2018 to 2022

Figure 04: Middle East and Africa Market Current and Forecast Value (US$ million), 2023 to 2033

Figure 05: Middle East and Africa Market Incremental $ Opportunity (US$ million), 2023 to 2033

Figure 06: GCC Market Share and BPS Analysis by Grade, 2023 and 2033

Figure 07: GCC Market Y-o-Y Growth Projections by Grade, 2023 to 2033

Figure 08: GCC Market Attractiveness Analysis by Grade, 2023 to 2033

Figure 09: GCC Market Absolute $ Opportunity by Synthetic Grade Segment, 2018 to 2033

Figure 10: GCC Market Absolute $ Opportunity by By-product Grade Segment, 2018 to 2033

Figure 11: GCC Market Share and BPS Analysis by Application, 2022 and 2033

Figure 12: GCC Market Y-o-Y Growth Projections by Application, 2023 to 2033

Figure 13: GCC Market Attractiveness Analysis by Application, 2023 to 2033

Figure 14: GCC Market Absolute $ Opportunity by Oil Well Acidizing Segment, 2018 to 2033

Figure 15: GCC Market Absolute $ Opportunity by Food Processing Segment, 2018 to 2033

Figure 16: GCC Market Absolute $ Opportunity by Steel Pickling Segment, 2018 to 2033

Figure 17: GCC Market Absolute $ Opportunity by Ore Processing Segment, 2018 to 2033

Figure 18: GCC Market Absolute $ Opportunity by Pool Sanitation Segment, 2018 to 2033

Figure 19: GCC Market Absolute $ Opportunity by Calcium Chloride Segment, 2018 to 2033

Figure 20: GCC Market Absolute $ Opportunity by Others Segment, 2018 to 2033

Figure 21: GCC Market Share and BPS Analysis by End Use, 2022 and 2033

Figure 22: GCC Market Y-o-Y Growth Projections by End Use, 2023 to 2033

Figure 23: GCC Market Attractiveness Analysis by End Use, 2023 to 2033

Figure 24: GCC Market Absolute $ Opportunity by Petroleum Segment, 2018 to 2033

Figure 25: GCC Market Absolute $ Opportunity by Food and Beverages Segment, 2018 to 2033

Figure 26: GCC Market Absolute $ Opportunity by Mining Segment, 2018 to 2033

Figure 27: GCC Market Absolute $ Opportunity by Steel Segment, 2018 to 2033

Figure 28: GCC Market Absolute $ Opportunity by Textile Segment, 2018 to 2033

Figure 29: GCC Market Absolute $ Opportunity by Water Treatment Segment, 2018 to 2033

Figure 30: GCC Market Absolute $ Opportunity by Chemical Industry Segment, 2018 to 2033

Figure 31: GCC Market Absolute $ Opportunity by Others Segment, 2018 to 2033

Figure 32: GCC Market Share and BPS Analysis by Country, 2023 and 2033

Figure 33: GCC Market Y-o-Y Growth Projections by Country, 2023 to 2033

Figure 34: GCC Market Attractiveness Analysis by Country, 2023 to 2033

Figure 35: GCC Market Absolute $ Opportunity by Kingdom of Saudi Arabia Segment, 2018 to 2033

Figure 36: GCC Market Absolute $ Opportunity by Middle East and Africa Segment, 2018 to 2033

Figure 37: GCC Market Absolute $ Opportunity by Kuwait Segment, 2018 to 2033

Figure 38: GCC Market Absolute $ Opportunity by Rest of GCC Segment, 2018 to 2033

Figure 39: Middle East and Africa Market Share and BPS Analysis by Grade, 2023 and 2033

Figure 40: Middle East and Africa Market Y-o-Y Growth Projections by Grade, 2023 to 2033

Figure 41: Middle East and Africa Market Attractiveness Analysis by Grade, 2023 to 2033

Figure 42: Middle East and Africa Market Absolute $ Opportunity by Synthetic Grade Segment, 2018 to 2033

Figure 43: Middle East and Africa Market Absolute $ Opportunity by By-product Grade Segment, 2018 to 2033

Figure 44: Middle East and Africa Market Share and BPS Analysis by Application, 2022 and 2033

Figure 45: Middle East and Africa Market Y-o-Y Growth Projections by Application, 2023 to 2033

Figure 46: Middle East and Africa Market Attractiveness Analysis by Application, 2023 to 2033

Figure 47: Middle East and Africa Market Absolute $ Opportunity by Oil Well Acidizing Segment, 2018 to 2033

Figure 48: Middle East and Africa Market Absolute $ Opportunity by Food Processing Segment, 2018 to 2033

Figure 49: Middle East and Africa Market Absolute $ Opportunity by Steel Pickling Segment, 2018 to 2033

Figure 50: Middle East and Africa Market Absolute $ Opportunity by Ore Processing Segment, 2018 to 2033

Figure 51: Middle East and Africa Market Absolute $ Opportunity by Pool Sanitation Segment, 2018 to 2033

Figure 52: Middle East and Africa Market Absolute $ Opportunity by Calcium Chloride Segment, 2018 to 2033

Figure 53: Middle East and Africa Market Absolute $ Opportunity by Others Segment, 2018 to 2033

Figure 54: Middle East and Africa Market Share and BPS Analysis by End Use, 2022 and 2033

Figure 55: Middle East and Africa Market Y-o-Y Growth Projections by End Use, 2023 to 2033

Figure 56: Middle East and Africa Market Attractiveness Analysis by End Use, 2023 to 2033

Figure 57: Middle East and Africa Market Absolute $ Opportunity by Petroleum Segment, 2018 to 2033

Figure 58: Middle East and Africa Market Absolute $ Opportunity by Food and Beverages Segment, 2018 to 2033

Figure 59: Middle East and Africa Market Absolute $ Opportunity by Mining Segment, 2018 to 2033

Figure 60: Middle East and Africa Market Absolute $ Opportunity by Steel Segment, 2018 to 2033

Figure 61: Middle East and Africa Market Absolute $ Opportunity by Textile Segment, 2018 to 2033

Figure 62: Middle East and Africa Market Absolute $ Opportunity by Water Treatment Segment, 2018 to 2033

Figure 63: Middle East and Africa Market Absolute $ Opportunity by Chemical Industry Segment, 2018 to 2033

Figure 64: Middle East and Africa Market Absolute $ Opportunity by Others Segment, 2018 to 2033

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

GCC Countries Halal Tourism Market Size and Share Forecast Outlook 2025 to 2035

GCC Adventure Tourism Market Size and Share Forecast Outlook 2025 to 2035

GCC Functional Food & Beverage Market Size and Share Forecast Outlook 2025 to 2035

GCC Natural Gas Market Size and Share Forecast Outlook 2025 to 2035

GCC Industrial Air Filtration Market Size and Share Forecast Outlook 2025 to 2035

GCC Mini Cranes Market Size and Share Forecast Outlook 2025 to 2035

GCC Functional Food Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

GCC Medical Gloves Market Trends - Growth, Demand & Forecast 2025 to 2035

GCC Countries Coated Fabrics Market Size, Share, Trends, and Forecast 2025 to 2035

GCC Secondhand Apparel Market Growth, Trends and Forecast from 2025 to 2035

GCC Automotive Turbocharger Market Trends – Growth, Demand & Forecast 2025–2035

GCC Yeast Market Trends – Growth, Demand & Forecast 2025–2035

GCC Green and Bio-based Polyol Market Trends – Growth, Demand & Forecast 2025–2035

GCC Natural Food Color Market Growth – Trends, Demand & Innovations 2025–2035

GCC Barite Market Trends – Growth, Demand & Forecast 2025–2035

GCC 1,4-Diisopropylbenzene Market Report – Trends, Demand & Industry Forecast 2025–2035

GCC Yacht Charter Service Market Analysis – Trends & Forecast 2025 to 2035

GCC Flare Gas Recovery System Market Report – Trends, Demand & Industry Forecast 2025–2035

GCC Magnetic Separator Market Outlook – Growth, Trends & Forecast 2025-2035

GCC Electric Golf Cart Market Outlook – Demand, Growth & Forecast 2025-2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA